文章编号:1004-0609(2012)10-2713-07

AZ31镁合金薄壁管挤压分流孔轴向倾角

影响规律的仿真模拟

张保军1,杨 合1, 郭良刚1,石 磊1,郑文达2,谷瑞杰2,寇永乐2

(1. 西北工业大学 凝固技术国家重点实验室,西安 710072;

2. 中国重型机械研究院有限公司,西安 710032)

摘 要:基于开发的AZ31镁合金薄壁管分流挤压精确、高效的DEFORM-3D有限元模型,模拟揭示分流孔轴向倾角β对挤压力、焊合压力及模口处坯料金属流速均匀性的影响规律,并对β进行优化设计。综合考虑挤压力、材料利用率、焊缝焊合质量、管材尺寸精度及其应用环境等因素,获得该规格AZ31镁合金薄壁管分流挤压模具的合理分流孔轴向倾角取值范围为-5°~1°,最优分流孔轴向倾角为β≈ -5°(即内斜5°)。

关键词:AZ31镁合金;薄壁管;分流组合模;分流孔轴向倾角;数值模拟

中图分类号:TG376.9 文献标志码:A

Numerical simulation of effect rules of porthole axial angle on extrusion process of AZ31 Mg alloy thin-walled tube

ZHANG Bao-jun1, YANG He1, GUO Liang-gang1, SHI Lei1, ZHENG Wen-da2, GU Rui-jie2, KOU Yong-le2

(1. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China;

2. China National Heavy Machinery Research Institute Co., Ltd., Xi’an 710032, China)

Abstract: Based on the developed precise and efficient DEFORM-3D model of the porthole extrusion process for the thin-walled AZ31 Mg alloy thin-walled tube, the influence laws of porthole axial angle β on the extrusion load, welding pressure and the uniformity of billet flow rate at the die export were investigated and revealed by the comprehensive numerical simulations, and the value of β was optimized. In integrated consideration of the extrusion load, the material utilization rate, quality of welding area and profiles size accuracy, and taking the tube application environment into account, it is proposed that the optimum β is -5°-1°, the most suitable value of β is about -5° for the AZ31 Mg alloy thin-walled tube profile die.

Key words: AZ31 Mg alloy; thin-walled tube; porthole die; porthole axial angle; numerical simulation

基金项目:国家科技重大专项资助项目(2009ZX04005-031-11);“111”高等学校学科创新引智计划资助项目(B08040)

收稿日期:2011-09-04;修订日期:2012-05-25

通信作者:杨 合,教授,博士;电话:029-88495632;E-mail: yanghe@nwpu.edu.cn

随着现代工业技术的高速发展,分流组合模以其具有短行程生产长型材、用模具刚度保证管材尺寸精度、可进行连续挤压等优势,越来越被广泛地应用于塑性成形领域铝镁合金空心型材的挤压生产中[1-2],该模型是空心型材分流挤压工艺中最为关键的工装,不仅决定着产品的形状、大小、尺寸精度和表面状态,而且影响产品的组织与性能,对挤压过程起着十分重要的作用[3-4]。近年来,航空航天、国防军工等高端科技领域得到了快速发展,对高精度、高性能、优良电磁性能的异型薄壁管材的需求日益广泛而迫切,因此,研究分流组合模各个结构要素对分流挤压过程的影响规律对其进行优化设计,对于提高挤压型材质量具有重要意义。

作为坯料金属进入模具焊合腔的通道,分流孔各结构要素(包括分流孔轴向倾角β)的合理设计对于平衡金属流速、降低挤压力、促进金属的流动和焊合以及提高模具寿命等都具有非常重要的意义[5]。因此,国内外许多学者对于分流孔的形状、数目、分布位置及相关结构要素对挤压过程的影响规律以及优化设计进行了大量的试验和模拟研究[3-8],探索出各个结构参数与挤压成形各个场变量的关系,从而为分流模具设计提供了理论参考依据。然而,分流挤压过程是一个极其复杂的材料流动过程,难以采用实验方法进行定量研究[1],在研究过程中研究者往往人为地忽略分流孔轴向倾角对挤压工艺的影响,因此,分流孔轴向倾角对分流挤压工艺过程的影响规律并没有得到深入研究,因而分流孔轴向倾角设计依赖于经验,需要反复修模,导致产品质量和模具寿命难以得到进一步的提高[7],因此,迫切需要应用先进科研手段对此展开深入研究。随着计算机技术的飞速发展,数值模拟仿真技术由于可获取塑性成形过程中各种动态变量信息(应力、应变和速度等),能大幅降低研究成本、缩短产品开发周期,已成为塑性加工研究领域不可或缺的重要研究手段。

