DOI:10.19476/j.ysxb.1004.0609.2018.11.05

织构对AZ31镁合金温热压缩变形机制影响

宋广胜1,赵原野1,张士宏2,徐 勇2

(1. 沈阳航空航天大学 材料科学与工程学院,沈阳 110036;

2. 中国科学院 金属研究所,沈阳 110016)

摘 要:在AZ31轧制板材上截取4种具有不同晶粒取向特征的试样,在170℃温热条件下,分别对上述试样进行压缩变形,分析了变形过程中力学性能变化、晶粒取向演化和织构变化,并基于压缩过程施密特因子的分布特征,对上述变形过程中各种微观变形模式的启动趋势进行了分析,最后对上述变形过程的微观启动模式进行了定量计算。分析结果表明:织构明显影响镁合金压缩变形过程的微观变形机制,从而对宏观力学性能产生明显影响,平行于晶粒c轴压缩因大量的柱面滑移系启动而呈现最高应力值。随着晶粒c轴与压缩方向夹角的增大,拉伸孪晶启动量增加而导致织构明显改变。

关键词: 织构;AZ31镁合金;温热压缩;滑移;孪晶

文章编号:1004-0609(2018)-11-2206-11 中图分类号:TG146.2 文献标志码:A

镁合金因其具有密度低、比刚度高和电磁屏蔽性好等优点,是潜在的绿色环保材料,在汽车和电子等行业中具有潜在的应用前景。虽然目前镁合金产品主要以压铸工艺生产,但产品中不可避免存在铸造缺陷,最终镁合金的规模应用还得采用塑性成形工艺。特别是可大规模生产的镁合金轧制板材,将是镁合金冲压等工艺的主要原材料。

由于镁合金具有低对称性的密排六方(HCP)晶体结构,室温下能够启动的独立滑移系较少,再加上镁合金型材在塑性加工过程所形成的强基面织构,导致了镁合金型材在室温下塑性成形能力差。但镁合金塑性成形能力对温度非常敏感,相关研究表明,当变形温度提高至200 ℃时,镁合金板材始终表现出明显的硬化行为,拉伸变形的塑性伸长率将从约14%提高至约20%[1-2],这是因为随着变形温度的提高,临界剪切应力(CRSS)值较高的<a>位错柱面滑移系和<c+a>位错的锥面滑移系将启动,从而协调晶粒间变形。基于此原理,近些年来相关学者开发了镁合金温热成型工艺[3-4],其主要特征是在100~250 ℃变形温度下,并在模具与板材同温条件下,可生产大塑性变形量的镁合金产品[5-7]。

从微观角度看,具有不同织构的镁合金型材在变形过程中,各种滑移系和孪晶将具有不同的取向因子,在变形过程中将对应不同的微观变形模式,从而表现出不同的宏观成形性。关于织构对镁合金塑性变形过程的影响,蒋佳等[8-9]通过制取晶粒c轴与板材法向(ND)成不同角度的试样,分析了上述不同织构试样在室温和150 ℃下压缩过程的力学性能和织构变化;吴新星等[10]在镁合金挤压棒材上制取3种不同织构特征的压缩试样,在523~723 K的温度范围内进行高温压缩变形,发现随着变形温度降低,初始取向对宏观力学行为影响显著增加;董勇等[11]研究了不同初始取向的镁合金板材在轧制过程中组织的演化及其对力学性能影响,结果表明轧制过程中孪生与板材初始取向密切相关,通过改变初始取向可控制板材晶粒细化和强度改善效果;WANG等[12]分别在镁合金挤压棒材和轧制板材上制取了4种织构特征试样,并对其进行室温压缩,结果表明初始织构显著地影响了镁合金的屈服强度和应变硬化特征。ZAMBALDI等[13]研究了晶粒取向对纯镁的压痕变形的力学性能及微观机制影响,发现晶粒取向对压痕区域的孪晶特征产生显著影响;XIONG等[14]对镁合金挤压棒材分别沿挤压方向(ED)和横向(TD)进行单向变形,分析结果表明变形过程的流动应力和硬化率显著受到晶粒初始取向影响,与ED试样不同,TD试样的在拉伸和压缩过程中孪晶启动量相同而不产生拉压非对称性。

