文章编号:1004-0609(2010)08-1447-08

热轧过程中AZ31镁合金的组织及织构演变

张 真,汪明朴,李树梅,蒋 念,胡海龙,郝诗梦

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:对AZ31镁合金铸轧板进行单道次热轧实验,利用光学显微镜、X射线和透射电镜对热轧过程中微观组织和织构的演变规律进行研究。结果表明:AZ31镁合金铸轧板具有较强的基面织构,当热轧变形量较小时,孪生是主要的变形机制;当热轧变形量较大时,位错滑移成为主要的变形机制;10%热轧态中出现的透镜状的 宽孪晶使基面织构明显减弱;20%热轧过程中则出现

宽孪晶使基面织构明显减弱;20%热轧过程中则出现 、

、 两种不同形貌的孪晶;当变形量大于20%时,位错滑移大量开动,基面织构也显著增强,并在随后的退火过程形成细小均匀的再结晶组织。

两种不同形貌的孪晶;当变形量大于20%时,位错滑移大量开动,基面织构也显著增强,并在随后的退火过程形成细小均匀的再结晶组织。

关键词:AZ31镁合金;热轧;变形机制;织构

中图分类号:TG146.2 文献标志码:A

Evolution of microstructure and texture of

AZ31 magnesium alloy during hot-rolling process

ZHANG Zhen, WANG Ming-pu, LI Shu-mei, JIANG Nian, HU Hai-long, HAO Shi-meng

(School of Materials Science and Engineering, Central South University, Changsha 410084, China)

Abstract: The single-pass hot-rolling was processed on the cast-rolled sheet of AZ31 magnesium alloy. The evolution of microstructure and texture was studied with OM, TEM and XRD. The results show that the cast-rolled sheet has a strong basal texture, and the main deformation mechanism is twinning in hot-rolling with small reduction while the dislocation slip becomes the main deformation mechanism in hot-rolling with large reduction. The thick lenticular  twins generated in 10% hot-rolling process seriously weakens the basal texture, while two types of twins

twins generated in 10% hot-rolling process seriously weakens the basal texture, while two types of twins  and

and with different morphologies are produced in 20% rolling process. As the rolling reduction exceeds 20%, the dislocation slip is activated in a wider range, thus intensifying the basal texture. And the fragmentation morphology produced in the rolling process transforms to equal-axis recrystallization grains in following annealing.

with different morphologies are produced in 20% rolling process. As the rolling reduction exceeds 20%, the dislocation slip is activated in a wider range, thus intensifying the basal texture. And the fragmentation morphology produced in the rolling process transforms to equal-axis recrystallization grains in following annealing.

Key words: AZ31 magnesium alloy; hot-rolling; deformation mechanism; texture

镁合金具有密度低、比强度和比刚度高以及优良的阻尼性能,同时具有尺寸稳定性好、机械加工性及电磁屏蔽性能优异等特点,被誉为是21世纪重要的 绿色轻质结构材料[1-2]。镁合金板材是应用范围最为广泛的镁合金初级产品之一,可以通过冲击挤压、拉伸或者弯曲等变形方式获得各种形状的成品和半成品。但是由于镁具有hcp的晶体结构,低温下其主要的变形机制为基面滑移与机械孪生,不能同时提供5个独立滑移系,因而塑性变形能力较差,变形方式受织 构[3]的影响较大。

镁合金轧制板材一般具有基面织构[4],这种织构对轧板的后续加工是不利的,通常为了制备具有良好机械加工性能的镁合金板材,生产中通常采用热轧方式,同时通过选择合理的轧制工艺获得均匀致密的组织[5]及有利于后续加工的织构,从而可以制备具有良好加工性能的镁合金板材。不少研究曾报道镁合金轧制过程的组织和织构特征。曾有研究者通过多道次大变形量热轧获得晶粒细小的组织,并且在轧制过程中观察到基面织构减弱的现象,认为这种织构减弱是由于旋转动态再结晶引起[6]。BARNETT等[7]对纯Mg、AZ31以及Mg-Ce合金进行了小变形量的多道次冷轧实验,其中Mg-Ce合金表现出良好的冷轧性能,在总变形量达到90%时仍未出现开裂,这种轧制工艺所获得的典型组织为剪切带、 孪晶及

