DOI: 10.11817/j.ysxb.1004.0609.2021-39670

薄壁中空型材分流模挤压缺陷产生机理及出口流速精确控制

刘志文1, 2,李落星2,符纯明1,何 洪2,李必文1

(1. 南华大学 机械工程学院,衡阳 421001;

2. 湖南大学 汽车车身先进设计制造国家重点实验室,长沙 410082)

摘 要:以汽车防撞梁为典型研究对象,开展型材分流模挤压试模出现的内加强筋壁厚减薄和开裂等缺陷产生机理研究,并提出挤压出模口横截面流速均匀性的精确控制方法。首先,基于任意拉格朗日-欧拉混合算法建立了型材分流模挤压稳态有限元模型。然后,基于材料流速均方差和焊合压力评价揭示型材挤压壁厚减薄和焊缝开裂的产生原因。最后,为了实现对出模口型材横截面流速的均匀控制,提出了“优化分流孔/引流槽、增添阻流块、基于Kriging近似模型和多岛遗传算法优化工作带”的分流模结构多步优化设计方法。结果表明:优化后出模口型材横截面流速均方差由23.75 mm/s减少到1.63 mm/s,型材壁厚尺寸误差小于0.1 mm。同时,型材横截面的温差大小和焊缝质量明显改善,最大温差降低27.2 ℃,焊合压力提升16.5%,焊缝基本为完全再结晶组织。

关键词:薄壁中空型材;多孔分流模;挤压缺陷;多步优化;截面流速控制;焊缝质量

文章编号:1004-0609(2021)-04-0917-14 中图分类号:TG376.2 文献标志码:A

引文格式:刘志文, 李落星, 符纯明, 等. 薄壁中空型材分流模挤压缺陷产生机理及出口流速精确控制[J]. 中国有色金属学报, 2021, 31(4): 917-930. DOI: 10.11817/j.ysxb.1004.0609.2021-39670

LIU Zhi-wen, LI Luo-xing, FU Chun-ming, et al. Defects formation mechanism and precision control of exit flow velocity in porthole die extrusion of hollow thin-walled aluminum profile[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(4): 917-930. DOI: 10.11817/j.ysxb.1004.0609.2021-39670

铝合金具有密度低,比强度、比刚度高,碰撞性能好,易回收和无污染等一系列优点,是车身理想的轻量化材料[1-2]。全铝车身相比钢制车身减轻质量30%以上,具有高刚性、耐撞性能好等特点,具有极好的发展前景,已成功应用于奥迪A2、路虎揽胜、特斯拉等中高端车型上[3]。为实现车身减轻质量且考虑到造型、设计和性能等方面要求,车身用铝型材断面多设计成薄壁、中空结构,尺寸精度和性能要求高。空心型材主要采用分流模挤压进行成形[4],与钢材相比,成形工艺不成熟,生产成本较高,目前,只在少数豪华车型和品牌上得到应用。

由于铸锭与工模具的摩擦以及焊合室死区的存在,铝合金分流模挤压过程中材料流动很不均 匀[5-6]。尤其在挤压复杂空心型材时,材料流动不均匀现象更为严重。由于型材断面本身通常为非对称性结构,与铸锭形状明显不一致,材料的流动行为相应表现为非对称性。另外,型材各部分的壁厚差异大,壁厚大的位置比表面小于壁厚薄的位置的比表面,变形程度小,材料的冷却速度较慢,导致该位置的挤压出口流速较快。材料的不均匀流动会使挤出型材产生很大的附加应力,导致缺陷和废品出现。为了克服挤压尺寸缺陷,使出模口型材横截面上的材料流速保持均匀一致,是获得良好产品尺寸精度的基本前提[7]。

挤压出口型材横截面流速不均匀和变形温差大,会严重影响产品的尺寸精度和性能。现有分流模设计方法主要依靠已有数据库和工程师设计经验,需要反复试模和修模,成品率较低[8]。如果一副模具的修试模次数超过5次,成本将非常昂贵。已有的理论解析法难以优化复杂挤压模具结构和工艺参数,而数值仿真具有计算精度和效率高、信息量大等优点,是挤压模具结构与工艺优化的最有效手段[9-11]。基于自适应网格技术的拉格朗日算法虽然能够对材料通过模具的瞬态全过程进行分析和跟踪[12-13],但对于焊合室内焊缝的自接触问题通常无能为力,计算过程网格畸变严重,需要不断进行重划分,求解时间长,只适合于实心型材和简单对称的空心型材,很难在工业型材分流模挤压进行推广应用。而任意拉格朗日-欧拉算法的计算中,网格与物质分离,在空间保持不动,同时在边界运动的处理上引入拉格朗日算法的优点,可以解决型材分流模挤压过程的焊合问题,同时求解时间快[14-15]。采用任意拉格朗日-欧拉算法可以准确分析型材分流模挤压过程的材料流动、变形温升和焊合行为。

XUE等[16]采用田口试验方法和有限元技术定量研究了铸锭和分流孔引导角、焊合室深度和分流桥结构形式对多孔分流模挤压铝型材过程材料流动平衡的影响。ZHANG等[17]研究阻流块对薄壁空心铝型材挤压出口横截面流速均匀性的影响规律,并提出了阻流块的基本设计原则。PAN等[18]研制了一种铝合金大型空心型材的弧形入口分流模结构,并系统研究了入口结构对金属流动和模具应力载荷的影响。GUAN等[19]分析了圆管四种不同分流孔数目模具的材料流动行为和模具强度,得出三孔分流模的出口流速分布更为均匀,模具寿命更高。LIU等[20]采用基于ALE算法,对大型轨道车体型材挤压过程进行了数值模拟,通过对二级焊合室、引流槽及工作带进行优化设计,将型材挤出横截面的流速差控制在合理的范围内。SUN等[21]采用响应面法和遗传算法相结合的优化技术对空调冷凝管型材的二级导流室形状进行优化设计,型材出口流速均方差减小到0.29 mm/s。ZHAO等[22]采用拉丁超立方实验设计进行采样,以Kriging法建立近似模型,建立以挤压出模口型材截面流速均方差、模具最大应力和模芯最大变形量为目标的优化模型;采用遗传算法求解,实现了分流孔入口角度、模孔位置和焊合室高度的优化设计。已有研究成果对空心型材分流模挤压材料流动行为研究提供了借鉴,但未见有空心型材内部加强筋减薄或焊缝开裂等缺陷形成机理及流动行为精确控制的相关研究报道。

