DOI: 10.11817/j.issn.1672-7207.2015.12.017

四效逆流降膜蒸发系统的建模与故障仿真

胡志坤1,李哲彬1,陈志文2,桂卫华3,阳春华3

(1. 中南大学 物理与电子学院,湖南 长沙,410083;

2. Institute for Automatic Control and Complex Systems, University of Duisburg-Essen,

Bismarckstr. 81 BB, Duisburg 47057, Germany;

3. 中南大学 信息科学与工程学院,湖南 长沙,410083)

摘要:针对氧化铝生产蒸发过程难以控制、故障数据难以采集的现象,根据热力学的基本原理,利用奥秘仿真系统,用高保真的模型元件通过模块化的方法建立四效逆流降膜蒸发加三级闪蒸的氧化铝生产蒸发过程模型。根据氧化铝蒸发系统的特点,将模型分为4个蒸发器模块、3个预热器模块和3个闪蒸器模块。为了体现系统的中间过程,模型中把蒸发器模块分为蒸汽单元和物料单元。通过软件中模型计算和仿真验证模型的有效性,与氧化铝蒸发过程实际测量值相比较,证明模型能够很好地反映氧化铝蒸发的动态生产过程。此外,模型还设置一些实际过程中常发生的故障。研究结果表明:通过数据分析发现故障仿真结果与理论结果相符合,为故障检测和优化控制系统奠定了基础。

关键词:蒸发过程;模块化;故障仿真

中图分类号:TP273 文献标志码:A 文章编号:1672-7207(2015)12-4504-08

Modeling and fault simulation of four-effect countercurrent falling film evaporator system

HU Zhikun1, LI Zhebin1, CHEN Zhiwen2, GUI Weihua3, YANG Chunhua3

(1. School of Physics and Electronics, Central South University, Changsha 410083, China;

2. Institute for Automatic Control and Complex Systems, University of Duisburg-Essen,

Bismarckstr. 81 BB, Duisburg 47057, Germany;

3. School of Information Science and Engineering, Central South University, Changsha 410083, China)

Abstract: In real evaporation process (EVP) of alumina production, the optimal control scheme is difficult to design and the abnormal working condition data are not easy to collect. To this end, a model of the evaporation process with four-effect countercurrent falling film evaporator and three-flash evaporation was established based on the basic principles of thermodynamics. The model was realized with the mysteries simulation system. The object model was divided into 4 evaporator modules, 3 preheater modules and 3 flash modules, depending on the process characteristics. To reflect the middle process of the system, the evaporator modules were divided into steam unit and material unit. Then, the model was verified and compared to the actual measured values, proving that the model can well reflect the dynamic evaporation of alumina production process. In addition, some frequently occurring faults were also modeled. The results show that the fault simulation results are consistent with the theoretical results through data analysis. This work has a great potential for developing a benchmark for process monitoring and optimal control for EVP system.