孪晶及 -

- 孪晶。PEREZ-PRADO等[8] 在对AZ61合金进行轧制的过程中发现,不同厚度的板材在轧制过程中的变形方式不同,且随着板材厚度的减少,变形机制由位错滑移和动态再结晶逐渐转变为孪生。KIM等[9]对ZMA611和ZW61合金铸轧板分别进行了热轧实验,发现添加了稀土元素Y的ZW61合金在热轧过程中形成的基面织构相对较弱,并且剪切带的密度较小。以往对于镁合金板材轧制过程的研究大多针对具体的轧制工艺,对比不同工艺所形成的微观组织和织构的区别,而没有系统全面地说明轧制过程中组织和织构的演变规律,系统地研究工艺参数对轧制过程的影响是很有必要的。本文作者采用不同变形量的单道次热轧实验,研究AZ31合金铸轧板轧制过程中的微观组织和织构随不同热轧变形量的演变规律,阐述AZ31合金单道次轧制下的变形行为。

孪晶。PEREZ-PRADO等[8] 在对AZ61合金进行轧制的过程中发现,不同厚度的板材在轧制过程中的变形方式不同,且随着板材厚度的减少,变形机制由位错滑移和动态再结晶逐渐转变为孪生。KIM等[9]对ZMA611和ZW61合金铸轧板分别进行了热轧实验,发现添加了稀土元素Y的ZW61合金在热轧过程中形成的基面织构相对较弱,并且剪切带的密度较小。以往对于镁合金板材轧制过程的研究大多针对具体的轧制工艺,对比不同工艺所形成的微观组织和织构的区别,而没有系统全面地说明轧制过程中组织和织构的演变规律,系统地研究工艺参数对轧制过程的影响是很有必要的。本文作者采用不同变形量的单道次热轧实验,研究AZ31合金铸轧板轧制过程中的微观组织和织构随不同热轧变形量的演变规律,阐述AZ31合金单道次轧制下的变形行为。

1 实验

实验材料为中铝洛阳铜业有限公司提供的AZ31合金铸轧板,合金成分为2.8%Al、0.88%Zn、0.2%Mn、0.003 1%Fe、0.001%Ni、0.001%Cu,余量Mg。原始板材尺寸为厚6.5 mm(ND)、宽600 mm(TD),将原始铸轧板经过430 ℃,2 h均匀化退火、淬火处理后,切割成尺寸为厚6.5 mm(ND),宽24 mm(TD),长50 mm(RD)的小块,去除表面氧化层,加热至375 ℃,保温5 min后,进行单道次10%、20%、30%、50%、60%的热轧,轧制前对轧辊预热。轧辊直径157 mm,转速18 r/min。热轧后进行300 ℃退火,对热轧态和热轧退火态的板材进行金相、织构及TEM的分析。

金相样品选取轧板侧面作为观察面,用酚醛树脂进行镶样,经过400#、600#、800#砂纸手工研磨,机械抛光后,用醋酸苦味酸腐蚀晶界,在Leica EC3金相显微镜下观察组织形貌。织构样品选取轧板的轧面为X射线扫描面,经过400#、600#、800#砂纸手工研磨平整后用硝酸-乙醇溶液腐蚀去除表面应力层,在装配有尤拉环的Bruker D8 Discover X射线衍射仪上进行极图测量,测量角度范围为α角在 0~75?之间,β角在0~360?之间。TEM实验同样选择热轧板的侧面作为样品膜面,机械研磨到厚度为0.1 mm以下,冲制成3 mm圆片,利用Gatan dimple仪器制备出厚度为20 μm的薄区后,在离子减薄仪上进行减薄,离子束能量选择为3 keV,上下离子枪轰击角度分别为4?和2?,减薄1 h后,在Hitachi H800型透射电镜进行观察,加速电压为200 kV。

