预应变和热处理对AZ31镁合金形变行为的影响

来源期刊:中国有色金属学报(英文版)2015年第11期

论文作者:陈红兵 刘天模 卢立伟 何杰军 翟彦博

文章页码:3604 - 3610

关键词:AZ31镁合金;孪生;退火硬化;预压缩;热处理;形变

Key words:AZ31 Mg alloys; twinning; annealing hardening; pre-compression; heat treatment; deformation

摘 要:对挤压态AZ31镁合金进行预压缩和热处理,研究预压缩和热处理对其形变行为的影响。结果表明:在低温下退火(170 °C退火4 h),试样经过退火处理或未经退火处理的几乎具有相等的屈服强度(~148 MPa),这是由于它们的显微组织几乎没有变化。然而在相同退火条件下,经预压缩并退火的试样的屈服强度(~225 MPa)高于只有预压缩试样的屈服强度(~200 MPa)。由于溶质原子在孪晶界偏析引起强化,前者显示出退火硬化效应。预压缩试样在400 °C退火1 h后,其伸长率(~28%)高于预压缩试样的伸长率(~15%),但其屈服强度(~125 MPa)低于预压缩试样的屈服强度(~200 MPa)。

Abstract: Pre-compression and heat treatment were performed on an extruded AZ31 Mg alloy, and their effects on subsequent deformation behavior were investigated. The results show that at low temperature annealing (170 °C for 4 h), the extruded samples with and without annealing exhibit a nearly equivalent yield stress (~148 MPa) because their microstructures are nearly unchanged. However, under the same annealing condition, the yield stress of sample with pre-twinning and subsequent annealing (~225 MPa) is higher than that of the pre-twinned one (~200 MPa). The former sample presents a hardening effect because the solute atoms segregated on twin boundaries lead to a strengthening effect. The pre-twinned sample annealed at 400 °C for 1 h shows a higher ultimate elongation (~28%) than the pre-twinned one (~15%), but its yield stress (~125 MPa) is much lower than that of the pre-twinned one (~200 MPa).

Trans. Nonferrous Met. Soc. China 25(2015) 3604-3610

Hong-bing CHEN1,2, Tian-mo LIU1, Li-wei LU3,4 , Jie-jun HE5, Yan-bo ZHAI2

1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. College of Engineering and Technology, Southwest University, Chongqing 400716, China;

3. College of Mechanical and Electrical Engineering, Hunan University of Science and Technology, Xiangtan 411201, China;

4. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

5. School of Materials and Metallurgical Engineering, Guizhou Institute of Technology, Guiyang 550003, China

Received 5 January 2015; accepted 7 May 2015

Abstract: Pre-compression and heat treatment were performed on an extruded AZ31 Mg alloy, and their effects on subsequent deformation behavior were investigated. The results show that at low temperature annealing (170 °C for 4 h), the extruded samples with and without annealing exhibit a nearly equivalent yield stress (~148 MPa) because their microstructures are nearly unchanged. However, under the same annealing condition, the yield stress of sample with pre-twinning and subsequent annealing (~225 MPa) is higher than that of the pre-twinned one (~200 MPa). The former sample presents a hardening effect because the solute atoms segregated on twin boundaries lead to a strengthening effect. The pre-twinned sample annealed at 400 °C for 1 h shows a higher ultimate elongation (~28%) than the pre-twinned one (~15%), but its yield stress (~125 MPa) is much lower than that of the pre-twinned one (~200 MPa).

Key words: AZ31 Mg alloys; twinning; annealing hardening; pre-compression; heat treatment; deformation

1 Introduction

Due to the low density (1.74 g/cm3 for pure Mg), Mg and its alloys have a large potential application as weight-saving materials and Mg alloys are therefore conceived as prime candidates for weight critical automotive and aerospace applications [1-4]. However, the use of Mg alloys which have the hexagonal close packed structure, has been seriously limited because of their poor formability at room temperature [5]. Slip systems in Mg and its alloys are insufficient to accommodate plastic deformation at room temperature. Therefore, twinning, another deformation mechanism, plays an important role in coordinating the plastic deformation. And the possible twinning modes for HCP metals have already been summarized and discussed in the previous reports [6,7]. For Mg and its alloys,  twinning,

twinning, twinning and

twinning and -

- double twinning are commonly observed. And

double twinning are commonly observed. And  extension twinning is responsible for the asymmetry of tensile and compressive deformation in the extruded AZ31 Mg alloys owing to a sharp initial texture and the polarity of deformation twinning [8-11].

extension twinning is responsible for the asymmetry of tensile and compressive deformation in the extruded AZ31 Mg alloys owing to a sharp initial texture and the polarity of deformation twinning [8-11].

