氧化球团矿中Fe2O3的结晶规律

陈耀明,李 建

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘要:以磁铁矿精矿(Fe3O4)为原料,添加粘结剂后进行混合、造球,将生球干燥预热后,在1 150~1 280 ℃氧化焙烧6~15 min。将所得氧化球团取样制片,采用显微镜和扫描电镜(SEM)对Fe2O3再结晶晶形进行研究。研究结果表明:Fe2O3再结晶主要形成3种晶形,即初晶、发育晶和互连晶;球团矿质量与Fe2O3的晶形有密切关系,3种不同晶形的球团抗压强度有明显差异;随着焙烧温度的升高,初晶→发育晶→互连晶形依次形成,球团抗压强度逐渐提高,当氧化球团矿内部Fe2O3大量形成互连晶时,氧化球团矿抗压强度最高,质量最好。解释了球团抗压强度随温度升高而升高的微观机理;同时验证了氧化球团矿主要靠Fe2O3再结晶的固相固结机理。

关键词:氧化球团;结晶规律;晶形;显微结构

中图分类号:TE52 文献标识码:A 文章编号:1672-7207(2007)01-0070-04

Crystal rule of Fe2O3 in oxidized pellet

CHEN Yao-ming, LI Jian

(School of Resources and Bioengineering, Central South University, Changsha 410083, China)

Abstract: Magnetite concentrate mixed with bentonite was balled, and then green ball was dried and preheated, pellets were fired for 6-15 min at 1 150-1 280 ℃ in oxidizing atmosphere. The re-crystallization of Fe2O3 in oxidized pellet was studied by microscope and scanning electron microscope. The results show that three major kinds of crystals are formed in oxidized pellets and different crystal types lead to different pellet compressive strengthes. With the increase of firing temperature, crystallization of Fe2O3 follows the sequence of primary crystal→developing crystal→interconnected crystal with the improvement of pellet compressive strength accordingly. When there are a large number of interconnected crystals of Fe2O3 in oxidized pellets, the pellet compressive strength and quality are the strongest and the best. The crystallization rules of Fe2O3 can explain the micro-mechanism of pellet compressive strength rising up with the increase of firing temperature and can proves that the agglomeration of oxidized pellets mainly depends on re-crystallization of Fe2O3.

Key words: oxidized pellet; crystal rules; crystal types; microstructure

生产实践表明,氧化球团矿是一种品位高、还原性好、强度高的酸性高炉炉料,而且优酸性球团矿与高碱度烧结矿搭配可以显著地改善炉料结构,使高炉增产节焦,降低生产成本[1]。近年来,随着我国钢铁工业的发展,氧化球团矿生产发展极快,年产已达到3 000万t。

磁铁矿精矿是生产氧化球团矿的主要原料,在焙烧过程中,Fe3O4逐渐被氧化成Fe2O3再结晶。氧化球团矿就是靠这种Fe2O3再结晶固结作为固结机理。因此,关于Fe2O3再结晶行为的研究很重要。国内外有关专家从不同角度对氧化球团矿进行了研究,但对Fe2O3结晶规律的研究很少。傅菊英等对固相扩散进行了研究[2-6]。研究结果表明,固体物质开始反应的温度远低于它们的熔点或它们的共熔点,在一定温度下,固态物质的质点不仅具有可动性,而且质点之间还可以直接反应。国内有关专家认为,Fe3O4氧化成Fe2O3,

由于晶格结构发生变化,新生的Fe2O3具有很强的迁移能力。在较高温度下,颗粒之间通过固相扩散形成赤铁矿晶桥将颗粒连接起来,使球团矿具有一定的强度[7-15]。为此,本文作者对氧化球团中Fe2O3再结晶规律进行研究。

1 实 验

1.1 原 料

本次实验所用铁精矿全部采用磁铁矿,铁精矿含铁较高,TFe为67.45%,其中FeO为23.53%;杂质较少,其中SiO2 4.02%,CaO 0.22%,MgO 0.20%,Al2O3 0.26%;有害元素含量低,S和P含量分别仅为0.021%和0.020%。此铁精矿是一种化学成分优良的球团用原料。所用磁铁矿粒径小于0.074 mm的比例为81.06%,其粒度适合造球。

球团中添加2%的粘结剂,粘结剂均采用A膨润土。A膨润土主要由铝硅酸盐组成,属于钠基膨润土,其SiO2高达60.29%,Al2O3含量为16.22%;此外,Fe2O3 2.67%,CaO 3.42%,MgO 4.19%,K2O 0.71%,Na2O 2.12%,P 0.18%,S 0.027%。粒径小于0.074 mm的粒子含量为97.50%。