Key words: the evaporation process; modualization; fault simulation

氧化铝蒸发是氧化铝拜耳法生产工艺中很重要的一个环节,蒸发工艺的能耗相对较高,约占氧化铝全工艺总气耗的40%~50%[1],因而提升蒸发效率能够很大程度降低能耗和成本。氧化铝蒸发工艺设备较多,如蒸发器、预热器和闪蒸器等;且流程较长,有4效蒸发单元和3效闪蒸单元;此外,在实际工况现场,氧化铝蒸发过程的操作参数难以控制,且受到原液和蒸汽参数的影响,使得生产过程很难维持稳定,成分波动较大[2]。而且,一旦出现故障,由于参数太多,很难在短时间内找出故障,严重影响了工厂效益。目前,已经有一些文献对氧化铝蒸发过程进行了建模。如聂晓凯等[3]建立了四效逆流降膜蒸发加三级闪蒸的氧化铝蒸发过程时滞动态数学模型,田荣海等[4]建立了硫氰酸钠溶液五效蒸发的数学模型,毕庆华等[5-7]建立了多效蒸发系统的数学模型,Russel等[8]建立了牛奶单效降膜蒸发系统动态过程模型,王雅琳等[9]设计了一种基于子流程图的氧化铝蒸发过程模拟系统。以上模型都对流程进行了简化,但都是把每效的蒸发器视为模块单元,对于蒸发器内部的中间过程描述不够,不能全面地模拟蒸发过程,且这种建模是在理想条件下,如没有热损失等,故误差较大。此外,以上模型也无法完成一些故障模拟的工作,如由于氧化铝蒸发过程中加热管温度较高而导致氧化铝结晶析出附着在加热管壁上,时间久了会造成加热管的堵塞。对于结垢问题,简化后的模型无法反映真实的现状,且无法采集大量的故障工况下的蒸发过程流量、温度和压力等数据,故用简化的数学模型方法不可行。杭州和利时自动化有限公司的奥秘仿真模型设计器是目前市场上比较先进的化工现场模拟软件,它的模型库包括大量的常用化工单元操作的高保真动态模型,包括流股、单元设备、控制器和传感器。可以根据实际情况的热损失来建模求解,误差较小且灵活性较强,从而可以更好地分析和优化控制系统。为了改善工艺,且由于氧化铝蒸发系统的故障实例较少,本文作者通过在奥秘仿真模型设计器中建模来研究氧化铝蒸发系统。这种模型可以反映蒸发系统不同工况下的动态特性,且便于设置各种类型的故障,如结垢或者阀门故障等,它还可以提供大量的模型故障数据,为以后的系统优化和故障检测的工作提供很好的平台。

1 工艺流程

本文以某厂五效氧化铝蒸发系统为例,一般会有一效检修,故由四效蒸发器,加三级闪蒸,构成一个逆流降膜蒸发系统,工艺流程如图1所示。原液从原液槽经泵分别送至3效和4效蒸发器,然后4效出口料液再经泵送至3效直接预热器中加热至接近3效的沸点温度后进3效蒸发器,类似依次进入2效和1效蒸发器。经1效蒸发器出来的碱液靠压差依次经1闪、2闪和3闪后经泵送至中间缓冲槽后去沉降槽。

图1 氧化铝蒸发工艺流程

Fig. 1 Evaporation process of alumina production

新蒸汽进入1效蒸发器,1效蒸发器乏汽进2效蒸发器,2效蒸发器乏汽进3效,3效蒸发器乏汽进4效,4效蒸发器乏汽经冷凝器进入真空泵,1闪、2闪、3闪产生的乏汽分别进入1效、2效、3效直接预热器;直接预热器的蒸汽也可来自本效蒸发器;冷凝水自蒸发产生的乏汽也进入蒸发器,充分利用利用。

由图1可以看出:工艺流程很长、变量很多,此外,有些变量之间有较强的耦合关系,如新蒸汽的压力升高会引起每1效的蒸汽流量的增加和温度的升高。且由于建模时要对流程做一些必要的简化,这会引起累积误差,从而使得模型很难反映实际情况。

2 数学模型

氧化铝蒸发的主要过程分为3个部分:蒸发器单元中蒸汽给物料加热从而蒸发出物料里的水分;预热器单元中闪蒸器出口乏汽和蒸发器出口物料混合;闪蒸器单元中通过降压后降低沸点来蒸发出物料中的水分。氧化铝蒸发过程包含4个单元模块:蒸发器、预热器、冷凝水罐和闪蒸器。这里将蒸发器单元、预热器单元和冷凝水罐单元作为整体蒸发单元。

