文章编号:1004-0609(2010)01-0079-07

TiAl基合金的高温塑性变形行为

李慧中1, 2, 3,李 洲1, 3,刘 咏2,张 伟2,王海军1, 3

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 粉末冶金国家重点实验室,长沙 410083;

3. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:采用Gleeble-1500热模拟机在变形温度为1 000~1 150 ℃、应变速率为10?3~100 s?1的变形条件下,研究Ti-47Al-2Cr-0.2Mo(摩尔分数,%)合金的热变形行为。利用光学显微镜和扫描电子显微镜分析合金在不同变形条件下的组织演化规律。结果表明:流变应力随着应变速率提高和变形温度降低而增大;在变形过程中,流变应力随着变形量增大而增大,当流变应力达到峰值后趋于平稳,表明合金在变形过程中发生了动态再结晶;热变形过程的流变应力可采用双曲正弦本构关系来描述,平均激活能为337.75 kJ/mol;从合金的组织演化过程中可以看出,合金中不均匀的原始组织得到明显均匀化,变形后的组织是由α2/γ层片晶团和γ晶粒组成的双态组织,在α2/γ层片晶团和γ晶粒的晶界交界处发现分布均匀的B2相,并且随着变形温度升高B2相数量逐渐减少。

关键词:TiAl基合金;热变形;流变应力;动态再结晶;激活能;B2相

中图分类号:TG 146.2 文献标识码:A

Plastic deformation behavior of TiAl based alloy at

high temperature

LI Hui-zhong1, 2, 3, LI Zhou1, 3, LIU Yong2, ZHANG Wei2, WHANG Hai-jun1, 3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

3. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: The hot deformation behaviors of the Ti-47Al-2Cr-0.2Mo (mole fraction, %) alloy were studied with a Gleeble-1500 machine at 1 000?1 150 ℃ with the strain rate of 10?3?100 s?1. The microstructural evolution of the alloy was investigated by optical microscopy and scanning electron microscopy. The results indicate that the flow stress of the alloy increases with increasing strain rate and decreasing deformation temperature. The flow stress increases with increasing strain until the stress reaches the peak value, then the flow stress remains constant, which indicates that dynamic recrystallization happens during deformation. The flow behaviors are described by the hyperbolic sine constitutive equation, and the activation energy calculated is 337.75 kJ/mol. The as-forged microstructure consists of refined α2/γ and γ grains, and the grains are much homogeneous than before. The B2 phase distributes uniformly at the grain boundary of α2/γ and γ grains. The B2 phase decreases with increasing deformation temperature.

Key words: TiAl based alloy; hot deformation; flow stress; dynamic recrystallization; activation energy; B2 phase

TiAl基合金具有较高的比强度和比刚度和较低的密度,以及良好的高温抗氧化和抗蠕变性能[1?3],是一种非常有潜力的轻质高温结构材料,在航空航天和汽车制造等工业领域有着广阔的应用前景[4?5],近年来一直是材料科学领域研究的热点。然而,由于TiAl基合金很脆,其室温塑性较低、变形困难以及850℃以上抗氧化性能不好,这些是工业应用的最大阻碍。TiAl基合金的变形性能与显微组织和变形条件密切相 关[6?7],张俊红等[8]研究TiAl基合金低温超塑性变形,结果表明TiAl基合金在变形温度为900 ℃、真应变为5×10?4 s?1时,伸长率最大值为413%。由于超塑性变形在工业中的应用效率很低,TiAl基合金高温变形最重要的手段是锻造。黄劲松等[9]研究热模拟包套锻造对TiAl基合金组织和变形性能的影响,结果表明,使用45#碳钢作为包套,TiAl基合金的实际最大相对变形量可达50%,晶粒被拉长和压扁。徐丽华等[10]研究包套锻造对高Nb-TiAl基合金组织的影响,分析合金中β相的分布情况和影响β相变的因素。李宝辉等[11]研究Ti-45Al-5Nb-0.3Y合金的热变形行为,并计算出合金的热变形激活能Q=399.5 kJ/mol。国内外学者对TiAl基合金的热变形行为已有相关的研究,但对Ti-47Al-2Cr-0.2Mo(摩尔分数,%)合金热变形行为和组织演化以及相变过程和相变对合金变形性能影响的研究鲜见报道。本文作者采用Gleeble?1500热模拟机对Ti-47Al-2Cr-0.2Mo(摩尔分数,%)合金在不同变形条件下进行等温压缩,建立热变形本构方程,研究合金在热变形过程中的组织演化规律,分析合金热变形时的相变过程,较为系统地研究合金的热变形行为,为合理制定合金的加工工艺提供理论基础。