1.2 实验方法

混合料润磨采用1 m×0.5 m(直径×高)的润磨机,润磨6 min后在直径为1 m的圆盘造球机上造球。预热焙烧小型实验在实验室卧式管炉中进行,扩大实验在中南大学烧结球团所链篦机-回转窑模拟装置上进行。

1.3 表征方法

成品球团矿取样制片后在Nikon透反两用显微镜上进行矿物组成和显微结构分析。

2 结果与分析

2.1 氧化球团焙烧试验结果

在不同工艺条件下进行氧化球团焙烧扩大性试验,其结果如表1所示。

2.2 氧化球团中Fe2O3的结晶规律

2.2.1 焙烧温度对Fe2O3结晶的影响

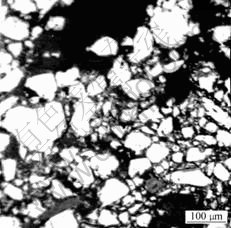

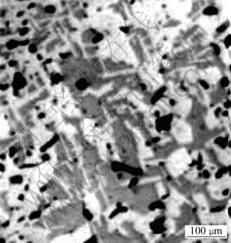

从表1可以看出,焙烧温度对氧化球团矿中Fe2O3的结晶影响很大,在1 150~1 200 ℃时焙烧出来的球团矿结晶特点是Fe2O3再结晶中单独颗粒状较多,少量呈线条状,晶粒稀散、微细(见图1,白色为Fe2O3),这种晶形称为初晶。说明焙烧温度偏低,矿物没有得到充分软熔,Fe2O3结晶不完善,而且焙烧时间较短,Fe3O4氧化不完全,球团内部残存的Fe3O4较多,故成品球团矿常常具有较强的磁性,用普通磁铁就可以吸起。球团矿强度不高,均低于2 kN/个,可供2 000 m3以下的小型高炉使用。

表1 熔烧工艺参数对球团的抗压强度的影响结果

Table 1 Effect of parameters of preheating and fired on pellet strength

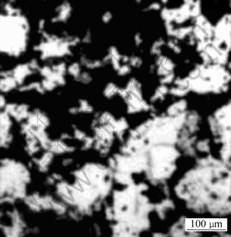

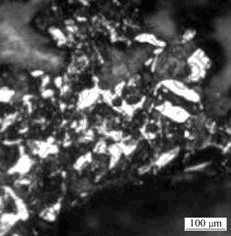

当焙烧温度升高到1 220~1 250 ℃时,氧化球团矿中Fe2O3再结晶的特点是初晶长大且相互靠近,部分晶粒开始相互连接,但仍有部分单独的粒状晶体,结构欠致密,这种晶形称为发育晶(见图2,白色的为Fe2O3)。说明焙烧温度较高,Fe3O4氧化较完全,Fe2O3再结晶处于成长发育阶段。成品球抗压强度处于中等水平,为2.5~3.2 kN/个,这种晶形的氧化球团矿可供3 000 m3以下的中小型高炉使用。

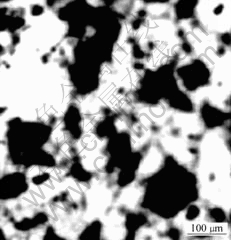

当焙烧温度继续上升到1 280 ℃时,球团中的Fe2O3再结晶的特点是晶粒互连成整体,晶粒粗大,连接紧密,结构力强,这种晶形称为互连晶(见图3,白色的为Fe2O3)。说明焙烧温度和时间都很适宜,Fe3O4软熔充分,氧化完全,残存的Fe3O4极少,成品球无磁性,单颗粒,无黏结,呈瓦灰色,强度高达4.556 kN/个,这种优质氧化球团矿能满足3 000 m3以上的大型高炉炼铁要求。

图1 氧化球团矿初晶的显微结构

Fig.1 Microstructure of primary crystal of oxidized pellet

图2 氧化球团矿发育晶显微结构

Fig.2 Microstructure of developing crystal of oxidized pellet

图3 氧化球团矿互连晶显微结构

Fig.3 Microstructure of flat crystal of oxidized pellet

2.2.2 焙烧时间对Fe2O3结晶的影响

焙烧时间对氧化球团中Fe2O3结晶有直接的影响。当焙烧时间短时,Fe3O4氧化不完全,Fe2O3再结晶差,基本都是一些初晶,单颗粒多、互连差,显微结构松散,强度低,图1所示的氧化球团矿就是这种初晶状的显微结构。随着焙烧时间的延长,Fe3O4氧化渐趋完全,Fe2O3再结晶从部分互连的发育晶过渡到全部连结成整体的互连晶,这时的氧化球团矿具有很高的强度。

