DOI: 10.11817/j.ysxb.1004.0609.2020-37459

超大规格宽幅薄壁中空镁合金型材挤压成形的数值模拟及实验研究

王敬丰1, 2,彭 星1, 2,王 奎1, 2,汪 清1, 2,高诗情1, 2,胡 豪1, 2,潘复生2

(1. 重庆大学 材料科学与工程学院,重庆 400044;

2. 重庆大学 国家镁合金材料工程技术研究中心,重庆 400044)

摘 要:采用DEFORM-3D数值模拟软件对超大规格的宽幅薄壁中空型材进行结构优化;利用HyperXtrude数值模拟软件对该型材的挤压工艺进行优化。型材结构优化后,明显改善速度分布不均匀的现象,规避充填不足、扭拧卷曲的问题;确定出具有一定成形速度及最小速度均方差的优选工艺。在此基础上,成功制备出了光亮平直的超大规格宽幅薄壁中空镁合金型材;该型材截面尺寸为502 mm×60 mm,是目前世界上规格最大的宽幅薄壁中空镁合金型材。对型材各区域进行显微组织观察和力学性能测试,各区域组织均匀细小,平均晶粒尺寸约为10~30 μm,抗拉强度在250 MPa以上,断后伸长率在15%以上。

关键词:镁合金;宽幅薄壁中空型材;大规格;挤压成形;数值模拟;微观组织;力学性能

文章编号:1004-0609(2020)-12-2809-11 中图分类号:TG379 文献标志码:A

镁合金以密度小、比强度及比刚度高、综合力学性能良好、便于切削加工等优点,近年来广泛应用于航空航天、国防军工、轨道交通及3C产品等领域[1-4]。宽幅薄壁中空镁合金型材既满足产品尺寸要求和力学性能要求,又符合环保性和轻量化的趋势,而且能够减少拼装工序,提高生产效率,降低生产成本[5-7]。随着镁合金产业的扩大应用,宽幅薄壁中空镁合金型材的需求日益增加,尺寸及性能要求也越来越高,对大规格宽幅薄壁中空镁合金型材挤压成形技术的研究开发,已经逐渐成为国内外研究的热点之一。然而,镁合金具有密排六方的晶体结构,基面滑移系容易开动,柱面及锥面滑移系难以开动,导致镁合金协调塑性变形能力差。一方面,型材的宽度越大、壁厚越小,对应横截面的稳定临界应力就越小,型材就越容易发生波浪、弯曲等失稳现象;另一方面,镁合金的薄壁中空型材,由于型材结构复杂,模具设计难度大,先分流后焊合的过程导致挤压力增大,对挤压设备的要求更高;此外,镁合金的大规格宽幅型材,由于存在很大的宽厚比,在挤压时型材横截面受力不均,型材成形不平直,后续矫直工作量大[8]。因此,大规格宽幅薄壁中空镁合金型材在常规技术下,研发周期长、试模成本高、挤压成形的难度大;德国KAINER曾提出“壁厚4 mm时,镁合金型材最大断面宽度不会超过250 mm”的观点,更加说明超大规格的宽幅薄壁中空镁合金型材在常规技术下难以挤压成形。随着计算机 模拟的发展,数值模拟的手段在镁合金塑性成形中起到了越来越重要的作用[9-12]。数值模拟与实验大数据的结合,目前是镁合金型材研发技术的重要手段。基于有限元方法(Finite element method, FEM)的DEFORM-3D软件虽然是针对锻造成形开发的数值模拟软件,但常用于挤压成形过程流变行为的数值模拟研究;基于Arbitrary lagrange-euler(ALE)的HyperXtrude软件是针对铝型材的挤压成形数值模拟而开发的,目前常用于镁合金型材的挤压成形仿真,而且在稳态分析时,计算速度快,方便用于挤压工艺优化的数值模拟研究。

