文章编号:1004-0609(2010)07-1260-07

镁基复合材料半固态压铸过程的数值模拟

胡 勇1,何柏林1,闫 洪2

(1. 华东交通大学 载运工具与装备教育部重点实验室,南昌 330013;

2.南昌大学 机电工程学院,南昌 330031)

摘 要:对镁基复合材料半固态充型凝固过程进行数值模拟,并进行半固态流变成形实验。结果表明,在液态充型过程中,压力变化非常紊乱;而在固态充型过程中,压力在推进方向上逐渐降低,这将产生有利于充型的背压。凝固过程的固相体积分数变化表明:在半固态充型条件下,整个铸件基本上是同时凝固,从而可有效地避免在液态充型时产生缩孔缩松。实验结果与模拟结果吻合,半固态流变成形件的质量优于液态成形件的质量。

关键词:镁基复合材料;半固态,复合材料,数值模拟

中图分类号:TB331 文献标志码:A

Numerical simulation of semi-solid die casting process of magnesium matrix composite

HU Yong1, HE Bo-lin1, YAN Hong2

(1. Key Laboratory of Ministry of Education for Conveyance and Equipment,

East China Jiaotong University, Nanchang 330013, China;

2. School of Mechanical-Electrical Engineering, Nanchang University, Nanchang 330031, China)

Abstract: The semi-solid filling and solidification process of magnesium composite was simulated and the semi-sold filling experiment was carried out. The results indicate that the distribution of pressure during the liquid filling process is inordinate, but the pressure reduces gradually in the filling direction during the semi-solid filling process, which is favorable to generate back pressure during filling process. According to the distribution of the solid volume fraction during the solidification, it is found that the casting solidifies at the same time during the semi-solid filling, which can reduce shrinkage cavity and porosity. And the simulation results are in accordance with the experimental results. The quality of semi-solid reho-forming casting is better than that of liquid forming casting.

Key words: Mg matrix composite; semi-solid; composite; numerical simulation

半固态金属浆料在压力作用下具有良好的流动性和充填性,但半固态金属充型过程的描述及充型工艺条件比较复杂,采用数值模拟技术可以对充型凝固过程进行动态显示,还可以预测铸件的缩孔缩松等缺陷的位置及严重程度,这对提高铸件质量、缩短生产周期、降低生产成本、指导工程技术人员采取合理措施优化工艺设计具有重要的意义。目前,基于牛顿流体流变成形过程的数值模拟已经非常成熟[1-5],对于基体合金非牛顿流体流变规律的研究工作开展得也很广 泛[6-13],但是关于复合材料非牛顿流体流变规律的模拟研究工作却很少报道。本文作者对半固态Mg2Si/AM60镁基复合材料的流变成形进行模拟,分析其充型凝固过程,并对可能出现的铸造缺陷进行预测,为流变压铸工艺提供参考依据。

1 基本方程

半固态金属的充型过程是不可压缩的非稳态流动过程,在充型过程中,其流动为层流流动,在充填过程中流动控制方程的三维数学模型如下[14]。

1) 连续性方程(质量守恒方程):

(1)

(1)

2) 动量方程(Navier-Stokes方程)。在成形过程中,半固态金属的流动伴随有动量的变化,采用动量守恒定律来描述流动速率,得到金属熔体流动方程:

(2)

(3)

(4)

式中:U、V、W为速度矢量在坐标系x、y、z方向上的分量;t为时间;p为压力;ρ为半固态浆料的流体密度;gx、gy、gz分别为x、y、z方向的重力加速度;ν为运动黏度; 为拉普拉斯算子。

为拉普拉斯算子。

3) 能量守恒方程。在半固态成形过程中,金属由半固态转变为固态,这个过程伴随有能量的转换。

(5)

式中:T为温度;λ为导热系数。

4) 体积函数方程:

(6)

(6)

式中:φ为液相体积分数。

5) 黏度模型。半固态合金流变成形的流动过程,仅仅用上述守恒方程还不能描述其流动,还需建立其黏度模型。黏度模型的正确与否直接关系到模拟结果的正确与否。模拟中采用自行拟合而得到的半固态Mg2Si/AM60镁基复合材料的稳态表观黏度模型[15]:

(7)

(7)