1 实验

实验采用的合金名义成分(摩尔分数,%)为Ti-47Al-2Cr-0.2Mo。用旋转电极雾化法制备合金粉末,粉末粒度为150~250 ?m。在温度为1 200 ℃、压力为140 MPa的条件下热等静压4 h,制得d 50 mm×100 mm的致密圆柱试样,其致密度达99.6 %。从热等静压后的试样上用线切割加工出尺寸为d 10 mm×12 mm,两端带有d 8 mm×0.2 mm凹槽的圆柱试样。将加工好的试样在Gleeble?1500热模拟机上进行等温压缩实验,压缩变形温度为1 000~1 150 ℃,应变速率为10?3~100 s?1,压缩变形量为0.7(真应变)。压缩前往圆柱试样两端的凹槽内填充玻璃粉,压缩时圆柱试样两端用钽片垫在压头和试样之间,以减少摩擦的影响。实验过程中,采用惰性气体(氩气)保护,热模拟机升温速度550 ℃/min,保温时间5 min,压缩后的试样空冷至室温。采用Gleeble?1500热模拟机的计算机系统自动采集应力、应变、位移、温度及时间等数据。将热压缩后的试样在中间垂直上下表面切开,采用Leica型光学显微镜(OM)和Sirion型高分辨场发射扫描电镜(SEM)对表面进行显微组织分析。

2 结果及分析

2.1 真应力—真应变曲线

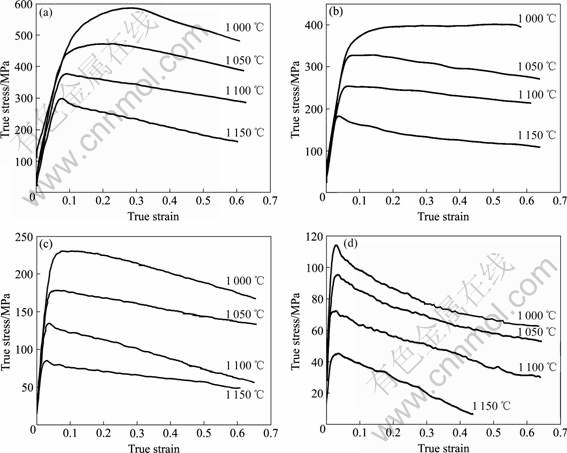

图1所示为不同变形条件下TiAl基合金的真应 力—真应变曲线。从图1中可以看出,合金在相同变形温度,不同应变速率的条件下变形时,峰值真应力随应变速率的提高而增大。在变形初期,真应力随应变的增加迅速增大,当真应力达到峰值之后,在高应变速率(应变速率为100、10?1和10?2 s?1)条件下,流变应力呈现出一定的稳态流变特征(见图1(a)、(b)和(c));而应变速率为10?3 s?1时,流变应力有明显的下降趋势(见图1(d)),说明合金在热变形过程中发生明显的动态再结晶。对在相同应变速率和不同变形温度条件下的流变应力进行比较可以看出,真应力随变形温度的升高逐渐减小。合金在同一变形温度下,随应变速率的增加,峰值真应力增大;在同一应变速率下,随变形温度的升高,峰值真应力明显下降,说明TiAl基合金在该实验条件下具有正的应变速率敏感性。

图1 在不同应变速率下压缩TiAl基合金的真应力—真应变曲线

Fig.1 Compressive true stress—true strain curves for TiAl based alloy at different strain rates: (a) 100 s?1; (b) 10?1 s?1; (c) 10?2 s?1; (d) 10?3 s?1