对于镁合金的挤压成形,许多学者做了大量深入的研究[13-15]。张治民等[16]对AZ31镁合金的管材进行了挤压成形的数值模拟,研究了在挤压过程中,温度、速度、润滑等因素对其流动的影响,为AZ31镁合金管材加工提供了科学依据。高飞等[17]利用DEFORM-3D软件对AZ31镁合金的连续挤压过程进行了数值模拟,研究了连续挤压过程中不同阶段的温度、等效应力及等效应变分布,模拟结果对最佳工艺制定和模具设计起到了指导作用。李永兵等[18]利用HyperXtrude软件对ZK60镁合金的空心型材进行了挤压过程的数值模拟,模拟结果得出合适的挤压工艺,并在此工艺下做了验证试验,得到形状性能合格的产品,规格达到225 mm,代表国内先进水平。管仁国等[19]利用数值模拟手段,分析了AZ31镁合金在连续流变挤压成形时的温度场与流场的分布规律。但是,随着镁产业的扩大应用和轨道交通行业的发展,对于超大规格宽幅薄壁中空镁合金型材,迫切需要满足更高的尺寸及性能要求,必须进一步深入研发其挤压成形技术。

超大规格镁合金型材的结构来源于铝合金型材,而挤压工艺参考的是小规格的挤压产品,需要利用数值模拟手段,根据超大规格镁合金型材挤压过程的流变行为进行结构优化及工艺优化,然后才能进行挤压试验。本文采用宽展挤压法,结合扁挤压筒设计和组合模具设计,首先利用DEFORM-3D软件对超大规格的宽幅薄壁中空AZ31镁合金型材进行了数值模拟,优化了型材的结构,平衡了型材截面各区域的速度分布,保证镁合金型材的顺利挤出;然后再利用HyperXtrude软件对其进行了挤压工艺优化,确定了成形速度均匀的优选工艺;最后根据数值模拟结果,在实际试验中进行了型材的挤压成形,并观察分析了型材的微观组织和测试分析了其力学性能,验证了数值模拟结果的正确性。

1 型材结构优化的数值模拟

1.1 几何模型建立

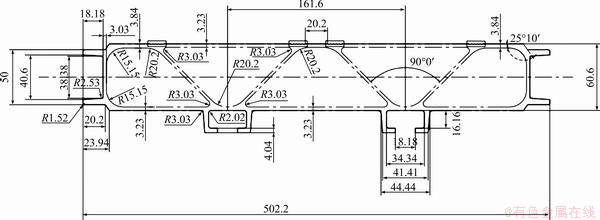

图1所示为型材的截面图和相关尺寸,其中壁厚2~5 mm,长宽比7,最大宽幅502 mm。采用SolidWorks2012软件,按照型材结构及相关尺寸建立挤压成形的三维几何模型,包括分流模、上模、下模、挤压筒、挤压杆以及坯料,利用软件的配合功能装配保存为STL.格式。

1.2 物理模型建立

按步骤依次导入坯料、挤压杆、挤压筒、分流模、上模及下模。对坯料进行网格划分,并在进模口区域局部细化网格。根据前期的研究,通过AZ31镁合金在不同温度和应变速率下的真应力-真应变曲线,自定义坯料的材质为AZ31镁合金,比热为1010 J/(kg·K),导热系数为145 W/(m·K)。挤压温度和挤压速度选择400 ℃和5 mm/s,据此设置各部件的温度为400 ℃,挤压杆的运动速度为5 mm/s。摩擦关系选取库伦摩擦模型,摩擦因数设为μ=0.4,默认选择模拟控制的相关参数,建立的挤压物理模型如图2(a)所示。图2(b)所示为宽幅型材的分流模模型,中间4个分流孔分别对应型材的4根肋板位置,四周5个分流孔对应型材的外壁。

1.3 优化前模拟结果分析

图1 宽幅型材断面结构与尺寸

Fig. 1 Cross section structure and dimensions of wide profile (Unit: mm)