2 实验结果

2.1 合金的金相组织

2.1.1 热轧态金相组织特征

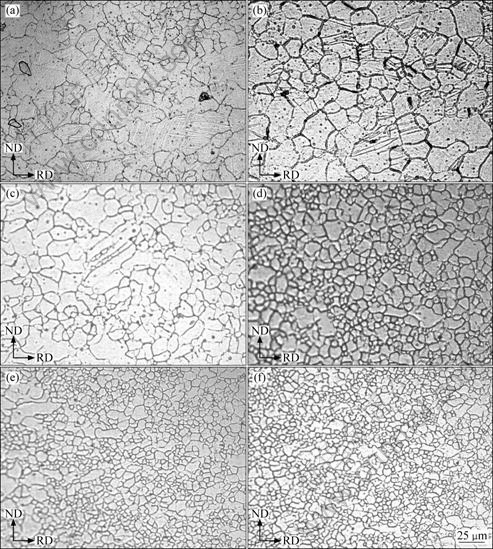

图1所示为AZ31合金铸轧板经430 ℃,2 h均匀化退火(以下简称为CRA)后及CRA态经过单道次热轧10%~60%(以下简称HR态)所获得的金相组织。由图1可以看出,铸轧板经过430 ℃,2 h均匀化退火后,形成完全等轴晶组织,平均晶粒尺寸为24 μm。10%HR态的晶粒中出现大量的透镜状的宽孪晶,孪晶和基体中均没有出现明显的再结晶现象(见图1(b)),这说明10%的热轧变形量并未使基体和孪晶中内部产生大量位错滑移,孪生应是小应变热轧的主要变形机制。在热轧20%的组织中(见图1(c))可以观察到两种形貌的孪晶[10-12]:一种是与10%热轧组织中形貌相似的透镜状宽孪晶,这种孪晶中没有发现再结晶晶粒;另一种是细长的窄孪晶,此种孪晶区域形成很多细小的再结晶晶粒,说明此种孪生的发生使得孪晶内部的晶体点阵转变到易发生滑移的取向[13-14],位错滑移得以大量开动,为再结晶的进行提供能量和结构基础。此外,在部分原始晶界和孪晶界面附近还出现动态再结晶的小晶粒。当热轧变形量达到50%时(见图1(d)),晶粒破碎成为一种主要的组织特征,大量细小的再结晶晶粒包围着一些未被再结晶组织所消耗的原始晶粒,这种组织形貌的形成可能与窄孪晶与及晶界附近的再结晶过程有关。

2.1.2 退火态的组织特征

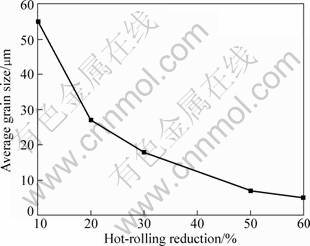

为研究不同热轧变形量的组织结构在退火过程的演变行为,对HR态样品进行300 ℃退火实验(以下称热轧后经过300 ℃退火的状态为HRA态)。HRA态的金相组织如图2所示。由图2可知,10%的HR态组织即使是在长时间退火(4 h)过程中也没有发生显著变化,孪晶和基体中很少出现再结晶晶粒(见图2(b));20%热轧板材经过300 ℃,1 h的退火处理后(见图2(c)),组织特征也没有发生明显的改变,透镜状宽孪晶仅在孪晶交截处形成再结晶的小晶粒,且原始晶界附近与窄孪晶内部的再结晶晶粒没有出现明显的长大现象。这些现象说明当热轧变形量小于20%时,热轧过程中的变形机制主要是孪生,晶粒内部的位错滑移并没有大量开动,因而退火过程中原始晶粒内部的静态再结晶难以发生。随着热轧变形量的增大,热轧退火态的再结晶晶粒尺寸逐渐减小,组织更加均匀。这也说明随着热轧变形量的增大,位错滑移成为一种重要的变形机制,为后续退火过程中静态再结晶的发生提供结构基础。50%热轧板经300 ℃,1 h退火(见图2(d))形成的再结晶晶粒的平均尺寸为8 μm;60%热轧板经300 ℃,1 h退火(见图2(e))形成的再结晶晶粒平均尺寸为4 μm左右。图3所示为HRA态的再结晶晶粒平均尺寸与退火前热轧变形量的关系。

图1 CRA态及HR态AZ31镁合金极的金相组织

Fig.1 Optical micrographs showing microstructures of CRA (a) and HR AZ31 magnesium alloy sheets with reduction of 10% (b), 20% (c), 50% (d) and 65% (e)