型材断面设计复杂度越高,挤压变形的不均匀性越显著,出模口横截面流速均匀性就越难控制,型材就越容易产生壁厚减薄、扭拧以及裂纹等缺陷,使一次挤压成功率较低。本文作者以汽车防撞梁为研究对象,为解决挤压试模出现的内加强筋壁厚严重减薄甚至拉裂等缺陷,采用任意拉格朗日-欧拉算法建立型材分流模挤压有限元模型。基于挤压出模口型材横截面流速均方差和焊合压力分析揭示型材挤压试模缺陷的形成机理。为了实现挤压出模口型材横截面流速均匀性的精确控制,提出模具结构多步优化设计方法,并对初始和优化后的分流模开展材料流动行为、出口横截面温度分布及焊合压力对比分析。最后,采用优化后的模具结构进行挤压试模,验证型材挤压尺寸的精度和焊合性能的好坏。研究结果对空心型材多孔分流模挤压模具的优化设计提供指导意见。

1 型材多孔分流模设计与虚拟试模技术

1.1 分流模设计与挤压试模缺陷

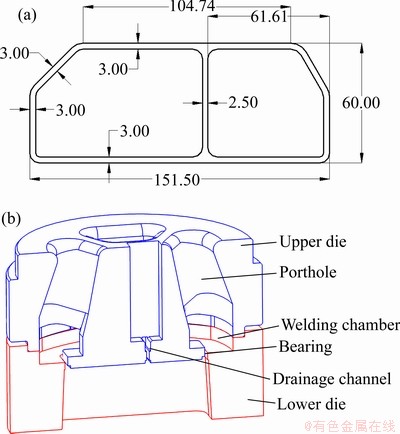

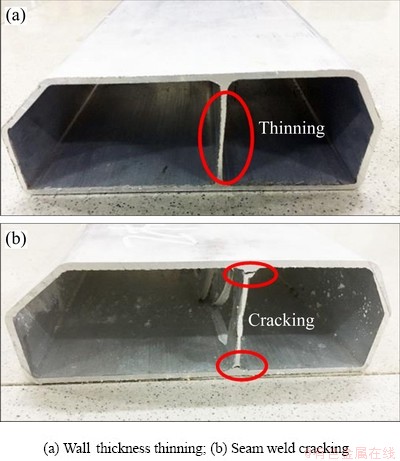

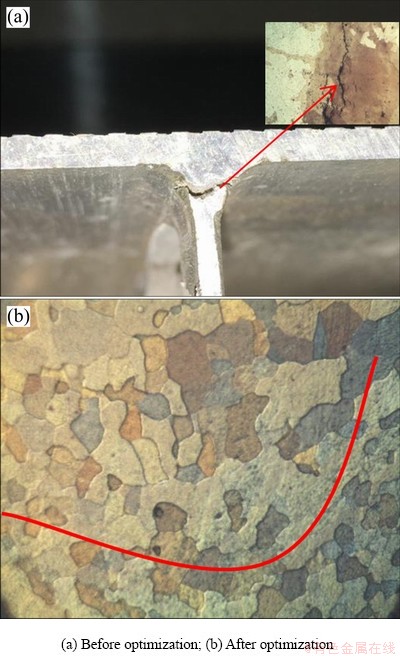

图1所示为研究的车身铝型材截面形状和设计的分流模,挤压试验在1800 t的卧式挤压机上进 行。为降低挤压力同时提升金属材料在分流模中流动的均匀性,型材外轮廓四个分流孔都进行宽展设计,同时上模在内加强筋部位的正上方开设一个方形分流孔,对该部位直接供料。上模中分流桥的宽度为8 mm,形状为水滴式,倒角为25°,圆角半径为3 mm。焊合室由上、下模焊合室构成,高度分别为7和15 mm。内加强筋位置处开设的引流槽宽度为6 mm,高度为12 mm。图2所示为挤压厂家初次试模时该型材出现的典型缺陷。由图2可知,型材内加强筋位置出现严重壁厚减薄,且内加强筋与上下腹边交接的焊缝位置在挤压过程中出现拉裂。

图1 空心型材截面尺寸和挤压分流模初始设计方案

Fig. 1 Cross-section shape of hollow profile(a) and initial design scheme of extrusion porthole die(b) (Unit: mm)

图2 型材挤压试模典型缺陷

Fig. 2 Typical defects of profile in extrusion tests

1.2 有限元建模技术

1.2.1 网格模型

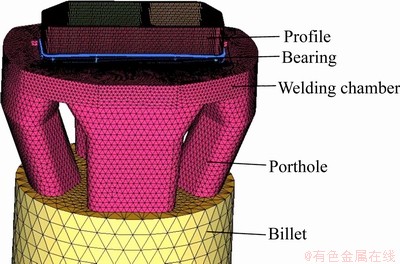

提取材料在挤压筒和分流模中流经的区域,导出Step几何格式,并导入到挤压有限元模型前处理软件Hypermesh,将几何模型切割成自由面、工作带、焊合室、分流孔和铸锭等6个模块,以根据挤压的变形特点,划分出高质量的网格。对于稳态分析,需满足挤出型材自由面的长度是模具工作带长度的3倍,铸锭的长度是挤压筒内径的2倍。为保证挤压材料不同网格部分的连续性,模型网格划分的基本原则是由小到大,划分顺序为工作带→自由面→焊合室→分流孔→铸锭。为提高求解精度和计算效率,挤出型材自由面和工作带划分为五面体网格,铸锭、焊合室和分流孔则划分为四面体网格。在型材横截面最薄处保证至少有四个自由节点,网格尺寸大约为型材最小壁厚的1/5,沿挤压方向的网格长宽比要小于3。其他区域的网格大小以工作带位置为基准,如焊合室的单元尺寸是工作带的5倍,分流孔的单元尺寸是焊合室的2~3倍,而铸锭的单元尺寸是分流孔的3~5倍。网格划分完成后,总的网格数量为562884,单元最小尺寸为0.5 mm,最小纵横比为2.25,最小角度为10.58°,满足单元质量要求。图3所示为所建立的型材多孔分流模挤压有限元稳态模型。

图3 挤压有限元模型网格划分

Fig. 3 Mesh generation of finite element model in porthole die extrusion

1.2.2 材料本构方程

铝合金挤压数值模拟中,通常假设材料是不可压缩黏塑性非牛顿流体。铝合金在热变形过程中呈现与高温蠕变过程一样的特征,即都存在热激活过程。为此,SELLARS等[23]建立了一种基于变形激活能Q和温度T的双曲正弦本构模型,并引入Arrhenius关系来描述铝合金的热激活稳态变形行为,其材料本构方程如下式所示。

(1)

(1)

(2)

(2)

式中: 为材料流动应力;Z为Zener-Hollmon参数;

为材料流动应力;Z为Zener-Hollmon参数; 是应变速率;A、

是应变速率;A、 、n为与温度无关的常数;R为气体常数,8.31 J/(mol·K);T为热力学温度,K;Q为变形激活能,J/mol,表示材料热加工过程加工硬化和温升软化之间的平衡关系。基于材料热压缩试验数据求出6063铝合金材料的本构模型相关参数分别为A=5.91×109 s-1,Q=1.416×105 J/mol,