Recently, it has been reported that twins induced by pre-deformation play a major role in subsequent deformation in Mg alloys. Static recrystallization of Mg alloys is also greatly affected by deformation twins [12]. The contraction twins generate inhomogeneous and localized deformation regions, where can provide potent sites for recrystallized nuclei [13,14]. However, the extension twins are quite resistant to nucleation owing to a lower strain accumulation within them [14]. Recrystallization is an effective procedure for softening and grain refinement of Mg alloys [13]. It is well known that annealing treatment can remove the lattice defect in metals and consequently reduce the strength. YANG et al [15] investigated static recrystallization (SRX) behavior of hot-deformed AZ31 Mg alloy during isothermal annealing. Generally, precipitates are absent in AZ31 Mg alloy. Nevertheless, XIN et al [16] revealed that the annealing hardening indeed exists in detwinning deformation of AZ31 Mg alloy. NIE et al [17] also confirmed that the migration and segregation of solute atoms are randomly distributed via the observation of high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM).

In this work, pre-strain, heat treatment, and subsequent deformation were tested on an extruded AZ31 Mg alloys, aiming to investigate the microstructure evolution, texture variation, and mechanical property in detail.

2 Experimental

The starting material was a commercial AZ31 Mg alloy, which was supplied in the form of cast ingots. The ingots were first homogenized at 420 °C for 12 h, and then were extruded under a velocity of 12 mm/s at 300 °C with an extrusion ratio of 25:1. As a result, a rod with a diameter of 16 mm can be got. To obtain pre-twinned samples, compressive specimens (16 mm in diameter and 24 mm in height) were machined from the extruded rod, and tests of 5% pre-compression were carried out on a CMT5105 material test machine along the extrusion direction (ED) in the extruded AZ31 Mg alloy at a constant rate of 10-3 s-1.

The as-extruded and pre-twinned specimens were annealed at 170 °C to investigate the annealing hardening effect and the influence of low temperature annealing on subsequent deformation behavior, respectively. Besides, other pre-twinned specimens were annealed at 400 °C for 1 h to investigate the effect of high temperature annealing on subsequent deformation behavior. It is noted that both annealing temperatures are higher than the recrystallization temperature (102 °C) of Mg alloy [15,18].

All mechanical tests were also carried out on a CMT5105 material test machine at a constant rate of 10-3 s-1. The microstructures were observed by optical microscopy (OM) and pole figures were detected via Rigaku D/max-2500 X-ray diffraction (XRD) using Cu Kα radiation (wave length λ=0.15406 nm) at 45 kV and 150 mA, and the tilt angle of sample was measured from 0 to 80°. To identify the type of twins, electron backscatter diffraction (EBSD) experiments were performed on an FEI Nova 400 scanning electron microscope equipped with an HKL-EBSD system using a step size of 1.0 μm. The specimens for EBSD observation were ground mechanically and cleaned with ethanol, followed by electrochemical polishing for 60 s at 20 V, 0.02 A and 20 °C in commercial AC2 electrolyte.