2.2 织构演变规律

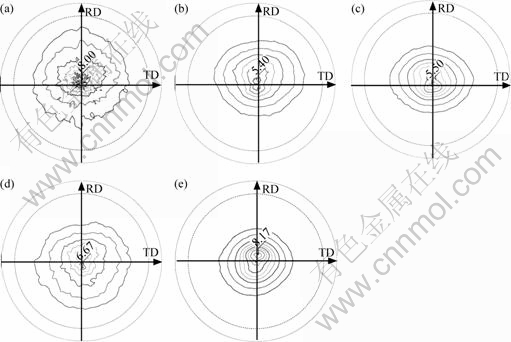

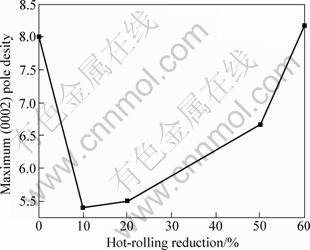

图4所示为CRA态和不同变形量HR态的(0002)面极图。图中数据表示最高极密度的大小。由图4可知,AZ31合金HR态(0002)面的最高取向极密度均位于ND附近,即大多数晶粒晶体坐标系中的c轴在样品坐标系的投影位于ND附近(后文用某个晶粒晶体坐标系的c轴在样品坐标系的投影表示该晶粒的取向),HR态板材具有明显的基面织构,只是不同变形量的HR态对应的织构强弱有所不同。CRA态的(0002)面的取向极密度最大值为8.00,经过10%热轧后,最高极密度减小到5.40,而极图中α角位于0~75?范围内并没有任何极密度明显升高的位置,也没有出现极密度等高线沿某个方向拉长的现象。20%HR态的基面织构比10%HR态的略强,其最高极密度为5.50,当热轧变形量达到20%后,随着变形量的增加,基面织构逐渐增强,热轧变形量为50%时最高极密度为6.67,热轧变形量为60%时,最高极密度达到8.17。图5所示为HR态基面织构的最高极密度随着热轧变形量的变化规律。

2.3 TEM分析

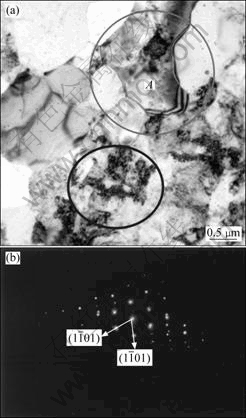

当热轧变形量达到20%并继续增大时,晶粒组织逐渐呈现出破碎的形貌特征,这种组织特征的出现与动态再结晶有关,60%热轧态组织具有典型的破碎特征,利用TEM对其微观组织进一步观察可以看出,60%HR态中存在大量细小的动态再结晶亚晶组织(见图6)。对图中圆圈所标示的区域进行选区电子衍射,并对衍射斑点进行标定,结果表明选区范围内的晶粒取相差较小,应为亚晶结构,这些亚晶的附近区域存在位错缠结组织(图中椭圆圈标示的区域)。

图2 不同变形量的HRA态AZ31镁合金板的金相组织

Fig.2 Optical micrograph showing microstructure of AZ31 magnesium alloy sheets annealed at 300 ℃ for 1 h after 10% (a), 20% (c), 30% (d), 50% (e), 65% (f) hot-rolling and 4 h after 10% hot-rolling (b)

图3 HRA态再结晶晶粒平均尺寸与热轧变形量的关系

Fig.3 Relationship between average recrystallization grain size and hot-rolling reduction of HRA sheet

3 分析与讨论

3.1 孪生主导的变形方式

由AZ31合金CRA态的基面极图中可以看出,热轧前的板材具有较强的基面织构。铸轧板经10%热轧后,最典型特征是晶粒内部出现大量的棱镜状宽孪晶。在随后进行的300 ℃,1 h甚至更长时间(4 h)的退火过程中,宽孪晶和基体内部均没有出现再结晶晶粒。原始晶粒中没有形成连续动态再结晶的晶粒,这说明在10%热轧过程中,基体内部的位错滑移特别是非基面滑移并未大范围开动,即使是密排六方晶体结构中相对容易开动的基面 位错的滑移能够在一定程度上起到协调变形的作用,单个晶粒内部仍无法形成位错网络或位错胞组织,也就无法为再结晶提供形核的结构基础,因而即使在较长的退火过程中基体中仍没有形成连续再结晶[15](CDRX)晶粒,所以我们可以得到这样一个结论:孪生是小变形热轧的主要变形机制。同时可以看到, 10%热轧时出现的宽孪晶在随后退火过程中保持稳定,这也说明孪生已经很大程度地协调材料在热轧过程的应变,使得晶粒内部的应力得以释放,因而孪生晶粒内部需要由位错滑移尤其是非基面位错滑移所协调的变形较小,不会形成再结晶的结构基础。

