文章编号:1004-0609(2015)-05-1128-08

热挤压AZ31镁合金单向压缩变形的应变硬化行为

周德智,鲁 月,马 茹,王轶农

(大连理工大学 材料科学与工程学院,大连 116024)

摘 要:对AZ31镁合金热挤压棒材在室温下沿挤压方向分别进行了应变为3%、6%、10%的单向压缩实验。利用OM、XRD和EBSD等技术研究了不同压缩应变量下的显微组织、织构及应变硬化的演变特征。结果表明:具有{0002}纤维织构的热挤压态AZ31镁合金沿着挤出方向压缩时,产生显著的应变硬化效应。其塑性变形可大致分为3个阶段:初始阶段主要发生{1012}拉伸孪生,表现为较低的应变硬化速率和应变硬化速率的急剧减小;随着压缩应变量的增加,孪晶界逐渐扩展,直至部分晶粒发生完全孪生,基面织构强度逐渐增强;拉伸孪晶生长所造成的强{0002}基面织构是产生高应变硬化速率的主要原因;应变硬化速率第Ⅱ~Ⅲ阶段的转折点大致与拉伸孪晶的生长停滞相对应。

关键词:AZ31镁合金;拉伸孪生;滑移;压缩变形;孪晶界

中图分类号:TG146.22 文献标志码:A

Strain hardening behavior during uniaxial compression of as-extruded AZ31 magnesium alloy

ZHOU De-zhi, LU Yue, MA Ru, WANG Yi-nong

(School of Materials Science and Engineering, Dalian University of Technology, Dalian 116024, China)

Abstract: Uniaxial compression tests were carried out on an as-extruded AZ31 magnesium alloy along extrusion direction at the strain of 3%, 6% and 10%, respectively, at room temperature. The evolution of microstructures, textures and strain hardening behavior were examined by OM, XRD and EBSD. The results show that the present as-extruded magnesium alloy with {0002} fiber texture exhibits distinct three plastic deformation stages. {1012} tension twinning takes place at the first stage of the plastic deformation, which results in the low strain hardening rate and rapid decrease in strain hardening rate. With increasing the compressive strain, {1012} twin boundaries gradually extend until some grains are entirely consumed by the twinning extension, which results in the strong basal texture. The increasing high strain hardening rate are mainly attributed to the formation of strong basal texture. The deformation transition from stage Ⅱ to stage Ⅲ roughly corresponds to the stop of {1012} twin extending.

Key words: AZ31 magnesium alloy; tension twining; slip; compressing deformation; twinning grain boundary

镁合金具有密度低、比强度高和比刚度、阻尼减震、电磁屏蔽效果好等一系列优异性能,在汽车制造、电子产品、航空航天等领域具有广泛的应用前景,被誉为“21世纪绿色工程金属”[1-3]。但是,镁合金是密排六方(HCP)晶体结构,室温下滑移系较少,难以满足Von Mises准则所要求5个独立滑移系,极大地限制了镁合金室温塑性变形能力,也因此阻碍了其在工程领域的大规模应用[4]。

研究表明,孪生是镁合金室温下塑性变形的一种重要机制。镁合金中常见的孪生类型有{1012}拉伸孪生、{1011}压缩孪生以及{1012}-{1011}二次孪生[5-11]等。由于拉伸孪生的临界切应力较压缩孪生要小得多[7],{1012}拉伸孪生经常出现在镁合金形变组织中。此外,由于孪生的极性特征,垂直于c轴方向压缩或者沿着c轴方向拉伸均有利于{1012}孪生,且{1012}孪生易于扩展,因此,对镁合金的变形有着重要影响。通常变形镁合金经热-机处理(Thermal-mechanical processing,TMP)后均产生特定的基面织构,如对于热轧板材,一般会产生{0002}<1010>基面织构,而对于热挤压的棒材,一般会产生{0002}基面平行于挤压方向(Extrusion direction,ED)的纤维织构。镁合金中基面织构的存在及孪生变形机制的作用是导致材料呈现各向异性,特别是拉-压塑性变形抗力不对称性的根本原因。彭颖红等[12]从织构角度研究了AZ31挤压棒材的拉压不对称性和板材的力学性能各向异性,雷前等[13 ]研究了镁合金的低温压缩变形过程,结合微观组织观察指出,孪晶是镁合金变形的重要变形机制,并且在孪晶交叉处有再结晶晶核形成,LIU等[14]研究了镁合金中不同的初始晶粒取向对压缩变形织构演变和应变硬化行为的影响,主要分析了拉伸孪生{1012}在镁合金变形的第二阶段的作用。通常,镁合金的塑性变形,是一个滑移和孪生的相互作用过程,根据变形条件和微观组织(织构)的差异,二者既相互竞争又相互补充[6]。因此,弄清镁合金中孪生变形的作用机制,对于理解镁合金的塑性变形、应变硬化行为以及优化塑性加工工艺具有重要指导意义。