2.2.3 预热时间和温度对Fe2O3结晶的影响

球团进行预热是生产氧化球团矿的重要环节。在900 ℃预热12 min时,铁酸镁、钙铁橄榄石等新生的矿物都基本形成、结晶完善、轮廓分明,只是颜色与高温下的矿物颜色有些差别;同时,大部分Fe3O4氧化成Fe2O3再结晶,但晶形不互连,显微结构强度 不高。

从9-12号球团预热、焙烧结果来看,适当地延长球团预热时间和升高温度对焙烧球团矿有利,可以弥补焙烧温度的不足。如表1中12号球团矿与4号球团矿相比,当预热时间从10 min增加到13 min,预热温度从900 ℃增加到920 ℃,在1 260 ℃焙烧10 min时,成品球团矿的Fe2O3结晶互连优良,相当于1 280 ℃时焙烧10 min的球团矿。

2.2.4 焙烧气氛对Fe2O3结晶的影响

生产氧化球团矿必须是在氧化性气氛中焙烧,才能保证Fe2O3再结晶完善。在弱还原性气氛中,Fe3O4氧化不完全,残存较多(见图4,Fe3O4为棕灰色,Fe2O3为浅白色),再结晶不完全。当还原性气氛较浓时,Fe3O4会还原成FeO,FeO与球团中的SiO2结合,生成铁橄榄石:

图4 弱还原气氛中焙烧的氧化球团矿显微结构

Fig.4 Microstructure of pellet in slightly reducing atmosphere

从而导致硅酸盐液相大量形成,球团互相粘结成葡萄状,单颗粒的氧化球团矿大量减少,球团矿质量变差。因此,保证较强的氧化性气氛是生产氧化球团矿的必要条件。

2.2.5 冷却速度对Fe2O3结晶的影响

矿物结晶是在冷却过程中形成的,所以,成品球团矿冷却速度越快,矿物结晶越不好,来不及结晶的便形成易脆的玻璃质。当将高温(1 280 ℃)焙烧后的氧化球团全部投放在冷水中进行急剧冷却时,发现球团矿中的互连晶被破坏,矿物结晶不完善,支离破碎,Fe2O3(浅白色)再结晶很差,全是单颗粒,残存的Fe3O4(灰色)呈块状,有大量的玻璃质(云雾状)形成,填充在各种裂缝中(见图5),氧化球团矿的矿物组成和显微结构很不理想。

图5 急剧冷却的球团矿显微结构

Fig.5 Microstructure of pellet by rapid cooldown

3 结 论

a. 采用铁品位高,杂质少的原料,制备高质量的生球是生产优质氧化球团矿的前提。

b. 焙烧后的成品球团矿需要选择合适的冷却速度,使矿物有充分的结晶时间。急剧冷却,球团矿内部会出现互连晶被破坏现象。

c. 以磁铁精矿为原料的球团在1 280 ℃左右焙烧,效果最好,氧化球团矿中Fe2O3结晶完善,全成互连晶,微观结构好,质量高,是理想的高炉炉料。

参考文献:

[1] 叶匡吾. 三种球团焙烧工艺述评[J]. 烧结球团, 2002, 27(1):1-7.

YE Kuang-wu. Review of three kinds of pelletizing process[J]. Sintering and Pelletizing, 2002, 27(1): 1-7.

[2] 傅菊英, 姜 涛, 朱德庆. 烧结球团学[M]. 长沙: 中南工业大学出版社, 1996.

FU Ju-ying, JIANG Tao, ZHU De-qing. Sintering and pelletizing[M]. Changsha: Central South University of Technology Press, 1996.

[3] Coetsee T, Pislorius P C, de Viuiers E E. Rate-determining steps for reduction in magnetite-coal pellets[J]. Mineral Engineering, 2002, 15(11): 919-929.

[4] 肖 琪. 团矿理论与实践[M]. 长沙: 中南工业大学出版社, 1991.

XIAO Qi. The theoretics and practice of nodulizing[M]. Changsha: Central South University of Technology Press, 1991.

[5] 朱德庆, 戴名笠, 宁吉亮. 铁精矿球团固结时物理特性的变化[J]. 烧结球团, 1994, 19(1): 6-10.