相关研究结果表明170 ℃是镁合金温热变形的一个重要参考温度,张士宏等[5, 15]的对镁合金板材冲压性能的研究结果表明,镁合金轧制板材在170 ℃下的拉伸极限比(LDR)可达2.6,与室温下的铝合金冲压性能相当;对镁合金板材的力学性能测试结果[15]表明,在170 ℃下压缩变形和拉伸变形的最大伸长率分别可达25%和50%以上,而当变形温度提高到230 ℃时,最大伸长率几乎无明显提高。上述结果表明,镁合金板材在170 ℃左右时已具有很好的成形性,故本文选取170 ℃的变形温度,通过对4种不同织构特征的镁合金试样进行压缩变形,分析织构对镁合金温热变形的力学性能和微观变形机制的影响。

1 实验过程

本研究所用材料为厚度是7 mm的商用AZ31镁合金热轧板材,试样尺寸及取样方式如图1所示,分别称为0°、30°、60°和90°试样,由于原始板材厚度的限制,不同角度压缩试样的尺寸(单位:mm)不尽相同。试样的压缩方向分别与ND成0°、30°、60°和90°,即与截取试样的角度相同,变形速率为1 mm/min。压缩变形在SANS-CMT-5105微机控制电子万能试验机上进行,试样加热至170 ℃并保温20 min后进行压缩变形。在压缩变形前后,采用EBSD技术对试样与压头的接触面进行晶粒取向测定,EBSD实验中,放大倍数设为300倍,步长为1.5 μm。

EBSD制样时,试样首先进行研磨和机械抛光,然后进行电解抛光,电解液为10%(体积分数)的高氯酸+90%乙醇,电解温度为-30 ℃,电解电压为15 V,电流强度为0.01 A,电解时间150 s,电解后的试样放入丙酮中进行超声波清洗2 min,最后冷风吹干,并防止氧化。EBSD实验在装有EBSD系统的钨灯丝扫描电镜(TESCAN5136XM )上进行,所测得数据采用HKL Channel5.0 软件进行处理。

图1 镁合金试样取样方式及尺寸

Fig. 1 Sampling method and size of Mg alloy sample

2 结果及分析

2.1 力学性能变化

试样在压缩过程中的应力应变曲线如图2所示,图中显示当压缩方向从0°增加到60°时,压缩曲线对应的应力值依次降低,而当压缩方向增至90°时,应力值又上升了,几乎与30°试样的曲线相当,引起上述各试样应力应变曲线的差异,实质上是各试样对应的微观变形模式的不同而导致的结果。镁合金的微观变形模式主要有<a>位错的基面滑移和柱面滑移,<c+a>位错的锥面滑移和 拉伸孪晶及

拉伸孪晶及 压缩孪晶。其中基面滑移和拉伸孪晶由于CRSS值最低而较易启动,但拉伸孪晶的启动需要应力与晶粒取向满足一定关系,通常为压应力垂直于晶粒c轴或拉应平行于晶粒c轴的关系,锥面滑移系和压缩孪晶由于CRSS值较高而不易启动。

压缩孪晶。其中基面滑移和拉伸孪晶由于CRSS值最低而较易启动,但拉伸孪晶的启动需要应力与晶粒取向满足一定关系,通常为压应力垂直于晶粒c轴或拉应平行于晶粒c轴的关系,锥面滑移系和压缩孪晶由于CRSS值较高而不易启动。

图2中的0°试样曲线为典型的依靠滑移系启动而实现塑性变形的硬化曲线,对于该类型沿轧制板材厚度方向的压缩变形,由于轧制板材通常具有基面织构,即晶粒c轴平行于板材ND,故沿ND压缩时基面和柱面滑移系处于硬取向,而CRSS值较高的锥面滑移系有可能启动[16],使该变形过程的曲线呈现最高应力值。而图中90°试样曲线为典型的拉伸孪晶完全启动的S形曲线,对于该试样,由于压缩变形方向垂直于晶粒的c轴,而易于拉伸孪晶启动,在变形初始阶段由于拉伸孪晶大量启动,使该曲线呈现低的屈服强度和较平缓的硬化特征,而在变形后期,由于CRSS值较高的滑移系启动,使曲线呈现快速硬化特征。

