超低速压铸慢压射速度下ADC12铝合金的显微组织和性能

纪莲清1,郭长江1,熊守美2, Masayuki Murakami3, Yoshihide Matsumoto3, Shingo Ikeda3, 刘坤1

(1. 郑州轻工业学院 机电工程学院,河南 郑州,450002;

2. 清华大学 机械工程系,北京,100084;

3. 日本东洋机械金属株式会社,兵库县明石市,674-0091)

摘 要:采用光学显微镜、扫描电镜、X线衍射和能谱等显微分析技术, 结合力学性能检测, 研究超低速压铸条件下慢压射速度对ADC12铝合金铸件显微组织及力学性能的影响,以优化超低速压铸工艺及其参数。通过对相同高速起速位置、不同低速速度及不同起速位置、相同低速速度2种超低速工艺得到的铸件比较发现:在超低速压铸工艺下,慢压射速度对铸件密度的影响不明显;当起速位置相同时,随着低速速度的增大,铸件的α(Al)枝晶越来越粗大,其性能降低;在相同低速速度、不同高速起速位置时,起速位置有最佳值,当铸件性能在高速起速位置为260 mm时,α(Al)枝晶较细小,其性能也较好。

关键词:ADC12铝合金;压铸;慢压射速度;超低速;显微组织;力学性能

中图分类号:TG249.2 文献标志码:A 文章编号:1672-7207(2010)03-0977-05

Microstructure and mechanical properties of ADC12 aluminum alloy under super slow speed die castings with low shot speed

JI Lian-qing1, GUO Chang-jiang1, XIONG Shou-mei2, Masayuki Murakami3,

Yoshihide Matsumoto3, Shingo Ikeda3, LIU Kun1

(1. College of Mechanical and Electrical Engineering, Zhengzhou University of Light Industry,

Zhengzhou 450002, China;

2. Department of Mechanical Engineering, Tsinghua University, Beijing 100084, China;

3. TOYO Machinery & Metal Co. Ltd., Hyogo 674-0091, Japan)

Abstract: Influences of low shot speed under die casting process of super slow speed(SSS) on microstructure and mechanical properties of ADC12 aluminum alloy were investigated in order to optimize SSS die casting process and parameters. Optical microscope, scanning electron microscope, X-ray diffractrometry and energy spectrum were taken to measure the microstructure and mechanical properties of this material. Compared with die castings under both producing conditions of different low-shot speeds at the same start position of high-speed injection stage and different start positions of high-speed injection stage at the same low-shot speed, the effect of low shot speed on casting density in the die casting process of the super slow speed is not obvious. With the increase of low-shot speed, α(Al) branches of this castings becomes larger and larger and its mechanical properties decrease at the same start position of high-speed injection stage. The optimized value of the start position of high-speed injection stage exists at the same low speed, and α(Al) branches are very small and the properties of castings are better at the start position of 260 mm.

Key words: ADC12 aluminum alloy; die casting; low shoot speed; super slow speed(SSS); microstructure; mechanical properties

孔洞类缺陷是压铸中公认的主要缺陷之一,铝合金中金属液流动过程的卷气和凝固过程的收缩是产生孔洞类型缺陷的主要原因[1-2],不仅使铸件不宜在高温条件下工作,而且极大降低了压铸件的热处理性能和机加工性能,限制了压铸件的使用。因此,减少压室及型腔中气体含量并采用合适的压射速度,从而减少压铸时卷气十分必要。压铸时,压室的工作状态大致可以分为浇料、慢压射、快压射、增压及保压5个阶段。对于压室的整个充填流程来说,压室内的慢压射过程是生产的第一个流程,也是经历时间最长的流程,金属液在慢压射时的速度变化会影响其流动形态,从而直接影响到其在浇道、浇口及型腔中的流动,进而影响到铸件中卷入的气体含量。采用合理的慢压射速度既可获得卷气少致密度高的铸件,也可保证一定的生产效率。

