纤维化膨润土强化氧化球团制备及其机理

黄柱成,王雨蒙,柴斌,赵立卓,姜涛

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘要:采用膨润土添加有机分散剂在搅拌机的作用下制备纤维化膨润土浆并对强化铁精矿造球进行研究。研究结果表明:添加有机分散剂制备的纤维化膨润土浆形成了良好的纤维化结构;造球混合料预配质量分数为1%的膨润土,利用纤维化膨润土浆进行强化造球,当球团强化层纤维化膨润土用量从0提高到0.18%时,落下强度和抗压强度分别从4.1次/(0.5 m)和14.63 N/个分别提高到5.8次/(0.5 m)和16.20 N/个,生球爆裂温度从530 ℃提高到610 ℃;预热球和焙烧球抗压强度从528 N/个和1 587 N/个分别提高到638 N/个和4 160 N/个,焙烧球内部结构由较疏松多孔变为结构致密,晶粒连接显著增强。

关键词:纤维化膨润土;有机分散剂;球团矿

中图分类号:TF046.6 文献标志码:A 文章编号:1672-7207(2014)07-2145-06

Preparation of oxide pellets with fibrosis bentonite and its mechanism

HUANG Zhucheng, WANG Yumeng, CHAI Bin, ZHAO Lizhuo, JIANG Tao

(School of Mineral Processing and Bioengineering, Central South University, Changsha, 410083, China)

Abstract: Fibrosis bentonite slurry was prepared by mixing organic dispersant and bentonite during the action of a blender, and the effect of fibrosis bentonite formation on iron ore pelletization and its mechanism were both studied. The results show that this fibrosis bentonite slurry was observed to form a fibrous structure. Bentonite dosage is 1.0% of mass concentration of iron ore, strengthening the pelletizing by spraying fibrosis bentonite in ball growing area. Drop strength, compression strength and burst temperature of green ball increase from 4.1 per 0.5 m, 14.63 N/pellet, at 530 ℃ to 5.8 per 0.5 m, 16.20 N/P at 610℃, respectively; the strength of preheated pellet and roasted pelltes respectively increase from 528 N/pellet and 1 587 N/pellet to 638 N/pellet and 4 160 N/pellet respectively while bentonite fiber dosage in the strengthened layer of pelletizing increases from 0% to 0.18%. The structure of roasted pellets changes from being loose and porous to being compact, and the contact of particles is improved.

Key words: fibrosis bentonite; organic dispersant; pellet

球团矿是一种优质的高炉炉料,提高入炉球团矿的铁品位,对高炉实现高产、低耗意义重大[1]。理论上,高炉入炉原料铁品位提高1%,焦比降低2%,产量可提高3%[2]。2011年我国球团矿产量突破1.271 0×108 t,膨润土作为国内氧化球团厂普遍采用的黏结剂,提高了生球强度,但膨润土几乎全部残留在球团中,降低了球团品位[3-4]。在相对稳定的原料条件下,为进一步稳定球团矿质量,通过提高膨润土性能,降低其用量是提高球团矿品位的一种有效方式。Ripke等[3]提出膨润土纤维结构的理论,发现膨润土吸水膨胀后,在压力、剪切力作用下,膨润土各片层产生滑动,促使膨润土纤维结构形成,并采用搅拌实现压力和剪切力作用,形成膨润土纤维结构。纤维结构的出现,提高了膨润土的黏结效果,使生球的落下和抗压强度明显提高[5]。本文作者以膨润土和有机分散剂为原料制备纤维化膨润土浆,并考察其对造球性能的影响。