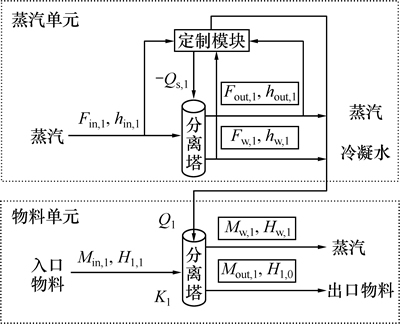

工业现场的设备是4效逆流降膜蒸发器,蒸汽与物料不直接接触,而是通过传热介质来传热,所以可以把整体蒸发单元分为2个单元:蒸汽单元和物料单元,这样可以更好地体现蒸发器内部的中间过程。

2.1 蒸汽单元

基于物料平衡原理,第i效蒸汽单元的物料平衡方程为

(1)

(1)

式中:Fin,i 为第i效蒸汽单元进蒸汽量;Fout,i为第i效蒸汽单元出口乏汽;Fw,i 为第i效蒸汽单元出口冷凝水。

对于第3效蒸发单元,蒸汽的进入量为出2效蒸发单元乏汽量与冷凝水罐入3效蒸发单元蒸汽量之和,即

(2)

(2)

基于热量平衡原理,第i效蒸汽单元的热量平衡方程为:

Qi=Qs,i-Ql,i (3)

Qs,i=Qin,i-Qout,i-Qw,i (4)

式中:Qi为第i效蒸汽单元蒸汽传递给物料的热量;Qin,i为第i效蒸汽单元入口蒸汽的热量;Qout,i为第i效蒸汽单元出口乏汽的热量;Qw,i为第i效蒸汽单元出口冷凝水的热量;Ql,i 为第i效蒸汽单元热传递过程中损失的热量;Qs,i 为第i效蒸汽单元释放的热量。

由上述公式转化可得

(5)

(5)

式中:hin,i为第i效蒸汽单元入口蒸汽的热焓;hout,i为第i效蒸汽单元出口乏汽的热焓;Tw,i为第i效蒸汽单元出口冷凝水的温度;Fout,w,i为第i效蒸汽单元出口冷凝水的流量;ci为第i效蒸汽单元入口蒸汽的比热容。

2.2 物料单元

基于物料平衡原理,可以得到第i效的物料单元的物料平衡方程为[10]:

(i=1,2,3,4) (6)

(i=1,2,3,4) (6)

(j=1,2,3) (7)

(j=1,2,3) (7)

式中:Min,i为第i效物料单元入口物料流量;Mout,i为第i效物料单元出口物料流量;Mw,i为第i效物料单元物料中蒸发的水蒸气的流量; 为第j级闪蒸器的出口乏汽量;Ki为第i效料室料液量。

为第j级闪蒸器的出口乏汽量;Ki为第i效料室料液量。

对于第3效原料单元,入口物料流量等于第4效的出口物料流量与进3效原料流量之和,即

(8)

(8)

对于第j级闪蒸器的物料平衡方程为

(9)

(9)

式中:M fin,i和M fout,i分别为第j级闪蒸器的进料量、出料量。

物料单元入口处物料中的Al2O3,NaOH和Na2CO3质量浓度分别为ρi,1,ρi,2和ρi,3;出口物料的质量浓度分别为ρi,10,ρi,20和ρi,30;闪蒸器进口物料质量浓度分别为ρfj,1,ρfj,2和ρfj,3;出口物料质量浓度分别为ρfj,10,ρfj,20和ρfj,30。物料单元内的Al2O3的质量平衡方程为[7]

(10)

(10)

由式(5)和(9)得到Al2O3质量浓度的微分方程为

(11)

(11)

同理,由NaOH和Na2CO3的质量平衡方程,得到其微分方程分别为

(12)

(12)

(13)

(13)

由质量平衡方程可得闪蒸器出口物料中溶质质量浓度微分方程为:

(14)

(14)

(15)

(15)

(16)

(16)

根据热量平衡原理可得第i效物料单元的热量平衡方程为[11]:

(17)

(17)

(18)

(18)