本文作者采取AZ31镁合金挤压棒材,沿挤压方向进行不同压缩量的室温压缩实验,利用金相、XRD和EBSD分析技术对不同压缩的应变量的样品的微观组织、织构进行表征,分析了不同的塑性变形阶段孪生、滑移及其交互作用行为,以期全面揭示镁合金不同塑性变形阶段的变形机制。

1 实验

以名义成分为Mg-3Al-1Zn-0.3Mn(质量分数,%)的AZ31镁合金铸锭为原始材料。利用挤压机在400 ℃下进行热挤压,挤压比为(d02/d2)为10(d0为原始铸锭直径,d为挤压棒直径)。对挤压后直径为10 mm的热挤压棒材材料进行400 ℃、4 h退火处理以进一步稳定组织。将退火后的热挤压棒沿挤压方向加工成直径8 mm、高16 mm的圆柱试样,在液压式万能实验机(CRIMS,DNS300)下沿挤压方向进行室温下单向压缩实验,变形速率为1×10-3 s-1,压缩应变量分别为3%、6%、10%。对压缩变形前后的样品进行金相组织观察,腐蚀剂为5 mL乙酸、5 g苦味酸、10 mL蒸馏水和100 mL乙醇配制的溶液;利用PANalytical X射线衍射仪(Cu Kα,波长l=0.154 nm)对样品的压缩平面按θ-θ方式扫侧(2θ=20°~60°),利用Ziss-55场发射扫描电子显微镜配备的EBSD系统测试微区织构,利用 HKL Channel 5软件对EBSD数据进行分析,以得到所观察区域的取向成像图、极图和取向差分布图等信息。EBSD样品的制备按标准金相制样方法用SiC砂纸打磨至2000号,再选用ACⅡ商用镁合金电解抛光液抛光150 s,抛光液温度-25℃,抛光电压20 V,电流0.3 mA。

2 实验结果

2.1 初始热挤压棒的组织与织构

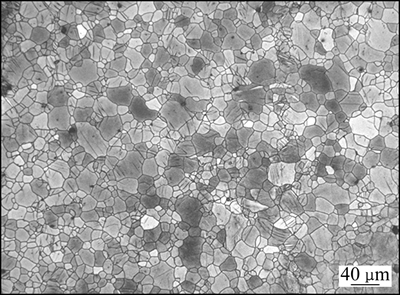

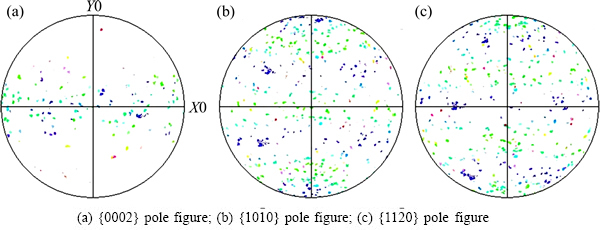

热挤压AZ31镁合金经400 ℃、4 h退火后的金相组织如图1所示。由图1可见,样品由平均晶粒尺寸约为30 μm的等轴晶粒组成,样品内几乎观察不到孪晶存在。图2样品挤压棒材横截面位置上的{0002}、{1010}和{1120}实测EBSD极图。由图2可见,挤压棒材中的大部分晶粒的{0002}基面与挤压轴ED方向垂直,表明热挤压棒材具有强烈的{0002}纤维织构,{0002}基面的漫散范围约为20°(±10°)。