位错的滑移能够在一定程度上起到协调变形的作用,单个晶粒内部仍无法形成位错网络或位错胞组织,也就无法为再结晶提供形核的结构基础,因而即使在较长的退火过程中基体中仍没有形成连续再结晶[15](CDRX)晶粒,所以我们可以得到这样一个结论:孪生是小变形热轧的主要变形机制。同时可以看到, 10%热轧时出现的宽孪晶在随后退火过程中保持稳定,这也说明孪生已经很大程度地协调材料在热轧过程的应变,使得晶粒内部的应力得以释放,因而孪生晶粒内部需要由位错滑移尤其是非基面位错滑移所协调的变形较小,不会形成再结晶的结构基础。

图4 CRA态和HR态的(0002)极图

Fig.4 (0002) pole figures of CRA (a) and HR sheet with reductions of 10% (b), 20% (c), 50% (d) and 65% (e)

图5 热轧变形量对HR态(0002)面最高极密度的影响

Fig.5 Influence of rolling reduction on maximum (0002) pole density of HR sheet

图6 60%HR态亚晶结构的TEM像及相应的选取电子衍射斑

Fig.6 TEM image of subgrain microstructure in 60% HR sheet (a) and corresponding SAED pattern of A zone (b)

LI等[16]对AZ31合金中不同形态的孪晶退火行为进行系统的研究。结果表明,具有棱镜状形貌的宽孪晶在退火过程中不易成为再结晶形核点,即使在长时间的退火过程中也不会发生再结晶。EBSD研究表明,这种透镜状宽孪晶为 孪晶。而另外一种平直细长的窄孪晶在退火过程中非常容易成为再结晶晶粒的形核点,这种平直、细长的窄孪晶被证明是

孪晶。而另外一种平直细长的窄孪晶在退火过程中非常容易成为再结晶晶粒的形核点,这种平直、细长的窄孪晶被证明是 -

-  双孪晶。因而可以推测,在10%热轧中过程中,产生的这种透镜状宽孪晶为

双孪晶。因而可以推测,在10%热轧中过程中,产生的这种透镜状宽孪晶为 拉伸孪晶,而

拉伸孪晶,而 孪生可以使基面偏转86.4?[17-19]。同时,退火态的铸轧板具有较强的基面织构,即大部分晶粒取向位于ND附近,如果在这些晶粒中产生

孪生可以使基面偏转86.4?[17-19]。同时,退火态的铸轧板具有较强的基面织构,即大部分晶粒取向位于ND附近,如果在这些晶粒中产生 孪晶,晶粒取向会偏转近90?而落到极图的圆周附近。这个推测从10%热轧态的(0002)极图可以得到验证,当铸轧板经过10%热轧后,(0002)基面织构明显减弱,最高极密度的值从8.00突然减少到5.4,取向极密度等高线没有出现沿某个方向拉长的现象,且在α角位于0~75?范围内并没有出现任何极密度明显升高的位置,因而可以推断基晶体取向位于ND附近的晶粒中,由于

孪晶,晶粒取向会偏转近90?而落到极图的圆周附近。这个推测从10%热轧态的(0002)极图可以得到验证,当铸轧板经过10%热轧后,(0002)基面织构明显减弱,最高极密度的值从8.00突然减少到5.4,取向极密度等高线没有出现沿某个方向拉长的现象,且在α角位于0~75?范围内并没有出现任何极密度明显升高的位置,因而可以推断基晶体取向位于ND附近的晶粒中,由于 孪晶的形成而使晶粒取向部分的偏转到α角位于75?~90?范围内。但是,取向位于ND附近的晶粒,在轧制过程中受到沿c轴方向压缩的应力,不利于产生