图2 试样在170 ℃下压缩变形的应力-应变曲线

Fig. 2 Stress-strain curves of samples compressed at 170 ℃

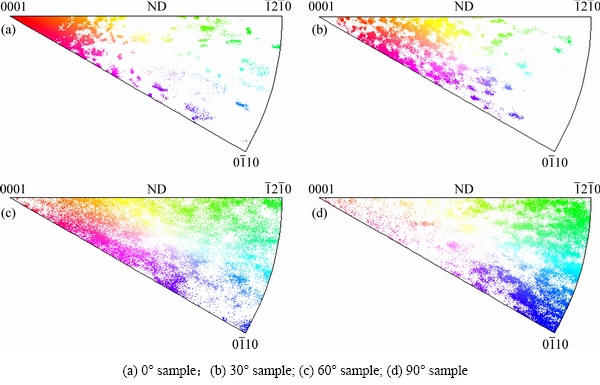

镁合金在单向压缩变形过程中的各滑移系和拉伸孪晶的最大Schmid因子(SF)分布特征如图3所示,而图4则显示了上述试样在变形前晶粒的各晶向相对于压缩方向(ND)的分布。滑移系和孪晶的启动通常遵循Schmid定律[17-18],即SF值越大越易启动。对比图3(a)和图4(b)可以看出,30°试样的变形方向最有利于基面滑移系启动,故图2中的30°试样的压缩曲线的应力值较0°试样明显降低。对照图4(c)与图3可以看出,60°试样的压缩方向同时有利于基面滑移系和拉伸孪晶的启动,而图4(b)与图3对照结果显示,30°试样中多数晶粒有利于基面滑移系启动,同时一部分晶粒有利于柱面滑移系的启动,即30°试样的微观变形模式应该主要以基面滑移和柱面滑移为主,而60°试样由于CRSS较低的拉伸孪晶的启动,故如图2所示,该试样压缩曲线的应力值明显低于30°试样。

图3 滑移系和孪晶的最大施密特因子分布

Fig. 3 Distributions of maximum SFs of slips and twinning

图4 试样在压缩变形前的反极图

Fig. 4 Inverse pole figures of samples before compression

对比图4(d)与图3显示,90°试样的变形方向最有利于柱面滑移和拉伸孪晶的启动,如图2所示,该试样在变形初期由于拉伸孪晶的大量启动,而呈现低屈服强度和缓慢硬化特征,而在变形后期由于柱面滑移系的大量启动而呈现快速硬化特征。相比于30°和60°试样,由于更多的CRSS值较高的柱面滑移系启动,使该试样的压缩曲线的呈现更高的应力值。

上述不同角度试样对应的应力应变曲线所呈现的应力值变化特征,在文献[9]中也有相同的报道结果。

2.2 晶粒取向及织构变化

轧制板材的晶粒取向及晶粒分布情况(轧板的RD×TD面)如图5(a)所示,可以看出原始板材为均匀分布的等轴晶组成,晶粒中很少有孪晶组织,参照取向标尺可以看出,除个别晶粒的c轴垂直于板材的ND外,绝大多数的晶粒的c轴与ND平行,即具有典型的轧制织构。图5(b)~(e)则显示了在总的压缩变形量为10%的上述试样的晶粒取向分布,其中图5(d)和(e)则分别显示出60°和90°试样的许多晶粒内出现孪晶带,而图5(c)显示30°试样的少数晶粒内出现了孪晶带。

图5(b)显示0°试样在变形后的组织中出现了交叉的剪切带(Shear band),剪切带内的晶粒得到明显的细化,剪切带为镁合金变形组织中常见的组织特征[19-22],因为镁合金室温塑性成形能力差,而在剪切带内可实现大的剪切变形从而满足总体变形需求,剪切带可作为除了滑移和孪晶之外的另一种镁合金塑性变形机制[20-22],剪切带内的组织典型特征通常为含有大量拉伸孪晶或压缩孪晶,有时还有少量的 二次孪晶[21],在加热条件下,并且随着变形量的增大,剪切带内大量的孪晶界提供了动态再结晶的形核源,而使剪切带内发生明显的动态再结晶[20,22]。镁合金变形过程中,剪切带内的大的切应变将使产生晶格旋转,从而使剪切带内的晶粒取向明显不同于周围晶粒[20]。

二次孪晶[21],在加热条件下,并且随着变形量的增大,剪切带内大量的孪晶界提供了动态再结晶的形核源,而使剪切带内发生明显的动态再结晶[20,22]。镁合金变形过程中,剪切带内的大的切应变将使产生晶格旋转,从而使剪切带内的晶粒取向明显不同于周围晶粒[20]。