超低速(Super slow speed, 简称SSS )压铸正是利用比慢压射速度还要低的快压射速度,将液态金属在高压(几十MPa至120 MPa)作用下以层流方式填充压铸模型腔,并在压力下快速凝固而获得气体含量很低的压铸件的一种工艺方法。近年来,国内外不少研究者开展了真空压铸、加氧压铸、挤压铸造、半固态压铸等特种压铸技术研究,并对一般压铸时加压开始时间、加压压力、速度等对铸件密度变化的影响进行了大量的研究[3-7],但对超低速压铸的研究还较少。日本是较早开展超低速压铸工艺研究的国家之一,且已将研究成果应用于生产,但发表这方面的研究成果较 少。清华-东洋镁铝合金成形技术研究开发中心近年来开展了这方面的研究工作,已取得了一定的研究成果[8-10]。本文作者在此研究基础上,以工业用压铸铝合金ADC12为研究对象,在设计的标准拉伸试棒金属模具上进行超低速压铸试验,从铸件密度、力学性能和显微组织等方面,考察不同慢压射速度对铸件性能的影响。

1 实验方法

实验所选材料为商业用压铸铝合金JIS(日本工业标准)ADC12,用ICP(等离子体发射光谱仪)测得其化学成分(质量分数)为:11.25% Si,3.09% Fe,2.51% Cu,0.21% Mn,0.096% Mg,1.74% Zn,其余为Al。

试样采用2种不同工艺的慢压射速度在650T冷室压铸机(TOYOBD-650-V4-N)上进行压铸。

工艺1:模具温度为150 ℃,内浇口直径为24 mm,高速速度为0.09 m/s(浇口速度0.39 m/s),铸造压力为100 MPa,浇注温度为700 ℃,溢流槽尺寸(直径×高)为20 mm×3.0 mm,料柄厚度为40 mm,压力阀开度为100,除气时间为20 min,持压时间为10 s;低速离型剂与水的体积比为1?30;冲头用低速润滑剂润滑。

工艺2:除增加了起高速位置对铸件性能的影响外,其他条件与工艺1的相同。工艺2增加了局部挤压。浇口侧挤压时间为8 s,挤压延时3.2 s;溢流侧挤压时间为8 s,挤压延时2.2 s),测试试件局部加压对铸件致密性的影响。

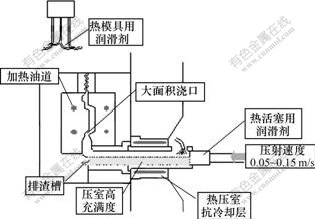

由于超低速压铸时的高速速度和低速速度都很低,溶液流动性不好,在压铸时需要采取一些特殊设计来保证铸件的质量(图1)。

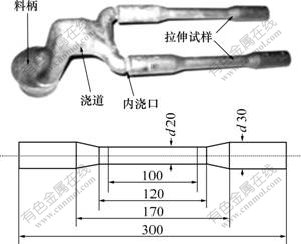

将试样从浇口处取下,测量不同试验条件下试样(图2)的密度(JT5003型电子天平,精度为±0.001 g)及其力学性能(CSS-2220B电子万能试验机),并在所得压铸件上截取并制备金相试样,在金相显微镜(DMM- 400C光学显微镜)及扫描电镜(LEO-1530热场发射扫描电镜)上观察微观组织及断口,用XRD(bruker axs公司的D8 ADVANCE X线衍射仪)和EDS(英国OXFORD)能谱仪测定相组成。在万能材料试验机上进行拉伸实验时,应变速率基本控制在1 mm/min左右,同一工艺条件下测量3~5个试样,并取平均值,作为最终测量结果。