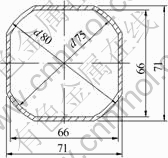

军用战地发射塔天线用薄壁管,其横截面形状及尺寸如图1所示,需要具有质地轻、电磁屏蔽性能优良等特点,吸引了大量研究人员将目光集中在密度低、电磁性能优良的镁合金材料如AZ31镁合金(国内牌号MB2)。但是,AZ31镁合金塑性成形窗口窄、对温度及挤压速度非常敏感,属于难变形合金种类,且该规格管材外径尺寸相对较大,管壁薄(相对壁厚m/D=0.031 3),分流组合模具内腔形状复杂,导致分流挤压成形过程中金属塑性变形异常剧烈、分流焊合尤为困难,这些均增加了获得高精度、高性能AZ31镁合金薄壁管的难度。因此,合理设计分流孔轴向倾角以达到降低挤压力、改善金属流动情况、提高焊缝焊合质量,在此薄壁管材挤压工艺过程中具有更为突出的作用。

图1 AZ31镁合金薄壁管材截面形状和尺寸

Fig. 1 Shape and sizes of cross-section of AZ31 Mg alloy thin-walled tube (mm)

基于上述背景,本文作者旨在利用有限元方法,通过单一改变分流孔轴向倾角β,模拟研究分流孔轴向倾角对AZ31镁合金薄壁管分流挤压过程的影响规律,为优化模具结构提供理论指导;综合考虑挤压力、焊合质量、管材尺寸精度等因素,对分流孔轴向倾角进行优化设计。

1 有限元模型的建立

基于DEFORM-3D平台,以军用战地发射塔天线用AZ31镁合金薄壁管分流挤压工艺过程为研究对象,在解决了几何与装配模型建立、材料模型建立、边界条件设定等关键技术的基础上,建立适用、可靠的AZ31镁合金薄壁管材分流挤压工艺过程的刚塑性有限元模型[9]。

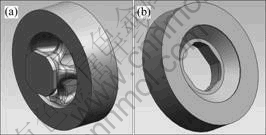

鉴于该规格管材形状对称性,分流组合模具选用四孔分流,分流孔断面形状为扇形。各有限元模型参数值如表1所列。根据表1中的几何模型建立的 AZ31镁合金异型薄壁管分流组合模几何模型如图2所示。

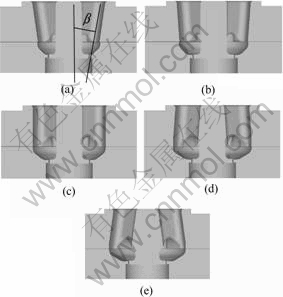

图2 分流组合模具几何模型

Fig. 2 Geometries of porthole dies: (a) Dividing die; (b) Welding die

采用数值模拟与理论分析相结合的方法,通过单一改变分流模分流孔轴向倾角,研究分析分流孔轴向倾角对挤压的影响规律。选取的分流孔轴向倾角β分别为-10°,-5°,0°,5°,10°(分流孔内斜为负值,分流孔外斜为正值)。图3所示为AZ31镁合金异型薄壁管分流组合模分流孔倾角示意图。

图3 分流模分流孔轴向倾角示意图

Fig. 3 Sketch map of porthole axial angle of porthole die: (a) -10°; (b) -5°; (c) 0°; (d) 5°; (e) 10°

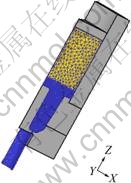

鉴于该规格管材及其分流组合模的对称性,取整体的1/8进行有限元建模,以提高计算效率,如图4所示,可以通过改变几何或者工艺参数,研究成形参数对挤压过程的影响规律,获得所需信息,为优化挤压模具或挤压工艺提供依据。

