文章编号:1004-0609(2013)S1-s0600-05

Ti55钛合金的热压缩变形及其本构方程

方 波1,陈志勇2,陈仲强1,王清江2,冯贞伟3,孙铁峰3,刘 艳1,宋玺玉1,魏明霞1,胡井祥1,吕晶晶1

(1. 中航工业沈阳黎明航空发动机(集团)有限责任公司,沈阳 110000;

2. 中国科学院 金属研究所,沈阳 110016;

3. 中国人民解放军驻黎明公司军代表室,沈阳 110043)

摘 要:采用Gleebe-3800热模拟实验在变形温度900~960 ℃、应变速率为0.001~10 s-1条件下进行Ti55钛合金的热压缩变形实验。结果表明:Ti55钛合金的热压缩真应力—应变曲线表现为流变软化的特点,当变形温度降低或应变速率增加时,Ti55钛合金的流变应力也随之增加。通过对真应力—应变曲线的回归分析,建立了Ti55钛合金的流变应力本构方程,在本研究中的变形温度与应变速率下,Ti55钛合金的Zener-Hollomon参数Z= exp[3.926 7×105/(RT)] =A[sinh(5.107 5×105σ)]4.001 46。

exp[3.926 7×105/(RT)] =A[sinh(5.107 5×105σ)]4.001 46。

关键词:Ti55高温钛合金;热压缩;流变应力;本构方程

中图分类号:TG146.23 文献标志码:A

Hot compression deformation and its constitutive equation of Ti55 alloy

FANG Bo1, CHEN Zhi-yong2, CHEN Zhong-qiang1, WANG Qing-jiang2, FENG Zhen-wei1, SUN Tie-feng3, LIU Yan1, SONG Xi-yu1, WEI Ming-xia1, HU Jing-xiang1, Lü Jing-jing1

(1. AVIC Shenyang Liming Aero-engine (Group) Co., Ltd, Shenyang 110000, China;

2. Division of Titanium Alloys, Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China;

3. The PLA Military Representative Office in AVIC Shenyang Liming Aero-engine (Group) Co., Ltd, Shenyang 110043, China)

Abstract: The hot compression deformation behavior of Ti55 alloy was investigated by hot compression testing on Gleeble-3800 thermal simulator at the temperature range of 900-960 ℃ with the strain rate varying from 0.001 s-1 to 10 s-1. The results indicate that the true stress—strain curves of Ti55 titanium alloy during hot compression show rheological softening characteristics. The flow stress increases when the deformation temperature decreases or the strain rate increases. Through the true stress—strain curve regression analysis, the flow stress constitutive equations of Ti55 titanium alloy is built and the Zener-Hollomon parameter of this alloy is Z= exp[3.926 7×105/(RT)] =A[sinh(5.107 5×105σ)]4.001 46.

exp[3.926 7×105/(RT)] =A[sinh(5.107 5×105σ)]4.001 46.

Key words: Ti55 high temperature titanium alloy; hot compression; flow stress; constitutive equations

Ti55钛合金是根据Ti3X相析出的电子浓度规律设计的一种近α型高温钛合金,由中科院金属所、宝钛集团和北京航空材料研究院等单位联合研制,是我国自行设计研制的一种近α型高温钛合金。该合金的工作温度可达550 ℃,主要用于航空发动机高压段的压气机盘、鼓筒和叶片等零件,在室温和高温下,该合金具有良好的工艺塑性,适合于各种压力加工成型,并可采用各种方式的机械加工。生产的半成品主要有棒材、锻件和板材等[1-3],也可用于生产铸件。

目前,主要通过优化热加工工艺来控制钛合金产品的显微组织和机械性能,而通过Gleeble热模拟的方法研究合金在热加工条件下的应力—应变行为是最常用的方法之一[4-10]。热加工工艺通常包括一系列的一次及二次变形工艺,这些工艺综合考虑了不均匀的热机械变形条件下合金中所发生的动态、静态还原机制及晶粒生长等复杂的冶金与相变过程。合金初始阶段(铸锭开坯)的结构特征及最后的成形及热处理工艺决定最终零件的显微组织状态。考虑到Ti55钛合金热加工窗口比较有限,有必要深入研究热加工工艺及其热加工变形行为,以保证最终Ti55钛合金在性能及可靠性上的进一步改善和提高。