图1 压铸时需要采用的特殊设计

Fig.1 Special design when casting

单位:mm

图2 超低速压铸件试样及尺寸

Fig.2 Super slow speed die cast test specimen and dimension

2 实验结果

2.1 慢压射速度对铸件显微组织的影响

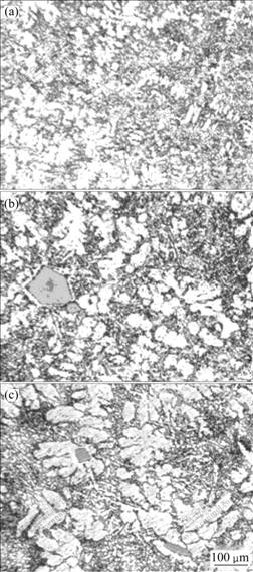

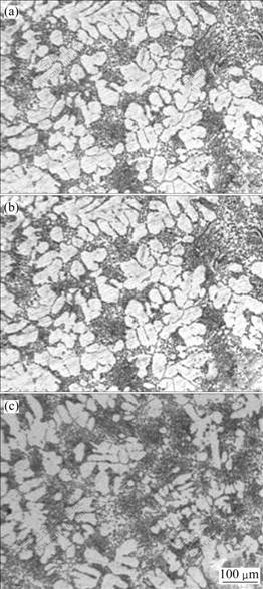

图3所示为工艺1中相同起速位置、不同慢压射速度时试样中部的显微组织。从图3可以看出:在其他条件不变的情况下,随慢压射速度的增加,α(Al)枝晶越来越粗大。图4所示为工艺2中相同慢压射速度、不同起速位置时试样中部的显微组织。从图4可以看出:当起速位置为260 mm时,α(Al)枝晶较细小。

速度/(m?s-1): (a) 0.05; (b) 0.2; (c) 0.3

图3 不同速度、相同起速位置下试样心部的显微组织

Fig.3 Center microstructures of test specimen at different slow speed on same injecting speed start locations

起速位置/mm: (a) 250; (b) 260; (c) 270

图4 相同速度、不同起速位置下试样心部的显微组织

Fig.4 Center microstructures of test specimen at same slow speed on different injecting speed start locations

2.2 慢压射速度对铸件密度的影响

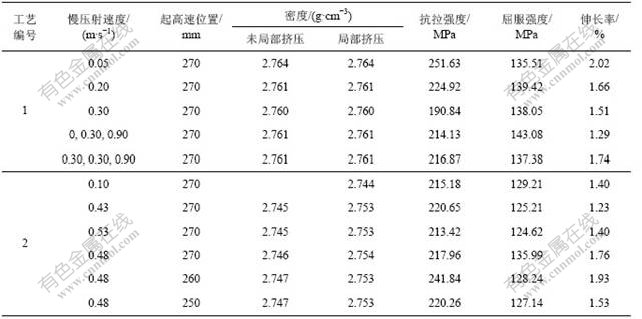

慢压射速度对超低速压铸件性能的影响见表1。从表1可见:工艺1中各种速度下铸件的密度明显均高于工艺2中各种速度下铸件的密度;慢压射速度越大,铸件的密度越低;恒速和加速下铸件的密度变化不大。采用工艺2,局部加压后,在相同速度条件下铸件的密度也均有明显提高。

超低速压铸时,慢压射速度很低,压室中的气体可以较充分排逸,故其铸件密度比一般压铸时的要高;但由于合金液温度较高,虽然慢压射速度很低,使其在压室中停留时间较长,导致合金液温度降低,但在很低的快压射速度下(0.09 m/s),冲头施加在合金液上的压力较小,合金液在型腔中的凝固速度较低,冲头压力施加在液态合金上不能引起铸件密度有大的提高。随着慢压射速度增加,铸件密度下降,是由于慢压射速度越大,合金液卷气量越大;但由于慢压射速度很低,合金液运动时卷气不是很严重,故只要冲头速度很低,恒速或加速密度变化不大。局部加压可以减少或消除壁厚处由于最后凝固收缩而产生的缩孔、缩松,故铸件的密度进一步提高。