式中:Hi,1为第i效入口物料热焓;Hi,0为第i效出口物料热焓;Hfi为第i效预热器入口的闪蒸汽热焓,Ff4Hf4=0;Ti 为第i效蒸发出的乏汽的温度;cw,i为第i效蒸发出的乏汽的比热容。

由式(5)可得:

(19)

(19)

建立第j级闪蒸器的热量平衡方程为

(20)

(20)

式中:Hfj为第j级闪蒸器出口物料的热焓,Hf0=H1,0。

闪蒸器出口物料热焓微分方程为

(21)

(21)

物料的热焓与物料的常压比热容cp之间存在如下关系[12]:

H=cpT (22)

其中[3]:

cp=4.186-2.923ρ1-3.266ρ2-0.071ρ3 (23)

ρ1,ρ2和ρ3分别为物料中的Al2O3、NaOH和Na2CO3的质量浓度。

式(1),(4),(5),(9),(11)~(16),(19),(21)~(23)组成氧化铝蒸发过程系统的动态模型,为1组状态微分方程。

对于以上数学模型,用编程的方法进行计算时,为了简化计算,需要对每1效做模型简化,并转化为状态空间方程进行求解,故无法对一些参数的变化做出响应,如无法响应新蒸汽的压力变化对各效蒸汽的流量和温度的影响,且无法设置一些故障,如结垢故障等。而流程仿真软件利用其强大的计算能力以及专业的计算模块,可以比较全面地反映工业现场的实际情况,而且便于设置故障并可以提供大量的故障工况下的蒸发过程流量、温度和压力等数据。

3 建模仿真与分析

3.1 建模

本文采用杭州和利时自动化有限公司的奥秘仿真模型设计器来建模。奥秘仿真模型设计器是目前市场上比较先进的化工现场模拟软件,它的模型库包括所有的常用化工单元操作的高保真动态模型,包括流股、单元设备、控制器和传感器。软件的特点如下:1) 软件的可定制性强,可以根据自己的需要自由组合单元设备来满足要求。即1个模块可以有多种实现方法供选择,可根据要求选出最佳方法。2) 软件有很强大的汽液相平衡计算功能,包括Var Laar,Wilson,NTRL,UNIQUAC和IDEAL等模型,可以比较精确地模拟换热过程。3) 软件同时采用序贯法和联立方程法。序贯算法提供了流程收敛计算的初值,联立方程算法提高了流程计算的收敛速度。

对于氧化铝蒸发系统,软件没有提供现成的模块,本文根据氧化铝蒸发的工艺流程来搭建模型。具体建模过程如下。

3.1.1 参数配置

用奥秘仿真模型设计器软件时,每新建一个工程都需要进行仿真基础配置,包括组分配置、物性包配置和反应配置。组分配置是将工业流程中所涉及的组分全部添加进模型所需的组分包。氧化铝蒸发系统中组分(杂质除外)包括Al2O3,NaOH,Na2CO3,H2O和N2,其中N2是用来作为容器中的初始组分。物性包配置是选择适合的汽液相平衡数学模型,本文假设蒸汽和溶液都是理想的,这里选择IDEAL模型。反应配置是在模型中添加工业流程中的一些化学反应。氧化铝的蒸发不存在化学反应,故这里不用添加反应配置。

3.1.2 搭建模型

搭建模型是根据具体的工业现场将模型库中已有的模型单元进行组合,从而模拟工业现场。模型库中有很多模型元件,根据具体情况,选择合适的元件,这里采用阀门、分离塔、泵、加热器、物质流和能量流、分离器和混合器。以1效蒸发器为例:

蒸汽单元:新蒸汽进入蒸发器后一部分液化为水进入冷凝水罐,剩余的2次蒸汽进入2效蒸发器,产生热量Qs,1,传递给物料的热量为Q1。用分离塔可以模拟这个过程,如图2所示。分离塔是一种将塔内物质实现理想的气液接触,并将气体与液体实现物理分离的单元操作。