镁合金中的剪切带通常在轧制或挤压等应变速率较高的变形过程中产生,相关研究表明在镁合金板材沿ND压缩过程中也有剪切带的产生[23],图5(a)显示原始轧制板材的组织中无剪切带,则意味着该剪切带是在沿ND压缩过程中产生。

观察图5(b)中剪切带内的晶粒取向特征可以看出,剪切内的晶粒取向明显不同于其周围晶粒,周围晶粒的取向特征为晶粒c轴平行于ND,而剪切内的晶粒取向特征为晶粒c轴垂直于ND,在沿ND压缩变形过程中剪切带内的晶粒取向最有利于拉伸孪晶的启动。参照图3可以看出,相比于其他3种压缩试样,0°试样的晶粒除了对于锥面滑移为软取向外,对基面和柱面滑移及拉伸孪晶都为硬取向,即0°试样的晶粒最不易变形,因为虽然其晶粒取向有利于锥面滑移系启动,但锥面滑移系的CRSS值最高而不易启动,此时剪切带的产生补充了滑移变形的不足,剪切带内的高剪切应变使晶粒取向发生偏转,即由晶粒c轴平行于ND而偏转为垂直于ND,在进一步的压缩变形过程,剪切带内的晶粒产生了大量的拉伸孪晶。

图6显示了上述试样在压缩变形量为10%的晶界分布,可以看出随着试样对应的角度的增加,拉伸孪晶的启动量逐渐增加,将图3(d)与图4进行对比可以看出,从0°试样到90°试样,随着对试样对应角度的增加,晶粒取向越来越有利于拉伸孪晶的启动。图6(a)也显示剪切带内含有大量的拉伸孪晶。

图5 原始板材及试样在变形量为10%时的晶粒取向图

Fig. 5 Grain orientation micrographics of initial sheet and samples after 10% compression

上述不同角度试样在压缩变形前及170 ℃下压缩10%变形量后的极图如图7所示,图7(a)显示轧制板材具有典型的基面织构,即多数晶粒的c轴与ND方向接近于平行,图7(b)显示0°试样经压缩变形后仍保持为基面织构,在镁合金的各种变形模式中,通常滑移系的启动不明显改变晶粒取向,而孪晶的启动将明显改变晶粒取向,虽然图5(b)显示该变形过程中在剪切带内出现一定量拉伸孪晶,但由于其含量较低所以没有明显改变晶粒取向。

图7(c)显示30°试样的晶粒c轴偏向X方向而与ND成30°角,与制样方向一致,图7(d)显示试样经过压缩变形后虽然晶粒取向有小幅偏转,但晶粒c轴仍保持与ND成约30°角,与0°试样一样,虽然变形过程中有少量拉伸孪晶启动,但滑移系启动仍为主要的变形模式,故晶粒取向无明显变化。

图7(e)和图7(f)显示60°试样的晶粒在压缩变形前后的晶粒c轴始终为偏向X方向而与ND成60°角,图5(d)和图6(c)则显示60°试样在变形后的一些晶粒内出现拉伸孪晶带,由图5(d)可以看出多数孪晶带内的晶粒c轴与ND接近于平行,在图5(d)中任选8个含有孪晶带的晶粒,如图8所示,上述晶粒基体与其内部孪晶带的取向关系,图中数字1~8表示上述8个晶粒的基体,符号1t~8t则分别表示各个晶粒内的孪晶带,可以看出晶粒基体的c轴与ND成60°角,由于拉伸孪晶启动而向ND偏转约86.3°,最终孪晶的c轴则与ND成30°角,形成了如图7(f)所示的晶粒取向特征。

图7(g)和(h)对比显示,90°试样在变形前晶粒的c轴垂直于ND而平行于X向,在压缩变形10%后,部分晶粒由于基体内启动拉了 拉伸孪晶而产生约86.3°的偏转,使孪晶带内晶粒的c轴与ND平行。如图7(h)所示,在压缩变形后的90°试样存在两种织构,少部分晶粒的c轴与ND平行,这是拉伸孪晶启动做形成基面织构,而大部分晶粒的c轴垂直于ND而与X平行,这是没有启动孪晶的晶粒基体的取向,如果变形量继续增大,晶粒基体将完全转变为孪晶[24-25],将形成单一的基面织构,即所有晶粒的c轴将与ND平行。