表1 慢压射速度对超低速压铸件的性能影响

Table 1 Effects of slow speed on properties of super slow speed die castings

2.3 慢压射速度对铸件力学性能的影响

采用工艺1的慢压射冲头恒速时,随着冲头速度增加,抗拉强度减小,伸长率也降低,屈服强度变化不明显。慢压射冲头加速时,2种加速方式(见表1)的抗拉强度均较低,屈服强度和伸长率与恒速相比变化不明显;工艺2采用恒慢压射速度,从表1可见:抗拉强度随着慢压射速度的变化影响不大,而与起高速位置有关[11]。在起高速位置为260 mm时抗拉强度最大,此时伸长率也最大。工艺2中的屈服强度与工艺1的相比明显减小,但受慢压射速度的变化影响不大。

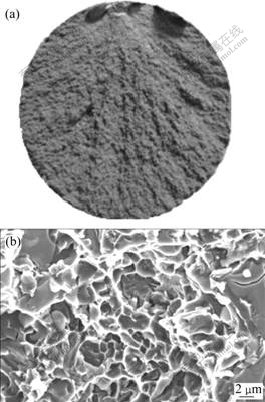

2.4 慢压射速度对铸件断口形貌的影响

2种工艺条件下铸件的拉伸断口均为静拉应力造成的混合断口,有典型的辐射状棱线形貌,可以据此找到裂纹源(图5(a))。扫描断口由多个解理平台组成,很少有韧窝,且断口上有较多的二次裂纹,呈典型的脆断特征(图5(b))。

3 分析与讨论

超低速压铸时压射速度很低,虽然可以保证压室内金属液平稳流动卷气较少,获得较大的密度,但由于速度太低,会出现压室内金属液温度下降的问题,难以保证充填时良好的流动性,甚至出现浇口处金属液凝固封堵浇口,造成充型不良。故应在保证良好的铸造性能的前提下选择合适的慢压射速度。在工艺1中,随着慢压射速度增加,铸件性能下降非常明显,这是由慢压射速度越大,合金液卷气越严重造成的,这可以从速度越大密度越低得到证明;冲头加速时,这2种加速方式的铸件性能都较差,说明在超低速压铸时,冲头恒速比加速铸件的性能要好。在工艺2中,随着慢压射速度的增加,性能先有小幅度提高,在慢压射速度增加到0.43 m/s后达到最大值,随后,随着慢压射速度的增加,铸件性能开始下降,但性能总的变化很小,说明铸件的性能主要取决于快压射、增压、保压及模具结构等其他压铸工艺参数,而与慢压射速度关系不大[12]。

(a) 宏观断口; (b) 断口的SEM形貌

图5 超低速下铸件的断口形貌

Fig.5 Fracture morphologies of super slow speed die cast specimens

起高速位置是由慢压射向快压射启动的位置,作为低高速的转化位置,决定着高速压射充型过程中金属液的流动状态。起高速位置发生在压射较早阶段时,金属液容易形成严重的翻转造成卷气;而当起高速位置过晚时,型腔已经充填一部分金属液,高速跟进的金属液可能迅速超过低速的金属液充填,导致充填速度不一致,造成流痕缺陷,并且由于慢速进入的金属液温度较低,可能提前凝固封堵浇口,造成充型不良等其他缺陷。合理的起高速位置可以避免上述缺陷发生,从而使金属液具有良好的力学性能。以上分析可知:在低速速度为0.48 m/s、高速速度为0.09 m/s时,起高速位置为260 mm时较为合适。

4 结论

(1) 超低慢压射压铸时铸件的含气量较低,密度较大,但压室中仍然存在卷气现象。

(2) 当起速位置相同时,铸件的性能随着低速速度的增大而降低。

(3) 在相同低速速度、不同高速起速位置时,起速位置有最佳值,铸件性能在高速起速位置为260 mm时较好。

(4) 为避免出现浇口处金属液凝固封堵浇口,造成充型不良,应在保证良好铸造性能的前提下选择合适的慢压射速度,兼顾充型时的卷气对铸件力学性能的影响和合金的流动性对铸件铸造性能的影响。

参考文献:

[1] Nogowizin B. Wahl der vorlaufbeschleunigung oder der vorlaufgesch windigkeit bei druckgiessmaschinen[J]. Giesserei- Praxis, 1994(3): 70-73.