图2 1效蒸发模块结构图

Fig. 2 Model diagram of the 1st effect evaporation module

因为这个过程属于放热过程,所以进入分离塔的能量流为负,然后再根据汽液相平衡计算得到出口处的蒸汽和冷凝水流量和温度。这里能量流大小的确定要根据工业现场采集的数据来计算,计算需要用到定制模块,定制模块是软件中的编程模块。通过采集入口和出口处的蒸汽和冷凝水的流量和温度来计算蒸汽释放的热量Qs,1,从而得到分离塔释放的热量Qs,1。计算式如式(24)所示,并根据式(24)在定制模块窗口中编写代码。由式(1)可得式(24):

(24)

(24)

物料单元:进入1效蒸发器的物料与蒸汽换热,一部分水分被蒸发出来,进入冷凝水灌,剩余的物料进入1闪蒸器。物料吸收的热量为Q1,分离塔根据汽液相平衡计算得到出口处的蒸汽和物料的流量和温度。为了模拟原料被泵传送到加热管的过程,用分离器分出一部分物料,并把蒸汽释放的热量用来加热这一部分物料,加热完后的物料又与入口物料用混合器混合。由式(6)和式(17)可得:

(25)

(25)

(26)

(26)

奥秘仿真软件包含3类计算:压力流量的计算、物料平衡的计算和热量平衡的计算。

图2中,通过压力流量计算,得到Mout,1和Mw,1,再通过物料和热量平衡计算得到Hw,1和H1,0和K1。并通过调节参数使Mout,1中只有液体,Mw,1中只有气体,且使K1稳定。

模型搭建完成后,可以设置不同的原料浓度和流量,以及蒸汽传热率和热损耗。

3.1.3 建立模块

把每1个蒸发器、预热器和闪蒸器作为1个模块,则模型分为4个蒸发器模块、3个预热器模块和3个闪蒸器模块。本仿真模型采取将对象划分为功能模块的形式。根据氧化铝蒸发系统的特点,将其分为蒸发器模块、预热器模块和闪蒸器模块,模型包含4个蒸发器模块、3个预热器模块和3个闪蒸器模块。分别建模并完成各自的子功能,然后将2个子模块中相关的上一级的输出参数与下一级的输入参数相连,如将4效蒸发器的出口物料与3效预热器的入口物料相连接。对每个模块调试好后,从4效蒸发器开始再逐一进行连接调试。最后将子模块组成一个整体,实现整个系统的功能。

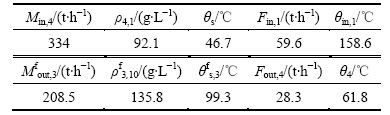

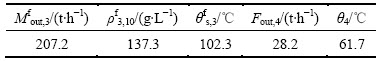

3.2 仿真

模型搭建完成后,取某工厂某一时刻流量、温度和压力的报表数据作为模型的输入,并用仿真结果和报表数据进行对比。现场的流量温度和质量浓度数据如表1所示,仿真结果如表2所示。

在每1效中加入热损失,通过调节热效率来使模型数据更接近现场采集数据。由于工业流程中入口原料和蒸汽的流量波动是没有规律的,所以在模型中给入口原料和蒸汽流量加上高斯白噪声,以便更好地模拟实际情况。

连续采集50组现场数据并用模型进行模拟,模型输出的出口质量浓度与现场数据比较曲线如图3所示。

表1 现场采集数据

Table 1 Data collected in site

表2 仿真结果

Table 2 Simulation results

由表1和表2可以看出:出口的蒸汽和物料流量和温度的最大相对误差都在5%以内,而三闪出口物料质量浓度误差在2%以内。图3中模型的出口物料质量浓度最大相对误差在5%以内,平均相对误差在3%以内,说明模型能够反映氧化铝蒸发过程。