本文作者拟通过Gleeble-3800热模拟试验机上进行热压缩实验,建立Ti55钛合金的热加工流变应力本构方程,为优化其热加工工艺进行必要的实验和理论储备。

1 实验

1.1 实验材料

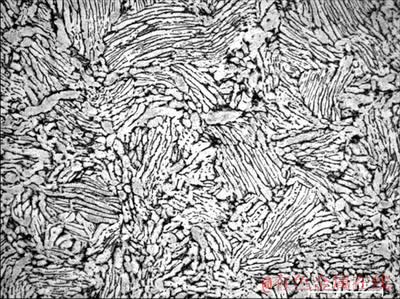

本实验用Ti55钛合金是一种近α型高温钛合金,名义化学成分为名义成分是Ti-5.6Al-3.5Sn-3Zr- 0.5Mo-0.3Si-0.4Nb-0.4Ta,实验材料为d 50 mm的Ti55钛合金棒材,β转变温度为1 010 ℃。热模拟实验前的显微组织如图1所示,主要由变形的条状α相组成。

图1 Ti55钛合金棒材的显微组织

Fig. 1 Microstructure of Ti55 alloy bar

1.2 热压缩实验

热压缩实验在 Gleeble-3800热模拟实验机上进行,整个试验过程在氩气保护下进行,以防止高温下试样被氧化。试样的两端采用Ta片润滑,不仅能减小摩擦对试样应力状态的影响,还能降低试样两端热量的损失,有利于试样的均匀变形。试样采用电阻加热法进行加热,并由焊于试样中部的铂金一铂锗热电偶来控制和测量试样的温度,升温速率为5 ℃/s,并在设定的温度保温10 min,然后按照设定的应变速率开始变形。压缩完成后,试样随压头快速冷却到300 ℃左右,再开箱空冷至室温,以此保留高温变形后的组织形貌。具体变形参数如下:

变形温度分别为900 ℃,920 ℃,940 ℃,960 ℃;应变速率分别为0.001 s-1,0.01 s-1,0.1 s-1,1 s-1,3 s-1,7 s-1,10 s-1;变形量为50%。

2 结果与分析

2.1 Ti55钛合金的真应力—真应变曲线

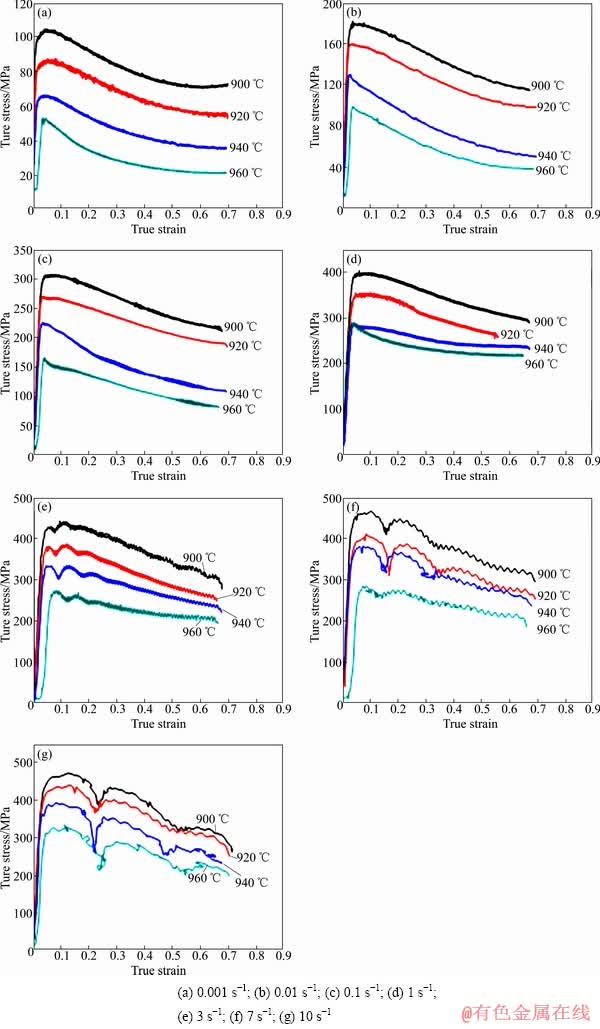

图2所示为不同应变速率下的Ti55钛合金真应 力—真应变曲线。由图2可以看出,在本研究中的应变速率和变形温度条件下,真应力—真应变曲线很快达到峰值应力后,均出现了流变软化现象,即真应力值随真应变速率的增加而减少。相同的应变速率条件下,变形温度在900~960 ℃变化时,流变应力达到峰值后,随应变的增加逐渐降低,在同一应变速率下,随变形温度的增加,峰值应力减少;在同一变形温度下,随着变形速率的增加,峰值应力增加。

2.2 流变应力本构方程的建立

为了进一步研究Ti55合金的热加工变形行为,有必要建立流变应力本构方程。通常,材料的变形温度、应变速率和流变应力的关系可以用一系列的函数模型表示。

(1)