图2 宽幅型材挤压物理模型及分流模

Fig. 2 Extrusion physical model of wide profile and shunt die

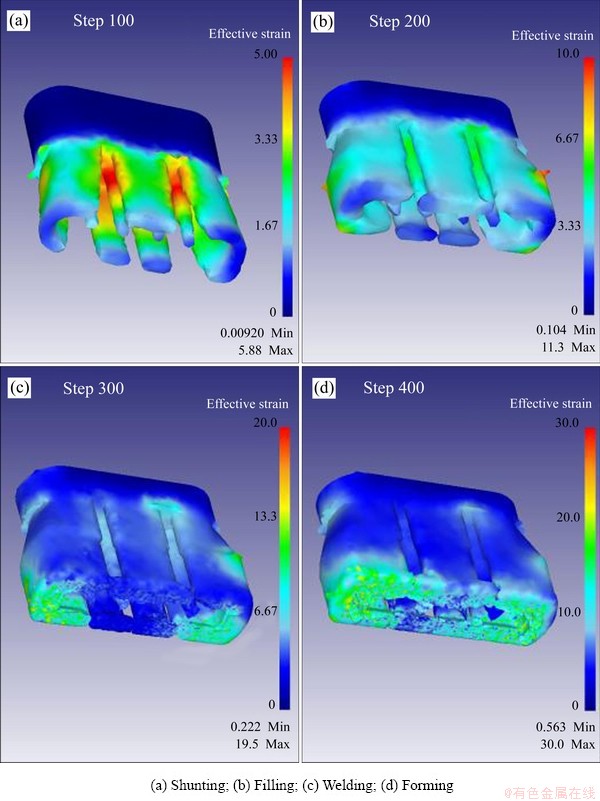

图3 宽幅型材挤压成形不同阶段的等效应变分布

Fig. 3 Effective strain distribution of wide profile extrusion in different stages

图3所示为宽幅型材在挤压成形过程中的等效应变分布情况。图3(a)所示为金属流流经分流模时的等效应变分布,此时靠近中间4个内分流孔处的金属流受到的等效应变最大,约为4.5~5.0;由于该区域孔径小,挤压比相对于另外5个外分流孔最大,在相同的挤压力下,发生更为剧烈的形变,使得其等效应变最大。图3(b)所示为金属流经过上模时的等效应变分布,随着挤压过程的进行,两侧金属流的等效应变呈增大趋势,坯料整体的等效应变分布更为均匀;金属流在充填上模两翼和下模焊合室的过程中,两侧横向流动增大,导致其等效应变增大。图3(c)所示为金属流开始焊合时的等效应变分布,明显可以看出,两侧的等效应变大于中部很多,两侧约为8.5~12.5,中部约为4.5~6.5;由于两侧区域厚度大于中部区域,随着挤压的进行,横向流动比中部区域大,则等效应变也比中部区域大。图3(d)所示为型材开始成形时的等效应变分布,其中两侧区域与中部区域的差值持续增加,两侧约为15.5~20.5,中部约为8.5~12.5;由于已经充填完成,成形时金属流与下模产生较大的摩擦力,使得其等效应变增加,而中部区域此时还未充填完成,圆柱体金属流前端基本仅受挤压力,等效应变增幅不大。

图4所示为宽幅型材在成形时的速度分布云图。由图4可以看出,两侧速度明显大于中部及肋板区域,其中两侧大约为25~35 mm/s,而中部及肋板区域仅有8~11 mm/s左右。由于两侧的厚度较大,相对挤压比小,故相同挤压力下,金属流速度更大,成形更快;同时,中部及肋板区域成形较慢,导致该区域金属流充填不足,对两侧的成形有牵扯作用,随着挤压的进行,两侧区域就会向内发生卷曲,最终导致型材发生充填不足、扭拧卷曲的问题,基本无法成形。

图4 宽幅型材成形时的速度分布

Fig. 4 Velocity distribution during wide profile forming

以上分析表明,在宽幅型材挤压成形的过程中,等效应变分布不均匀,不利于挤压成形,而成形速度差值过大,导致最终发生充填不足和扭拧卷曲,型材无法成形。

1.4 优化后模拟结果分析

根据以上模拟结果,提出以下两点优化型材结构的方案。一是增加肋板的设计壁厚,从而减小肋板成形阻力,提高充形速度;二是增大两侧内圆半径并减小外圆半径以减小两侧外壁的厚度,从而增大挤压比,减缓两侧的成形速度。进而减小两侧与中部及肋板的厚度差值,平衡挤压成形过程中金属流在中部与两翼间的成形速度,避免发生充填不足、扭拧卷曲,提高型材整体成形质量。

宽幅型材结构优化后在挤压成形过程中的速度分布如图5所示。从图5(a)和(b)可以看出,在挤压成形过程前期,金属流流经分流模,两侧和中部的速度分布差别很小,分流速度和充填速度比较均匀。在挤压成形中后期,如图5(c)和(d)所示,型材整体速度呈增大趋势,但速度分布更趋于平衡,两侧与中部成形速度的差值更小,为4~8 mm/s左右,在误差范围内,基本不影响型材最终成形。