图4 挤压工艺的有限元模型

Fig. 4 FE model of extrusion for thin-walled AZ31 Mg alloy

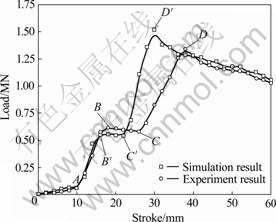

通过改变坯料和模具的几何模型,可使该AZ31镁合金薄壁管分流挤压有限元模型适用于其他空心类型材分流挤压成形过程的数值模拟。因此,为验证该有限元模型的可靠性,基于该有限元模型,采用与文献[12]相同的几何模型及成形条件,对AZ31镁合金矩形管分流挤压工艺过程进行了模拟分析,结果与文献[12]中试验结果吻合良好:挤压力峰值的模拟值和试验值误差小于13%,如图5所示,峰值出现的时刻不同是有限元几何模型与实际模具型腔有所差异造成的:峰值温度的模拟和试验误差小于6 ℃,稳定挤出阶段坯料金属峰值温度均在460~470 ℃之间。这些结果均证明本文作者采用的军用战地发射塔天线用AZ31镁合金薄壁管分流挤压有限元模型是适用、可靠的。

图5 模拟与实验的挤压力对比

Fig. 5 Comparison of extrusion load between simulation result and experiment one

表1 有限元模型参数设置

Table 1 FE model parameters used in this study

2 结果与讨论

2.1 分流孔对挤压过程的影响规律

2.1.1 挤压力

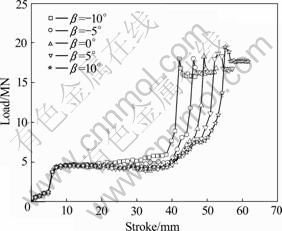

挤压力的大小对于模具寿命、设备吨位选取和挤压生产效率有着十分重要的影响。图6所示为不同分流孔轴向倾角时挤压力—行程曲线。由图6可以看出:1) 挤压力随行程的变化趋势不随分流孔轴向倾角的改变而改变。2) 随着分流孔的增大,挤压力峰值及稳定挤出阶段挤压力不断增大。这是因 为:焊合室内约束材料流动的Z向投影面积随分流孔轴向倾角的增大而增大(见图3),导致材料填充焊合室以及突破工作带时材料流动更加困难,挤压力有所增加。3) 分流孔轴向倾角越小、挤压力峰值出现越早,管材稳定挤出阶段开始越早。这是因为分流孔轴向倾角越小,分流孔及焊合室的模腔容积越小,需要填充的坯料金属越少(废料越少),金属突破工作带成形的时间越短,所以,挤压力峰值的出现也就越早。因此,选用较小的分流孔轴向倾角,不但可以降低挤压力,而且还可以提高坯料金属材料的利用率。

图6 不同分流孔轴向倾角时挤压力—行程曲线

Fig. 6 Load—stroke curves at different porthole axial angles

2.1.2 焊合压力

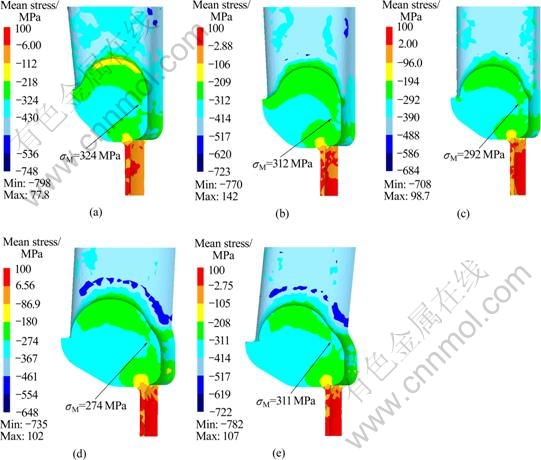

焊合面上的静水压应力是分流挤压过程中非常重要的成形指标,其大小直接影响型材焊缝质量:焊合面上的静水压应力值越大,焊合效果越好,所挤出的型材综合质量也就越好[13-14]。图7所示为不同分流孔轴向倾角下挤压成形阶段焊合面局部静水压应力云图。由图7可以看出:焊合面上有一个横向贯穿的高静水压应力区域,所有从分流孔经过焊合面进入工作带的金属质点必通过该区域;随着分流孔轴向倾角的增大,该焊合区域面积不断增加,分流的坯料金属焊合时间得到了延长,从而可以提高焊合质量。将该区域内最小静水压应力值定义为分流焊合挤压过程的焊合压力,其大小关系到焊合面金属质点是否能焊合及焊合质量的优劣,是评价分流焊合挤压工艺优劣最为重要的指标。