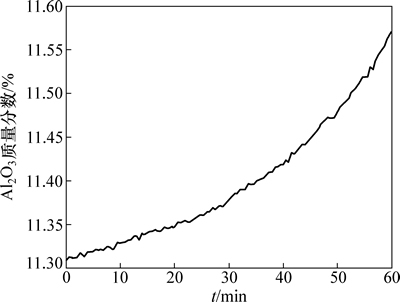

为了验证模型对于不同原料流量的适应性,设置入口原料在1h之内呈线性渐变至原来的80%,观察3闪蒸器出口物料的Al2O3质量分数变化情况。采样周期为5 s,把采集的数据绘制成图,Al2O3质量分数的变化趋势如图4所示。

由图4可以看出:3闪蒸器出口物料的Al2O3质量分数渐增。这是由于入口原料流量渐减使出口物料的流量也渐减,而蒸发掉的水分不变,所以Al2O3质量分数渐增。结果表明模型具有较好的适应性。

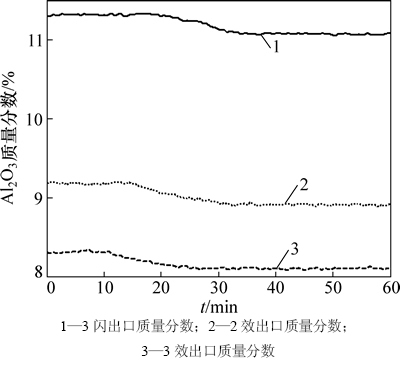

在工艺流程中有时会发生蒸汽管道漏气的问题,这时候漏气管道所在的蒸发器单元以及后面几效蒸发器单元的蒸汽流量会降低,从而造成蒸水量的减少,出口质量分数也会降低。在模型正常运行10 min后,设置2效蒸发器出口管道蒸汽泄漏20%,则3效和4效蒸发器入口蒸汽流量会降低。采集2效、3效和3闪蒸器出口物料的Al2O3质量分数数据,并绘制成图。仿真结果中的出口物料Al2O3质量分数的变化曲线如图5所示。

图3 模型与现场的出口Al2O3质量浓度比较

Fig. 3 Comparison of outlet Al2O3 mass concentration between model and field

图4 出口Al2O3质量分数变化趋势图

Fig. 4 Change trend of outlet Al2O3 mass fraction

图5 出口Al2O3质量分数的变化趋势

Fig. 5 Change trend of outlet Al2O3 mass fraction

由图5可以看出:2效出口蒸汽泄漏后,3效出口物料质量分数会先降低,一段时间后,2效的出口质量分数也会因为3效出口物料质量分数的降低而降低,最后导致3闪出口物料质量分数的降低。

蒸发过程中需要用到大量的传感器实时测量过程状态,通过实时分析测量数据,对过程进行有效的监控,以保证蒸发过程的平稳有效的进行。因为蒸发过程的环境恶劣,工作温度较高,传感器容易发生故障。传感器故障在所有发生故障中所占比例最大。传感器故障的发生只体现测量数值上的误差,而实际生产过程是正常进行的;且蒸发过程每一类传感器所测变量之间的耦合性非常强(例如各效蒸汽温度之间的关系),因此,对于某一类中1个传感器的故障,可以通过对该类中其他传感器所测数据进行分析,因为过程是正常的,所以其他传感器所测数据是不会发生变动。这样通过分析其他传感器所测数据,可以检测到哪一个传感器发生了故障。在模型中设置2效蒸发器的蒸汽出口流量传感器发生漂移故障,采集1效、2效、3效和4效的出口流量结果,并绘制成图。仿真结果如图6所示。