1 原料性能与研究方法

1.1 原料性能

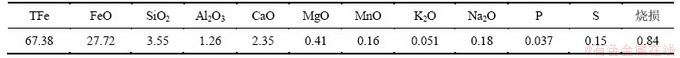

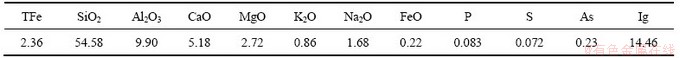

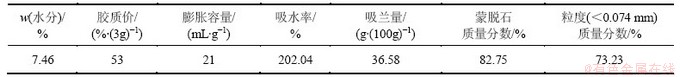

试验所用铁精矿的化学成分(质量分数)如表1所示,精矿铁品位较高,SiO2含量较低,含有少量的P,S,K2O和Na2O。铁精矿中粒度低于0.074 mm的质量分数为69.44%。试验所用的膨润土的化学组成和物理性能分别如表2和表3所示。

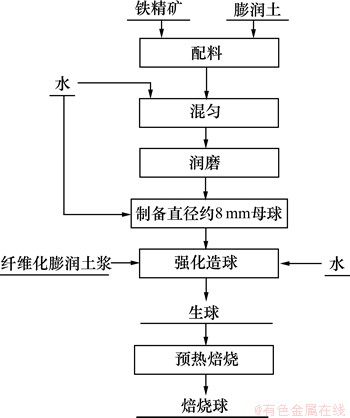

1.2 研究方法

纤维化膨润土强化氧化球团制备试验流程图如图1所示。造球混合料采用人工配料和混匀,每次称取5 kg铁精矿,加入5%的水分进行湿润,并配加质量分数为1.0%的膨润土,混合料润磨预处理采用规格(直径×长度)为540 mm×530 mm的润磨机,转速为31 r/min,润磨时间10 min。生球的制备是在圆盘造球机上进行的,造球机的直径为1 000 mm,转速为26 r/min,倾角为47°。首先在12 min内加料加水造球制备8 mm左右的球团(质量为m1),然后采用纤维化膨润土浆强化造球,喷洒纤维化膨润土浆(质量为m2),逐步加混合料(质量为m3)继续造球长大至直径为12~14 mm的生球,形成2~3 mm厚生球纤维化膨润土强化层。其中纤维化膨润土浆的制备采用在膨润土中添加0.33%的有机分散剂在机械搅拌力的作用下加水制备膨润土质量分数为16.6%的纤维化膨润土浆。球团强化层纤维化膨润土用量W为

(1)

(1)

其中:W为球团强化层纤维化膨润土用量,%;混合料水质量分数为5%。

对生球进行落下强度,抗压强度和爆裂温度的检测。生球在105 ℃烘箱中烘干,用于进行预热及焙烧实验。预热、焙烧实验在卧式管状电炉中进行,预热温度900 ℃,时间15 min。焙烧温度1 280 ℃,时间10 min。球团矿的抗压强度在最大载荷为10.0 kN的智能球团压力机上测定。

2 结果与讨论

2.1 球团强化层纤维化膨润土用量对球团性能的影响

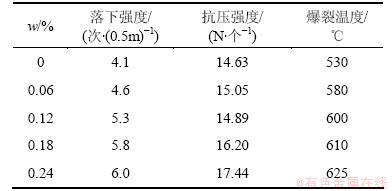

纤维化膨润土强化球团制备试验结果如表4和图2所示。

由表4可知:随球团强化层纤维化膨润土用量的增加,生球的落下强度、抗压强度明显提高,爆裂温度也有所提高,预热球和焙烧球的抗压强度迅速提高。当纤维化膨润土用量从0提高到0.24%时,生球的落下强度、抗压强度和爆裂温度分别从4.1次/(0.5 m),14.63 N/个和530 ℃分别提高到6.0次/(0.5 m),17.44 N/个和625 ℃。

表1 铁精矿化学组成(质量分数)

Table 1 Chemical composition of iron concentrates %

表2 膨润土的化学组成(质量分数)

Table 2 Chemical composition of bentonite %

表3 膨润土的物理性能

Table 3 Physical properties of bentonite

图1 试验流程图

Fig. 1 Flowsheet of experiment

表4 球团强化层纤维化膨润土用量w对生球质量的影响

Table 4 Effects of bentonite fiber dosages in strengthened layer of pelletizing on quality of green balls