、n为与温度无关的常数;R为气体常数,8.31 J/(mol·K);T为热力学温度,K;Q为变形激活能,J/mol,表示材料热加工过程加工硬化和温升软化之间的平衡关系。基于材料热压缩试验数据求出6063铝合金材料的本构模型相关参数分别为A=5.91×109 s-1,Q=1.416×105 J/mol, =4×10-2 m2/N,n=5.385。

=4×10-2 m2/N,n=5.385。

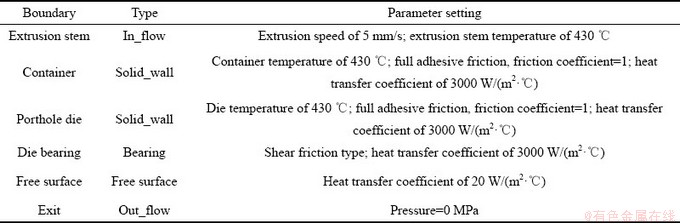

1.2.3 摩擦和热边界条件

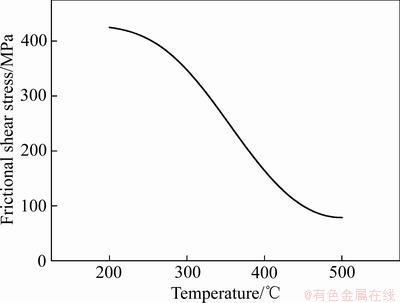

表1所示为型材分流模挤压过程中材料不同部位的接触界面边界条件设置。其中直接与工模具接触的界面有挤压垫、挤压筒、模具以及工作带。摩擦是影响挤压材料流动和变形温升的重要因素[24]。国内外大量学者普遍研究认为在高温挤压条件(大于450 ℃),挤压垫、挤压筒、模具位置界面摩擦是全黏着摩擦类型,可以较好地表征接触界面的黏铝行为,在有限元仿真中摩擦因数取值为1,能够得到足够的精度;模具工作带位置的摩擦较为复杂,静水压力从入口到出口逐渐减少为0,从入模口到出模口由全黏着摩擦向滑动摩擦逐渐过渡,且摩擦因数沿工作带长度方向不是恒定的,单纯采用摩擦因数来描述是不合适的[25]。因此,工作带位置的摩擦边界条件采用短距离球盘摩擦试验建立的剪切摩擦应力模型来等效表征。通过TCL语言二次开发把不同温度条件下单位面积的摩擦应力变化曲线(见图4)输入到仿真软件的边界条件中。挤压过程中材料与模具、外界环境的换热对金属流动、挤压温升也具有重要影响。其中挤压筒、模具与材料界面之间的换热系数为3000 W/(m2·℃)[26],挤出型材与外界环境的换热系数为20 W/(m2·℃)。

图4 稳态剪切摩擦应力随温度的变化

Fig. 4 Change of steady shear friction stress with temperature

1.3 挤压缺陷产生机理与仿真模型验证

为准确描述挤压出模口型材横截面上材料流速的均匀程度,引入流速均方差 (SDV)作为衡量型材挤压金属流动均匀性的评价指标,其定义为

(SDV)作为衡量型材挤压金属流动均匀性的评价指标,其定义为 。vi为型材横截面上第i个节点在挤压方向上的材料流速;

。vi为型材横截面上第i个节点在挤压方向上的材料流速; 和n分别为横截面的平均材料流速和总的节点数。流速均方差越小,挤压出模口的材料流速越均匀。

和n分别为横截面的平均材料流速和总的节点数。流速均方差越小,挤压出模口的材料流速越均匀。

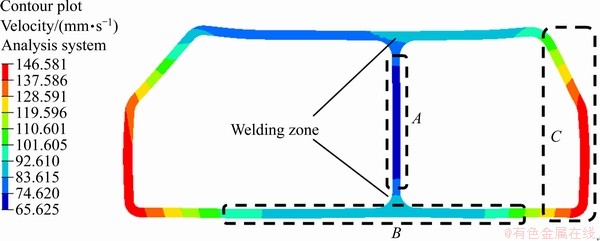

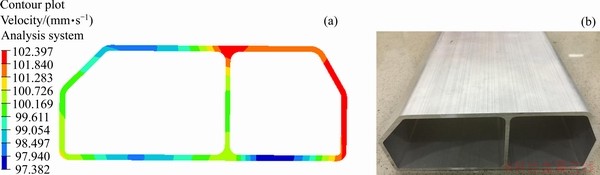

图5所示为稳态挤压时出模口型材横截面上沿挤压方向的速度分布。由图5可知,模具初始设计方案,型材出口横截面上的材料流速分布严重不均匀,流速均方差 =23.75 mm/s。型材两端C区域挤出速度最快,平均流速为125 mm/s,最大值为146.58 mm/s;上下直端面B区域材料流速次之,平均流速为93 mm/s;内加强筋位置A区域材料流速最小,最小值为65.62 mm/s,平均流速为75.76 mm/s。根据理论分析,挤压出模口横截面的平均流速

=23.75 mm/s。型材两端C区域挤出速度最快,平均流速为125 mm/s,最大值为146.58 mm/s;上下直端面B区域材料流速次之,平均流速为93 mm/s;内加强筋位置A区域材料流速最小,最小值为65.62 mm/s,平均流速为75.76 mm/s。根据理论分析,挤压出模口横截面的平均流速 (

( 为挤压比,v0为挤压杆速度),计算出平均流速

为挤压比,v0为挤压杆速度),计算出平均流速 =100 mm/s。B区域材料流速接近理论值,C区域和A区域材料流速偏离理论值较大,主要是由于A区域的材料供应明显不足,结果A区域出现内加强筋壁厚严重减薄或挤不出来。

=100 mm/s。B区域材料流速接近理论值,C区域和A区域材料流速偏离理论值较大,主要是由于A区域的材料供应明显不足,结果A区域出现内加强筋壁厚严重减薄或挤不出来。