图1 热挤压AZ31镁合金金相组织

Fig. 1 Microstructure of as-extruded AZ31 magnesium alloy

2.2 压缩应力-应变曲线特征

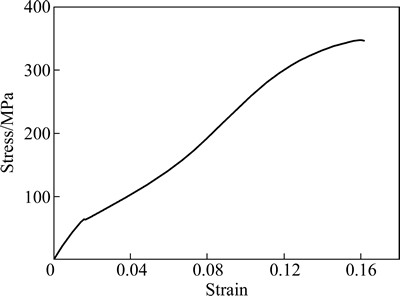

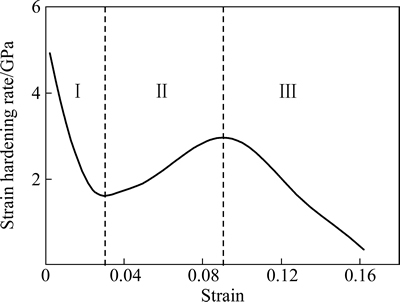

图3所示为热挤压AZ31镁合金样品的室温压缩应力-应变曲线,由图3可见,应力-应变曲线表现出明显的“S型”曲线特征。通过对图3的数据求导,可得到热挤压AZ31镁合金的应变硬化速率-应变曲线(如图4所示)。图4清晰地显示出其应变硬化的3个阶段。初始塑性变形阶段(ε<3%,Ⅰ阶段),随应变量的增加,应变硬化速率急剧降低,在ε=3%时,到达最小值(dσ/dε=1.5 GPa),为低应变硬化速率阶段;随着应变的增加(3%<ε<9%,Ⅱ阶段),应变硬化率快速增加,并在ε=9%时,达到最大值(dσ/dε=3 GPa),为高的应变硬化速率阶段;随着应变的继续增加(ε>9%,Ⅲ阶段),应变硬化速率随应变的增加逐渐降低直至断裂。

图2 热挤压AZ31镁合金EBSD极图

Fig. 2 EBSD pole figures of as-extruded AZ31 magnesium alloy

图3 热挤压AZ31镁合金的压缩应力-应变曲线

Fig. 3 Compressive stress-strain curves of as-extruded AZ31 magnesium alloy (loaded direction is parallel to extrusion direction)

图4 热挤压AZ31镁合金的应变硬化速率-应变曲线

Fig. 4 Strain hardening rate(dσ/dε)-strain (ε) curve of as-extruded AZ31 magnesium alloy

2.3 压缩过程中的显微组织演变

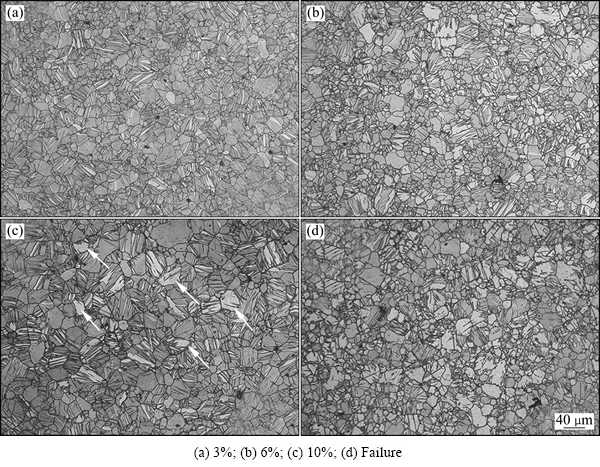

图5所示为热挤压AZ31镁合金室温下不同压缩应变量的显微组织。压缩应变量约3%时,已经产生大量孪晶,孪晶形态为透镜状,是{1012}拉伸孪晶在光学显微镜下的典型特征;当压缩应变量为6%时,孪晶数量未见明显增多,但孪晶宽度明显增加;当应变量达到10%时,孪晶数量不再增加,但孪晶宽度继续增宽,部分晶粒甚至已被完全孪晶化(如图5(c)箭头所示)。图5(d)所示为材料断裂后(应变量约为16%)的金相组织,从金相形态上看,其孪晶形态与应变量为10%产生的孪晶形态无明显变化,表明孪生的作用在压缩变形后期已基本结束。

图5 不同压缩应变量下AZ31镁合金的显微组织

Fig. 5 Microstructures of AZ31 magnesium alloy at different compressive strain

图6 AZ31镁合金不同压缩应变量下的横截面XRD谱

Fig. 6 XRD patterns of cross-section plane from extruded AZ31 samples subjected to compressive deformation at different strains