由以上分析得知,宽幅型材结构优化后,挤压成形过程中的速度分布比较均匀,模拟结果和预期符合,规避了充填不足、扭拧卷曲问题的产生,改善了型材的成形质量。

2 挤压工艺优化的数值模拟

2.1 模拟的工艺选择

为保证宽幅型材能够挤出,并达到一定生产效率,模具温度定为450 ℃,挤压速度设为5 mm/s,仅设坯料温度为变量。按照表1的宽幅型材挤压工艺,利用HyperXtrude软件对每一组参数进行数值模拟,分析每组工艺参数下成形速度分布情况,得出最佳的挤压工艺,为实际挤压试验提供科学可靠的依据。

2.2 模拟前处理设置

在HyperXtrude软件中导入宽幅型材模具的几何模型,置于原点,调整挤压方向与Z轴方向一致;提取流体,并删除多余固体;设置工作带长度为15 mm,挤出型材长度为45 mm;将流体划分为202 mm的开口、14 mm的接合室及10 mm的导流腔;选择AZ31镁合金作为坯料的材料;坯料与挤压筒内壁、坯料与模具接触面设置成剪切摩擦类型,坯料与模具工作带设置成库伦摩擦类型;最后设置相应的挤压工艺参数。

图5 宽幅型材结构优化后不同模拟步数的速度分布

Fig. 5 Velocity distribution of structure optimized wide profile in different steps

表1 宽幅型材挤压工艺参数

Table 1 Process parameters of wide profile extrusion

2.3 模拟结果分析

经过挤压变形想要获得合格的型材产品,首要的条件是金属流出模口的速度基本一致[5]。图6所示为模拟结果的速度分布云图。在不同的工艺下,都呈现出1、5、6、11处速度最大,3、7、8、9、10处速度次之,2、4、12、13、14、15处速度最小的分布情况。分析原因发现,在速度大的区域,其轴向上都有分流孔对应,不需要横向流动就能直接填充;两侧又因为拥有最大的壁厚,故填充得最快;而心部4条肋板处,虽然有轴向的分流孔,但由于壁厚太薄,严重阻碍了金属流的流动,在相同的挤压力作用下,充填的速度就最小。

1~15处不同工艺下的速度值如表2所列。在每一处相同的区域内,工艺Ⅰ条件下的速度值最小,工艺Ⅱ条件下的速度值次之,工艺Ⅲ条件下的速度值最 大;且它们之间的增幅比较小。坯料温度升高,促进了该合金柱面及锥面滑移系的协同开动,一定程度上改善了其塑性变形能力,使得坯料的变形抗力减小;在相同的挤压速度推进下,金属流的速度就会呈上升趋势。其次,由于其他挤压工艺参数相同,且坯料温度相差比较小,同一区域不同工艺下的速度增幅就比较小。

型材模口速度的均匀程度与型材的成形质量密切相关,速度越均匀,型材发生扭拧弯曲等缺陷的可能性越小,成形质量越好[5]。标准出口速度场偏差(SDV) 是评价金属流动速度均匀性的重要方法,SDV值越小,表明金属流动越均匀,SDV值越大,表明金属流动越混乱,SDV值即为速度的均方差。由表2中的不同工艺下各代表区域的速度值计算得出的不同工艺下1~15处速度的平均值及均方差如图7所示。工艺Ⅰ条件下的速度平均值及均方差最小,分别为169.9 mm/s、94.50 mm/s;工艺Ⅱ条件下的速度平均值及均方差次之,分别为175.3 mm/s、98.33 mm/s;工艺Ⅲ条件下的速度平均值及均方差最大,分别为195.4 mm/s、118.93 mm/s。其他工艺参数一定时,由于各区域的速度值都随着坯料温度的升高而增加,故其速度平均值也随之增大。同时,坯料温度升高使得其变形抗力减小,在型材截面厚壁的区域表现得更为明显,故此厚壁处的速度提升的幅度更大,而其他区域的速度提升幅度较小,导致了随着坯料温度的升高,型材截面速度均方差增大的现象。速度均方差越大,表明速度分布越不均匀,型材成形就更为困难,故工艺Ⅰ更有利于型材的挤压成形。

图6 宽幅型材不同工艺下的速度分布

Fig. 6 Velocity distribution of wide profile in different processes

表2 不同工艺下1~15处的速度值

Table 2 Values of velocity at point 1-15 by different processes

图7 不同工艺下1~15处的速度平均值及均方差值

Fig. 7 Average values and mean square errors of velocity at point 1-15 by different processes