表1 挤压仿真分析中接触边界条件

Table 1 Contact boundary conditions in extrusion simulation

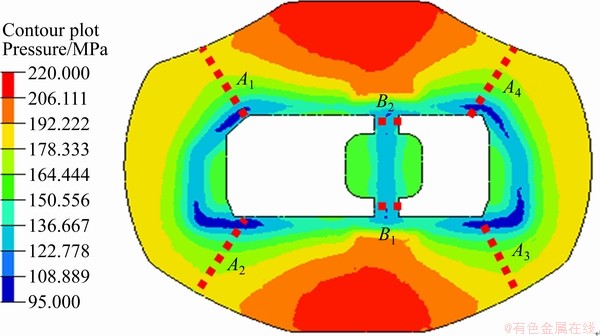

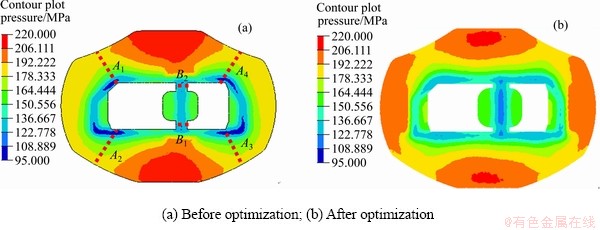

在连续挤压过程中,由于B区域和C区域的材料流速明显高于A区域,导致A区域与B区域的交界面会产生强烈的附加拉应力。同时,A区域与B区域的交界面处于分流桥下面,分流孔的材料在此交汇形成焊缝。挤压焊缝是影响型材力学性能的关键因素,主要由焊合室内的焊合压力和材料流动应力综合控制。DONATI等[27]和LI等[28]认为焊合压力与流动应力的比值越大,焊缝质量越好。AKERET[29]和DONATI等[30]通过仿真分析和试验验证,焊合压力与流动应力比值至少达到3倍以上,才能获得良好的焊缝质量。图6所示为焊合室焊合压力分布云图。由图6可知,提取焊缝位置的焊合压力,其中中间内加强筋B1和B2位置的焊合压力值为110.2 MPa,焊合压力与流动应力比值为2.97,小于3。由于焊缝处材料的强度小于基体材料的强度,进一步加剧材料在焊缝交界面处断裂。由图5还可知,C区域材料流速高于B区域,导致型材两端材料有向中心内凹的趋势。

通过与型材实际挤压试模的缺陷(见图2)对比可知,仿真结果与挤压试模的缺陷吻合一致,表明本文所建立的边界条件和仿真分析模型能较好地反映出实际挤压试模暴露出的问题。由于型材横截面材料流速的不均匀严重影响型材挤出后的尺寸精度和焊缝质量,有必要对模具结构进行优化设计。

图5 挤压出模口型材横截面上沿挤压方向的速度分布

Fig. 5 Velocity distribution along extrusion direction on cross-section of profile at die exit

图6 焊合室内焊合压力分布

Fig. 6 Welding pressure distribution in welding chamber

2 挤压出模口型材横截面流速精确控制方法

2.1 优化分流孔与导流槽

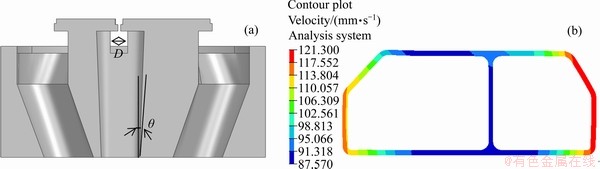

通过对模具初始设计方案出模口型材横截面的流速分析,可知内加强筋位置流速过慢,供料严重不足。为平衡金属流速,首先采用修改分流孔和导流槽结构来控制材料通过分流模中的流动均匀性。分流孔形状、数目和大小及其在上模中的分布,对于调控材料流速、促进焊合性能和降低挤压载荷具有重要作用。分流孔应尽量布置在型材挤压困难的部位,对于日字形型材来说,型材的内加强筋材料流动较慢。分流孔在布置时应正对着内加强筋位置,以便材料能直接充填进去,减小流动阻力。同时,分流孔应尽量设计成宽展方式,扩大对流动慢部位的材料供应量。导流槽是内加强筋能否充填完整的关键因素,导流槽设置的目的是增加从分流孔流出的金属在加强筋位置的汇聚量,最大程度保证该部位充满。导流槽设计的数目应该与加强筋的数目保持一致,截面通常设计成长方形或梯形。为了不浪费初始模具,节省开发成本和缩短开发周期,首先对内加强筋直接供料的中间分流孔设计成诱导形式,角度 为1.8°,同时对导流槽宽度D扩大10 mm(见图7(a))。由图7(b)可知,与初始方案相比,型材截面的最大最小速度差减小,最大流速为121.3 mm/s,下降5.3%;最小流速为87.57 mm/s,增大33.45%;出口流速均方差

为1.8°,同时对导流槽宽度D扩大10 mm(见图7(a))。由图7(b)可知,与初始方案相比,型材截面的最大最小速度差减小,最大流速为121.3 mm/s,下降5.3%;最小流速为87.57 mm/s,增大33.45%;出口流速均方差 显著下降,值为11.74 mm/s。型材内加强筋位置材料的供给量增大,速度得到显著提高,与上下腹边的速度基本一致。

显著下降,值为11.74 mm/s。型材内加强筋位置材料的供给量增大,速度得到显著提高,与上下腹边的速度基本一致。

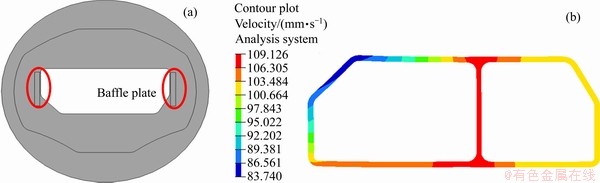

2.2 增添阻流块

阻流块是一种有效的调控分流模材料流速的方法,采用阻流块不需要重新开模,修模过程也简单可行。阻流块的设计参数包括布置位置和个数、截面形状、宽度、高度以及与模孔之间的距离。首先根据出模口型材截面流速分布确定在下模的布置位置和数目,然后对截面形状和宽度进行优化,最后优化其高度和到模孔的距离。经过分流孔与导流槽优化以后的型材中间部位流速分布较为均匀,两端流速相对较大。因此,为进一步调整流速分布,在型材两端分别添加一个阻流块,增加其材料流动的阻力,其位置分布和尺寸如图8(a)所示。阻流块的截面形状为长方形,宽度为6 mm,高度为5 mm,离模孔入口的距离为0.5 mm。由图8(b)可知,添加阻流块后,挤压出模口型材截面上的流速均匀性进一步提高,流速均方差SDV由11.74 mm/s下降到7.92 mm/s,相比初始方案下降了66.65%,内加强筋部位的材料流速得到显著提高。

图7 上模分流孔和导流槽优化设计示意图及出模口型材横截面流速分布

Fig. 7 Schematic diagram of optimization design of portholes in upper die and drainage channels(a) and cross-sectional velocity distribution at die exit(b)

图8 增添阻流块示意图和出模口型材横截面流速分布

Fig. 8 Schematic diagram of adding baffle plate(a) and cross-sectional velocity distribution at die exit(b)

2.3 基于Kriging近似模型和多岛遗传算法的工作带长度精细优化

2.3.1 设计变量与优化目标的确定

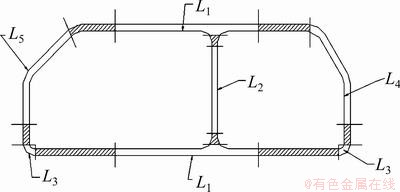

前面两种优化方案从宏观上对材料出口流速的均匀性进行了有效调控,但仍达不到精细控制,需要进一步采用调整工作带长度来保证。工作带是调整金属在分流模中流动的最后一个关键因素。工作带设计不当,型材截面上各部分流出模孔的速度不一致,挤压型材会产生壁厚减薄、扭拧、弯曲和平面间隙大等缺陷。工作带阻碍材料在分流模具中的流动,越长产生的摩擦阻力越大,使该处的静水压力增大,迫使材料向阻力小的模孔部位流动,从而使出模口型材截面上的材料流速趋于均匀。确定工作带长度时,需要综合考虑模孔位置、型材壁厚、分流孔和分流桥的布置及尺寸等因素的影响。