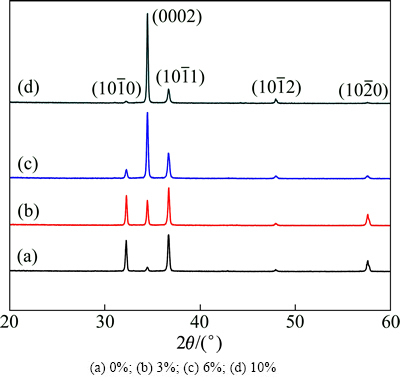

图6(a)所示为热挤压AZ31镁合金的初始状态衍射峰,(0002)与(1010)的峰强比约为I(0002)/I(1010)=0.20,可以表明,测试平面内(热挤压棒横截面)(1010)晶面垂直于挤压方向的晶粒数远高于(0002)面垂直于测试平面内的,显示了镁合金在热挤压过程中,形成了较强的(0002)晶面平行于挤压方向的纤维织构,即(0002)纤维织构,这与实测极图(见图2)的结果相一致,并且可以看出,随着压缩应变量的增加,(0002)衍射峰强度逐渐增强。压缩应变量为3%时,I(0002)/I(1010)=0.86(见图6(b));压缩应变量为6%时,I(0002)/I(1010)=8.03(见图6(c));压缩至应变量为10%时,I(0002)/I(1010)=43.35(见图6(d))。显然,(0002)衍射峰强度的增加与{1012}拉伸孪晶密切相关。由于初始样品取向有利于{1012}拉伸孪晶,经过压缩变形后,产生{1012}拉伸孪晶,拉伸孪晶与基体的取向关系为86.3°<1120>,这就是说,当{0002}基面平行于压缩轴的晶粒发生孪生时,孪晶内的{0002}基面相对于基体产生86.3°转动,即孪晶中{0002}基面由垂直于压缩轴方向转向近似平行于压缩轴方向,使得(0002)衍射峰的强度增加。对比金相(见图5)可见,压缩至应变量为3%时,已形成了大量孪晶,此时(0002)衍射峰的增强主要源于{1012}拉伸孪晶的大量形成,压缩应变量从3%至10%的过程中,因孪晶数量增加不明显,因此可以推断,(0002)衍射峰强度的增加主要源于孪晶的生长所导致的(0002)基面数量的增多,后续的EBSD测试证实了上述推断,这是镁合金压缩变形后形成强基面织构的主要原因[15]。

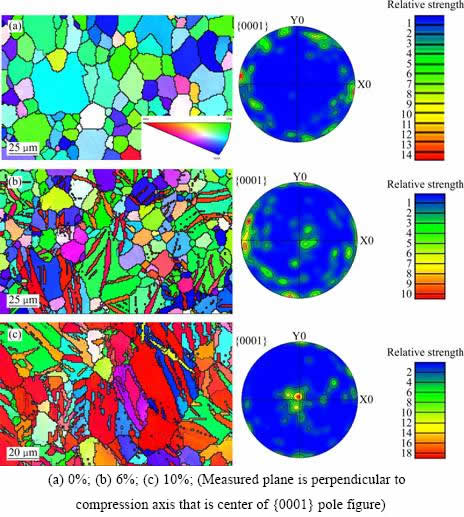

2.4 不同压缩变形阶段的EBSD取向分析

图7所示为热挤压态AZ31镁合金不同应变量下的压缩样品在横截面位置上的取向成像图(OIM)。图7(a)所示为初始的未变形状态,从(0002)极图中可以看出,绝大部分晶粒的(0002)面平行于挤出方向,与图2(a)的实测极图及图6(a)的XRD测试结果一致。该取向的晶粒沿挤压方向压缩变形时,很容易产生{1012}拉伸孪晶。压缩变形至应变量为6%时,如图7(b),绝大多数(0002)基面平行于压缩轴的晶粒都已产生拉伸孪晶(片状红色区域),即拉伸孪晶使(0002)基面发生了约86°的转动,使得晶粒的c轴转到与压缩轴近乎平行的方向,基面织构强度显著增强(见图7(b)对应的极图)。继续变形至应变量为10%时,拉伸孪晶界扩展以及孪晶变体的合并导致孪晶长大(红色区域扩大),部分晶粒甚至发生完全孪生,基面织构变得更强,与XRD测试结果吻合很好。