图7 不同分流孔轴向倾角下坯料焊合面局部静水压应力云图

Fig. 7 Mean stress on billet welding area at different porthole axial angles: (a) -10°; (b) -5°; (c) 0°; (d) 5°; (e) 10°

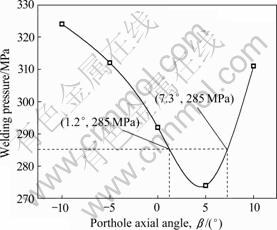

根据图7可以获得分流孔轴向倾角对焊合压力的影响规律,结果如图8所示。由图8可以看出:焊合压力随分流孔轴向倾角的增大先减小后增大,当β≈5°时,出现极小值。这是因为,一方面,分流孔轴向倾角的增大改变了分流金属的流动路径,4股分流的坯料趋于相互远离的方向流动,起到降低焊合压力的作用,另一方面,随着分流孔轴向倾角的增大,焊合室容积和焊合面面积均不断增大,延长了坯料金属在焊合室内的堆积时间,且焊合室内坯料金属突破工作带的局部挤压比也在不断增大,有利于增大焊合压力,所以,当β=5°时,焊合压力出现极小值。

图8 不同分流孔轴向倾角时的焊合压力

Fig. 8 Welding pressure at different porthole axial angles

2.1.3 模口处坯料金属流速均匀性

模具出口处金属流速不均匀容易导致型材发生扭拧、波浪、侧弯等常见缺陷,严重影响型材质量及尺寸精度,因此,保证产品断面上的各质点流出模孔工作带的速度均衡性,成为模具设计和维修遵循的基本原则。所以,必须合理设计模具结构以起到调节金属流速的作用,提高模具出口处的金属流速均匀性,进而提高型材质量和尺寸精度。为了有效地表示金属挤压时流动的不均匀性,以出口处速度场标准偏差Es值来衡量流速的均匀程度[15-16],其计算公式如下:

(1)

(1)

式中:N为模具出口处节点数目; 为规定平面上节点轴向速度;

为规定平面上节点轴向速度; 为规定平面上平均轴向速度。

为规定平面上平均轴向速度。

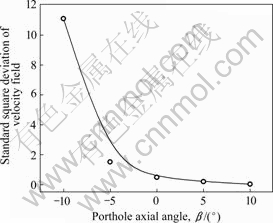

Es值越小,说明模口处坯料金属流动越均匀;Es值越大,说明模口处坯料金属流动越不均匀。图9所示为不同分流孔轴向倾角下模具出口处的金属流速均方差。由图9可以看出,模具出口处坯料金属流速均方差Es值随着分流孔轴向倾角的增大而减小,当β>-5°时,均方差减小,速度骤降。这是因为分流孔轴向倾角的变化改变了坯料金属从分流孔进入焊合室并从焊合室突破工作带的流动路径,从而影响金属流出工作带的速度均匀性。

图9 不同分流孔轴向倾角下模口处的金属速度场标准 偏差

Fig. 9 Standard deviation of velocity field at different porthole axial angles

2.2 分流孔轴向倾角优化

基于上述AZ31镁合金薄壁管分流挤压过程中分流孔轴向倾角对挤压力、焊合压力及模口处坯料金属流速均方差等指标的影响规律,对该规格管材分流组合模的分流孔轴向倾角进行优化设计。优化过程如下:

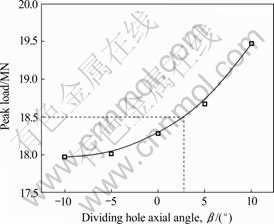

1) 采用20 MN挤压机进行生产,安全系数取1.08[9],挤压力峰值应小于20/1.08≈18.5 MN。图10所示为分流孔轴向倾角对挤压力峰值曲线。由图10可以看出,挤压力峰值随分流孔轴向倾角的增大而增大,且增大速度不断上升。所以,需控制β<2.5°,才能保证挤压力峰值小于18.5 MN。由图6可以看出,分流孔轴向倾角越小,挤压力峰值越小,且分流孔及焊合室的模腔容积越小,需要填充的坯料金属越少,因此,选用较小的分流孔轴向倾角,可以起到降低挤压力的作用,同时还可提高坯料金属材料的利用率。