由图6可以看出:除了3效出口物料流量数据发生漂移外,其他几效数据都正常,若分布在3效的其他传感器也正常,则可以判断是3效出口物料流量传感器出现故障。

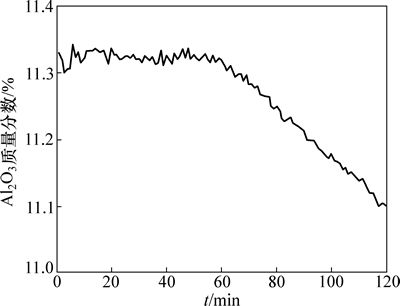

在蒸发过程中,随着溶液的浓缩,溶质由不饱和变为过饱和,发生相变而析出成为结垢[13],所以需要定时的对蒸发器加热室进行清洗。物料结垢容易在蒸发器加热室内的加热管壁处形成。结垢的主要成分是苛性碱、碳酸钠、硫酸钠和铝硅酸钠的混合物。在实际生产中,1效加热温度高,1效内结疤速度加快。这里对1效进行故障设置。结垢故障造成的直接影响有:1) 通过加热管的流量会减小;2) 传热效率降低。

由直接影响会引发以下几点间接影响:1) 蒸水量降低,出料质量浓度降低;2) 蒸发器内液位升高。

在模型中可以通过减少进料量和与蒸汽换热的物料量并降低传热效率来模拟结垢故障。

在恒热流的情况下,污垢系数将随时间线性增 加[14-15],在模型正常运行一段时间后设置加热管进料量在1 h内呈线性渐变至原来的70%,传热率降为原来的70%,仿真结果中的出口物料Al2O3质量分数的变化曲线如图7所示。

图6 1~4效出口物料流量采集结果

Fig. 6 1-4 exported material flow results

图7 出口Al2O3质量分数变化趋势图

Fig. 7 Change trend of outlet Al2O3 mass fraction

由图7可以看出:当模拟结垢故障时,出口物料Al2O3质量分数呈线性下降趋势,符合实际的变化趋势,说明模型能够模拟结构故障,为以后进行氧化铝蒸发过程故障检测提供了很好的仿真平台。

4 结论

1) 以物料平衡和热量平衡原理为基础,通过把传统蒸发单元一分为二,建立了氧化铝蒸发的动态过程模拟,可以根据各个单元的实际情况设定热损失,从而更准确的模拟实际,用仿真结果与现场测量数据进行比较,验证了该方法的可行性,有较高的准确度。

2) 在模型中模拟了结垢故障和传感器故障,得到了比较理想的结果。为改进氧化铝蒸发过程及其故障检测的研究奠定了基础,有利于优化蒸发系统的控制研究。

参考文献:

[1] 陈勤霞. 降低氧化铝生产汽耗的途径探讨[J]. 有色冶金节能, 2006, 23(1): 27-29.

CHEN Qinxia. Discussion on the ways to reduce steam consumption in alumina production[J]. Energy Saving of Nonferrous Metallurgy, 2006, 23(1): 27-29.

[2] 郑传增, 何小阳. 氧化铝蒸发过程的机理建模与仿真[J]. 计算技术与自动化, 2011, 30(3): 26-29.

ZHENG Chuanzeng, HE Xiaoyang. Knowledge modeling and simulation of alumina evaporation process[J]. Computing Technology and Automation, 2011, 30(3): 26-29.

[3] 聂晓凯, 阳春华, 柴琴琴, 等. 氧化铝蒸发的动态过程建模与仿真[J]. 化工自动化及仪表, 2010, 38(2): 279-283.

NIE Xiaokai, YANG Chunhua, CHAI Qinqin, et al. Alumina evaporation dynamic process modeling and simulation[J]. Chemical Automation and Instrumentation, 2010, 38(2): 279-283.

[4] 田荣海, 陈国礼, 吴俊生, 等. 五效蒸发装置软测量模型的建立[J]. 化工自动化及仪表, 2000, 27(6): 8-10.

TIAN Ronghai, CHEN Guoli, WU Junsheng, et al. Establish five-effect evaporation plant soft sensor model[J]. Chemical Automation and Instrumentation, 2000, 27(6): 8-10.

[5] 毕庆华, 唐朝晖, 桂卫华, 等. 氧化铝蒸发系统的模拟[J]. 计算机测量与控制, 2008, 16(8): 1119-1121.