(1)

(2)

(2)

且

(3)

(3)

式中:A(s-1)、m、n、α(MPa-1)和β(MPa-1)均为与材料有关的常数,且α=β/m;Q为热变形激活能(kJ/mol);R为摩尔气体常数(8.314 J/mol);T为绝对温度(K);Z为Zener-Hollomon参数; 为应变速率(s-1);σ为流变应力(MPa)。

为应变速率(s-1);σ为流变应力(MPa)。

图2 不同温度和应变速率下Ti55钛合金的热压缩真应力—真应变曲线

Fig. 2 True stress—strain curves of Ti55 alloy at different temperatures and stain rates

将式(3)中低应力水平(ασ<0.8)和较高应力水平(ασ>1.2)条件下F(σ)的不同表达式代入式(2)中,分别得到

ασ<0.8时,

(4)

(4)

ασ>0.8时,

(5)

(5)

对式(4)和(5)两边同取自然对数分别得到

(6)

(6)

(7)

(7)

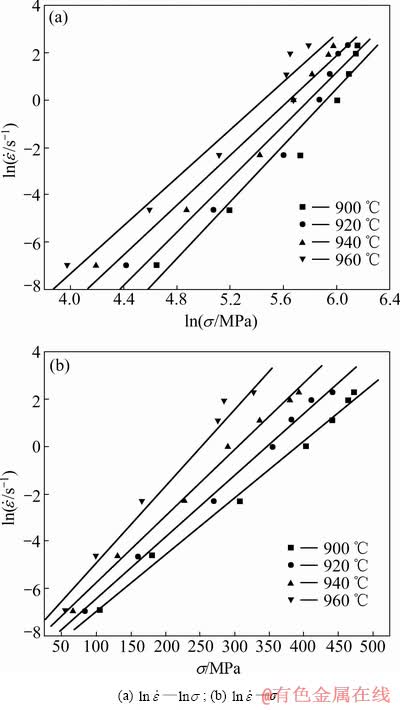

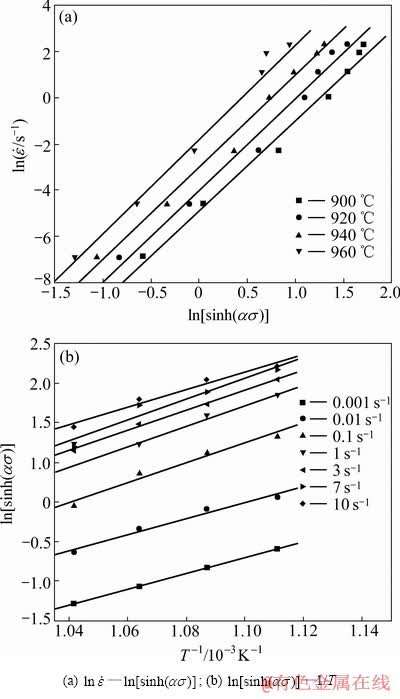

分别作 —

— 和

和 —σ关系曲线,其中σ为峰值流变应力,见图3,根据式(6)和(7),

—σ关系曲线,其中σ为峰值流变应力,见图3,根据式(6)和(7), —

— 曲线的斜率为m,

曲线的斜率为m, —σ曲线的斜率为β。由于α=β/m,可计算出α的平均值为5.107 5×10-3 MPa-1。

—σ曲线的斜率为β。由于α=β/m,可计算出α的平均值为5.107 5×10-3 MPa-1。

图3 应变速率和峰值流变应力的关系

Fig. 3 Relationships between strain rates and peak stress

将式(3)中各种应力水平条件下F(σ)的表达式代入式(2)中,可以得到具有普遍意义的流变应力的本构

方程:

(8)

(8)

对以上式(8)中方程两侧同时取自然对数,可得

(9)

(9)

因此,可以求出应力指数n及热变形激活能Q的表达式如下:

(10)

(10)

(11)

(11)

根据式(10)和式(11),分别作 —

— 和

和 —1/T关系曲线,如图4所示。由图4(a)和(b)可以分别得出,n=4.001 46和Q= 392.67 kJ/mol。根据上面求出的n和Q值,根据式(9)及

—1/T关系曲线,如图4所示。由图4(a)和(b)可以分别得出,n=4.001 46和Q= 392.67 kJ/mol。根据上面求出的n和Q值,根据式(9)及 —

— 关系曲线可求出不同温度下的A值分别为:900 ℃时,A=2.307 4×1015 s-1;920 ℃时,A=2.746 0×1015 s-1;940 ℃时,A=3.940 1×1015 s-1;960 ℃时,A=6.943 6×1015 s-1。