3 Results and discussion

3.1 Microstructure and texture evolution during pre- compression

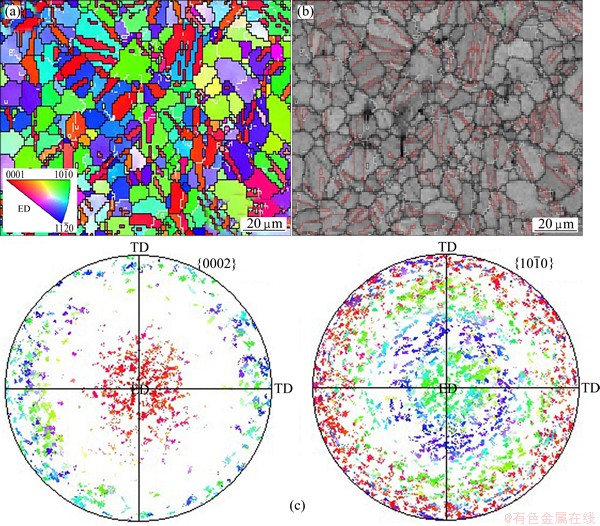

Figure 1 shows the optical micrographs of AZ31 Mg alloys before and after 5% pre-compression. The as-extruded materials present equiaxed grains with an average grain size of 10 μm following the ASTM E112 standard norm at equally spaced intervals [19] (Fig. 1(a)). However, a large number of lenticular shaped twins appear without changing the original grain size (Fig. 1(b)). To reveal the variation of pole figures, the typical pole figures of the samples before and after 5% pre-compression are presented in Fig. 2. Most basal planes are nearly parallel to ED (Fig. 2(a)) in the extruded Mg alloy, which is apt to generate the  twinning if there is appropriate compression along ED [20-22]. Nevertheless, most of basal planes are rotated by about 90° (Fig. 2(b)), which is caused by the generation of lenticular shaped twins. To exactly identify the twinning mode, the typical EBSD images are shown in Fig. 3 for the 5% pre-compressed sample, where the lenticular shaped twins are identified as tensile twinning

twinning if there is appropriate compression along ED [20-22]. Nevertheless, most of basal planes are rotated by about 90° (Fig. 2(b)), which is caused by the generation of lenticular shaped twins. To exactly identify the twinning mode, the typical EBSD images are shown in Fig. 3 for the 5% pre-compressed sample, where the lenticular shaped twins are identified as tensile twinning  , and the misorientation between matrix and twin is about (86±5)° (Figs. 3(a) and (b)). Correspondingly, the areas of

, and the misorientation between matrix and twin is about (86±5)° (Figs. 3(a) and (b)). Correspondingly, the areas of  are mainly distributed around ED axis (Figs. 3(a) and (c)).

are mainly distributed around ED axis (Figs. 3(a) and (c)).

Fig. 1 Optical micrographs of AZ31 Mg alloys

Fig. 2 Pole figures of AZ31 Mg alloys

Fig. 3 Inverse pole figure of pre-compressed sample (a), misorientation analysis of  twin boundaries, as indicated in red (b), and pole figures (c) of AZ31 Mg alloy

twin boundaries, as indicated in red (b), and pole figures (c) of AZ31 Mg alloy

3.2 Effects of pre-strain and heat treatment on deformation behavior

To investigate the possible roles of precipitation on the annealing hardening in the extruded samples, the annealing treatment at 170 °C for 4 h was carried out. It is found that there is no obvious effect of low temperature annealing on the yield stress of the extruded samples, and they exhibit the same yield stress (~148 MPa) and the stress-strain curves also present the same evolution trend (Fig. 4(a)). The mechanical properties derived from the curves in Fig. 4 are listed in Table 1. Low temperature annealing can not supply the as-extruded samples with enough activation energy to quickly impel the grain growth, thus their grain sizes are similar, i.e., the movement of point defects is the main activity, and they can only move to the crystal boundary or dislocation. LIU et al [11] conducted AZ80 Mg alloy aging at 170 °C from 6 to 100 h. Finally, they found that the discontinuous precipitation occurred. The Al content of AZ31 Mg alloy is less than that of AZ80 Mg alloy, the annealing time is also shorter than that reported in Ref. [11], and the amount of β-Mg17Al12 is negligible in AZ31 Mg alloy [23]. Therefore, the precipitation hardening effect can probably be neglected for the extruded AZ31 Mg alloy during low temperature annealing. HUANG et al [24] studied the annealing behavior of AZ31 Mg alloy sheet, and they found that annealing at 150 °C for AZ31 Mg alloy sheet can trigger SRX and the basal texture intensity weakened significantly with no change of inclination angle. YANG et al [25] concluded that the microstructure evolution at low temperature annealing for cold-deformed Mg alloy was composed of nucleation, followed by large-distance migration of their boundaries. The process was called discontinuous static recrystallization (dSRX). HUMPHREY and ATHERLY [26] reported that the migration rate of grain boundary was dominated by the grain boundary structure, various point defects (solute atoms, etc), annealing temperature and so on. At low temperature annealing, the solute diffusion can control the boundary mobility, and the movement of point defects leads to the decrease of their densities. However, the mechanical property has no obvious change, which may be the main reason for this phenomenon.