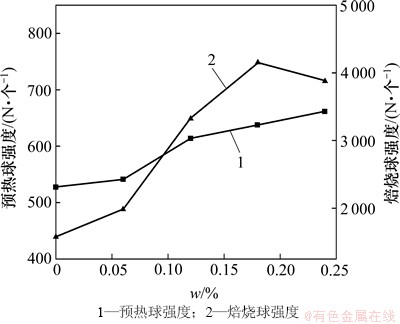

由图2可见:随球团强化层纤维化膨润土用量的增加,预热球的抗压强度从528 N/个提高到638 N/个。未喷洒纤维化膨润土的焙烧球抗压强度较低,为1 587 N/个;而当喷洒纤维化膨润土后,焙烧球团强度显著提高[6];当球团强化层纤维化膨润土浆固体质量分数为0.18%时,焙烧球抗压强度提高到4 160 N/个;当球团强化层纤维化膨润土浆固体含量超过0.18%,焙烧球团的抗压强度提高不明显。

图2 球团强化层纤维化膨润土用量w对预热球和焙烧球强度的影响

Fig. 2 Effects of bentonite fiber dosages in strengthened layer of pelletizing on compression strength of preheated pellets and roasted pellets

2.2 纤维化膨润土提高球团强度的机理分析

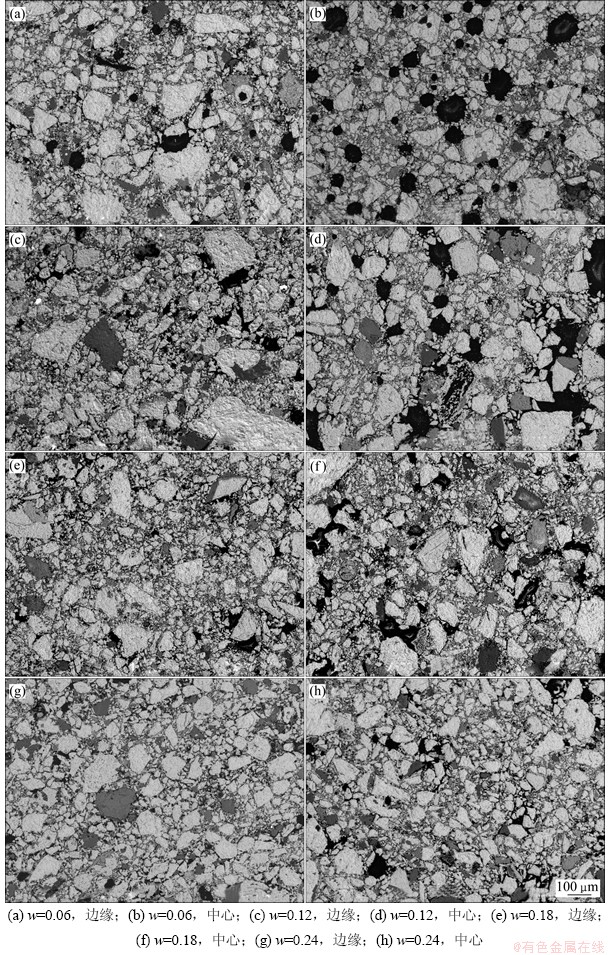

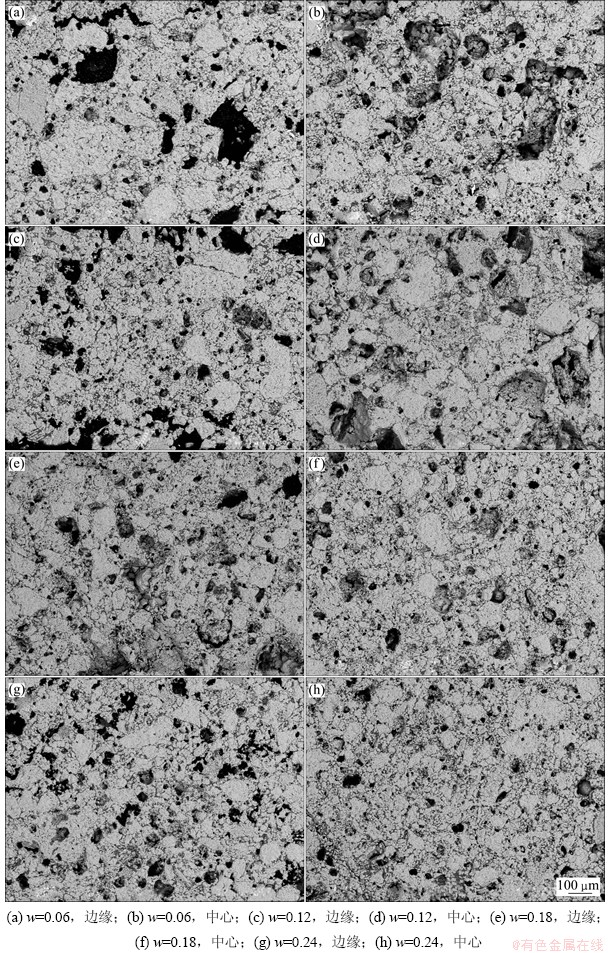