图10 不同分流孔轴向倾角下的挤压力峰值

Fig. 10 Peak load at different porthole axial angles

2) LI等[17]认为焊缝质量主要取决于焊合压力与材料流动应力的比值,该值越大,焊缝质量越好。黄东男等[6]认为焊合压力需达到焊合面焊合工作温度、应变速率下金属屈服应力σs(焊合面处AZ31镁合金材料温度为380~400 ℃,等效应变速率为0.5~1 s-1,则σs≈50 MPa)的5.7 倍,即焊合压力应大于50×5.7= 285 MPa[9],才能保证挤压得到合格焊缝的管材。由图8可以看出,该规格AZ31镁合金薄壁管材分流挤压模具的分流孔轴向倾角应避免在1°~7.5°的范围内取值。

3) 由图9可以看出,分流孔轴向倾角的改变对于模口处坯料金属流速均方差有着重要影响:分流孔轴向倾角β越大,Es值越小,模口处坯料金属流速越均匀,越有利于提高型材尺寸精度和整体质量,而当β<-5°时,Es值随分流孔轴向倾角的减小而急剧增大,所以,分流孔轴向倾角应避免在-10°~-5°范围内取值。

综合考虑挤压力、焊合压力、模口处坯料金属流速均匀性的要求,可得到AZ31镁合金薄壁管材在20 MN挤压机上进行分流挤压的模具分流孔轴向倾角合理取值范围为-5°~1°。由于该战地发射塔天线用AZ31镁合金在实际应用过程中会受到相当大的径向及扭转载荷,对于其焊缝质量要求较高,所以,应在满足挤压力、焊合压力、流出速度均匀性等指标要求的基础上,提高管材分流挤压焊合压力为主要参考因素,尽量选取较小的分流孔轴向倾角(见图7)。因此,确定20 MN挤压机上挤压该规格军用占地发射塔用AZ31镁合金薄壁管分流挤压模具的最优分流孔轴向倾角为β≈-5°(内斜5°)。

3 结论

1) 随分流孔轴向倾角的增大,挤压力峰值以及稳定挤出阶段挤压力均增大;模具出口金属流速越均匀;分流孔及焊合室的模腔容积越大,导致废料增多,材料利用率降低;焊合压力随分流孔轴向倾角的增大先减小后增大,β=5°时出现极小值,焊合效果最差。

2) 综合考虑挤压力、材料利用率、焊缝焊合质 量、管材尺寸精度等因素,基于20 MN挤压机,获得该规格AZ31镁合金薄壁管分流挤压模具合理分流孔轴向倾角为-5°~1°;以提高管材焊缝焊合质量为优化目标,获得了最优分流孔轴向倾角β≈-5°(即内斜5°)。

REFERENCES

[1] 张 杨, 邓小民. 铝型材挤压成型过程有限元模拟及模具优化设计[J]. 有色金属加工, 2009, 39(3): 36-39.

ZHANG Yang, DENG Xiao-min. Numerical simulation of the extrusion process of aluminum profile and die structure optimization[J]. Nonferrous Metals Processing, 2009, 39(3): 36-39.

[2] 程 磊, 谢水生, 黄国杰, 和优锋. 焊合室高度对分流组合模挤压成形过程的影响[J]. 稀有金属, 2008, 32(4): 442-446.

CHENG Lei, XIE Shui-sheng, HUANG Guo-jie, HE You-feng. Effects of height of welding chamber on extrusion forming process of porthole die[J]. Chinese Journal of Rare Metals, 2008, 32(4): 442-446.

[3] 倪正顺, 帅词俊, 钟 掘. 热挤压模具热力耦合三维数值分析[J]. 中南大学学报: 自然科学版, 2004, 35(1): 86-90.

NI Zheng-shun, SHUAI Ci-jun, ZHONG Jue. Three-dimensional coupled thermal-mechanical numerical analysis of hot extrusion dies[J]. Journal of Central South University: Science and Technology, 2004, 35(1): 86-90.

[4] ARIF A F M, SHEIKH A K, QAMAR S Z. A study of die failure mechanisms in aluminum extrusion[J]. Journal of Materials Processing Technology, 2003, 134(3): 318-328.

[5] 刘静安. 铝型材挤压模具设计、制造及维修[M]. 北京: 冶金工业出版社, 1999.