拉伸孪晶而产生约86.3°的偏转,使孪晶带内晶粒的c轴与ND平行。如图7(h)所示,在压缩变形后的90°试样存在两种织构,少部分晶粒的c轴与ND平行,这是拉伸孪晶启动做形成基面织构,而大部分晶粒的c轴垂直于ND而与X平行,这是没有启动孪晶的晶粒基体的取向,如果变形量继续增大,晶粒基体将完全转变为孪晶[24-25],将形成单一的基面织构,即所有晶粒的c轴将与ND平行。

2.3 微观变形机制

镁合金微观变形机制包括基面滑移、柱面滑移和锥面滑移及孪晶,对于镁合金实际变形过程微观机制的分析包括定性和定量两方面,对于定性分析可采用滑移线分析法或透射分析法(TEM),前者是根据变形后试样表面的宏观滑移线的方向,并结合EBSD的晶粒取向测试结果,能够确定滑移线所在的晶粒内实际启动的滑移系[26-28],这种方法能够确定一定数量晶粒内实际启动的滑移系类型,结果具有一定统计意义;而后者是通过对几个晶粒进行透射分析,通过所测定的晶粒取向来确定实际启动的滑移系[29-30],该方法只能测定一个或几个晶粒内的实际启动滑移系,结果不具有统计意义。相比于滑移系启动机制的分析,对于孪晶机制的分析要容易得多,目前采用EBSD方法通过测定晶粒取向,可以精确测定晶粒内所启动的孪晶特征。

图6 试样在变形量为10%时的晶界

Fig. 6 Grain boundaries of samples after 10% compression(Red lines represent  extension twin boundaries)

extension twin boundaries)

图7 试样在压缩变形前及压缩变形量为10%后的极图

Fig. 7 Pole figures of samples before compression and after 10% compression

对于镁合金变形过程微观变形机制的定量分析,目前主要有晶体塑性有限元法(CPFEM)[31-32]和黏塑性自洽法(VPSC)[33-34],两者都是基于晶体塑性理论。虽然CPFEM考虑了具体晶粒的形状和位置,并在模拟织构演化精度方面更具优势,但VPSC具有明显的易学易用的优点,特别是在HCP晶体的微观塑性变形机制分析方面得到大量应用。

在VPSC模型中,每个晶粒被看作为镶嵌在各向异性的黏塑性基体中的一个各向异性的黏塑性椭球体,为了保持应变的连续性,每个晶粒的应变速率被强制相同,VPSC有关的原理和数学模型已有大量文献报道,在具体的应用中,需要首先确定每种变形模式的5个主要物性参数:τ0、τ1、θ0、θ1和h,它们依次为某滑移系或孪晶系的初始CRSS、反推的CRSS、初始硬化率、渐近硬化率及潜在硬化耦合系数。上述参数的确定方法:将VPSC输出的模拟曲线与实测曲线进行对比,如果两者差别明显,则不断调整上述参数直至模拟曲线与实测曲线基本吻合为止,此时就可以直接采用基于上述调整后参数所得到的晶粒取向演化和微观变形模式等模拟结果。

图8 60°试样在压缩变形后部分晶粒的极图

Fig. 8 Pole figures of some grains in 60°sample after compression

通过调整上述物性参数,将VPSC计算得到的各试样应力应变曲线分别与图2中各曲线进行对比,直至每个试样的模拟与实测应力应变曲线吻合较好,最终得到应力应变曲线的模拟结果与实测结果比较情况如图9所示,从而确定170 ℃下的AZ31镁合金的各种微观变形机制对应的参数如表1所示。

表1 AZ31镁合金在170 ℃下变形过程中微观变形机制的CRSS及硬化的拟合参数

Table 1 Fitted model parameters describing CRSS and hardening response of micro deformation mechanism of AZ31 Mg alloy deformed at 170 ℃

上述变形过程中微观变形模式的VPSC模拟结果如图10所示,模拟结果显示对于上述不同角度试样,锥面滑移系在变形过程中都没有启动,0°和30°试样主要以基面和柱面滑移系启动为主,而60°和90°试样在变形初期为基面滑移和拉伸孪晶启动,在变形后期则为柱面和基面滑移系启动。依据图10所示的模拟结果,分析图2中的各试样力学性能曲线,0°试样由于柱面滑移系的大量启动,其应力应变曲线呈现最高应力值,90°试样在变形初期拉伸孪晶大量启动,而在变形后期则柱面滑移系大量启动,故呈现S形硬化曲线。60°试样在变形过程中柱面滑移系的启动量始终低于30°试样的,故其应力值也始终低于后者的。