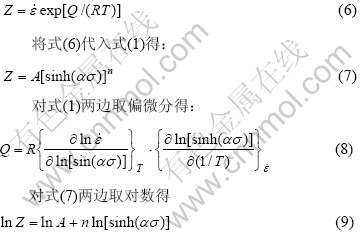

2.2 本构方程的建立

合金的流变应力与热加工参数的制定都要参考本构关系,本构关系是合金塑性变形工艺设定和控制的基础。本研究采用已广泛用于金属材料热变形中的双曲正弦模型来描述流变应力与变形温度和应变速率的关系[12?13],即

式中:σ为高温流变应力; 为应变速率;T为变形温度;n为应力指数;A和

为应变速率;T为变形温度;n为应力指数;A和 为材料常数;R为摩尔气体常数;Q为热变形激活能,它反映材料热变形的难易程度,也是材料在热变形过程中重要的力学性能参数。

为材料常数;R为摩尔气体常数;Q为热变形激活能,它反映材料热变形的难易程度,也是材料在热变形过程中重要的力学性能参数。

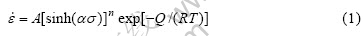

材料的指数关系模型和幂指数关系模型如下:

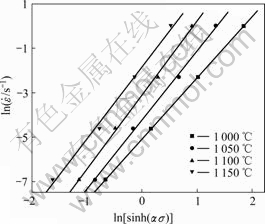

由式(4)和(5)可知,当温度一定时,n1和β分别为 —

— 和

和 —

— 曲线的斜率,采用线性回归处理,得

曲线的斜率,采用线性回归处理,得 —

— 关系曲线如图2(a)所示。

关系曲线如图2(a)所示。 —

— 关系曲线如图2(b)所示,相关系数均大于 0.99。由图2可求出n1的平均值为4.138和β的平均值为0.017 97,利用α=β/ n1,求得α为0.004 343。

关系曲线如图2(b)所示,相关系数均大于 0.99。由图2可求出n1的平均值为4.138和β的平均值为0.017 97,利用α=β/ n1,求得α为0.004 343。

图2 在不同温度下流变应力与应变速率的关系

Fig.2 Relationships between strain rate and flow stress at different temperatures: (a)  —

— ; (b)

; (b)  —

—

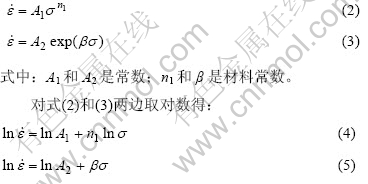

Zener-Hollomon(Z)参数综合材料的热变形条件,Z参数表达式如下:

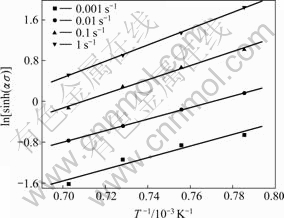

采用线性回归处理,绘制出相应的 —

— 关系曲线如图3所示。并采用同样方法绘制出

关系曲线如图3所示。并采用同样方法绘制出 —1/T关系曲线,结果如图4所示。将其斜率值代入式(8),可求得不同温度和不同应变速率条件下的变形激活能Q,取其平均值为337.75 kJ/mol。

—1/T关系曲线,结果如图4所示。将其斜率值代入式(8),可求得不同温度和不同应变速率条件下的变形激活能Q,取其平均值为337.75 kJ/mol。

图3 在不同温度下应变速率与流变应力的关系

Fig.3 Relationships between strain rate and flow stress at different temperatures

图4 在不同应变速率下流变应力与温度的关系

Fig.4 Relationships between flow stress and deformation temperature at different strain rates

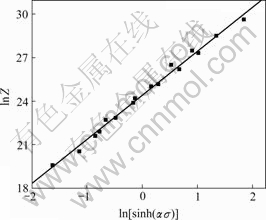

绘制 —lnZ的关系曲线如图5所示。采用一元线性回归处理,其相关系数为0.99。显然可用双曲正弦模型来描述Ti-47Al-2Cr-0.2Mo(摩尔分数,%)合金的高温变形行为。