图7 热挤压AZ31镁合金样品不同压缩应变量的EBSD取向分析

Fig. 7 EBSD maps of AZ31 samples compressed at different strains

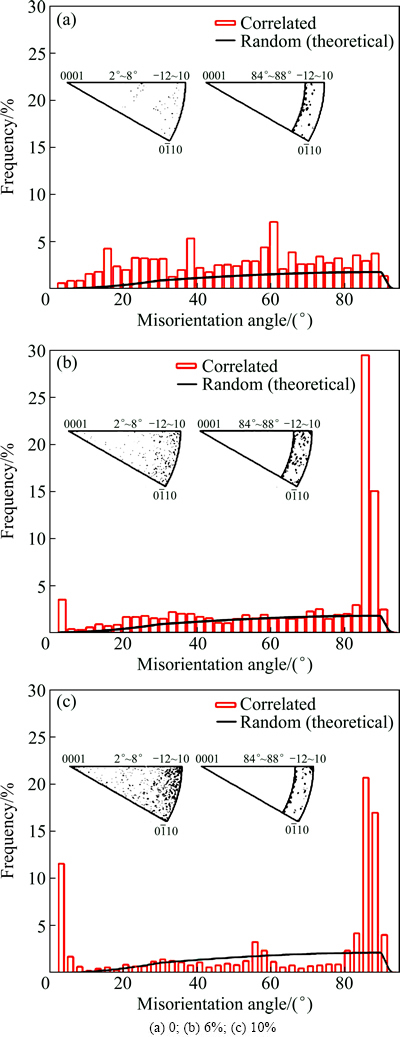

图8所示为热挤压AZ31镁合金不同应变量的取向差角分布。由图8可以看出,经过6%的压缩变形,最大的取向差角分布在84°~88°之间,显然这是由{1012}拉伸孪生所产生的大量孪晶界导致的结果,由于{1012}拉伸孪晶与基体的取向关系为86.3°<1120>。此外,2°~8°小角度取向差分布略有增加,说明在压缩至6%的变形过程中,有少许滑移系开动,形成了少量小角度晶界。继续压缩变形至应变量为10%,一方面,84°~88°间的取向差角出现频度较大的下降,表明孪晶界数量明显减少,这说明孪生过程主要是孪晶界的扩展及孪生变体的合并长大使得孪晶界密度降低;另一方面,2°~8°小角度取向差分布明显增加,表明变形过程位错滑移所占比例明显增加,即变形的主导机制由孪生转为滑移。

3 分析与讨论

3.1 压缩屈服行为分析

镁合金中,通常具有3种主要滑移系和两种主要孪生系,即{0001}<1120>基面滑移、{1010}<1120>柱面滑移、{1121}<1123>锥面滑移、{1012}<1011>拉伸孪生和{1011}<1012>压缩孪生。一般来讲,镁及镁合金在室温下变形时,主要是滑移和孪生相互协调进行的。滑移和孪生开动所需的临界切应力(CRSS)的大小随温度变化存在较大差异。室温下,纯镁基面滑移的CRSS值为0.5~0.7MPa,且与温度关系不大;柱面和锥面滑移的CRSS值则高达40MPa以上,但随温度升高显著降低[6];而镁合金中{1012}拉伸孪生所需CRSS约为2~3 MPa,远小于{1011}压缩孪生所需CRSS(76~153 MPa)[16]。从图2及图7(a)热轧态AZ31镁合金的(0002)极图可以看出,变形前样品存在(0002)基面法向(即 c 轴)垂直于ED方向的基面纤维织构,而c轴在垂直于ED方向为随机分布。因此,当沿ED方向压缩时,基面滑移系的 Schmid 因子几乎为零,基面滑移难以启动,沿ED拉伸时,其屈服强度较高,即产生所谓的织构强化[4,12]。而此时{1012}拉伸孪生的取向因子(Schmid 因子)最大,约为0.498,因此,其屈服行为将由拉伸孪生主导。BARNETT等[17]给出了由孪晶主导AZ31镁合金的Hall-Petch公式: ,其中d为平均晶粒尺寸(mm)。由以上公式可得,平均晶粒尺寸为30 mm的AZ31镁合金的压缩屈服强度为82 MPa,与本研究实测的屈服强度69 MPa非常接近,这表明,具有{0002}纤维织构的AZ31镁合金的压缩屈服行为是由孪生控制的,金相组织观察及EBSD测试均证实了这一点。

,其中d为平均晶粒尺寸(mm)。由以上公式可得,平均晶粒尺寸为30 mm的AZ31镁合金的压缩屈服强度为82 MPa,与本研究实测的屈服强度69 MPa非常接近,这表明,具有{0002}纤维织构的AZ31镁合金的压缩屈服行为是由孪生控制的,金相组织观察及EBSD测试均证实了这一点。