图9 试样在170 ℃下压缩变形的实测和模拟得到的应力-应变曲线

Fig. 9 Measured and simulated stress-strain curves of samples compressed at 170 ℃

图11显示了上述压缩过程中当变形量为10%时的模拟极图,与图7中各试样的实测极图进行对比,可以看出模拟极图与实测极图中所显示的试样织构特征较吻合,表明图10所显示的微观变形模式的模拟结果准确。

图10 试样在170 ℃下压缩变形的微观变形模式的模拟结果

Fig. 10 Simulation results of micro deformation modes of samples compressed at 170 ℃

图11 试样在压缩变形量为10%后的模拟极图

Fig. 11 Simulated pole figures of samples compressed to 10% strain

3 结论

1) 在170 ℃下,随着压缩方向与晶粒c轴成夹角的变化,镁合金压缩变形过程的力学性能曲线呈现明显不同的硬化特征,其中0°夹角对应着最高的应力值。

2) 当压缩方向与晶粒c轴夹角较小时,滑移系启动没有明显改变晶粒取向,随着压缩方向与晶粒c轴夹角的增大,拉伸孪晶的启动量则增加,从而明显改变镁合金的基面织构。

3) 镁合金板材在170 ℃的压缩变形过程中,当压缩方向与晶粒c轴夹角较小时,微观变形机制为基面和柱面滑移系启动,而当压缩方向与晶粒c轴夹角较大时,变形初期的微观变形机制为基面滑移和拉伸孪晶启动,而基面和柱面滑移系则成为变形后期的主要微观变形模式。

REFERENCES

[1] 秦 博, 王忠堂. AZ31镁合金温热变形本构方程[J]. 沈阳理工大学学报, 2016, 35(3): 91-95.

QIN Bo, WANG Zhong-tang. Constitutive equation of warm deformation of AZ31 magnesium alloy[J]. Journal of Shenyang Ligong University, 2016, 35(3): 91-95.

[2] WANG Xin-wei, XU Jie, SHAN De-bin, GUO Bin, CAO Jian. Modeling of thermal and mechanical behavior of a magnesium alloy AZ31 during electrically-assisted micro-tension[J]. International Journal of Plasticity, 2016, 85: 230-257.

[3] HUANG Guang-sheng, WANG Yan-xia, WANG Li-fei, HAN Ting-zhuang, PAN Fu-sheng. Effects of grain size on shift of neutral layer of AZ31 magnesium alloy under warm condition[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(3): 732-737.

[4] GAO Tie-jun, LIU Qing, ZHANG Wen-zhuo. Viscous warm pressure bulging process of AZ31B magnesium alloy with different ellipticity dies[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(1): 157-162.

[5] 张士宏, 王忠堂, 周丽新, 徐永超. 镁合金板件温热成形技术的几个新进展[J]. 材料导报, 2006, 20(8): 114-118.

ZHANG Shi-hong, WANG Zhong-tang, ZHOU Li-xin, XU Yong-chao. Several new progresses in warm forming processes of magnesium alloy sheet parts[J]. Material Review, 2006, 20(8): 114-118.

[6] 张佩武, 夏 伟, 刘 英, 张卫文, 陈维平. 变形镁合金成形工艺研究及其应用[J]. 材料导报, 2005, 19(7): 82-85.

ZHANG Pei-wu, XIA Wei, LIU Ying, ZHANG Wei-wen, CHEN Wei-ping. The research of wrought magnesium alloy forming technology and its application[J]. Material Review, 2005, 19(7): 82-85.

[7] 高 仑. 镁合金成型技术的开发与应用[J]. 轻合金加工技术, 2004, 32(3): 5-12.

GAO Lun. Exploit and application of magnesium alloy forming technology[J]. Light Alloy Fabrication Technology, 2004, 32(3): 5-12.

[8] JIANG J, GODFREY A, LIU W, LIU Q. Microtexture evolution via deformation twinning and slip during compression of magnesium alloy AZ31[J]. Materials Science and Engineering A, 2008, 483/484: 576-579.