—lnZ的关系曲线如图5所示。采用一元线性回归处理,其相关系数为0.99。显然可用双曲正弦模型来描述Ti-47Al-2Cr-0.2Mo(摩尔分数,%)合金的高温变形行为。

图5 流变应力与参数Z的关系

Fig.5 Relationship between flow stress and Zener-Hollomon parameter

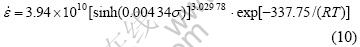

通过以上计算所求得的真应变—真应力关系方程为

2.3 热变形过程中的组织演化

2.3.1 热变形前后的光学金相组织

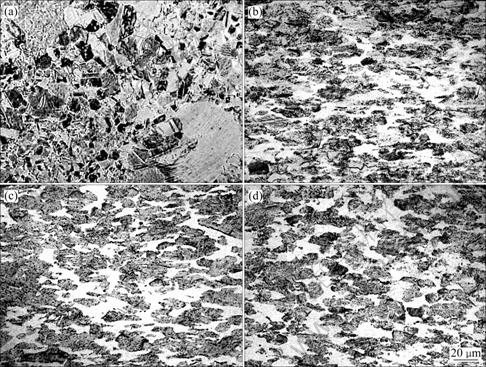

Ti-47Al-2Cr-0.2Mo(摩尔分数,%)合金热变形前后的OM像如图6所示。由图6(a)可以看出,合金变形前的组织中晶粒大小很不均匀,有的晶粒很细小,有的晶粒却非常粗大。从图6(b)、(c)和(d)可以看出,合金中不均匀的原始组织得到明显均匀化,并且出现很多新的动态再结晶晶粒,合金在热变形过程中发生动态再结晶,软化机制主要以动态再结晶为主。从金相照片中还可以看出,合金热变形后的显微组织为细小均匀的双态组织,由被拉长破碎的α2/γ层片晶团和γ晶粒组成,γ晶粒主要是热变形过程中动态再结晶的产物。在高应变速率(应变速率为100 s?1)变形时,合金再结晶的γ晶粒尺寸波动较大,有的已经长大,有的由于变形速率大,变形时间短,没有时间长大,非常细小,并多分布在α2/γ片层晶团边界或内部比较脆弱的部位(见图6(b));随着应变速率的减小和变形时间的延长,细小的γ晶粒逐渐长大(见图6(c));当应变速率为10?3 s?1时,细小的γ晶粒基本消失,γ晶粒明显长大(见图6(d))。

图6 Ti-47Al-2Cr-0.2Mo合金热变形前后的OM像

Fig.6 OM images of Ti-47Al-2Cr-0.2Mo alloy before and after hot deformation: (a) Before hot deformation; (b) 1 150 ℃, 100 s?1; (c) 1 150 ℃, 10?2 s?1; (d) 1 150 ℃, 10?3 s?1

2.3.2 扫描电镜及能谱分析

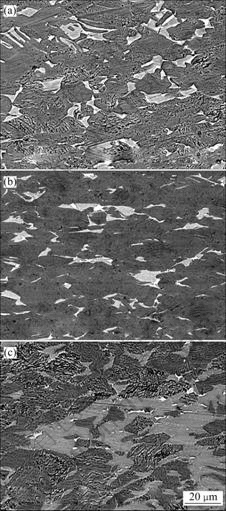

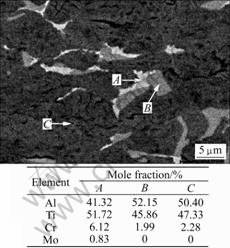

在应变速率为100 s?1、不同变形温度的变形条件下,试样的SEM像如图7所示。从图7中可以看出,在α2/γ层片晶团和γ等轴晶粒的晶界处有更细小的白色亮点相。图8所示为变形温度为1 050 ℃、应变速率为100 s?1时试样的SEM像及不同区域的EDS分析结果。由图8中A、B和C处的能谱分析结果可知,细小的白色亮点相中Cr和Mo的含量非常高,几乎所有的Mo都聚集在这个相中,与之相连接的基体相和灰色相中Cr含量不高,且没有发现Mo。由于Cr和Mo是β相稳定元素,使高温的β相保留到室温,形成B2相。经以上分析可知白色亮点相是B2相。在1 000 ℃时,B2相分布很均匀,形状不规则,大量存在合金的组织中(见图7(a));随温度的升高B2相逐渐减少,并有球化的趋势(见图7(b));当温度升高到1 150 ℃时,B2相的数量不但明显减少,且已经球化成圆球或椭球状(见图7(c))。

