Trans. Nonferrous Met. Soc. China 22(2012) 901-906

Numerical simulation and physical analysis for dynamic behaviors of

P/M TiAl alloy in hot-packed forging process

ZHANG Wei1, LIU Yong1, WANG Li1, LIU Bin2

1. State Key Lab oratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Institute for Materials Research, Tohoku University, Sendai 980-8577, Japan

Received 9 September 2011; accepted 16 January 2012

Abstract: The hot forging of large-scale P/M TiAl alloy billet deformation was investigated based on a joint application of Deform-3D-based numerical simulation and physical simulation techniques. The temperature dependence on the thermal and mechanical properties of the billet was considered and the optimum hot working temperature of packed TiAl alloy was 1150- 1200 ℃. Based on the simulation, the material flow and thermo mechanical field variables, such as stress, strain, and temperature distribution were obtained and the relationships of load—displacement and load—time were figured out. To verify the validity of the simulation results, the experiments were also carried out in a forging plant, and a pancake with diameter of 150 mm was obtained exhibiting a regular shape.

Key words: TiAl; hot packed forging; numerical simulation; physical simulation

1 Introduction

Lightweight heat-resistant alloys based on the intermetallic compound TiAl have been positioned as next-generation structural materials and investigated extensively [1]. However, until now, components made of TiAl alloy have been limited, and cast material is used for only turbochargers turbine wheels [2,3] and automotive engine valves [4,5]. Wrought material has been used only for rolled thin plates [6] and automotive engine valves, but all these components are small and have comparatively simple configurations. If large TiAl components could be fabricated with high dimensional precision, expanded applications for TiAl alloys could be expected.

In the manufacturing of TiAl alloy for high temperature structural components, process parameters are chosen and kept within narrow ranges due to the strict workability windows as well as close control in the microstructure specifications of the final component. Hot packed forging technique can improve not only the performance but also the mechanical properties of the product. However, some disadvantages are convinced, such as increased pressure and inhomogeneous deformation in the inner part of metal because of contact frictions. The surface crack and coarse structure near the contact area are both in existence [7,8]. These shortcomings restrain the properties of large-scale parts. Besides, the existence of the friction between forging tools and the top and bottom surface of the billet, and the heat radiating varying between different regions of the billet during upsetting process result in non-uniform temperature, stress and strain distributions and then inconsistent deformation. These lead to uneven grain size and affect the performance of forgings [9] . Therefore, it is necessary to simulate the plastic deformation process during hot packed forging for the real production.

In this study, a procedure for designing and optimization of the hot packed forging process of large scale TiAl alloys was studied based on the combined use of experimental and numerical techniques. Numerical analysis was carried out by Deform-3D simulation of the deformation characteristics in the hot packed forging process. The experimental analysis is addressed to properly calibrate the numerical model and combine physical simulation experiments on real-material samples. The developed procedure is successfully applied in an industrial forging process.

2 Model building and simulation control

2.1 Hot packed compression tests

TiAl alloy compacts with a nominal composition of Ti-47Al-2Cr-0.2Mo (molar fraction, %) was prepared by powder metallurgy technique, the dimensions and relative density are approximately d50 mm×100 mm and more than 99.6%, respectively. TiAl alloy powder with particle size of 100-150 μm was filled into steel can and degassed at 400 ℃, then HIPed under 140 MPa at 1200 ℃ for 4 h. Pieces with size of d10 mm×12 mm were cut by electric-discharge from the above-mentioned large compact. To entrap the lubricant, the ends of the specimens were recessed to a depth of 20 μm. After being ground with No. 800 abrasive paper and removal of oil on samples with acetone, these samples were degassed in 1.5 mm thick cans made by special steel. The high temperature compression tests were conducted in a Gleeble-1500 thermo-simulation machine at 1000, 1050, 1100, 1150, 1200 and 1250 ℃ and strain rate of 0.1 s-1, respectively. Specimens were heated by induction coils at testing temperatures for 5 min before compression.

2.2 Simulation control of hot packed forging process

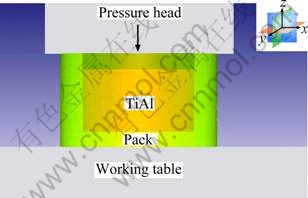

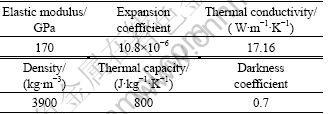

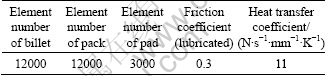

Rigid-plastic model was applied because the plastic deformation degree of TiAl alloy was far more than the elastic deformation in the hot deformation processing. The research of pack design and optimization was described explicitly in Ref. [10]. A pack composed of special steel with a thickness of 20 mm and thermal insulation at billet ends was the optimization result as to cylinders with size of d60 mm×100 mm. Figure 1 shows the simulation model of hot packed forging. The properties of the TiAl alloy are presented in Table 1. The temperature of the furnace was 1150 ℃ and the reduction of the pack-forging was 50%. The processing parameters used in the simulations are listed in Table 2.