Fig. 4 Stress-strain curves of samples

Table 1 Mechanical properties of as-extruded and pre-twinned AZ31 Mg alloy under different annealing conditions

However, the pre-twinned samples with and without low temperature annealing exhibit different yielding behaviors (Fig. 4(b)). The pre-twinned sample annealed at 170 °C for 4 h shows a higher yield stress (~225 MPa) than that of the pre-twinned sample without annealing (~200 MPa). It is noted that the increased value of yield stress (25 MPa) nearly equals the value obtained in Ref. [16], which has an obvious difference from other structural materials such as Al and steel. Generally, the recovery will take place after annealing, and the yield stress shows a decrease tendency for most structural materials. However, a reverse effect presents in twinned Mg alloy, which is also known as annealing hardening. To reveal the reason of annealing hardening in Mg alloy, XIN et al [16] found that Al and Zn solutes were distributed at the  twin boundaries in the pre-strained and annealed AZ31 sample. At low temperature annealing, the twin will still exist. LI et al [13] reported that the

twin boundaries in the pre-strained and annealed AZ31 sample. At low temperature annealing, the twin will still exist. LI et al [13] reported that the  twins cannot be removed even after annealing at 350 °C for 11 h in a pre-rolled AZ31 Mg alloy. LEVINSON et al [14] found that there were about 67%

twins cannot be removed even after annealing at 350 °C for 11 h in a pre-rolled AZ31 Mg alloy. LEVINSON et al [14] found that there were about 67%  twins still in the pre-strained AZ31 Mg alloy even after annealing at 275 °C for 16 h. From the point of view of the rate of changes, the annealing condition (200 °C for 60 min) represents a relative early stage of microstructure evolution [27]. At lower temperature, grain boundary mobility may be controlled by solute diffusion, and then its activation energy may equal that of solute diffusion [25]. The segregation of Al and Zn solutes in the

twins still in the pre-strained AZ31 Mg alloy even after annealing at 275 °C for 16 h. From the point of view of the rate of changes, the annealing condition (200 °C for 60 min) represents a relative early stage of microstructure evolution [27]. At lower temperature, grain boundary mobility may be controlled by solute diffusion, and then its activation energy may equal that of solute diffusion [25]. The segregation of Al and Zn solutes in the  twin boundaries can play a pin role, which makes the migration of the twin boundary more difficult [16], so the extension twin

twin boundaries can play a pin role, which makes the migration of the twin boundary more difficult [16], so the extension twin  grows difficultly. That is to say, the subsequent compression of annealed pre-twinned sample will need more activation stress for twin growth. NIE et al [17] reported that Zn and Gd solute atoms would segregate in twin boundaries for the pre-twinned Mg alloy annealed at a relative low temperature, which provides a pinning effect on twin boundaries, leading an annealing strengthening to the twinned Mg alloy rather than softening. It can be concluded that the segregation of solute atoms in

grows difficultly. That is to say, the subsequent compression of annealed pre-twinned sample will need more activation stress for twin growth. NIE et al [17] reported that Zn and Gd solute atoms would segregate in twin boundaries for the pre-twinned Mg alloy annealed at a relative low temperature, which provides a pinning effect on twin boundaries, leading an annealing strengthening to the twinned Mg alloy rather than softening. It can be concluded that the segregation of solute atoms in  twin boundaries makes the subsequent deformation more difficult, resulting in increased yield stress of the pre-strained and subsequent annealed Mg alloy.

twin boundaries makes the subsequent deformation more difficult, resulting in increased yield stress of the pre-strained and subsequent annealed Mg alloy.

By comparison between Figs. 4(a) and (b), it is found that the pre-twinned sample annealed at 400 °C for 1 h and the pre-twinned sample without annealing also exhibit different deformation behaviors and their stress-strain curves also present an obvious difference. The stress-strain curve of the former sample shows no plateau and the stress is practically linear with strain. However, for the latter sample, an obvious plateau emerges, which is controlled by the predominant occurrence of  twinning. Besides, the former sample presents a higher ultimate elongation (~28%) than that of the latter one (~15%), but the yield stress (~125 MPa) is much lower than that of the latter one (~200 MPa).

twinning. Besides, the former sample presents a higher ultimate elongation (~28%) than that of the latter one (~15%), but the yield stress (~125 MPa) is much lower than that of the latter one (~200 MPa).