图7 应变速率为100 s?1在不同变形温度下试样的SEM像

Fig.7 SEM images of specimens at strain rate of 100 s?1 and different temperatures: (a) 1 000 ℃; (b) 1 050 ℃; (c) 1 150 ℃

图8 当变形温度为1 050 ℃、应变速率为100 s?1时试样的SEM像及不同区域的EDS分析结果

Fig.8 SEM image of specimen and EDS analysis results of different areas at temperature of 1 050 ℃ and strain rate of 100 s?1

3 讨论

Ti-47Al-2Cr-0.2Mo(摩尔分数,%)合金在高温度塑性变形时,同时存在着加工硬化和动态软化两个过程(见图1)。在变形初期,流变应力迅速增大,合金变形表现为加工硬化。加工硬化主要是由于在高温变形时,γ晶粒内部的变形主要通过位错滑移来进行,由于受到热激活的作用,有大量位错源开动,位错密度迅速增加,位错之间互相交割,形成位错网络,以致许多位错被钉扎住而滑移困难。动态软化则是使位错密度降低和位错重新排列成低能量状态的组织,合金在热变形过程中,主要的软化过程为动态再结晶过程。流变应力达到峰值之后,在高应变速率变形时逐渐趋于稳定,此时,合金变形的实质为位错增值和位错间由于相互作用而引起的相互销毁和重组之间达到动态平衡,加工硬化和动态软化达到平衡;在低应变速率变形时,流变应力逐渐降低,主要是由于变形速度较慢,相互销毁和重组位错的速度比增值位错的速度快,加之动态再结晶晶粒的长大,动态软化强于加工硬化。

TiAl基合金在高温热变形过程中,动态软化过程基本都由动态再结晶引起[14?16]。TiAl 基合金是低层错能金属,Mo的添加进一步降低了Ti-47Al-2Cr-0.2Mo合金的层错能[17],低层错能金属位错的扩展宽度较大,不易发生交滑移,因而TiAl基合金在热变形的回复过程中容易发生动态再结晶。合金显微组织在热变形之前很不均匀,且以层片晶团为主,由于层片状组织的边界呈锯齿状,在变形的过程中很难协调好,因此在层片晶团边界产生较大的应力集中,引起层片晶团边缘局部变形,导致动态再结晶的发生,形成环绕层片晶团的细小再结晶晶粒,并使层片状晶团尺寸有所减小。在高应变速率时,由于变形速度快,变形时间短,部分再结晶晶粒没有时间长大,就形成如图6(b)所示的部分细小晶粒分布在层片晶团边界或晶团内比较脆弱的部位;且随着应变速率的减小,变形时间的延长,新形成的细小的再结晶晶粒有较充足的时间长大,导致细小的再结晶晶粒消失,形成较大较均匀的新晶粒(见图6(d))。