3.2 压缩流变行为分析

图3和4均清晰地显示了热挤压AZ31镁合金样品的室温压缩应力-应变曲线及加工硬化的3个阶段。由于{1012}拉伸孪生所需CRSS较小,加之(0002)纤维织构有利于{1012}拉伸孪生,因此,初始的塑性变形阶段(ε<3%,Ⅰ阶段)主要由{1012}拉伸孪生主导。由于孪生属于非热激活过程,一旦拉伸孪晶形成,它就会快速沿孪晶长轴方向生长,表现出较低的应变硬化率和快速的应变硬化速率的降低。由于孪生形成和沿长轴生长速率较快,因此,第Ⅰ应变硬化阶段所对应的应变也较小。若将ε=2%看成是塑性变形的开始点,最低硬化速率一般为3%[14],如图3所示,那么单纯由孪生贡献的塑性应变量只有1%左右。这就是为什么应变硬化第Ⅰ阶段具有应变量小和硬化速率低的主要原因。当孪生变体相遇、单变体与晶界相遇以及孪晶界横向扩展时,孪生的生长开始遇到阻力,于是加工硬化速率开始增加,进而进入应变硬化的第Ⅱ阶段。对于HCP结构的镁合金,{1012}孪晶系共有6个孪晶变体[18],在外力作用下,任何两个相邻变体或相间变体相继开动,都会相截而发生交互作用。其中交互作用的一种形式是,预先形成的孪晶(又称障碍孪晶)与后开动的孪晶(又称入射孪晶)相遇时,入射孪生位错就会在交截线处塞积,引起应力集中。只有这些塞积的位错通过适当的分解,在障碍孪晶中形成可动位错才能使应力集中松弛。该机制与位错主导的Hall-Petch机制相类似,因此,由BARNETT等[19]认为孪晶的形成相当于细化了晶粒,可减小位错滑移的有效距离,进而增强应变硬化速率。问题是,该阶段由于应力较小,尚不足以诱发大量的非基面滑移,只有当非基面滑移启动时,孪晶界的Hall-Petch机制才起作用。图8(b)所示为应变量为6%时的取向差角分布图,未见小角度晶界数量的增多,一般认为小角度晶界的产生主要由滑移产生,而非孪生。BROWN等[20]指出理论上拉伸孪晶可提供的最大轴向应变为6.5%。因此可以认为,当压缩应变小于6.5%时,压缩应变主要由孪生提供,很少有滑移系被激活。由于压缩应变为3%时,已有大量孪晶形成(如图5(a)所示),表面此时孪生形核已基本饱和,应变硬化第Ⅱ阶段的前期塑性变形主要由孪晶的长大所控制,由于孪生长大过程不产生明显的位错塞积,生长阻力较小,因此应变硬化速率也并不高,据此判断,应变硬化第Ⅱ阶段前期 (ε<6%)的塑性变形主要为孪晶-孪晶交互作用机制所控制。

图8 AZ31镁合金样品不同压缩应变量下的取向差角分布

Fig. 8 Misorientation angle distributions of AZ31 samples at different compressive strains

随着孪晶变体相截及孪晶界移动阻力增加,应力水平不断提高,使得一些晶粒中的非基面滑移达到了其临界分切应力,非基面滑移开始启动,并随着应力水平的持续增加,非基面滑移的开动数量也逐渐增加。因此,非基面滑移的位错与孪晶界、位错与位错等的交互作用使得应变硬化速率开始明显增加,图8(c)所示的小角度晶界出现的频度显著增加也预示着位错滑移机制的出现。值得说明的是,随着孪晶变体的合并长大,孪晶界的数量随之减少(见图8(c)),于是孪晶细化晶粒的Hall-Petch机制的作用也随之减弱。大量研究结果也显示[21-23],镁合金中所产生的{1012}拉伸孪晶引起晶粒细化所产生的Hall-Petch效应并不明显。显然,孪晶细化晶粒的Hall-Petch机制并非产生高应变硬化速率的主要原因。同时,随着孪晶的长大,基面织构强度(或基面取向晶粒的体积分数)显著增加(如图7所示),对于压缩变形而言,这种基面取向的晶粒不利于基面滑移,而只能依靠非基面滑移和{1011}压缩孪晶机制,即产生所谓的织构硬化,进而导致应变硬化速率的显著增加。本实验中应变硬化速率最大值(3 GPa)位于应变量ε=9%(见图4),图7(c)所示为应变量为ε=10%时晶粒的取向差分布图,可见大量由拉伸孪晶被消耗而形成的基面取向的晶粒,也就是说,当拉伸孪晶界扩展基本停止时,即使存在孪晶细化的Hall-Petch机制,其作用也变得很弱,而这时所形成的大量基面取向的晶粒的硬化效应达到最大,从而表现为最大的应变硬化速率。实验结果显示,第Ⅱ-Ⅲ阶段的转折点大致与拉伸孪晶界扩展停滞(基面织构强度最大)相对应。当变形进入第Ⅲ阶段后,应变硬化机制一般认为由非基面滑移和{1011}压缩孪晶所控制。由于变形进入第Ⅲ阶段时,已积累了高密度位错,使得位错密度的持续增加的速率明确减少,因此表现为较低的应变硬化速率。当位错塞积密度达到一定程度后,便开始萌生裂纹直至断裂。由上述分析可知,{1012}拉伸孪生在压缩变形过程中起着重要作用,其中,由拉伸孪晶长大所导致的基面织构的增强是产生的高应变硬化速率的主要原因(即织构硬化)。显然,影响拉伸孪晶产生的各种因素均会影响镁合金的应变硬化行为,如增加晶粒尺寸[14]、降低实验温度[24]、增加应变速率[25]及增加纤维基面织构强度[14]等均促进{1012}拉伸孪晶的激活,进而增强由拉伸孪晶生长造成的基面取向晶粒的强化效应,增加镁合金的应变硬化速率,上述研究结果均较好地验证了本文作者所提出的观点。