式中:ηm为复合材料的表观黏度;γ为剪切速率;φα-Mg为α-Mg的体积分数; 为增强相Mg2Si的体积分数。

为增强相Mg2Si的体积分数。

2 模拟结果与分析

2.1 模拟模型和参数

模拟的零件结构如图1所示。模具材料为H13,零件材料选用半固态Mg2Si/AM60镁基复合材料,Mg2Si的体积分数为1%,环境温度为室温,半固态浇注温度为600 ℃(固相体积分数为41%),黏度模型如式(7),压射比压为40 MPa,冲头压射速度为2.5 m/s,模具温度为220 ℃。为了进行比较,同时进行液态压铸模拟,浇注温度为660 ℃,η=10-3 Pa·s,其他参数不变。材料的热物性参数如表1所列。

数值模拟程序的流程如图2所示。首先采用CAD软件进行三维实体造型,经格式转换导入前处理模块中进行网格划分和参数设置;接着进行数据整理,检查参数设置是否合理,无误后进行模拟计算;最后,经后处理模块进行动态显示,对充型凝固过程及铸件中的缺陷进行观察和分析,然后针对缺陷对工艺优化,由此反复,直到得出满意的结果。

图1 圆盘件CAD图

Fig.1 CAD drawing of disk cast

表1 材料的热物性参数

Table1 Physical parameters of materials

图2 模拟程序的流程图

Fig.2 Program flow chart of simulation

2.2 充型过程的压力分布

液态金属的黏度跟水的接近,具有很好的流动性,充型时会产生飞溅,呈紊流特征;而半固态金属浆料中具有一定量的固相体积分数,其黏度大大增加,充型过程平稳,呈层流特征。

图3和4所示分别为液态和半固态充型过程的压力分布情况。从图3可以看出,金属液充满浇口后,迅速前冲至对壁,然后沿着壁面冲向顶壁(见图3(b));

图3 液态充型的压力分布

Fig.3 Distribution of pressure during liquid casting: (a) Filling with 25%; (b) Filling with 35%; (c) Filling with 55%; (d) Filling with 65%; (e) Filling with 80%; (f) Filling with 100%

图4 半固态充型的压力分布

Fig.4 Distribution of pressure during semi-solid casting: (a) Filling with 25%; (b) Filling with 45%; (c) Filling with 55%; (d) Filling with 75%; (e) Filling with 90%; (f) Filling with 100%

之后,液流沿着顶壁面向两侧扩散(见图3(c));然后,金属液沿着型壁折回(见图3(d)),充填80%时,液流将型腔封闭,并形成两股涡流(见图3(e)),该区域往往是卷气夹渣等铸造缺陷存在的地方。由图3可知,液态充型过程中压力分布比较紊乱,这就使得液态充型时在型腔中容易产生飞溅,从而使得铸件质量出现问题。而半固态充型过程的压力在推进的方向上逐渐降低,即在液流的最前沿压力最低(见图4),因此在半固态流体中产生了背压,这有利于充型。压力的降低是由半固态之间存在的固相产生摩擦力以及半固态浆料与铸型之间的摩擦力造成的。

根据图5所示的各节点所在位置,测得液态充型过程中内部节点压力随时间的变化如图6所示。由于型腔中有气体,因此在铸液没达到各节点位置时,其

图5 各节点所在部位

Fig. 5 Positions of nodes

压力都为1.01×105 Pa。液态充型时,当铸液经过节点1时,压力突然增大,当前端铸液冲击型壁折回之后,压力稍降,而后在前方铸液的冲击下,压力逐渐增大。节点2的压力开始一直为1.01×105 Pa,分析其原因,

图6 液态充型过程各节点的压力随时间的变化

Fig.6 Relationship between pressure of nodes with time during liquid casting

是因为液态充型时,该处在充填量达到65%时,仍然没有铸液充填(见图(3d)),当铸液即将充满型腔时,压力突然增大。节点3处的压力与节点2处的变化类似,其区别在于其压力增大的时间早于节点2的,这是因为该处出现铸液的时间早于节点2的。节点4和5处的压力变化情况与节点2处的类似。节点6处的压力变化较复杂,该处压力先增大,当铸液碰到型壁折回后,该处压力突然降低,但是在前方铸液的冲击之下,其压力又将逐渐增大。

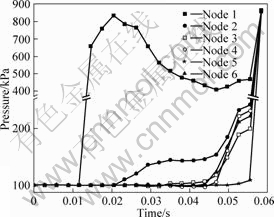

半固态充型时,内部节点压力随时间的变化关系如图7所示。由图7可看出,节点1的压力变化波动

较大,当铸液到达该处时,压力突然增大,然后又降低。这是因为半固态流体的黏度大,流动过程中产生了压力损耗,同时半固态流体与铸型之间的摩擦也要消耗一部分压力,所以压力会下降。当流动平稳之后,压力又开始上升,并在充满型腔的时候达到最大。其他几个节点的压力变化比较平稳,主要特征表现为当铸液到达节点位置时,压力开始增大,并且铸液后到达节点的压力要小于铸液先到达节点处的压力,这是由半固态金属与铸型之间的摩擦以及半固态金属之间的摩擦作用导致压力降而造成的。当铸液充满型腔时,各节点压力都达到最大。