在Ti-47Al-2Cr-0.2Mo合金热变形后显微组织的背散射相中发现存在大量B2相,且B2相主要分布 α2/γ 层片晶团和γ晶粒的晶界处。由于室温下有序的B2相结构沿(100)解理面的解理强度较低而容易萌生裂纹,降低合金的强度和室温塑性,极大的损害合金的力学性能,所以热变形后的组织中应该尽量减少B2相的数量。合金中的Cr和Mo都是B2相的稳定元素,由能谱分析可以清楚的看到Cr和Mo主要聚集在B2相内,由于Cr和Mo的扩散速度较慢,在合金热变形的过程中,应该提高合金的变形温度,加快Cr和Mo的扩散速度,才能有效的减少室温组织中的B2相的数量。从图7可以看出,变形温度较低时,合金中的B2相分布非常广泛,且均匀的分布在α2/γ层片晶团和γ等轴晶粒境界处(见图7(a)和(b)),这样的分布会直接破坏合金的力学性能。随着温度的升高,合金中的B2相逐渐减少,在变形温度达到1 150 ℃时,B2相的数量不但大量减少,还明显球化(见图7(c)),能有效地减少合金在变形过程中裂纹源的产生,有利于提高合金的力学性能。由以上分析可知,Ti-47Al-2Cr-0.2Mo合金在 1 150 ℃高温变形,能有效地减少和球化B2相,为提高合金的力学性能打下良好的基础。

4 结论

1) Ti-47Al-2Cr-0.2Mo合金高温塑性变形的流变应力随着变形温度的升高而减小,随着应变速率的增加而增大,说明合金为正应变速率敏感材料。

2) 采用双曲正弦模型来描述Ti-47Al-2Cr-0.2Mo合金的高温变形行为,其平均激活能为337.75 kJ/mol。

3) Ti-47Al-2Cr-0.2Mo合金高温塑性变形的软化机制主要以动态再结晶为主,热变形后的金相组织由被拉长破碎的α2/γ层片晶团和γ等轴晶粒组成。

4) 在变形温度为1 150 ℃、应变速率为100 s?1的条件下变形时,Ti-47Al-2Cr-0.2Mo合金显微组织中的B2相被有效地减少和球化,为提高合金的力学性能打下良好的基础。

REFERENCES

[1] 张俊红, 黄伯云, 贺跃辉, 周科朝, 唐建成. TiAl基合金板材制备技术的发展现状[J]. 材料导报, 2002, 16(2): 16?18.

ZHANG Jun-hong, HUANG Bai-yun, HE Yue-hui, ZHOU Ke-chao, TANG Jian-cheng. Development of technologies for manufacturing TiAl based alloy sheets[J]. Materials Review, 2002, 16(2): 16?18.

[2] ROTH M, BIEMANN H. Thermo-mechanical fatigue behaviour of a modern γ-TiAl alloy[J]. International Journal of Fatigue, 2008, 30(2): 352?356.

[3] COURET A, MOLEN′AT G, GALY J, THOMAS M. Microstructures and mechanical properties of TiAl alloys consolidated by spark plasma sintering[J]. Intermetallics, 2008, 16(9): 1134?1141.

[4] BYSTRZANOWSKI S, BARTELS A, CLEMENS H, GERLING R. Characteristics of the tensile flow behavior of Ti-46Al-9Nb sheet material analysis of thermally activated processes of plastic deformation[J]. Intermetallics, 2008, 16(5): 717?726.

[5] WANG Y H, LIN J P, XUA X J, HE Y H, WANG Y L, CHEN G L. Effect of fabrication process on microstructure of high Nb containing TiAl alloy[J]. Journal of Alloys and Compounds, 2008, 458(1/2): 313?317.

[6] XU X J, LIN J P, WANG Y L, LIN Z, CHEN G L. Deformability and microstructure transformation of pilot ingot of Ti-45Al-(8-9)Nb-(W,B,Y) alloy[J]. Mater Sci Eng A, 2006, 416(1/2): 98?103.

[7] KIM J H, SHIN D H, SEMIANTIN S L, LEE C S. High temperature deformation behavior of a γ TiAl alloy determined using the load-relaxation test[J]. Mater Sci Eng A, 2003, 344(1/2): 146?157.

[8] 张俊红, 黄伯云, 贺跃辉, 孟力平. TiAl基合金低温超塑性变形的力学行为[J]. 中国有色金属学报, 2003, 13(2): 442?447.

ZHANG Jun-hong, HUANG Bai-yun, HE Yue-hui, MENG Li-ping. Mechanical behaviors of TiAl alloy during low temperature superplastic deformation[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 442?447.

[9] 黄劲松, 黄 岚, 刘 彬, 张永红, 刘 咏, 贺跃辉, 黄伯云. TiAl合金的热压缩模拟[J]. 稀有金属, 2007, 31(2): 154?159.