[9] PEI Y, GODFREY A, LIU W, JIANG J, LIU Q. Effect of crystal orientation on the deformation behavior of the magnesium alloy AZ31 during plane strain compression[J]. Journal of Chinese Electron Microscopy Society, 2009, 28(1): 6-10.

[10] 吴新星, 杨续跃, 张 雷, 张之岭. 初始取向对AZ31镁合金微观织构演化的影响[J]. 金属学报, 2011, 47(2): 140-144.

WU Xin-xing, YANG Xu-yue, ZHANG Lei, ZHANG Zhi-ling. Effect of original orientation on microtexture evolution of AZ31 Mg alloy[J]. Acta Metallurgical Sinica, 2011, 47(2): 140-144.

[11] 董 勇, 刘吉兆. 初始取向对大应变轧制AZ31镁合金板材显微组织和力学性能的影响[J]. 中国有色金属学报, 2014, 24(7): 1700-1706.

DONG Yong, LIU Ji-zhao. Effects of initial orientation on microstructure and mechanical properties of AZ31 magnesium alloy sheets fabricated by large strain rolling[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(7): 1700-1706.

[12] WANG B S, XIN X L, HUANG G J, LIU Q. Effect of crystal orientation on the mechanical properties and strain hardening behavior of magnesium alloy AZ31 during uniaxial compression[J]. Materials Science and Engineering A, 2012, 534: 588-593.

[13] ZAMBALDI C, ZEHNDER C, RAABE D. Orientation dependent deformation by slip and twinning in magnesium during single crystal indentation[J]. Acta Materialia, 2015, 91: 267-288.

[14] XIONG Y, YU Q, JIANG Y Y. Deformation of extruded ZK60 magnesium alloy under uniaxial loading in different material orientations[J]. Materials Science & Engineering A, 2018, 710: 206-213.

[15] 张士宏, 宋广胜, 宋鸿武, 程 明. 镁合金板材温热变形机理及温热成形技术[J]. 机械工程学报, 2012, 48(18): 28-34.

ZHANG Shi-hong, SONG Guang-sheng, SONG Hong-wu, CHENG Ming. Deformation mechanism and warm forming technology for magnesium alloys sheets[J]. Journal of Mechanical Engineering, 2012, 48(18): 28-34.

[16] JAIN A, AGNEW S R. Modeling the temperature dependent effect of twinning on the behavior of magnesium alloy AZ31B sheet[J]. Materials Science and Engineering A, 2007, 462: 29-36.

[17] 詹美燕, 李春明, 尚俊玲. 镁合金塑性变形机制和孪生变形研究[J]. 材料导报, 2011, 5(2): 1-7.

ZHAN Mei-yan, LI Chun-ming, SHANG Jun-ling. Investigation of the Plastic Deformation mechanism and twinning of magnesium alloys[J]. Material Review, 2011, 5(2): 1-7.

[18] GODET S, JIANG L, LUO A A, JONAS J J. Use of Schmid factors to select extension twin variants in extruded magnesium alloy tubes[J]. Scripta Materialia, 2006, 55: 1055-1058

[19] SCOTT J, MILES M, FULLWOOD D, ADAMS B, KHOSRAVANI A, MISHRA R K. Room temperature shear band development in highly twinned wrought magnesium AZ31B sheet[J]. Metallurgical and Materials Transactions A, 2013, 44: 512-516.

[20] CHUN Y B, DAVIES C H J. Texture effects on development of shear bands in rolled AZ31 alloy[J]. Materials Science & Engineering A, 2012, 556: 253-259.

[21] BARNETT M R, NAVE M D, BETTLES C J. Deformation microstructures and textures of some cold rolled Mg alloys[J]. Materials Science and Engineering A, 2004, 386: 205-211.

[22] YAN H, XU S W, CHEN R S, KAMADO S, HONMA T, HAN E H. Twins, shear bands and recrystallization of a Mg-2.0%Zn-0.8%Gd alloy during rolling[J]. Scripta Materialia, 2011, 64: 141-144.

[23] KIM H L, LEE J H, LEE C S, BANG W, AHN S H, CHANG Y W. Shear band formation during hot compression of AZ31 Mg alloy sheets[J]. Materials Science & Engineering A, 2012, 558: 431-438.