对工作带已有的优化研究大多是根据截面流速差进行人工调整,由于工作带对材料流动影响敏感,人工调整方法优化时间长,且难以对材料流动实现精确控制。为了获得最优的工作带长度分布,本文提出一种基于Kriging近似模型和多岛遗传算法的工作带长度智能优化方法,达到精确控制出模口型材截面流速。由于工作带主要靠增加或减小摩擦力来调节金属出口的流动阻力,工作带长度的变化同时会带来挤压力和型材横截面温差的变化。因此,本文以型材出口截面流速均匀差SDV最小为优化目标,同时约束截面相对温差Trd小于3.95%,稳态挤压力F小于1338 t。优化的工作带长度变量设计由L1~L5构成,图9所示为入模口的工作带长度分布图。整个优化问题定义如下:

Variable: L1, L2, L3, L4, L5

Minimize: SDV(L1, L2, L3, L4, L5)

Subject to constraints:

Trd(L1, L2, L3, L4, L5)≤3.95%;

F(L1, L2, L3, L4, L5)≤1138 T (3)

Within ranges:

6.5 mm≤L1≤8.5 mm; 5.5 mm≤L2≤7.0 mm;

6.0 mm≤L3, L4, L5≤8.0 mm

图9 模具工作带分布和优化变量定义

Fig. 9 Distribution of die bearings and definition of optimization variables

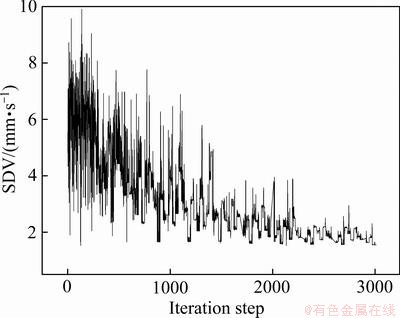

2.3.2 拉丁超立方试验设计

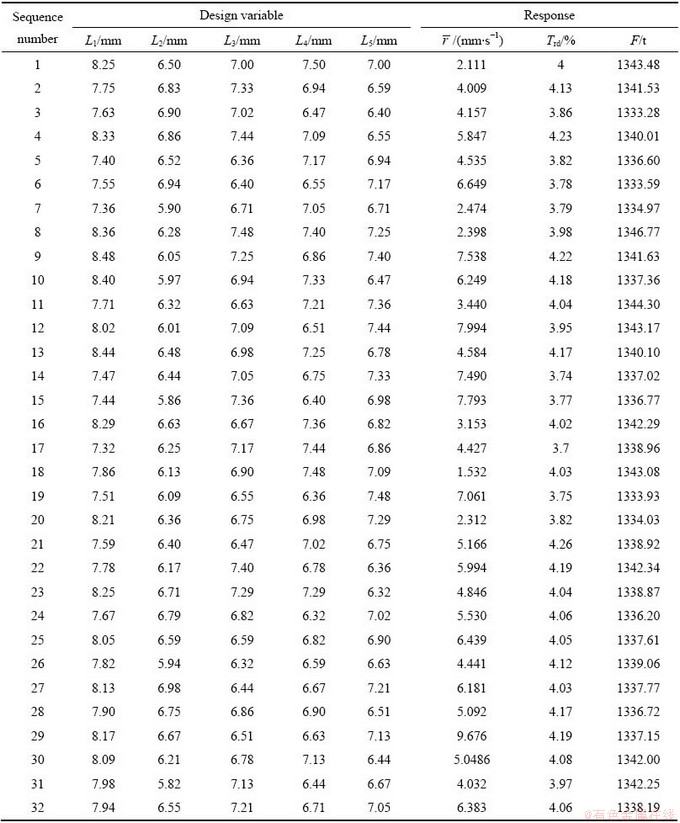

拉丁超立方技术是一种基于随机数学理论的均匀样本点生成的采样方法,适合于大型设计空间样本点的获取。该方法所有因子的试验空间都被均匀划分,且水平数相同,同时,所有因子的单个水平只研究一次。由于每个因子和水平都可以获得均匀利用,获得的样本点能够相对均匀地布满整个设计空间,以较少的试验规模体现设计空间的特性。采用拉丁超立方试验设计方法,得到不同工作带长度下的32组样本点数据。根据每个样本点数据的差异,更新型材挤压仿真模型中对应位置的工作带长度,并提交HyperXtrude软件平台求解,从而获得不同方案下的型材截面流速均方差。表2所示为不同工作带长度的拉丁超立方采样分布和试验结果。

2.3.3 Kriging近似模型建立

根据已有样本点数据采用近似模型进行拟合,并用来预测设计空间其他点的响应,可以大幅度提高优化求解效率。Kriging近似模型基于统计学理论,以已有样本点数据的动态构造为基础,充分考虑到变量在空间内的相关特性,建立对象问题的近似函数关系来预测未知点。前人研究表明[31],Kriging近似模型在预测型材挤压过程中的材料流速均方差和挤压力等响应时具有较好效果。Kriging近似模型由两部分构成:参数模型和一个非参数随机过程,定义如下:

(4)

(4)

式中:在样本设计空间中, 为变量x的多项式函数,提供模拟的全局近似,即

为变量x的多项式函数,提供模拟的全局近似,即 的数学期望;

的数学期望; 为回归系数;而

为回归系数;而 提供模拟局部偏差的近似,即

提供模拟局部偏差的近似,即 的局部变化。

的局部变化。 的形式对预测精度不起决定性作用,一般情况下定义为常数。

的形式对预测精度不起决定性作用,一般情况下定义为常数。 服从正态分布,但是协方差非零,即

服从正态分布,但是协方差非零,即 不独立,但是同分布。它的协方差矩阵为

不独立,但是同分布。它的协方差矩阵为

(5)

(5)

式中: ,

, 是任意两个样本点

是任意两个样本点 和

和 的空间相关方程,它决定Kriging近似模型的预测精度;

的空间相关方程,它决定Kriging近似模型的预测精度; 为均方差;研究表明高斯相关函数具有较好的计算能力而在Kriging模型中被采用,形式定义如下:

为均方差;研究表明高斯相关函数具有较好的计算能力而在Kriging模型中被采用,形式定义如下:

(6)

(6)

式中: 为设计变量的个数;