关系曲线可求出不同温度下的A值分别为:900 ℃时,A=2.307 4×1015 s-1;920 ℃时,A=2.746 0×1015 s-1;940 ℃时,A=3.940 1×1015 s-1;960 ℃时,A=6.943 6×1015 s-1。

图4 应变速率、峰值流变应力以及温度的关系

Fig. 4 Relationships between strain rates peak flow stress and temperature

因此,可以得出在900~960 ℃范围内,Ti55合金的流变应力本构方程为

A[sinh(5.107 5×10-3σ)]4.001 46·exp[-3.926 7×105/(RT)]

A[sinh(5.107 5×10-3σ)]4.001 46·exp[-3.926 7×105/(RT)]

也可以算出Zener-Hollomon参数为

Z= exp[3.926 7×105/(RT)]=A[sinh(5.107 5×10-3σ)]4.001 46

exp[3.926 7×105/(RT)]=A[sinh(5.107 5×10-3σ)]4.001 46

3 结论

1) 进行在变形温度900~960 ℃、应变速率为0.001~10 s-1条件下Ti55钛合金的热压缩实验,Ti55钛合金的热压缩真应力—应变曲线表现为流变软化的特点。

2) 通过线性回归分析, Ti55钛合金的Zener- Hollomon参数为Z= exp[3.926 7×105/(RT)]=A[sinh(5.107 5×10-3σ)]4.001 46,其中应力指数n=4.00146,热变形激活能Q=392.67 kJ/mol。

exp[3.926 7×105/(RT)]=A[sinh(5.107 5×10-3σ)]4.001 46,其中应力指数n=4.00146,热变形激活能Q=392.67 kJ/mol。

REFERENCES

[1] 方 波, 陈志勇, 陈仲强, 等. Ti-55钛合金连续冷却转变曲线的测绘及显微组织演变[J]. 中国有色金属学报, 2010, 20(S1): s32-s35.

FANG Bo, CHEN Zhi-yong, CHEN Zhong-qiang, et al. Continuous cooling transformation diagram and microstructure evolution of Ti-55 alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s32-s35.

[2] 王娟华, 王红武, 陈志勇, 等. Ti-55钛合金超塑性板材的显微组织与力学性能[J]. 中国有色金属学报, 2010, 20(S1): s91- s93.

WANG Juan-hua, WANG Hong-wu, CHEN Zhi-yong, et al. Microstructure and properties of superplastic plate of Ti-55 alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s91-s93.

[3] 赵子博, 葛敬鲁, 陈志勇, 等. Ti-55钛合金板材的超塑性变形行为[J]. 中国有色金属学报, 2010, 20(S1): s847-s851.

ZHAO Zi-bo, GE Jing-lu, CHEN Zhi-yong, et al. Superplastic deformation of Ti-55 alloy shet [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s847-s851.

[4] FENG Xi-ya, YI Dan-qing, WANG Bin, WU Chun-ping, ZHANG Hong. Hot compression deformation of the Mg-Al-Y- Zn magnesium alloy [J]. Rare Metals, 2008, 27(2): 121-126.

[5] LIU Z C, LIN J P, WANG Y L, LIN Z, CHEN G L, CHANG K M. High temperature deformation behavior of as cast Ti-46Al-8.5Nb-0.2W alloy [J]. Materials Letters, 2004, 58: 948-952.

[6] LIN Y C, CHEN Ming-Song, ZHANG Jue. Effect of temperature and strain rate on the compressive deformation behavior of 42CrMo steel [J]. Journal of Materials Processing Technology, 2008, 205: 308-315.

[7] ZONG Y Y, SHAN D B, XU M, Lü Y. Flow softening and microstructure evolution of TC11 titanium alloy during hot deformation [J]. Journal of Materials Processing Technology, 2009, 209 (19): 1988-1994.

[8] CUI W F, JIN Z, GUO A H, ZHOU L. High temperature deformation behavior of a+β type biomedical titanium alloy Ti-6Al-7Nb [J]. Mater Sci Eng A, 2009, 499(1/2) : 252-256.

[9] LI Miao-quan, XIONG Ai-ming, HUANG Wei-chao, WANG Hai-rong, SU Shao-bo, SHEN Li-chuang. Microstructural evolution and modelling of the hot compression of a TC6 titanium alloy [J]. Materials Characterization, 2003, 49: 203- 209.

[10] DUAN Yuan-pei, LI Ping, XUE Ke-min, ZHANG Qing. Flow behavior and microstructure evolution of TB8 alloy during hot deformation process [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1199-1204.

(编辑 李艳红)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:方 波,研究员;电话:024-24383380;E-mail: fb1281@163.com