孪晶的形成而使晶粒取向部分的偏转到α角位于75?~90?范围内。但是,取向位于ND附近的晶粒,在轧制过程中受到沿c轴方向压缩的应力,不利于产生 拉伸孪晶。WONSIEWCZ和BACKOFEN[20] 在对Mg单晶的c轴压缩的原位观察实验中发现,小应变的单轴压缩过程中只出现基面滑移的痕迹,但在压缩外应力释放的时候产生大量的透镜状宽孪晶。因而在本实验中同样可以认为,由于

拉伸孪晶。WONSIEWCZ和BACKOFEN[20] 在对Mg单晶的c轴压缩的原位观察实验中发现,小应变的单轴压缩过程中只出现基面滑移的痕迹,但在压缩外应力释放的时候产生大量的透镜状宽孪晶。因而在本实验中同样可以认为,由于 孪生的CRSS和孪晶界面能都比较低[21],在具有基面织构的铸轧板进行小变形量热轧时,热轧卸载过程中所释放的大量内应力可能会超过

孪生的CRSS和孪晶界面能都比较低[21],在具有基面织构的铸轧板进行小变形量热轧时,热轧卸载过程中所释放的大量内应力可能会超过 孪生的CRSS,因而产生了大量的

孪生的CRSS,因而产生了大量的 透镜状宽孪晶。

透镜状宽孪晶。

同样可以认为,20%热轧时产生的少量不易发生再结晶的透镜状宽孪晶是 孪晶。与文献[20]的研究结果类似,另一种细长的窄孪晶可能就是

孪晶。与文献[20]的研究结果类似,另一种细长的窄孪晶可能就是 -

- 双孪晶[20],这种孪晶是首先在基体中生成

双孪晶[20],这种孪晶是首先在基体中生成 孪晶,随后在

孪晶,随后在 初次孪晶内部产生

初次孪晶内部产生 二次孪晶,二次孪生会使基面旋转到滑移易于开动的取向,并随着变形的继续进行,在孪晶界面塑性协调应力的影响下,二次孪晶内部的

二次孪晶,二次孪生会使基面旋转到滑移易于开动的取向,并随着变形的继续进行,在孪晶界面塑性协调应力的影响下,二次孪晶内部的 位错[22]滑移也大量开动,大量位错滑移的开动为动态再结晶提供能量和结构的基础,这也是

位错[22]滑移也大量开动,大量位错滑移的开动为动态再结晶提供能量和结构的基础,这也是 -

- 孪晶中容易发生再结晶的原因。

孪晶中容易发生再结晶的原因。

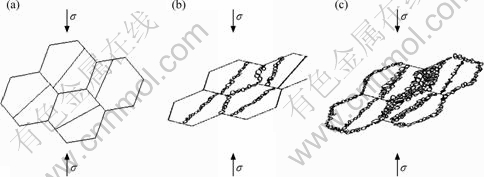

3.2 滑移主导的变形

从以上的实验结果可以看出,当压缩变形量小于20%时,变形机制以孪生为主,随着热轧变形量的增加,滑移逐渐成为主要的变形机制。当热轧变形量大于50%时(见图1(d)和(e)),晶粒破碎成为一种主要的组织特征,大量细小的再结晶晶粒包围着一些未被再结晶组织所消耗的原始晶粒。图7所示为破碎组织形貌的形成模型。晶粒内部首先形成细长的窄孪晶,此类孪晶使晶粒转动到位错滑移容易开动的取向,孪晶内部的位错滑移能够大量开动,动态再结晶优先在窄孪晶内部和晶界附近产生。这样,在孪晶内部和原始晶界附近的再结晶晶粒将原始的晶粒分割成小块破碎的形貌,随着变形的进行,再结晶晶粒逐步向晶粒内部扩张,晶粒内部的位错滑移也逐步开动,未被再结晶组织消耗的原始晶粒也出现明显的扭曲变形现象。TEM实验中对再结晶晶粒进行选取电子衍射时发现,衍射斑点出现分裂,说明相邻的晶粒取向差较小,属于小角度的亚晶结构。在再结晶晶粒附近区域还发现位错缠结组织,这说明晶粒中位错滑移已经大量开动,已经形成位错缠结组织,位错缠结组织通过位错的抵消或重组正逐渐发展成为亚晶[23-26],这为后续的再结晶提供结构基础,亚晶结构最终通过晶界的迁移与合并形成再结晶晶粒。在随后的退火过程中,破碎的变形态组织内部发生连续的静态再结晶,形成一种完全等轴晶组织。从热轧板坯的(0002)极图中也可以得出一致的结论,当变形量大于20%时,随着变形量的增大,基面织构逐步增强,这也进一步说明随着变形量的增加,位错滑移,尤其是基面滑移起越来越重要的作用。