为设计变量的个数; 为相关性参数。

为相关性参数。

表2 拉丁超立方采样分布和试验结果

Table 2 Sampling distribution of Latin Hypercube method and test results

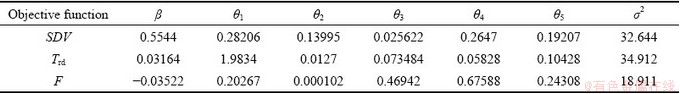

本文研究的Kriging近似模型中,回归方程采用常数表达式,相关函数模型采用高斯函数。基于表2中数据,建立工作带设计变量与3个响应目标之间的近似模型。表3所示为不同响应目标Kriging近似模型的拟合参数。由于Kriging近似模型严格的通过所选样本点,不存在拟合误差。因此,为了进一步验证Kriging模型对设计空间其他未知点的预测能力,在设计空间中随机再选取5个样本点,重新建立分流模挤压仿真模型,提交HyperXtrude软件平台求解,将获得的仿真结果与Kriging近似模型的预测值比较。由表4可知,仿真值与近似模型的预测值之间的误差都不超过8%,表明所建立的Kriging近似模型具有较高的预测精度。

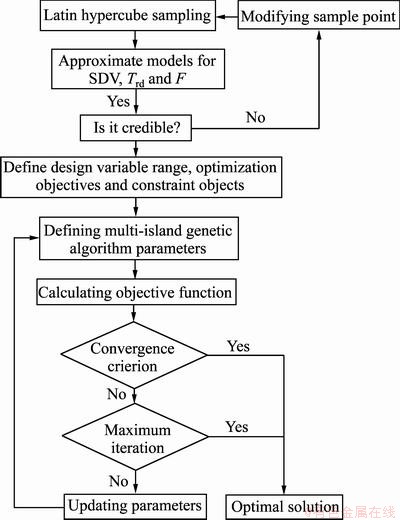

2.3.4 基于多岛遗传算法的寻优

遗传算法主要是模拟生物进化论的“优胜劣汰”原理和遗传学机理生物进化过程中的理论模型。由于传统遗传算法存在着收敛过早、求解精度低等问题。本研究采用多岛遗传算法对上述优化问题进行求解。多岛遗传算法本质上是对并行分布遗传算法的改进,与传统遗传算法比较,它的全局寻优能力和求解效率更好,优化流程如图10所示。子群规模设为30,岛(子群)的个数为10,总共进化的代数为10,交叉概率pc取值1.0,变异概率pm取值0.01,岛间迁移率取值0.01,迁移的间隔代数取值为5,参与竞赛的子群个体比率取值0.5,传递到下一代的优异个体数为1。

图10 多岛遗传算法寻优流程

Fig. 10 Flow chart of iterative optimization process by multi-island genetic algorithm

表3 响应目标的Kriging近似模型拟合结果

Table 3 Fitting results of response targets by Kriging approximate model

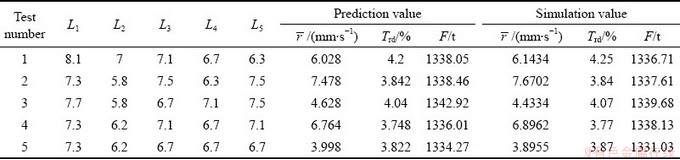

表4 Kriging近似模型预测结果与模拟结果对比

Table 4 Comparison of prediction results of Kriging approximate model prediction and FEM simulation results

图11所示为采用多岛遗传算法寻优出模口型材截面材料流速均方差的收敛曲线。由图11可知,迭代次数在1500次以前,目标函数流速均方差SDV的起伏较大。随着迭代次数的逐渐增加,流速均方差逐渐收敛,函数值的变化也趋于平缓,最后基本达到稳定。经过近3000次迭代,目标函数SDV达到最优值,为1.63 mm/s,其他指标也基本保持不变。优化后的工作带长度分别为:L1=7.67 mm,L2= 6.12 mm,L3=6.43 mm,L4=7.19 mm,L5=6.74 mm。

图11 多岛遗传算法寻优目标函数的收敛历程

Fig. 11 Convergence process of objective function by multi-island genetic algorithm

3 结果分析与实验验证

3.1 出口流速分析

图12所示为优化后的模具结构挤压出模口型材横截面的流速分布。优化后的型材截面流速均方差SDV=1.42 mm/s,与基于多岛遗传算法优化的SDV相比,误差仅为0.21 mm/s。型材截面上材料的最小与最大速度之差为5.02 mm/s。相比初始设计方案,优化方案挤压出模口型材截面流速分布均匀,有利于避免出现挤压尺寸超差问题。将所优化后的模具结构设计方案进行挤压试模,型材内加强筋位置没有出现因供料不足导致壁厚减薄和焊缝开裂等问题(见图13(b)),各边的壁厚尺寸误差小于0.1 mm。挤压尺寸满足汽车防撞梁在车身上的尺寸精度要求,证明了模具结构优化方法可靠性及优化结果的准确性。

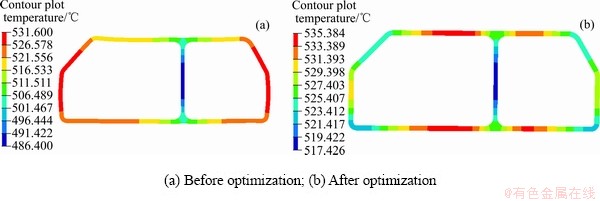

3.2 型材横截面温度分布

型材横截面上的温度分布决定了挤压产品组织与力学性能的均匀性。挤压过程中各项热流对铸锭和型材温度变化的影响因素主要有塑性变形热、摩擦热、金属与工模具之间的传热。其中,横截面温度的分布主要取决于材料通过分流模产生的塑性变形热和摩擦热。图13所示为优化前后的型材横截面温度分布。由图13可知,模具初始方案由于挤压过程材料塑性变形的严重不均匀,内加强筋位置由于材料供应不足,塑性变形热远低于其他部位,温度最低,其值为486.4 ℃。型材两端由于分流孔的扩展以及与模具界面强烈的摩擦作用,温度最高,达到531.6 ℃。型材最高最低温度差为45.2 ℃;对模具结构优化以后,材料的流动行为更好,塑性变形的均匀程度提高,达到了对挤压过程中材料塑性变形热和摩擦热的合理调控。优化后的型材内加强筋位置温度虽然还是最低,但上升到517.4 ℃,整个横截面的最大温差为18 ℃,相比初始设计方案降低27.2 ℃,大幅度改善了横截面温度的不均匀分布,温升分布的均匀性有利于获得一致的微观组织和力学性能。

图12 模具优化后型材横截面上流速分布和挤压型材质量

Fig. 12 Cross-sectional velocity distribution at die exit after die optimization(a) and extruded profile quality(b)