As for high temperature annealing, recrystallization plays a significant role in microstructure evolution and mechanical properties improvement. The process of annealing at 400 °C for only 60 s is sufficient to change the microstructure. YANG et al [25] suggested that one possible mechanism of dSRX occurring in the high temperature regime may be controlled by the migration rate of grain boundary in Mg alloys. The grain boundary diffusion may be independent of solute atoms at high temperature, so more nucleation sites for dSRX can be activated not only at the grain boundaries but also in the grain interiors, leading to an acceleration of the kinetics of dSRX and the grain growth, and the grain size is therefore bigger than that of annealing at lower temperature [26]. Although impurity atoms (Al, Zn, etc) might accumulate at the grain boundaries and exert a retarding force on the grain boundary migration, they can not alter the activation energy of grain growth [28]. For the high temperature annealing, the recrystallization leads to grains growth and twins disappearance, as shown in Figs. 5 and 6(b). Annealing at 300 °C for 2 min can lead to full recrystallization, and most twins were eliminated [27]. It can be deduced that the Al and Zn solutes will lose pinning effect on the twin boundary motion because twin boundary disappeared at high temperature annealing. According to the classic Hall–Petch relationship, the average grain size is bigger, the yield stress is lower. The annealing treatment can decrease the dislocation density and residual stress in the pre-compressed sample. Therefore, the yield stress of the pre-twinned sample annealed at 400 °C for 1 h is lower than that of the pre-twinned one.

Fig. 5 EBSD results of sample subjected to 5% pre-compression and annealing at 400 °C for 1 h

The EBSD results of the pre-twinned sample annealed at 400 °C for 1 h is shown in Fig. 5. The recrystallization takes place completely, and the ED//<0001> texture component disappears in most grains, which is a large difference from the pre-twinned sample with obvious twinning and ED//<0001> texture component (Fig. 3(a)). The EBSD maps of as-extruded sample and pre-twinned sample annealed at 400 °C for 1 h are shown in Fig. 6. The microstructure of the former one shows a typical inhomogeneous distribution with fine grains of 7 μm and elongated grains of 40 μm. The elongated grains are probably the result of abnormal grain growth, which is also referred to as secondary recrystallisation grain growth. A few grains grow exclusively, consuming the matrix grains, i.e., some energetically favorable grains (crystallites) grow rapidly in a matrix of finer grains [29]. The main factors which lead to abnormal grain growth include surface effects, second-phase particles, solute drag effect and texture [30]. However, the latter one presents a nearly equiaxed distribution with the average grain size of 10 μm, which can be attributed to the twinning providing nucleation sites for recrystallization [31,32].

Fig. 6 Microstructures of sample only with annealing at 400 °C for 1 h (a), and with 5% pre-compression and annealing at 400 °C for 1 h (b) (compression axis (CA) perpendicular to paper)

The annealing hardening effect of the pre-twinned samples takes place at low temperature annealing, while high temperature annealing has the reverse effect, as shown in Fig. 4(a). The mechanical property of the sample with pre-twinning and subsequent annealing at 400 °C for 1 h shows a lower yield stress (~125 MPa) than that of the pre-twinned sample without annealing (~200 MPa) (Fig. 4(b)). From Fig. 5, one can see that recrystallization fully takes place in grains and most twins are removed. Hence, there is no annealing hardening effect because there are no segregated solutes in the twin boundary, resulting from the twinning disappearance.

4 Conclusions

1) For low temperature annealing, the as-extruded samples with and without annealing exhibit a nearly equivalent yield stress (148 MPa) and their stress-strain curves also present the similar evolution trend. However, the pre-twinned and then the annealed sample shows a higher yield stress (225 MPa) than that of the pre-twinned sample (200 MPa) due to the annealing hardening effect.

2) For high temperature annealing, the pre-compressed sample presents a higher ultimate elongation (28%) than the extruded sample (20%), and the mean grain size of the former sample is smaller than that of the latter one, which can be attributed to more nucleation sites provided by twins for recrystallization.

3) Due to the grain growth, twins disappearance and residual stress elimination at high temperature annealing, the pre-twinned and subsequently annealed sample presents a higher ultimate elongation (28%) than that of the pre-twinned sample without annealing (15%). On the contrary, their yield stress is reverse.

References

[1] ZHANG H, HUANG G S, LI J H,WANG L F, ROVEN H J. Influence of warm pre-stretching on microstructure and properties of AZ31 magnesium alloy [J]. Journal of Alloys and Compounds, 2013, 563: 150-154.

[2] CHINO Y, KIMURA K, MABUCHI M. Twinning behavior and deformation mechanisms of extruded AZ31 Mg alloy [J]. Materials Science and Engineering A, 2008, 486(1-2): 481-488.