图7 晶粒破碎形貌的形成模型

Fig.7 Formation models for fragmentation morphologies of grains: (a) Formation of thin twins; (b) Recrystallization within twinned region and near grain bounders; (c) Grain fragmentation

4 结论

1) 退火态铸轧板具有较强的基面织构,当热轧变形量较小时,孪生为主要的变形机制,经过10%热轧时,由于出现 孪晶,基面织构明显减弱。经过20%热轧出现了两种形貌的孪晶,其中透镜状的宽孪晶为

孪晶,基面织构明显减弱。经过20%热轧出现了两种形貌的孪晶,其中透镜状的宽孪晶为 孪晶,难以发生再结晶,而细长的窄孪晶为

孪晶,难以发生再结晶,而细长的窄孪晶为 -

- 双孪晶,非常容易成为再结晶的形核点。

双孪晶,非常容易成为再结晶的形核点。

2) 当热轧变形量大于20%时,位错滑移成为主要的变形机制,组织出现破碎的特征,随着变形量的增加,板材的基面织构逐渐增强,组织中出现位错缠结及再结晶亚晶组织,在随后的退火过程中,组织呈现一种完全的等轴晶形貌。

REFERENCE

[1] 师昌绪, 李恒德, 王淀佐. 加速我国金属镁工业发展的建议[J]. 材料导报, 2001, 15(4): 5-6.

SHI Chang-xu, LI Heng-de, WANG Dian-zuo. Some recommendation on accelerating the development of magnesium industry[J]. Materials Review, 2001, 15(4): 5-6.

[2] 余 琨, 黎文献, 王日初. 镁合金塑性变形机制[J]. 中国有色金属学报, 2005, 15(7): 1086-1091.

YU Kun, LI Wen-xian, WANG Ri-chu. Plastic deformation mechanism of magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 1086-1091.

[3] 唐伟琴, 张少睿, 范晓慧, 李大永, 彭颖红. AZ31镁合金的织构对其力学性能的影响[J]. 中国有色金属学报, 2010, 20(3): 371-377.

TANG Wei-qin, ZHANG Shao-rui, FAN Xiao-hui, LI Da-yong, PENG Ying-hong. Texture and its effect on mechanical properties of AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 371-377.

[4] 赵 虎, 李培杰, 何良菊. AZ31镁合金铸轧和常规轧制板的变形组织及形变特[J]. 中国有色金属学报, 2009, 19(11): 1887-1893.

ZHAO Hu, LI Pei-jie, HE Liang-ju. Deformation microstructure and characteristics of cast-rolling and normal rolling AZ31 magnesium alloy sheets[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(11): 1887-1893.

[5] 汪凌云, 黄光胜, 范永革, 黄光杰. 变形AZ31镁合金的晶粒细化[J]. 中国有色金属学报, 2003, 13(3): 594-598.

WANG Ling-yun, HUANG Guang-sheng, FAN Yong-ge, HUANG Guang-jie. Grain refinement of wrought AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 594-598.

[6] DELVALLE J A, PEREZ-PRADO M T, RUANO O A. Texture evolution during large-strain hot rolling of Mg AZ61 alloy[J]. Materials Science and Engineering A, 2003, 355(1): 68-78.

[7] BARNETT M R, NAVE M D, BETTLES C J. Deformation microstructure and textures of some cold rolled Mg alloys[J]. Materials Science and Engineering A, 2004, 386(1): 205-211.

[8] PEREZ-PRADO M T, DEL VALLE J A, RUANO O A. Effect of sheet thickness on the microstructural evolution of an Mg AZ61 alloy during large strain hot rolling[J]. Scipta Materialia, 2004, 50(5): 667-671.

[9] KIM K H, SUH B C, BAE J H, SHIM M S, KIM S, KIM N J. Microstructure and texture evolution of Mg alloys during twin-roll casting and subsequent hot rolling[EB/OL]. http://dx.doi.org/10.1016/j.scriptamat.2009.12.