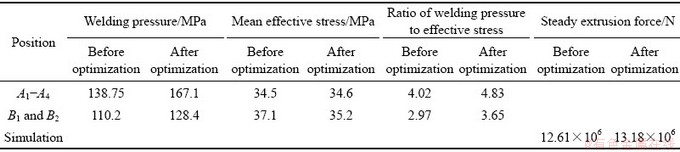

3.3 焊合质量分析

图14所示为模具结构优化前后的焊合室焊合压力分布云图。由图14可知,优化后型材6条焊缝处的焊合压力明显增大。通过提取型材外轮廓4条焊缝和内加强筋部位2条焊缝的焊合压力和流动应力,其结果见表5。由表5可知,模具初始设计方案,内加强筋焊缝位置的焊合压力小于外轮廓四条焊缝位置,其焊合压力与流动应力的比值为2.97,略小于3,可能获得不良的焊缝质量。经过优化后,内加强筋和外轮廓焊缝位置处的焊合压力分别提升16.5%,20.4%。焊合压力与流动应力的比值分别为3.65和4.83,超过临界值3,焊缝质量得到提高。这主要是由于增添阻流块和优化工作带长度,材料在焊合室内需要克服更大的阻力才能挤出模孔,使焊合压力增加。此外,模具初始方案和优化方案的挤压力分别为12.61×106 N和13.18×106 N,优化后挤压力增大。图15所示为优化前后内加强筋位置的焊缝组织。由图15可知,优化后,焊缝处焊合良好,晶粒基本为完全再结晶组织。

图13 型材横截面温度分布

Fig. 13 Temperature distribution on profile cross-section

图14 焊合室焊合压力分布

Fig. 14 Welding pressure distribution in welding chamber

表5 焊合室的焊合压力、有效应力和挤压力对比

Table 5 Comparisons of mean welding pressure, flow stress on welding chamber and steady extrusion force

图15 内加强筋部位的焊缝组织

Fig. 15 Microstructures of seam weld on internal stiffener

4 结论

1) 基于材料流速均方差和焊合压力评价揭示型材挤压内加强筋壁厚减薄和开裂的产生机理。原设 计的分流模挤压出模口型材横截面上的材料流速分布严重不均匀,流速均方差SDV大小为23.75 mm/s,内加强筋部位的流速显著小于其他部位,导致壁厚严重减薄,且焊缝处的焊合压力与流动应力比值过低,挤压流速差产生的强烈拉应力使焊缝位置产生拉裂。仿真分析结果与挤压试模结果吻合较好。

2) 为了实现对出模口型材横截面流速的均匀性控制,提出了“优化分流孔/引流槽、增添阻流块、基于Kriging近似模型和多岛遗传算法优化工作带”的模具结构多步优化设计方法。优化后出模口型材横截面流速均方差由23.75 mm/s减少到1.63 mm/s,型材壁厚尺寸误差小于0.1 mm。

3) 多步优化设计后,材料在分流模中的流动均匀性明显改善,使型材出口横截面温度分布均匀性以及焊缝质量均有显著提高。型材横截面的最大温差降低27.2 ℃,内加强筋处的焊合压力提升16.5%,焊缝基本为完全再结晶组织。

REFERENCES

[1] ZHANG Xin-ming, FENG Di, SHI Xing-kuan, et al. Oxide distribution and microstructure in welding zones from porthole die extrusion[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 765-772.

[2] LIU Zhi-wen, YI Jie, LI Shi-kang, et al. Study on inhomogeneous cooling behavior of extruded profile with unequal and large thicknesses during quenching using thermo-mechanical coupling model[J]. Transactions of Nonferrous Metals Society of China, 2020, 30(5): 1-16.

[3] 刘志文, 李落星. 轻量化构件弯曲短流程工艺研究现状与进展[J]. 中国有色金属学报, 2014, 24(8): 2003-2012.

LIU Zhi-wen, LI Luo-xing. Review of bending short process for lightweight component[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(8): 2003-2012.

[4] 薛江平, 黄东男, 左壮壮, 等. 挤压温度对6005A铝合金焊合区域显微组织和力学性能的影响[J]. 中国有色金属学报, 2018, 28(7), 1291-1298.

XUE Jiang-ping, HUANG Dong-nan, ZUO Zhuang-zhuang, et al. Influence of extrusion temperature on microstructure and mechanical properties of welding zone of 6005A aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(7): 1291-1298.

[5] 黄东男, 张志豪, 李静媛, 等. 焊合室深度及焊合角对方形管分流模挤压成形质量的影响[J]. 中国有色金属学报, 2010, 20(5): 954-960.

HUANG Dong-nan, ZHANG Zhi-hao, LI Jing-yuan, et al. Influences of welding chamber depth and welding angle on forming quality of extrusion of square tube by porthole die[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 954-960.

[6] 侯文荣, 张志豪, 谢建新, 等. 基于质点逆向追踪的铝合金空心型材横断面温度的不均匀性[J]. 中国有色金属学报, 2015, 25(7): 1798-1807.

HOU Wen-rong, ZHANG Zhi-hao, XIE Jian-xin, et al. Temperature inhomogeneity on cross section of Al alloy hollow profile based on reverse point tracking method[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1798-1807.

[7] YI Jie, WANG Zhen-hu, LIU Zhi-wen, et al. Fe analysis of extrusion defect and optimization of metal flow in porthole die for complex hollow aluminium profile[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(10): 2094-2101.

[8] GAGLIARDI F, CIANCIO C, AMBROGIO G. Optimization of porthole die extrusion by Grey-Taguchi relational analysis[J]. The International Journal of Advanced Manufacturing Technology, 2018, 94(1/4): 719-728.

[9] 张保军, 杨 合, 郭良刚, 等. AZ31镁合金薄壁管挤压分流孔轴向倾角影响规律的仿真模拟[J]. 中国有色金属学报, 2012, 22(10): 15-21.

ZHANG Bao-jun, YANG He, GUO Liang-gang, et al. Numerical simulation of effect rules of porthole axial angle on extrusion process of AZ31 mg alloy thin-walled tube[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 15-21.

[10] 侯文荣, 张志豪, 谢建新, 等. 铝合金空心型材分流模挤压成形全过程温度场的数值模拟[J]. 中国有色金属学报, 2013, 23(10): 2769-2778.

HOU Wen-rong, ZHANG Zhi-hao, XIE Jian-xin, et al.Numerical simulation of temperature field during whole extrusion process of aluminum hollow profile with porthole die extrusion forming[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 2769-2778.

[11] HUA Tian-run, YAO Yao, LI Hao-ran, et al. Study on the numerical simulation application in the design and optimization of aluminum extrusion forming mold[J]. Hydromechatronics Engineering, 2016, 44(12): 88-95.

[12] 刘 鹏, 谢水生, 程 磊, 等. 导流室设计对薄壁铝型材挤压出口速度的影响[J]. 塑性工程学报, 2010, 17(4): 27-32.