图3和图4所示分别为不同纤维化膨润土用量的预热球和焙烧球的显微结构图。由图3可见:预热球中心磁铁矿氧化不充分,球团内部存在片状的Fe3O4,且中心孔洞明显多于边缘;随着球团强化层纤维化膨润土用量的增加,预热球团边缘处孔隙逐渐减少,结构更为致密,中心的孔隙也明显减小,预热球强度逐渐提高。由图4可知:当采用1 280 ℃高温氧化焙烧时,球团中铁氧化物主要以Fe2O3存在,球团边缘孔隙多于中心,球团边缘处Fe3O4充分氧化为Fe2O3,晶体收缩,产生较多的孔隙;随着球团强化层纤维化膨润土用量的增加,焙烧球团边缘处颗粒之间孔隙逐渐减少,颗粒黏结力逐渐增强,焙烧球强度显著提高。

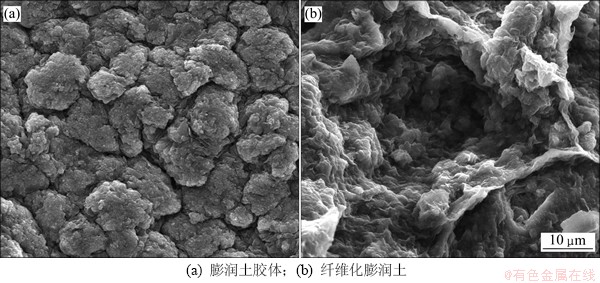

图5所示为膨润土质量分数为16.6%的膨润土胶体和纤维化膨润土浆在300℃脱水后的扫描电镜(SEM)照片。由图5可见:膨润土胶体脱水干燥后,膨润土呈多层、边界形状不规则的聚集体。而经纤维化后膨润土粒度变小、比表面积变大,分散度提高,原来的多层片状结构基本解离成单层结构,形成纤维化结构,呈现出强烈的胶体性质[7-8]。纤维化膨润土均匀喷洒在造球混匀料颗粒上,强化了造球颗粒的聚集,优化了造球过程中铁精矿粗颗粒与细颗粒的嵌布关系,在预热和焙烧过程中,有利于细颗粒首先氧化并形成微结晶连接,使晶体结构更为致密,提高了预热球和焙烧球的强度。