BI Qinghua, TANG Chaohui, GUI Weihua, et al. Simulation of alumina evaporation system[J]. Computer Measurement & Control, 2008, 16(8): 1119-1121.

[6] 阮奇, 陈文波, 黄诗煌, 等. 复杂并流多效蒸发系统的数学模型与矩阵解法[J]. 中国工程科学, 2001, 3(4): 36-41.

RUAN Qi, CHEN Wenbo, HUANG Shihuang, et al. Model and matrix method of complex and multi-effect flow evaporation system[J]. China Engineering Science, 2001, 3(4): 36-41.

[7] 阮奇, 黄诗煌, 叶长燊, 等. 复杂逆流多效蒸发系统常规设计的模型与算法[J]. 化工学报, 2001, 52(7): 616-621.

RUAN Qi, HUANG Shihuang, YE Changshen, et al. Conventional design model and algorithm of complex countercurrent multi-effect evaporation system[J]. Chemical Engineering, 2001, 52(7): 616-621.

[8] Russel N T, Bakker H H C, Chaplin R I. A comparison of dynamic models for an evaporation process[J]. Transactions of the Institution of Chemical Engineers, 2000, 78(8): 1120-1128.

[9] 王雅琳, 邱海峰, 桂卫华, 等. 基于子流程图的氧化铝蒸发过程模拟系统[J]. 计算机工程, 2009, 35(23): 260-262.

WANG Yalin, QIU Haifeng, GUI Weihua, et al. Simulation system of alumina evaporation process based on sub-flowchart[J]. Computer Engineering, 2009, 35(23): 260-262.

[10] Cadet C, Touré Y, Gilles G, et al. Knowledge modeling and nonlinear predictive control of evaporators in cane sugar production plants[J]. Journal of Food Engineering, 1999, 40(1/2): 59-70.

[11] 毕诗文, 于海燕. 氧化铝生产工艺[M]. 北京: 冶金工业出版社, 2006: 23-27.

BI Shiwen, YU Haiyan. The technology of alumina production[M]. Beijing: Chemical Industry Press, 2006: 23-27.

[12] 杨重愚. 氧化铝生产工艺学[M]. 北京: 冶金工业出版社, 1993: 160-175.

YANG Zhongyu. The technology of alumina production[M]. Beijing: Metallurgical Industry Press, 1993: 160-175.

[13] 彭志宏, 陈科云, 李小斌, 等. 铝酸钠溶液蒸发过程中的结垢与防垢[J]. 中南大学学报(自然科学版), 2008, 39(1): 69-74.

PENG Zhihong, CHEN Keyun, LI Xiaobin, et al. Scaling and anti-scale in evaporation process of sodium aluminate solutions[J]. Journal of Central South University (Science and Technology), 2008, 39(1): 69-74.

[14] 刘中良, 施明恒, 戴锅生. 结晶垢结垢过程的传热传质模型[J]. 化工学报, 1997, 48(4): 401-407.

LIU Zhongliang, SHI Mingheng, DAI Guosheng. Heat and mass transfer model of crystallization fouling scale processes[J]. Chemical Engineering, 1997, 48(4): 401-407.

[15] Mueller-steinhagen H M, Jmialahmadi M. Effect of surface material and salt concentration on pool boiling heat transfer to aqueous solutions[C]//Hetsroni G. Heat Transfer 1990: Proceedings of 9th International Heat Transfer Conference. New York: Hemisphere Publishing Co., 1990: 473-479.

(编辑 罗金花)

收稿日期:2015-01-02;修回日期:2015-03-20

基金项目(Foundation item):国家自然科学基金资助项目(61273159,61105080)(Projects (61273159, 61105080) supported by the National Natural Science Foundation of China)

通信作者:胡志坤,博士,教授,从事复杂系统状态监测与故障诊断研究;E-mail:huzk@csu.edu.cn