Fig.1 3D simulation assembly drawing of hot pack forging of TiAl based alloy

Table 1 Properties of TiAl alloy

Table 2 Processing parameters used in simulations

3 Result and discussion

3.1 Physical simulation of hot packed forging process

Figure 2 shows the vertical macrostructures of TiAl alloy along the compression direction after hot packed compression. The results show that the packed TiAl alloys almost have not deformed below 1050 ℃, start to deform at 1100 ℃ at a relatively high strain while the temperature is up to or higher than 1150 ℃.

As known from the results, at temperature lower than 1100 ℃, the TiAl alloy almost does not deform and just the pack deforms, indicating that the force resisting deformation is severe at temperature below 1100 ℃, and the alloy cannot be hotly worked. The pack and the TiAl alloy both deform at 1100 ℃, although the deformation degree of TiAl alloy is relatively small. The vertical section of the alloy is perfect without defects. This means the force resisting deformation of the hot compressed TiAl alloy decreases while the temperature increases up to 1100 ℃, and the packed TiAl alloy can be hotly worked at temperature up to or higher than 1100 ℃. The pack and the TiAl alloy both deform with appropriately large reduction at 1150 and 1200℃, which means that its force resisting deformation decreases apparently. The vertical section of the alloy is perfect without cracks and the products can be hot compressed with a minimum force and enough deformation. However, when hot compressed at 1250 ℃, the TiAl alloy exhibits local serious deformation. The pack is deformed seriously and thinned in local position resulting from the local molten of pack by overheating. This means that the pack of special steel cannot be hotly worked at 1250 ℃ or higher. When hot worked at temperature higher than 1250 ℃, the local position of pack would melt due to overheating and the compression stress of the pack on the alloy would lose. Thus, the cracks generate and propagate easily, and the TiAl alloy finally fails. Apparently, the optimum temperature for the hot working of TiAl alloy with special steel is 1150-1200 ℃.

Fig. 2 Photos of typical sections of hot pack compressed TiAl based alloys along compression direction at different temperatures: (a) 1100 ℃; (b) 1150 ℃; (c) 1200 ℃

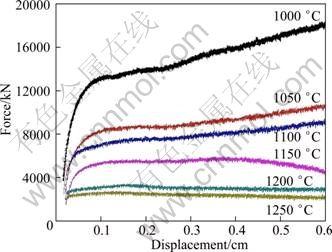

Figure 3 shows the displacement—force curves of the packed TiAl alloy during hot compression. When the packed TiAl alloy is hot compressed under given experimental conditions, the force increases with increasing displacement; but at 1150 ℃, the force increases with increasing displacement at first and then decreases drastically. In this study, TiAl billet is packed by special steel, and the deformation behavior of TiAl alloy is different from that of pack apparently. The comprehensive deformation behavior of packed TiAl alloy is complicated, and the true stress—true strain curve of TiAl alloy in can is very hard to detect and its practical meaning is finite. The displacement—force curves of the packed TiAl alloy reflect more exactly the true deformation situation of the TiAl alloy, so the displacement—force curves of the packed TiAl alloy during hot compression are analyzed. It is seen that the displacement rapidly increases with increasing force while packed TiAl alloy is hot compressed at temperature lower than 1100 ℃, which indicates that the force resisting deformation of the alloy is very large when hot compressed in the temperature range. The work-hardening rate is very high, the elasticity is large and the plasticity is small. The alloy cannot be hot worked at temperature below 1100 ℃. The displacement increases with increasing force while the packed TiAl alloy is hot compressed at 1150-1200 ℃, then the force maintains at a stable value but the displacement increases continuously. This means that the packed TiAl alloy deforms in elastic model at first, then work-hardens when compressed by force. The packed TiAl alloy softens because of the heat transformed from the deformation energy [11]. When the effect of work-hardening equals that of flow softening, the displacement continuously increases with the force maintaining at a relatively stable value. Apparently, the optimum hot working temperature of the packed TiAl alloy is 1150-1200 ℃. When the packed TiAl alloy is hot compressed at temperature higher than 1200 ℃, the displacement increases with increasing force at first due to the effect of work-hardening and then rapidly decreases due to the loss of compression stress on TiAl alloy because of the local melting of the steel pack. From the analyses and discussion mentioned above, the optimum hot working temperature of packed TiAl alloy is 1150-1200 ℃.