图3 预热温度为900 ℃时预热球的微观结构

Fig. 3 Microstructure of preheated pellets at 900 ℃

图4 焙烧温度为1 280 ℃时焙烧球的微观结构

Fig. 4 Microstructure of roasted pellets at 1 280 ℃

图5 300 ℃脱水后膨润土的SEM分析

Fig. 5 SEM analysis of bentonite after dehydration at 300 ℃

3 结论

(1) 膨润土添加有机分散剂制备膨润土浆,形成了持水性能良好的纤维化结构,优化了造球过程中铁精矿粗颗粒与细颗粒的嵌布关系,有利于细颗粒首先氧化并形成微结晶连接,使晶体结构更为致密,提高了预热球和焙烧球的强度。

(2) 纤维化膨润土浆显著改善了生球质量。当球团强化层纤维化膨润土用量从0提高到0.18%时,落下强度和抗压强度分别从4.1次/(0.5 m)和14.63 N/个提高到5.8次/(0.5 m)和16.20 N/个,生球爆裂温度从530 ℃提高到610 ℃。

(3) 随着球团强化层纤维化膨润土用量的提高,预热球和焙烧球强度明显提高。当纤维化膨润土用量从0提高到0.18%时,预热球和焙烧球抗压强度分别从528 N/个和1 587 N/个提高到638 N/个和4 160 N/个。

参考文献:

[1] 傅菊英, 朱德庆. 铁矿氧化球团基本原理、工艺及设备[M]. 长沙: 中南大学出版社, 2004: 2-17.

FU Juying, ZHU Deqing. Basic principles, techniques and equipments of iron oxidized pellets[M]. Changsha: Central South University Press, 2004: 2-17.

[2] 张新兵, 朱梦伟. 膨润土对我国球团生产的影响[J]. 烧结球团, 2003, 28(6): 3-7.

ZHANG Xinbing, ZHU Mengwei. The effect of bentonite on pellets production in our country[J]. Sintering and Pelleting, 2003, 28(6): 3-7.

[3] Ripke S J, Kawatra S K. Can fly-ash extend bentonite binder for iron ore agglomeration[J]. Int J Miner Process, 2000, 60: 181-198.

[4] 张永祥, 田发超, 张克诚, 等. 添加复合黏结剂的球团实验[J]. 烧结球团, 2004, 29(5): 9-11.

ZHANG Yongxiang, TIAN Fachao, ZHANG Kecheng. Pelletizing test of adding various complex binders[J]. Sintering and Pelletizing, 2004, 29(5): 9-11.

[5] Kawatra S K, Ripke S J. Laboratory studies for improving green ball strength in bentonite-bonded magnetite concentrate pellets[J]. Int J Mineral Processing, 2003, 72: 429-441.

[6] 陈许玲, 甘敏, 范晓慧, 等. 有机黏结剂氧化球团固结特性及强化措施[J]. 中南大学学报(自然科学版), 2009, 39(6): 550-555.

CHEN Xuling, GAN Min, FAN Xiaohui. Concretion properties of organic-binder oxidate pellets and strengthen measures[J]. Journal of Central South University: Science and Technology, 2009, 39(6): 550-555.

[7] 黄柱成, 江源, 韩志国, 等. 球团矿中膨润土的作用机理研究[J]. 化工矿物与加工, 2005(8): 13-15.

HUANG Zhucheng, JIANG Yuan, HAN Zhiguo, et al. The mechanism research of bentoniet in pellets[J]. Mineral and chemical processing, 2005(8): 13-15.

[8] 杨永斌, 黄桂香, 姜涛, 等. 有机黏结剂替代膨润土制备氧化球团[J]. 中南大学学报(自然科学版), 2007, 38(5): 850-856.

YANG Yong-bin, HUANG Gui-xiang, JIANG Tao, et al. Application of organic binder as substitutes for bentonite in pellet preparation[J]. Journal of Central South University: Science and Technology, 2007, 38(5): 850-856.

(编辑 邓履翔)

收稿日期:2013-04-05;修回日期:2013-06-05

基金项目:国家自然科学基金资助项目(51234008)

通信作者:黄柱成(1964-),男,湖南长沙人,教授,博士生导师,从事钢铁冶金、综合利用等研究;电话:0731-88830542;E-mail: zchuangcsu@126.com