HUANG Jin-song, HUANG Lan, LIU Bin, ZHANG Yong-hong, LIU Yong, HE Yue-hui, HUANG Bai-yun. Hot compression simulation of TiAl alloy[J]. Chinese Journal of Rare Metals, 2007, 31(2): 154?159.

[10] 徐丽华, 徐向俊, 林均品, 王艳丽, 宋西平, 林 志, 陈国良, 李树索, 苏喜孔, 韩雅芳. 包套锻造对高Nb-TiAl基合金组织的影响[J]. 材料工程, 2004(8): 21?24.

XU Li-hua, XU Xian-jun, LIN Jun-pin, WANG Yan-li, SONG Xi-ping, LIN Zhi, CHEN Guo-liang, LI Shu-suo, SU Xi-kong, HAN Ya-fang. Effect of canned forging on microstructure of high Nb-containing TiAl alloy[J]. Journal of Materials Engineering, 2004(8): 21?24.

[11] 李宝辉, 陈玉勇, 孔凡涛. Ti-45Al-5Nb-0.3Y合金的等温热变形模拟及包套锻造[J]. 航空材料学报, 2007, 27(3): 42?46.

LI Bao-hui, CHEN Yu-yong, KONG Fan-tao. Isothermal deformation simulation and canned forging of Ti-45Al-5Nb-0.3Y alloy[J]. Journal of Aeronautical Materials, 2007, 27(3): 42?46.

[12] 王蕊宁, 奚正平, 赵永庆, 戚运连, 杜 宇. Zr-4合金的热变形和加工图[J]. 稀有金属材料与工程, 2007, 36(5): 808?812.

WANG Rui-ning, XI Zheng-ping, ZHAO Yong-qing, QI Yun-lian, DU Yu. Hot deformation and processing maps of Zr-4 alloy[J]. Rare Metal Material and Engineering, 2007, 36(5): 808?812.

[13] BALASUBRAHMANYAM V V, PRASAD Y V R K. Deformation behaviour of beta titanium alloy Ti-10V-4.5Fe-1.5Al in hot upset forging[J]. Mater Sci Eng A,2002, 336(1/2): 150?158.

[14] LI S S, SU X K, HAN Y F, XU X J, CHEN G L. Simulation of hot deformation of TiAl based alloy containing high Nb[J]. Intermetallics, 2005, 13(3/4): 323?328.

[15] 贺跃辉, 黄伯云. 包套锻复合热机械处理技术中TiAl基合金显微组织细化的机理[J]. 中南工业大学学报: 自然科学版, 1997, 28(4): 355?358.

HE Yue-hui, HUANG Bai-yun. Mechanism of refining microstructure of TiAl based alloy in processing of multi-steps thermol mechanical treatment for sample canned[J]. Journal of Central South University of Technology: Natural Science, 1997, 28(4): 355?358.

[16] ZHANG Jun-hong, HUANG Bai-yun, HE Yue-hui, ZHOU Ke-chao, MENG Li-Ping. Physical simulation of hot deformation of TiAl based alloy[J]. Journal of Central South University of Technology, 2002, 9(2): 73?76.

[17] 张俊红, 黄伯云, 周科朝, 李志友, 何双珍, 刘 咏, 贺跃辉. 包套轧制制备TiAl基合金板材[J]. 中国有色金属学报, 2001, 11(6): 1055?1058.

ZHANG Jun-hong, HUANG Bai-yun, ZHOU Ke-chao, LI Zhi-you, HE Shuang-zhen, LIU Yong, HE Yue-hui. Pack rolling of TiAl based alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(6): 1055?1058.

基金项目:国家高技术研究发展计划资助项目(2008AA03A233);中国博士后基金资助项目(20070420828);中南大学博士后基金资助项目(2008-8)

收稿日期:2009-02-23;修订日期:2009-07-01

通信作者:李慧中,副教授,博士;电话:0731-88830377;E-mail: lhz606@mail.csu.edu.cn

(编辑 李艳红)