Fig. 3 Displacement—force curves of P/M TiAl based alloy under hot pack compression

3.2 Numerical simulation of hot packed forging process

In order to ensure that the simulation agrees with the actual forging process as possible, the whole pack-forging process is divided into three stages: 1) the billet is transferred from the furnace to the press, which about costs 10 s; 2) the billet is placed on the press, which about costs 2 s; 3) the pack-forging is at a loading speed of 15 mm/s.

The whole hot packed forging process costs about 16 s, and the thermal loss of the billet during this period is shown in Fig. 4. From the temperature distribution of the billet, it can be concluded that the heat drop of the top and bottom surface is about 30 ℃ higher than the side face. But the final forging temperature of the billet can be maintained above 1150 ℃ and the distribution of the temperature is relatively uniform, that is to say the hot packed forging process has realized basically the quasi isothermal environment. The “chilling effect” locates at the ends of the billet during conventional forging disappears. During stages 1 and 2, the minor temperature drop (about 2 ℃) between the billet and the pack occurs at point 2 due to the heat conduction, while the temperatures at the points 1 and 3 show insignificant temperature loss. Because Point 1 is in the centre of the billet and the temperature loss can be ignored, and with the function of the thermal barrier, Point 3 also does not suffer obvious temperature loss. During stage 3, the temperature at points 1, 2 and 3 continue to increase, but the extents of the temperature variations are differed and obey the order: ΔT1>ΔT2>ΔT3 owing to the different deformation extents of the three zones.

Fig. 4 Temperature distribution (a) and curves (b) for three points during forging

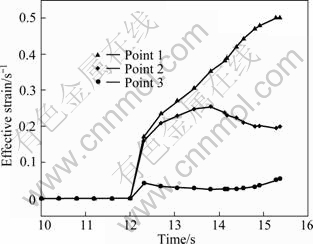

Figure 5 shows the effective strain distribution of the billet during hot packed forging. It is seen that the deformation zones of conventional forging also locate in the billet. However, the easy-deformation zone of the billet is enlarged, and the effective strain of Point 3 in the hard-deformation zone reaches 0.2, which means the deformation extent of the billet is increased significantly. Because of the novel pack, more uniform temperature- distribution of the billet can promote the homogenous deformation. From the effective strain rate—time curves in Fig. 6, it is obtained that the effective strain rate of Point 1 in the easy-deformation is larger than that of the other two points, which shows great consistency with that from the effective strain distribution.

Fig. 5 Effective strain distribution (a) and curves (b) for three points during forging

Fig. 6 Relationship of effective stress rate and time for three points during forging

It is well known that the work hardening and flow softening of the billet would occur in the process of hot deformation [12], which is embodied in the curves of effective stress—time for points 1, 2 and 3, as shown in Fig. 7. When the forging starts, the effective stresses at points 1 and 2 increase to the maximum (about 200 MPa) very fast with the increment of the strain. But the effective stress at Point 3 rises to about 125 MPa at a lower speed (the work hardening stage). Then the effective stresses at points 1 and 2 reduce to 46 and 76 MPa, respectively and the reduction at Point 1 (144 MPa) is more than that at Point 2 (124 MPa) in the flow softening stage. However, as for Point 3, after the effective stress drops to about 104 MPa, the effective stress remains constant although the strain increases in the steady rheological stage. Finally, the stress increases to 122 MPa again. The reason for this phenomenon is as follows. In the hardening stage, although the temperatures at points 1, 2 and 3 show insignificant difference, the effective strain at Point 3 is far less than that at Points 1 and 2. As a consequence, the effective stress at Point 3 is also less than that at points 1 and 2. Subsequently, with the temperature increment induced by the heat from the deformation energy, the temperature at points 1, 2 and 3 accords in the sequence: T1>T2>T3, and thus the deformation ability at point 1 is more severe than those at points 2 and 3.

Fig. 7 Effective stress distribution (a) and curves (b) for three points during whole forging

3.3 Experimental verification of hot packed forging process

In order to prove the suitability of the hot working parameters deduced from the simulation experiments to an engineering size billet, hot packed forging of TiAl alloy with initial dimensions of d80 mm×100 mm were carried out in a 500 t hydraulic press. The experimental results show that a total deformation of 60% is successfully realized through two or three steps of hot packed forging at temperature of 1150 ℃ and strain rate of 0.1 s-1.