ZHU De-qing, DAI Ming-li, NING Ji-liang. Variation in physical properties of iron ore concentrate pellets during hardening process[J]. Sintering and Pelletizing, 1994, 19(1): 6-10.

[6] 傅菊英, 朱德庆. 铁矿氧化球团基本原理、工艺及设备[M]. 长沙: 中南大学出版社, 2005.

FU Ju-ying, ZHU De-qing. Theory and techniques and equipment of iron ore concentrate oxidized pellet[M]. Changsha: Central South University Press, 2005.

[7] 黄柱成, 张元波, 朱尚朴, 等. 以赤铁矿为主配加磁铁矿制备氧化球团的研究[J]. 钢铁, 2004, 39(4): 9-13, 59.

HUANG Zhu-cheng, ZHANG Yuan-bo, ZHU Shang-pu, et al. Study on mainly made from hematite based oxidized pellets with addition of some magnetite[J]. Iron and Steel, 2004, 39(4): 9-13, 59.

[8] 傅菊英, 李云涛, 姜昌伟, 等. 磁铁矿球团氧化动力学[J]. 中南大学学报: 自然科学版, 2004, 35(6): 950-954.

FU Ju-ying, LI Yun-tao, JIANG Chang-wei, et al. Oxidation kinetics of magnetite concentrate pellets[J]. Journal of Central South University: Science and Technology, 2004, 35(6): 950-954.

[9] 陈铁军, 张一敏, 王昌安, 等. 镁橄榄石在铁矿球团中的应用试验研究[J]. 烧结球团, 2005, 30(2): 5-8.

CHEN Tie-jun, ZHANG Yi-min, WANG Chang-an, et al. Experimental study on application of forsterite in iron ore pelletization[J]. Sintering and Pelletizing, 2005, 30(2): 5-8.

[10] 王昌安, 王新继, 张一敏, 等. 原料高压辊磨对球团氧化活化能的影响[J]. 钢铁研究, 2005, 33(1): 8-10, 16.

WANG Chang-an, WANG Xin-ji, ZHANG Yi-min, et al. Effect of high pressure grinding on activation energy of magnetite materials of pellet[J]. Research on Iron & Steel, 2005, 33(1): 8-10, 16.

[11] 熊守安, 朱德庆, 范晓慧, 等. 链篦机-回转窑法氧化球团矿试验研究[J]. 烧结球团, 2002, 27(4): 1-6.

XIONG Shou-an, ZHU De-qing, FAN Xiao-hui, et al. Experiment of grate-kiln oxidized pelletizing process[J]. Sintering and Pelletizing, 2002, 27(4): 1-6.

[12] 彭志坚, 陈铁军, 曾小宁. 玛瑙山磁铁精矿氧化球团试验研究[J]. 钢铁研究, 2004, 32(1): 5-8.

PENG Zhi-jian, CHEN Tie-jun, ZENG Xiao-ning. Laboratory study on preparation of acid pellet using Manaoshan concentrate[J]. Research on Iron & Steel, 2004, 32(1): 5-8.

[13] 黄柱成, 李 骞, 杨永斌, 等. 混合料润磨预处理对氧化球团矿质量的影响[J]. 中南大学学报: 自然科学版, 2004, 35(5): 753-758.

HUANG Zhu-cheng, LI Qian, YANG Yong-bin, et al. Effect of wet-grinding of mix on quality of iron ore concentrate pellet[J]. Journal of Central South University: Science and Technology, 2004, 35 (5): 753-758.

[14] 张汉泉. 优化大冶竖炉球团焙烧工艺参数的试验研究[J]. 钢铁研究, 2002, 30(4): 1-4.

ZHANG Han-quan. Experimental study on optimization of roasting process parameters for Daye iron mine shaft furnace[J]. Research on Iron & Steel, 2002, 30(4): 1-4.

[15] 黎前程, 朱德庆, 潘 建. 南非HI磁铁精矿球团试验[J]. 烧结球团, 2005, 30(3): 1-4.

LI Qian-cheng, ZHU De-qing, PAN Jian. Pelletizing test of HI magnetite concentrate[J]. Sintering and Pelletizing, 2005, 30(3): 1-4.

收稿日期:2006-02-15

基金项目:中南大学创新工程资助项目(1343-75213)

作者简介:陈耀明(1952-),男,湖南长沙人,副教授,从事烧结球团矿微观结构的研究

通讯作者:李 建,男,湖南长沙人,博士研究生;电话:0731-8836942(O);E-mail: lijiancsu@126.com