对比图6和7可以发现,半固态充型的压力较液态充型的大,因此,半固态压铸时对压铸机的吨位要求较高;且液态充型时压力变化比较紊乱,半固态充型时压力变化则比较平稳。

2.3 凝固过程固相体积分数的变化

凝固过程中固相的体积分数的变化如图8所示。

图7 半固态充型过程中各节点的压力随时间的变化

Fig.7 Variations of pressure of nodes with time during semi-solid casting

图8 凝固过程中固相体积分数的变化

Fig.8 Variations of volume fraction of solid phases during solidification: (a) Liquid; (b) Semi-solid

由图8(a)可以发现,液态成形时,当浇口固相的体积分数为1时,图中箭头所指的固相的体积分数只有65%左右,因此该位置在后续的凝固过程中不能得到金属液的补充而产生缩孔缩松。由图8(b)可知,半固态成形时,当铸件其他部位固相的体积分数达到1时,方框处和箭头所指位置还没完全凝固,但箭头所指固相的体积分数已经达到0.95,基本上已完全凝固。而方框处固相的体积分数也达到0.9,且该位置和浇口相通,凝固时的收缩仍然可以得到有效的补充,因而,不易产生缩孔缩松。

2.4 缺陷预测

图9所示为两种流态下铸件缺陷分布图。液态充型时,铸件出现缺陷的几率最高位置如图9(a)中箭头所示,这也是在充型过程中产生涡流的位置(见图3(e))。半固态充型时,由于充型平稳,在铸件内部未出现缺陷。且通过对图8的分析发现,液态充型易出现缩孔缩松缺陷的位置与图9(a)所示的吻合,而半固态充型时不易出现缺陷。

图9 缺陷分布图模拟

Fig.9 Simulation of distribution of defects: (a) Liquid; (b) Semi-solid

3 实验验证

试验材料为采用机械搅拌法制备的半固态Mg2Si/AM60镁基复合材料浆料。实验采用的半固态流变成形模具照片如图10所示。

图10 半固态流变成形模具照片

Fig.10 Photos of mold during semi-solid rheo-forming

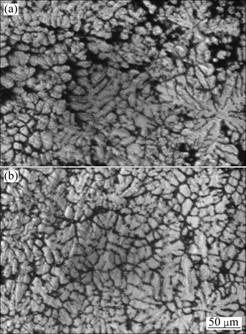

图11所示为半固态流变成形铸件。由图11可以看出,零件表面光滑,成形质量较好。图12所示为液态成形和半固态成形铸件的显微组织。由图12可见,液态成形时,其微观组织为枝晶状,且微观组织中有孔洞出现(见图12(a));而半固态成形时,其微观组织为(类)球状,微观组织中也没有出现孔洞缺陷(图12(b)),这可有效地提高铸件的使用寿命。从图11和图12可知,实验结果与模拟预测结果吻合较好。

图11 半固态流变成形铸件

Fig.11 Photo of semi-solid rheo-forming casting

图12 铸件的微观组织

Fig.12 Microstructures of castings: (a) Liquid; (b) Semi-solid

4 结论

1)自行推导的半固态Mg2Si/AM60镁基复合材料的表观黏度模型适合对该材料进行半固态流变成形模拟,模拟结果正确。

2) 液态充型过程中,压力分布比较紊乱,充型时在型腔中容易产生飞溅;半固态充型过程中,压力变化平稳,在铸液推进的方向上压力逐渐降低,半固态流体中会产生有利于充型的背压,且半固态充型的压力较液态充型的大。

3) 液态充型时,浇口先凝固而阻止补缩通道;半固态充型时,铸件基本上同时凝固,可有效地避免液态充型时产生缩孔缩松缺陷。

4) 半固态流变成形的实验结果与模拟结果比较吻合,半固态流变成形件的质量优于液态成形件的。

REFERENCES

[1] 熊守美, 许庆彦, 康进武. 铸造过程模拟仿真技术[M]. 北京:机械工业出版社, 2004.

XIONG Shou-mei, XU Qing-yan, KANG Jin-wu. Simulation technology of casting process[M]. Beijing: China Machine Press, 2004.