[3] KIM H L, BANG W K, CHANG Y W. Deformation behavior of as-rolled and strip-cast AZ31 magnesium alloy sheets [J]. Materials Science and Engineering A, 2011, 528(16-17): 5356-5365.

[4] HU Guang-shan, ZHANG Ding-fei, ZHAO Ding-zang, SHEN Xia, JIANG Lu-yao, PAN Fu-sheng. Microstructures and mechanical properties of extruded and aged Mg-Zn-Mn-Sn-Y alloys [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 3070-3075.

[5] GENG Chang-jian, WU Bao-lin, DU Xing-hao, WANG Yan-dong, ZHANG Yu-dong, CLAUDE E, FRANCIS W. Low cycle fatigue behavior of extruded AZ31B magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(6): 1589-1594.

[6] MULLNER P, SOLENTHALER C. On the effect of deformation twinning on defect densities [J]. Materials Science and Engineering A, 1997, 230(1-2): 107-115.

[7] HE Jie-jun, LIU Tian-mo, XU Shun, ZHANG Yin. The effects of compressive pre-deformation on yield asymmetry in hot-extruded Mg-3Al-1Zn alloy [J]. Materials Science and Engineering A, 2013, 579: 1-8.

[8] XIN Yun-chang, ZHOU Xiao-jun, LIU Qing. Suppressing the tension–compression yield asymmetry of Mg alloy by hybrid extension twins structure [J]. Materials Science and Engineering A, 2013, 567: 9-13.

[9] YIN De-liang, WANG Jing-tao, LIU Jin-qiang, ZHAO Xiang. On tension–compression yield asymmetry in an extruded Mg-3Al-1Zn alloy [J]. Journal of Alloys and Compounds, 2009, 478(1-2): 789-795.

[10] SINGH A, SOMEKAWA H, MUKAI T. Compressive strength and yield asymmetry in extruded Mg-Zn-Ho alloys containing quasicrystal phase [J]. Scripta Materialia, 2007, 56(11): 935-938.

[11] LIU Ran, YIN De-liang, WANG Jing-tao. Elimination of yielding asymmetry in extruded AZ80 alloy by ageing [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(4): 915-921.

[12] Xin Yun-chang, Zhou Hua, Yu Hui-hui, Hong Rui, Zhang Hong, Liu Qing. Controlling the recrystallization behavior of a Mg-3Al-1Zn alloy containing extension twins [J]. Materials Science and Engineering A, 2015, 622: 178-183.

[13] LI X, YANG P, WANG L N, MENG L, CUI F. Orientational analysis of static recrystallization at compression twins in a magnesium alloy AZ31 [J] Materials Science and Engineering A, 2009, 517(1-2): 160-169.

[14] LEVINSON A, MISHRA R K, DOHERTY R D, KALIDINDI S R. Influence of deformation twinning on static annealing of AZ31 Mg alloy [J]. Acta Materialia, 2013, 61(16): 5966-5978.

[15] YANG Xu-yue, ZHU Ya-kun, MIURA H, SAKAI T. Static recrystallization behavior of hot-deformed magnesium alloy AZ31 during isothermal annealing [J]. Transaction of Nonferrous Metals Society of China, 2010, 20(7): 1269-1274.

[16] XIN Yun-chang, ZHOU Xiao-jun, CHEN Hou-wen, NIE Jian-feng, ZHANG Hong, ZHANG Yuan-yuan, LIU Qing. Annealing hardening in detwinning deformation of Mg-3Al-1Zn alloy [J]. Materials Science and Engineering A, 2014, 594: 287-291.

[17] NIE J F, ZHU Y M, LIU J Z, FANG X Y. Periodic segregation of solute atoms in fully coherent twin boundaries [J]. Science, 2013, 340: 957-960.

[18] YI S B, BROKMEIER H G, LETZIG D. Microstructural evolution during the annealing of an extruded AZ31 magnesium alloy [J]. Journal of Alloys and Compounds, 2010, 506(1): 364-371.

[19] ASTM E112-2010. Standard test methods for determining average grain size [S].

[20] SARKER D, CHEN D L. Dependence of compressive deformation on pre-strain and loading direction in an extruded magnesium alloy: Texture, twinning and de-twinning [J]. Materials Science and Engineering A, 2014, 596: 134-144.

[21] SARKER D, CHEN D L. Texture transformation in an extruded magnesium alloy under pressure [J]. Materials Science and Engineering A, 2013, 582: 63-67.