[2] Wohlfahrt H. Einfluβ der ersten gieβphase auf dengasgehalt von aluminium druckguβteilen[J]. Giesserei, 1999, 86(5): 73-75.

[3] 于彦东, 蒋海燕, 雷黎, 等. 镁合金压铸工艺的数值模拟[J]. 中南大学学报: 自然科学版, 2006, 37(5): 867-873.

YU Yan-dong, JIANG Hai-yan, LEI Li, et al. Numerical simulation of die casting process of magnesium alloy[J]. Journal of Central South University: Science and Technology, 2006, 37(5): 867-873.

[4] Tannechill J C, Anderson D A, Pletcher R H. Computational fluid mechanics and heat transfer[M]. 2nd ed. washington DC: Taylor & Francis, 1997.

[5] 郭洪民, 杨湘杰. 流变压铸YL112铝合金的微观组织特征[J]. 中国有色金属学报, 2008, 18(3): 400-408.

GUO Hong-min, YANG Xiang-jie. Microstructures characteristics of YL112 aluminum alloy produced by rheo- diecasting process[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 400-408.

[6] Garber L W. Filling of the cold chamber during slow-shot travel[J]. Die Casting Engineer, 1981, 25(4): 36-38.

[7] Garber L W. Theoretical analysis and experimental observation of air Entrapment during cold chamber filling[J]. Die Casting Engineer, 1982, 26(3): 14-22.

[8] 纪莲清, 熊守美, 村上正幸, 等. 内浇口速度和尺寸对ADC12铝合金组织及性能的影响[J]. 特种铸造及有色合金, 2008, 28(9): 693-695.

JI Lian-qing, XIONG Shou-mei, Masayuki Murakami, et al. Effects of gate speed and dimension on microstructure and mechanical properties of super slow speed die castings of ADC12 aluminum alloy[J]. Special Casting & Nonferrous Alloys, 2008, 28(9): 693-695.

[9] 纪莲清, 熊守美, 村上正幸, 等. 浇注温度对ADC12铝合金超低速压铸件组织性能的影响[J]. 特种铸造及有色合金, 2008, 28(7): 529-531.

JI Lian-qing, HE Pei-ying, XIONG Shou-mei, et al. Effects of injection temperature on microstructure and mechanical properties of ADC12 aluminum alloy in super slow speed sie sasting[J]. Special Casting & Nonferrous Alloys, 2008, 28(7): 529-531.

[10] 纪莲清, 熊守美, 村上正幸, 等. 压力对ADC12铝合金超低速压铸件组织及力学性能的影响[J]. 铸造, 2007, 56(11): 1167-1170.

JI Lian-qing, XIONG Shou-mei, Masayuki Murakami, et al. Effects of casting pressure on microstructure and mechanical properties of super slow speed die castings of ADC12 aluminum alloy[J]. Foundry, 2007, 56(11): 1167-1170.

[11] 袁烺. 压铸压室压射过程数值模拟技术研究[D]. 北京: 清华大学机械工程学院, 2006.

YUAN Lang. Study on the numerical simulation of flow field of the flow shot phase in the die casting shot sleeve[D]. Beijing: Tsinghua University. Department of Mechanical Engineering, 2006.

[12] 潘宪曾. 正确选择慢压射速度[J]. 铸造技术, 2005, 26(5): 397-400.

PAN Xian-zeng. Correct selecting slow shot speed[J]. Foundry Technology, 2005, 26(5): 397-400.

收稿日期:2009-06-11;修回日期:2009-08-04

基金项目:河南省科技攻关项目(082102240041)

通信作者:纪莲清(1966-),女,河南淇县人,教授,从事材料成形及计算机辅助设计;电话:13838298657;E-mail: jilq@zzuli.edu.cn

(编辑 陈爱华)