4 结论

1) 具有{0002}纤维织构的热挤压AZ31镁合金沿着挤出方向压缩时,可产生明显的三阶段的应变硬化特征。

2) 热挤压AZ31镁合金压缩变形第Ⅰ阶段较低的应变硬化率和小的应变量主要源于{1012}拉伸孪生的形成;第Ⅱ阶段高的应变硬化速率主要归因于拉伸孪晶的生长所造成的织构硬化效应。

3) 应变硬化速率第Ⅱ-Ⅲ阶段的转折点大致与拉 伸孪晶的生长停滞相对应,第Ⅲ阶段的应变硬化机制由非基面滑移和{1011}压缩孪晶所控制。

REFERENCES

[1] 陈振华. 镁合金[M]. 北京: 化学工业出版社, 2004: 202-241.

CHEN Zhen-hua. Magnesium alloy[M]. Beijing: Chemical Industry Press, 2004: 202-241.

[2] 吴远志, 严红革, 朱素琴, 陈吉华, 刘先兰, 刘安民. 多向锻造ZK60镁合金组织和性能的均匀性[J]. 中国有色金属学报, 2014, 24(2): 310-316.

WU Yuan-zhi, YAN Hong-ge, ZHU Su-qin, CHEN Ji-hua, LIU Xian-lan, LIU An-ming. Homogeneity of microstructure and mechanical properties of ZK60 magnesium alloys fabricated by high strain rate triaxial-forging[J]. The Chinese Journal of Nonferrous Metals,2014, 24(2): 310-316.

[3] DEL VALLE J A, PEREZ-PRADO M T, RUANO O A. Texture evolution during large-strain hot rolling of the Mg AZ61 alloy[J]. Materials Science and Engineering A, 2003, 355(1/2): 68-78.

[4] KHAN A S, PANDEY A, GNAUPEL-HEROLD T, MISHRA R K. Mechanical response and texture evolution of AZ31 alloy at large strains for different strain rates and temperatures[J]. International Journal of Plasticity, 2011, 27(5): 688-706.

[5] 常丽丽. 变形镁合金AZ31的织构演变与力学性能[D]. 大连: 大连理工大学,2009: 68-88.

CHANG Li-li. Textural evolution and mechanical properties of wrought magnesium alloy AZ31[D]. Dalian: Dalian University of Technology, 2009: 68-88.

[6] 刘庆. 镁合金塑性变形机理研究进展[J]. 金属学报, 2010, 46(11): 1458-1472.

LIU Qing. Research progress on plastic deformation mechanism of Mg alloy[J]. Acta Metall Sin, 2010, 46(11): 1458-1472.

[7] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, Wang Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[8] BARNETT M R. Twinning and the ductility of magnesium alloys Part II. "Contraction" twins[J]. Materials Science and Engineering A, 2007, 464(1/2): 8-16.

[9] MARTIN E, CAPOLUNGO L, JIANG L A, JONAS J J. Variant selection during secondary twinning in Mg-3%Al[J]. Acta Materialia, 2010, 58(11): 3970-3983.

[10] BARNETT M R, KESHAVARZ Z, BEER A G, MA X. Non-Schmid behaviour during secondary twinning in a polycrystalline magnesium alloy[J]. Acta Materialia, 2008, 56(1): 5-15.

[11] CHINO Y, KIMURA K, HAKAMADA M, MABUCHI M. Mechanical anisotropy due to twinning in an extruded AZ31 Mg alloy[J]. Materials Science and Engineering A, 2008, 485(1/2): 311-317.

[12] 唐伟琴, 张少睿, 范晓慧, 李大永, 彭颖红. AZ31镁合金的织构对其力学性能的影响[J]. 中国有色金属学报, 2010, 20(3): 371-377.

TANG Wei-qin, ZHANG Shao-rui, FAN Xiao-hui, LI Da-yong, PENG Ying-hong. Texture and its effect on mechanical properties of AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 371-377.

[13] 李树梅, 汪明朴, 张 真, 李 周, 唐 宁, 雷 前. AZ31B 镁合金的低温压缩变形机制[J]. 中国有色金属学报, 2010, 20(7): 1254-1259.