[22] XIONG Ying, YU Qin, JIANG Yan-yao. An experimental study of cyclic plastic deformation of extruded ZK60 magnesium alloy under uniaxial loading at room temperature [J]. International Journal of Plasticity, 2014, 53: 107-124.

[23] LI X, JIAO F, SAMMAN T A, CHOWDHURY S G. Influence of second-phase precipitates on the texture evolution of Mg-Al-Zn alloys during hot deformation [J]. Scripta Materialia, 2012, 66(3-4): 159-162.

[24] HUANG X S, SUZUKI K, CHINO Y. Annealing behavior of Mg-3Al-1Zn alloy sheet obtained by a combination of high- temperature rolling and subsequent warm rolling [J]. Journal of Alloys and Compounds, 2011, 509(14): 4854-4860.

[25] YANG X Y, OKABE Y, MIURA H, SAKAI T. Effect of pass strain and temperature on recrystallisation in magnesium alloy AZ31 after interrupted cold deformation [J]. Journal of Materials Science and Technology, 2012, 47(6): 2823-2830.

[26] HUMPHREY F J, ATHERLY M. Recrystallization and related annealing phenomena [M]. 2nd ed. Oxford: Elsevier Ltd, 2004.

[27] JAGER A, LUKAC P, GARTNEROVA V, HALODA J, DOPITA M. Influence of annealing on the microstructure of commercial Mg alloy AZ31 after mechanical forming [J]. Materials Science and Engineering A, 2006, 432(1-2): 20-25.

[28] LIU F, KIRCHHEIM R. Comparison between kinetic and thermodynamic effects on grain growth [J]. Thin Solid Films, 2004, 466(1-2): 108-113.

[29] KO K J, PARK J T, KIM J K, HWANG N M. Morphological evidence that Goss abnormally growing grains grow by triple junction wetting during secondary recrystallization of Fe-3% Si steel [J]. Scripta Materialia, 2008, 59(7): 764-767.

[30] WU W X, JIN L, ZHANG Z Y, DING W J, DONG J. Grain growth and texture evolution during annealing in an indirect-extruded Mg-1Gd alloy [J]. Journal of Alloys and Compounds, 2014, 585: 111-119.

[31] MOLODOV K D, AL-SAMMAN T, MOLODOV D A, GOTTSTEIN G. Mechanisms of exceptional ductility of magnesium single crystal during deformation at room temperature: Multiple twinning and dynamic recrystallization [J]. Acta Materialia, 2014, 76: 314-330.

[32] ZHU S Q, YAN H G, CHEN J H, WU Y Z, LIU J Z, TIAN J. Effect of twinning and dynamic recrystallization on the high strain rate rolling process [J]. Scripta Materialia, 2010, 63(10): 985-988.

陈红兵1,2,刘天模1,卢立伟3,4,何杰军5,翟彦博2

1. 重庆大学 材料科学与工程学院,重庆 400044;

2. 西南大学 工程技术学院,重庆 400716;

3. 湖南科技大学 机电工程学院,湘潭 411201;

4. 中南大学 材料科学与工程学院,长沙 410083;

5.贵州理工学院 材料与冶金工程学院,贵阳 550003

摘 要:对挤压态AZ31镁合金进行预压缩和热处理,研究预压缩和热处理对其形变行为的影响。结果表明:在低温下退火(170 °C退火4 h),试样经过退火处理或未经退火处理的几乎具有相等的屈服强度(~148 MPa),这是由于它们的显微组织几乎没有变化。然而在相同退火条件下,经预压缩并退火的试样的屈服强度(~225 MPa)高于只有预压缩试样的屈服强度(~200 MPa)。由于溶质原子在孪晶界偏析引起强化,前者显示出退火硬化效应。预压缩试样在400 °C退火1 h后,其伸长率(~28%)高于预压缩试样的伸长率(~15%),但其屈服强度(~125 MPa)低于预压缩试样的屈服强度(~200 MPa)。

关键词:AZ31镁合金;孪生;退火硬化;预压缩;热处理;形变

(Edited by Mu-lan QIN)

Foundation item: Project (XDJK2013C106) supported by the Fundamental Research Funds for the Central Universities of China; Project (51201140) supported by the National Natural Science Foundation of China

Corresponding author: Tian-mo LIU; Tel: +86-13368223083; E-mail: tmliu@cqu.edu.cn

DOI: 10.1016/S1003-6326(15)64001-8