LIU Jing-an. The design, manufacturing, usage and maintenance of aluminum profile extrusion dies[M]. Beijing: Metallurgical Industry Press, 1999.

[6] 黄东男, 张志豪, 李静媛, 谢建新. 焊合室深度及焊合角对方形管分流模挤压成形质量的影响[J]. 中国有色金属学报, 2010, 20(5): 954-960.

HUANG Dong-nan, ZHANG Zhi-hao, LI Jing-yuan, XIE Jian-xin. Influences of welding chamber depth and welding angle on forming quality of extrusion of square tube by porthole die[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 954-960.

[7] 于宝义, 闫 丽, 郑 黎, 宋鸿武, 王永祥. 分流组合模的数值分析及优化设计[J]. 塑性工程学报, 2007, 14(5): 79-82.

YU Bao-yi, YAN Li, ZHENG Li, SONG Hong-wu, WANG Yong-xiang. Numerical analysis and optimal design of porthole compound dies[J]. Journal of Plasticity Engineering, 2007, 14(5): 79-82.

[8] 邸利青, 张士宏. 分流组合模挤压过程数值模拟及模具优化设计[J]. 塑性工程学报, 2009, 16(2): 123-127.

DI Li-qing, ZHANG Shi-hong. Porthole die extrusion process numerical simulation and optimal die design[J]. Journal of Plasticity Engineering, 2009, 16(2): 123-127.

[9] 石 磊. AZ31镁合金管材精密成形工艺研究[D]. 郑州: 河南科技大学, 2010.

SHI Lei. Study on technology of closed extrusion forging of AZ31 magnesium alloy tubing[D]. Zhengzhou: Henan University of Science, 2010.

[10] 王其军. 镁合金自行车曲柄等温闭式锻造数值模拟研究[D]. 长春: 吉林大学, 2008.

WANG Qi-jun. Study on numerical simulation of AZ31 magnesium alloy AZ31 cycling crank isothermal closed-die forging[D]. Changchun: Jilin University, 2008.

[11] 叶永南. AZ31镁合金往复挤压成形热力耦合模拟研究[D]. 西安: 西安理工大学, 2007.

YE Yong-nan. Thermal-mechanical coupling numerical simulation of reciprocating extrusion processes on AZ31 Mg alloy[D]. Xi’an: Xi’an University of Technology, 2007.

[12] LIU G, ZHOU J, DUSZCZYK J. FE analysis of metal ?ow and weld seam formation in a porthole die during the extrusion of a magnesium alloy into a square tube and the effect of ram speed on weld strength[J]. Journal of Materials Processing Technology, 2008, 200: 185-198.

[13] JO H H, LEE S K, JUNG C S, KIM B M. A non-steady state FE analysis of Al tubes hot extrusion by a porthole die[J]. Journal of Materials Processing Technology, 2006, 173(4): 223-231.

[14] LI Qiang, CHRIS H, JOLLY M R. Finite element modeling simulation of transverse welding phenomenon in aluminum extrusion process[J]. Material Design, 2003, (24): 493-496.

[15] 王 尧, 周照耀, 潘健怡, 刘 亮, 吴苑标. 铝型材挤压成形过程金属流动状态的数值模拟[J]. 机械设计与制造, 2010(8): 198-200.

WANG Yao, ZHOU Zhao-yao, PAN Jian-yi, LIU Liang, WU Yuan-biao. Numerical simulation analysis of metal flowing state on aluminum profile extrusion process[J]. Machinery Design & Manufacture, 2010(8): 198-200.

[16] 闫 洪, 夏巨谌, 李志刚, 董湘怀, 杨国泰, 何成宏. 工艺参数对铝型材挤压变形规律的影响[J]. 中国有色金属学报, 2002, 12(6): 1154-1161.

YAN Hong, XIA Ju-kan, LI Zhi-gang, DONG Xiang-huai, YANG Guo-tai, HE Cheng-hong. Effect of technological parameters on profile extrusion forming process[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1154-1161.

[17] LI L, ZHANG H, ZHOU J, DUSZCZYK G Y, LI Z, ZHONG H. Numerical and experimental study on the extrusion through a porthole die to produce a hollow magnesium profile with longitudinal weld seam[J]. Materials and Design, 2008, 29: 1190-1198.

(编辑 龙怀中)