LI Shu-mei, WANG Ming-pu, ZHANG Zhen, LI Zhou, TANG Ning, LEI Qian. Compression mechanism of AZ31B Mg alloy at low temperature[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1254-1259.

[14] WANG, B S, XIN R L, HUANG G J, LIU Q. Effect of crystal orientation on the mechanical properties and strain hardening behavior of magnesium alloy AZ31 during uniaxial compression[J]. Materials Science and Engineering A, 2012, 534: 588-593.

[15] WANG Y N, HUANG J C. The role of twinning and untwinning in yielding behavior in hot-extruded Mg-Al-Zn alloy[J]. Acta Materialia, 2007, 55(3): 897-905.

[16] CHEN Y J, WANG Q D, ROVEN H J, LIU M P, KARLSEN M, YU Y D, HJELEN J. Network-shaped fine-grained microstructure and high ductility of magnesium alloy fabricated by cyclic extrusion compression[J]. Scripta Materialia, 2008, 58(4): 311-314.

[17] BARNETT M R, KESHAVARZ Z, BEER A G, ATWELL D. Influence of grain size on the compressive deformation of wrought Mg-3Al-1Zn[J]. Acta Materialia, 2004, 52(17): 5093-5103.

[18] PEI Y, GODFREY A, JIANG J, ZHANG Y B, LIU W, LIU Q. Extension twin variant selection during uniaxial compression of a magnesium alloy[J]. Materials Science and Engineering A, 2012, 550: 138-145.

[19] BARNETT M R, KESHAVARZ Z, BEER A G, ATWELL D. Influence of grain size on the compressive deformation of wrought Mg-3Al-1Zn[J]. Acta Materialia, 2004, 52(17): 5093-5103.

[20] BROWN D W, AGNEW S R, BOURKE M, HOLDEN T M, VOGEL S C, TOME C N. Internal strain and texture evolution during deformation twinning in magnesium[J]. Materials Science and Engineering A, 2005, 399(1/2):1-12.

[21] EL K H, OPPEDAL A L. A crystal plasticity theory for latent hardening by glide twinning through dislocation transmutation and twin accommodation effects[J]. Journal of the Mechanics and Physics of Solids, 2010, 58(4): 613-624.

[22] 娄 超, 张喜燕, 汪润红, 段高林, 刘 庆. 退孪生行为以及 孪晶片层结构对镁合金力学性能的影响[J]. 金属学报, 2013, 49(3): 291-296.

孪晶片层结构对镁合金力学性能的影响[J]. 金属学报, 2013, 49(3): 291-296.

LOU Chao, ZHANG Xi-Yian, WANG Run-Hong, DUAN Gao-Lin, LIU Qing. EFFECTS of untwining and  twin lamellar structure on the mechanical properties of Mg alloy[J]. Acta Metall Sin, 2013, 49(3): 291-296.

twin lamellar structure on the mechanical properties of Mg alloy[J]. Acta Metall Sin, 2013, 49(3): 291-296.

[23] 况新亮, 刘天模, 何杰军. 基于镁合金 孪生的织构调整及屈服行为演变[J]. 中国有色金属学报, 2014, 24(5): 1111-1117.

孪生的织构调整及屈服行为演变[J]. 中国有色金属学报, 2014, 24(5): 1111-1117.

KUANG Xin-liang, LIU Tian-mo, HE Jie-jun. Evolution of texture and yielding behaviour induced by  twining of magnesium alloy[J]. Acta Metall Sin, 2014, 24(5): 1111-1117.

twining of magnesium alloy[J]. Acta Metall Sin, 2014, 24(5): 1111-1117.

[24] 吴新星, 杨续跃, 张 雷, 张之岭. 初始取向对AZ31镁合金微观织构演化的影响[J]. 金属学报, 2011, 47(2): 140-144.

WU Xin-Xing, YANG Xu-Yue, ZHANG Lei, ZHANG Zhi-Ling. Effect of original orientation on microtexture evolution of AZ31 Mg alloy[J]. Acta Metall Sin, 2011, 47(2): 140-144.

[25] 王长义, 刘 正, 毛萍莉. AZ31B镁合金动态力学行为及变形机制[J]. 沈阳工业大学学报, 2012, 34(5): 509-514.

WANG Chang-yi, LIU Zheng, MAO Ping-li. Dynamic mechanical behavior and deformation mechanism of AZ31B magnesium alloy[J]. Journal of Shenyang University of Technology, 2012, 34(5): 509-514.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51271046)

收稿日期:2014-08-25;修订日期:2015-01-19

通信作者:王轶农,教授,博士;电话:0411-84708441;E-mail:wynmm@dlut.edu.cn