LIU Peng, XIE Shui-sheng, CHENG Lei, et al. Effect of pocket designs on exit velocity during thin-walled aluminium profile extrusion[J]. Journal of Plasticity Engineering, 2010, 17(4): 27-32.

[13] 林高用, 陈兴科, 蒋 杰, 等. 铝型材挤压模工作带优 化[J]. 中国有色金属学报, 2006, 16(4): 561-566.

LIN Gao-yong, CHEN Xing-ke, JIANG Jie, et al. Optimization of die bearing for aluminum profile extrusion die[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(4): 561-566.

[14] HE Zhao, WANG He-nan, WANG Meng-jun, et al. Simulation of extrusion process of complicated aluminium profile and die trial[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(7): 1732-1737.

[15] ZHUANG Xin-cun, ZHAO Zhen, XIANG Hua, et al. Simulation of sheet metal extrusion processes with Arbitrary Lagrangian-Eulerian method[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(5): 1172-1176.

[16] XUE X, VINCZE G, PEREIRA A, et al. Assessment of metal flow balance in multi-output porthole hot extrusion of AA6060 thin-walled profile[J]. Metals, 2018, 8(6): 462-476.

[17] ZHANG C, ZHAO G, SUN X, et al. Optimization design of baffle plates in porthole die for aluminium profile extrusion[J]. Journal of Materials Design and Applications, 2011, 225(L4): 255-265.

[18] PAN J Y, XUE X. Numerical investigation of an arc inlet structure extrusion die for large hollow sections[J]. International Journal of Material Forming, 2008, 11(3): 405-416.

[19] GUAN Y J, ZHANG C S, ZHAO G Q, et al. Design of a multihole porthole die for aluminum tube extrusion[J]. Materials and Manufacturing Processes, 2012, 27(2): 147-153.

[20] LIU P, XIE S S, CHENG L. Die structure optimization for a large, multi-cavity aluminum profile using numerical simulation and experiments[J]. Materials & Design, 2012, 36: 152-160.

[21] SUN X M, ZHAO G Q, ZHANG C S, et al. Optimal design of second-step welding chamber for a condenser tube extrusion die based on the response surface method and the genetic algorithm[J]. Materials and Manufacturing Processes, 2013, 28(7): 823-834.

[22] ZHAO G Q, CHEN H, ZHANG C S, et al. Multiobjective optimization design of porthole extrusion die using Pareto-based genetic algorithm[J]. The International Journal of Advanced Manufacturing Technology, 2013, 69(5/8): 1547-1556.

[23] SELLARS C M, TEGART W J M G. Hot workability[J]. International Metallurgical Reviews, 1972, 17(1): 1-24.

[24] WANG S Q, YUAN L H, LIANG S. Effects of the friction coefficient on cold extrusion process of axial symmetry parts[J]. Machine Tool & Hydraulics, 2018,46(12): 71-75.

[25] 刘志文, 李落星, 张 明, 等. 铝合金热挤压过程中界面摩擦的研究进展[J]. 中国有色金属学报, 2017, 27(7): 1311-1322.

LIU Zhi-wen, LI Luo-xing, ZHANG Ming, et al. Research progress of interface friction in hot extrusion of aluminium alloys[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(7): 1311-1322.

[26] LIU Z W, LI L X, WANG G, et al. Analysis and improvement of material flow during extrusion process using spreading pocket die for large-size, flat-wide, and multi-ribs profile[J]. The International Journal of Advanced Manufacturing Technology,2020, 107(3/4): 1115-1129.

[27] DONATI L, TOMESANI L. The prediction of seam welds quality in aluminum extrusion[J]. Journal of Materials Processing Technology, 2004, 153: 366-373.

[28] LI L, ZHANG H, ZHOU J, et al. Numerical and experimental study on the extrusion through a porthole die to produce a hollow magnesium profile with longitudinal weld seams[J]. Materials & Design, 2008, 29(6): 1190-1198.

[29] AKERET R. Properties of pressure welds in extruded aluminium alloy sections[J]. Journal of the Institute of Metals, 1972, 10: 202-207.

[30] DONATI L, TOMESANI L. The effect of die design on the production and seam weld quality of extruded aluminum profiles[J]. Journal of Materials Processing Technology, 2005, 164: 1025-1031.

[31] ZHAO G Q, CHEN H, ZHANG C S. Multiobjective optimization design of porthole extrusion die using Pareto-based genetic algorithm[J]. The International Journal of Advanced Manufacturing Technology, 2013, 69(5/8): 1547-1556.

Defects formation mechanism and precision control of exit flow velocity in porthole die extrusion of hollow thin-walled aluminum profile

LIU Zhi-wen1, 2, LI Luo-xing2, FU Chun-ming1, HE Hong2, LI Bi-wen1

(1. School of Mechanical Engineering, University of South China, Hengyang 421001, China;

2. State Key Laboratory of Advanced Design and Manufacture for Vehicle Body, Hunan University, Changsha 410082, China)

Abstract: Taking the automobile collision beam as a typical research object, the formation mechanism of extrusion defects, such as wall thickness thinning and cracking, on internal stiffener of profile in porthole die extrusion was revealed. The method for accurately controlling the uniformity of cross-sectional velocity at die exit was proposed. Firstly, an accurate steady-state finite element model for simulating the porthole die extrusion process of profile was established based on the arbitrary Lagrangian-Eulerian formulation. Then, the formation mechanism of extrusion defects was analyzed based on the evaluation of material flow velocity standard deviation (SDV) at die exit and welding pressure. Finally, to solve the problem of the non-uniform velocity distribution, three steps of the die optimization were proposed, including optimization of portholes and drainage channels, introduction of baffle plates and optimizing the die bearings using Kriging approximation model and multi-island genetic algorithm. The results show that, after optimization, the SDV value in the cross-section of extrudate decreases from 23.75 mm/s to 1.63 mm/s. At the same time, the temperature uniformity on the cross-section of profile and seam weld quality are improved significantly. The maximum cross-sectional temperature difference is reduced by 27.2 ℃, the welding pressure is increased by 16.5%, and the grains of seam weld are basically completely recrystallized.

Key words: hollow thin-walled profile; porthole die; extrusion defects; multiple-step optimization; cross-sectional velocity control; seam weld quality

Foundation item: Project(52005244) supported by the National Natural Science Foundation of China; Project (18B285) supported by the Scientific Research Fund of Hunan Provincial Education Department, China; Project(2019JJ50510) supported by the Natural Science Foundation of Hunan Province, China

Received date: 2020-05-06; Accepted date: 2020-10-20

Corresponding author: LIU Zhi-wen; Tel: +86+734-88578031; E-mail: liuzhiwen1008@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(52005244);湖南省教育厅科研项目(18B285);湖南省自然科学基金资助项目(2019JJ50510)

收稿日期:2020-05-06;修订日期:2020-10-20

通信作者:刘志文,副教授,博士;电话:0734-88578031;E-mail:liuzhiwen1008@163.com