[24] SONG G S, CHEN Q Q, ZHANG S H, XU Y. Deformation micro-mechanism for compression of magnesium alloys at room temperature analyzed by electron backscatter diffraction[J]. Materials and Design, 2015, 65: 534-542.

[25] 黄洪涛, ANDREW G, 刘 伟, 付宝勤, 刘 庆. 多向压缩中AZ31镁合金变形行为的EBSD跟踪研究[J]. 金属学报, 2013, 49(8): 932-938.

HUANG Hong-tao, ANADREW G, LIU Wei, FU Bao-qin, LIU Qing. Deformation behavior of AZ31 magnesium alloy during multiaxial compression by EBSD tracking[J]. Acta Metallurgical Sinica, 2013, 49(8): 932-938.

[26] KESHAVARZ Z, BARNETT M R. EBSD analysis of deformation modes in Mg-3Al-1Zn[J]. Scripta Materialia, 2006, 55: 915-918.

[27] LI H, BOEHLERT C J, BIELER T R, CRIMP M A. Analysis of slip activity and heterogeneous deformation in tension and tension-creep of Ti-5Al-2.5Sn (wt%) using in-situ SEM experiments[J]. Philosophical Magazine, 2012, 92(23): 2923-2946.

[28] BOEHLERT C J, CHEN Z, CHAKKEDATH A, GUTIERREZ-URRUTIA I, LLORCA J, BOHLEN J, YI S, LETZIG D, PEREZ-PRADO M T. In situ analysis of the tensile deformation mechanisms in extruded Mg-1Mn-1Nd (wt%)[J]. Philosophical Magazine, 2013, 93(6): 598-617.

[29] KANG F, LI Z, WANG J T, CHENG P, WU H Y. The activation of hc + ai non-basal slip in magnesium alloys[J]. Journal of Material Science, 2012, 47: 7854-7859.

[30] KANG F, LIU J Q, WANG J T, ZHAO X. The effect of hydrostatic pressure on the activation of non-basal slip in a magnesium alloy[J]. Scripta Materialia, 2009, 61: 844-847.

[31] TANG W Q, LI D Y, HUANG S Y, ZHANG S R, PENG Y H. Simulation of texture evolution in magnesium alloy: Comparisons of different polycrystal plasticity modeling approaches[J]. Computers and Structures, 2014, 143: 1-8.

[32] QIAO H, BARNETT M R, WU P D. Modeling of twin formation, propagation and growth in a Mg single crystal based on crystal plasticity finite element method[J]. International Journal of Plasticity, 2016, 86: 70-92.

[33] JAIN A, AGNEW S R. Modeling the temperature dependent effect of twinning on the behavior of magnesium alloy AZ31B sheet[J]. Materials Science and Engineering A, 2007, 462: 29-36.

[34] WANG H, WU P D, TOME C N, WANG J. A constitutive model of twinning and detwinning for hexagonal close packed polycrystals[J]. Materials Science and Engineering A, 2012, 555: 93-98.

Effect of texture on deformation mechanism of AZ31 Magnesium alloy warm compression

SONG Guang-sheng1, ZHAO Yuan-ye1, ZHANG Shi-hong2, XU Yong2

(1. School of Materials Science and Engineering, Shenyang Aerospace University, Shenyang 110036, China;

2. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: Four kinds of samples with different grain orientation were machined from the rolled AZ31 Mg alloy sheet, and they were compressed at warm temperature of 170 ℃, the mechanical property, grain orientation and texture evolution, micro deformation mode activation tendency were analyzed based on the Schmid factor distribution of compression, and quantitative analysis on the micro deformation modes of above deformations was carried out. The analysis results show that texture evidently affects micro deformation mechanism of Mg alloy compression, subsequently obviously affects the macro mechanical property. The compression along the c axis of grains displays the highest stress due to amounts of prismatic slips activation. The texture is obviously changed due to more extension twins activation with the angle between the compression direction and c axis of grains increased.

Key words: texture; AZ31 magnesium alloy; warm compression; slip; twin

Foundation item: Project(51174189) supported by the National Natural Science Foundation of China

Received date: 2017-09-05; Accepted date: 2018-04-03

Corresponding author: SONG Guang-sheng; Tel: +86-13604066091; E-mail: songgs17@163.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51174189)

收稿日期:2017-09-05;修订日期:2018-04-03

通信作者:宋广胜,副教授,博士;电话:13604066091;E-mail:songgs17@163.com