[2] 胡 勇, 闫 洪, 陈国香, 钟子明, 聂文卿. 数值模拟技术在汽车螺塞压铸工艺设计中的应用[J]. 铸造, 2006, 55(3): 262-265.

HU Yong, YAN Hong, CHEN Guo-xiang, ZHONG Zi-ming, NIE Wen-qing. Application of numerical simulation to the design of automobile plug in die casting[J]. Foundry, 2006, 55(3): 262-265.

[3] 吴士平, 郭景杰, 贾 均. TiAl基合金排气阀立式离心铸造充型及凝固过程数值模拟[J]. 金属学报, 2004, 40(3): 326-330.

WU Shi-ping, GUO Jing-jie, JIA Jun. Numerical simulation of mold filling and solidification of TiAl base alloy exhaust valve in vertical centrifugal casting process[J]. Acta Metal Sinca, 2004, 40(3): 326-330.

[4] YAN Hong, ZHANG Wen-wei, HU Yong, ZHANG Quan-sheng, HONG Jin. Numerical simulation of AZ91D alloy automobile plug in pressure die casting process[J]. Journal of Materials Processing Technology, 2007, 187/188: 349-352.

[5] XIONG S M, LAU F, LEE W B. Numerical methods to improve the computational efficiency of thermal analysis for the die casting process[J]. Journal of Materials Processing Technology, 2003, 1/3: 457-461.

[6] ZHOU J X, LIU R X, CHEN L L, LIAO D M, WEI H S. Numerical simulation of casting mold filling process[J]. Acta Metal Sinca, 2005, 18(6): 724-730.

[7] ALEXANDROU A, BARDINET F, LOUE W. Mathematical and computational of die filling in semi-solid metal processing[J]. Journal of Materials Processing Technology, 1999, 96(1/3): 59- 72.

[8] BAI Yue-long, MAO Wei-min, XU Jun, XU Hong, HOU Hua. Numerical simulation on rheo-diecasting mould filling of semi-solid key-shaped component[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(3): 682-685.

[9] 白月龙, 毛卫民, 徐 宏, 侯 华, 毛红奎, 徐 俊. 半固态A356铝合金流变压铸充填过程的数值模拟[J]. 特种铸造及有色合金, 2008, 28(6): 428-432.

BAI Yue-long, MAO Wei-min, XU Hong, HOU Hua, MAO Hong-kui, XU Jun. Numerical simulation of rheo-diecasting filling of semi-solid A356 alloy[J]. Special Casting & Nonferrous Alloys, 2008, 28(6): 428-432.

[10] 李 强, 毛卫民, 白月龙, 徐 宏, 侯 华. 半固态AZ91D镁合金触变压铸充型过程的数值模拟[J]. 北京科技大学学报, 2006, 28(8): 755-758.

LI Qiang, MAO Wei-min, BAI Yue-long, XU Hong, HOU Hua. Numerical simulation of thixo-diecasting filling of semi-solid AZ91D alloy[J]. Journal of University of Science and Technology Beijing, 2006, 28(8): 755-758.

[11] 江运喜, 黄国杰, 谢水生, 李 雷. 半固态AZ91D镁合金压铸过程的数值模拟[J]. 塑性工程学报, 2006, 13(2): 89-92.

JIANG Yun-xi, HUANG Guo-jie, XIE Shui-sheng, LI Lei. Numerical simulation of die casting process of semi-solid AZ91D magnesium alloy[J]. Journal of Plasticity Engineering, 2006, 13(2):89-92.

[12] PETERA J, KOTYNIA M. The finite element model of non-isothermal semi-solid fluid flow[J]. International Journal of Heat and Mass Transfer, 2004, 47: 1483-1498.

[13] NATHER S, BRABAZON D, LOONEY L. Simulation of the stir casting process[J]. Journal of Materials Processing Technology, 2003, 143/144: 561-571.

[14] 毛卫民. 半固态金属成形技术[M]. 北京:机械工业出版社, 2004.

MAO Wei-min. Semi-solid metal forming technology[M]. Beijing: China Machine Press, 2004.

[15] 胡 勇. 原位镁基复合材料制备及流变成型研究[D]. 南昌: 南昌大学, 2009.

HU Yong. Study on fabricating and rheoforming of in-situ synthesized magnesium matrix composites[D]. Nanchang: Nanchang University, 2009.

(编辑 杨 华)

基金项目:国家自然科学基金资助项目(50765005);载运工具与装备省部共建教育部重点实验室开放基金资助项目

收稿日期:2009-07-15;修订日期:2010-01-20

通信作者:胡 勇,讲师,博士;电话:13576012078;E-mail:huyong2136@163.com