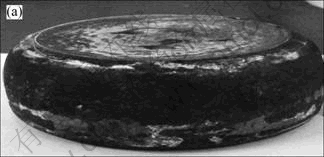

It can be seen from Fig. 8 that the pancake with diameter of 150 mm is obtained after forging and pack removal, which exhibits a regular shape without macro-cracks and oxidization scale strips on the surface. X-ray test was used to inspect the internal porosity of the TiAl alloy pancake after rough machining. The results indicate that the pancake has no detectable cracks or defects.

Fig. 8 Photo of TiAl alloy pancake after hot forging

4 Conclusions

1) Accurate prediction of temperature distributions and constitutive characteristics of TiAl alloy produced by novel forging process is basically realized under quasi isothermal deformation conditions.

2) Large pancake without macro-cracks and oxidization scale strips on the surface show that the novel package unit can basically realize the quasi isothermal environment and ensure the quality of the forging part. Industrial trials demonstrate the effectiveness of this hot packed forging process optimization.

References

[1] TETSUI T, ONO S. Endurance and composition and microstructure effects on endurance of TiAl used in turbochargers [J]. Intermetallics, 1999, 7(6): 689-697.

[2] TETSUI T. Application of TiAl in a turbo-charger for passenger vehicles [J]. Advanced Engineering Materials, 2001, 3(5): 307-310.

[3] TETSUI T. Development of TiAl turbocharger for passenger vehicle [J]. Materials Science and Engineering A, 2002, 329-331: 582-588.

[4] FU PX, KANG XH, MA YC, LIU K, LI DZ, LI YY. Centrifugal casting of TiAl exhaust valves [J]. Intermetallics, 2008, 16(2): 130-138.

[5] BADAMI M, MARINO F. Fatigue tests of un-HIP'ed γ-TiAl engine valves for motorcycles [J]. International Journal of Fatigue, 2006, 28(7): 722-732.

[6] CLEMENS H, KESTLER H, EBERHARDT N, KNABL W. Processing of γ-TiAl-based alloys on an industrial scale [C]// KIM Y W, DIMIDUK D M, LORETTO M H. Gamma Titanium Aluminides 1999. Warrendale, PA: TMS, 1999: 209-223.

[7] KANG Da-tao, YE Guo-bin. Material and heat treating of large-scale parts [M]. Beijing: Longman Press, 1998: 12. (in Chinese)

[8] GUO Hui-guang, REN Yue-yong, CHEN Hui-qin, LI Yun-hai. Innovation research and development tactics of heavy forgings [J]. Large-scale Casting Forging Part, 2002, 97(3): 45-47. (In Chinese)

[9] ZHANG Z J, DAI G Z, WU S N, DONG L X, LIU L L. Simulation of 42CrMo steel billet upsetting and its defects analyses during forming process based on the software DEFORM-3D [J]. Materials Science and Engineering A, 2009, 499: 49-52.

[10] ZHANG Wei. Study on hot working behaviors and technology of powder metallurgy TiAl based alloys [D]. Changsha: Central South University, 2010. (in Chinese)

[11] HUANG J S, HUANG L, LIU B, ZHANG Y H, ZHANG W, HE X Y, LIU Y. Simulation of hot compression of Ti-Al alloy [J]. Intermetallics, 2007, 15: 700-705.

[12] ZHANG W, LIU Y, LI H Z, LI Z, WANG H, LIU B. Constitutive modeling and processing map for elevated temperature flow behaviors of a powder metallurgy titanium aluminide alloy [J]. Journal of Materials Processing Technology, 2009, 209(12-13): 5363-5370.

热包套锻造过程中P/M钛铝合金动态行为的数值模拟与物理分析

张 伟1, 刘 咏1, 王 丽1, 刘 彬2

1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 东北大学 材料研究院,仙台 980-8577,日本

摘 要:基于Deform-3D数值模拟技术和物理模拟技术,对大尺寸粉末冶金TiAl合金坯的热锻过程进行模拟分析,研究锻坯的热力学性能与温度场的相关性,获得应力、应变和温度场的分布规律以及载荷随行程和时间的变化规律等一系列高温塑变特征。在此基础上,设计新型的锻造包覆机构,并进行工程实验验证。结果表明:1150~1200 ℃是热包覆锻造的最优热加工温度区间,最终获得外观良好的大尺寸钛铝合金锻饼,其直径大于 150 mm。

关键词:TiAl;热包覆锻造;数值模拟;物理模拟

(Edited by FANG Jing-hua)

Foundation item: Project (2011CB605505) supported by the National Basic Research Program of China; Project (2011QNZT041) supported by the freedom explore Program of Central South University, China; Project (84088) supported by the and Postdoctoral Foundation Supported Project of Central South University, China

Corresponding author: ZHANG Wei; Tel: +86-731-88879943; E-mail: w.zh.csu@gmail.com

DOI: 10.1016/S1003-6326(11)61263-6