[10] HARTT W H, REEDHILL R E. The irrational habit of second-0rder twins in magnesium[J]. Transaction of the Metallurgical Society of AIME, 1967, 239(10): 1511-1517.

twins in magnesium[J]. Transaction of the Metallurgical Society of AIME, 1967, 239(10): 1511-1517.

[11] BARNETT M R. Twinning and the ducStility of magnesium alloys Part Ⅰ: “Tension” twins[J]. Materials Science and Engineering A, 2007, 464(1): 1-7.

[12] BARNETT M R. Twinning and the ductility of magnesium alloys Part Ⅰ: “compression” twins[J]. Materials Science and Engineering A, 2007, 464(1): 8-16.

[13] REEDHILL R E. A study of the  and

and  twinninng modes in magnesium[J]. Transaction of the Metallurgical Society of AIME, 1960, 218(3): 554-558.

twinninng modes in magnesium[J]. Transaction of the Metallurgical Society of AIME, 1960, 218(3): 554-558.

[14] HARTT W H, REEDHILL R E. Internal deformation and fracture of second-order  twins in magnesium[J]. Transaction of the Metallurgical Society of AIME, 1968, 242(6): 1127-1133.

twins in magnesium[J]. Transaction of the Metallurgical Society of AIME, 1968, 242(6): 1127-1133.

[15] TAN J C, TAN M J. Dynamic continuous recrystallization characteristics in two stage deformation of Mg-3Al-1Zn alloy sheet[J]. Materials Sciences and Engineering A, 2003, 339(1): 124-132.

[16] LI X, YANG P, WANG L N, MENG L, CUI F. Orientational analysis of static recrystallization at compression twins in amagnesium alloy AZ31[J]. Materials Science and Engineering A, 2009, 517(1): 160-169.

[17] KELLEY E W, HOSFORD W F. Plane-strain compression of magnesium and magnesium alloy crystals[J]. Transaction of the Metallurgical Society of AIME, 1968, 242(1): 5-13.

[18] COULING S L, PASHAK J F, STURKEY L. Unique deformation and aging characteristics of certain magnesium-base alloys[J]. Transaction of the ASM, 1958, 51(1): 94-107.

[19] MENG L, YANG P, XIE Q, MAO W. Analyses on compression twins in magnesium[J]. Materials Transaction, 2008, 49(4): 710-714.

[20] WONSIEWCZ B C, BACKOFEN W A. Plasticity of magnesium crystals[J]. Transaction of the Metallurgical Society of AIME, 1967, 239(9): 1422-1431.

[21] ROBERTS C S. Magnesium and its alloy[M]. USA: John Wiley & Sons, Inc, 1960: 81-107.

[22] QBARA T, YOSHINGA H, MOROZUMI S.

slip system in magnesium[J]. Acta Metallurgica, 1973, 21(7): 845-853.

slip system in magnesium[J]. Acta Metallurgica, 1973, 21(7): 845-853.

[23] DOHERTY R D, HUGHES D A, HUMPHREYS F J, JONAS J J, JENSEN D J, KASSNER M E, KING W E, MCNELLEY T R, MCQUEEN H J, ROLLETT A D. Current issues in recrystallization:a review[J]. Materials Science and Engineering A, 1997, 238(1): 219-274.

[24] YIN D L, ZHANG K F, WANG G F, HAN W B. Warm deformation of hot-rolled AZ31 Mg alloy[J]. Materials Science and Engineering A, 2005, 392(2): 320-325.

[25] KAIBYSHEV R, GALIEV A, SITDIKOV O. On the possibility of producing a nanocrystalline structure in magnesium and magnesium alloys[J]. Nanostructured Materials, 1995, 6(5): 621-624.

[26] MCQUEEN H J. Initiating nucleation of dynamic recrystallization,primarily in polycrystals[J]. Materials Science and Engineering A, 1988, 101(1): 149-160.

(编辑 龙怀中)

基金项目:国家科技部“十一五”科技支撑计划资助项目(2006BAE04B02)

收稿日期:2009-09-06;修订日期:2010-04-19

通信作者:汪明朴,教授;电话:0731-88830264;E-mail:wangmp@mail.csu.edu.cn