由以上分析可知,其他工艺参数一定时,随着坯料温度的升高,都是两侧的成形速度最快,型材截面各区域的速度、速度平均值及速度均方差都呈增大趋势;工艺Ⅰ具有一定的成形速度和相对最小SDV值,各区域流动更为均匀,型材成形质量更好是该宽幅型材挤压成形的优选工艺。

3 超大规格型材的挤压试验

3.1 挤压过程

将AZ31镁合金扁锭经370 ℃、18 h均匀化退火后置于400 ℃电阻炉中预热2 h,模具在450 ℃电阻炉中预热足够长时间,采用3600 T挤压机,温度设为450 ℃,待挤压力平衡后,挤压速度稳定在5 mm/s左右。

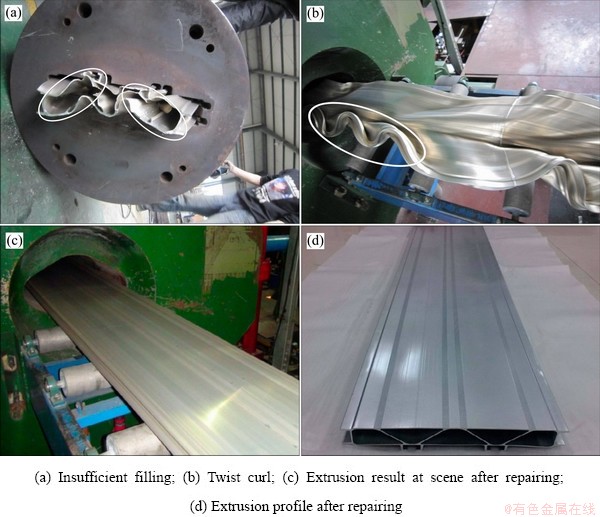

如图8所示,为宽幅型材挤压试验的结果,其中图8(a)和(b)是未修模的挤压结果,图8(c)和(d)是修模后的挤压结果。图8(a)中出现了筋板充填不足的问题,部分地方厚度不足,甚至有的地方筋板缺肉。原因是筋板处流速最小,心部分流时充填不足,挤压时来不及成形。图8(b)中的扭拧卷曲现象是挤压失稳的表现,根本原因是金属流动持续不均匀。因为两侧的流速大于中间区域的,在一定时间后,两侧金属的位移比中间金属的大,导致伸长过快的两侧金属受到已挤出型材的挤压应力作用,限制其较快挤出,而伸长较慢的中间金属受到已挤出型材拉伸应力作用,促进其加快挤出,使得在型材的同一断面内,为了保证连续的挤压变形,型材的拉压应力持续不平衡,最终出现了扭拧卷曲的问题。按上文中的修模方案进行修模之后,采用优选的挤压工艺,最终成功挤出了如图8(c)和(d)所示的光亮平直、尺寸正常、表面质量良好的超大规格宽幅薄壁中空镁合金型材。该型材截面尺寸为502 mm×60 mm,壁厚2~5 mm,以此突破了德国KAINER“壁厚4 mm时,镁合金型材最大断面宽度不会超过250 mm”的观点,是目前世界上规格最大的宽幅薄壁中空镁合金型材,促进了镁合金挤压成形技术的研发,进一步拓展了镁合金的应用领域,推动了镁产业发展。

3.2 微观组织分析

按图9中a、b、c、d四个位置取样,在垂直于ED的方向上和平行于ED的方向上分别观察分析宽幅型材的微观组织。

图8 宽幅型材的挤压成形结果

Fig. 8 Extrusion results of wide profile

图9 样品选取的位置

Fig. 9 Locations of sample selections

图10 宽幅型材不同位置的微观组织

Fig. 10 Microstructures of wide profile in different locations

图10所示为宽幅型材a、b、c、d四个不同位置的微观组织,Ⅰ为垂直于ED的观察结果,Ⅱ为平行于ED的观察结果。四个位置的晶粒都比较细小且均匀,晶粒尺寸大约在10~30 μm,表明宽幅型材成形质量良好。a区中在垂直于ED方向观察到,晶粒细小且致密均匀,明显呈等轴晶分布,说明已经完全再结晶,平均晶粒半径大约为5~10 μm;在平行于ED方向上,组织都呈等轴晶分布,晶粒已经发生了完全再结晶,而在局部区域存在异常粗大的再结晶晶粒。b区中沿ED横截面上,组织明显呈等轴晶分布,晶粒尺寸约为10~15 μm;沿ED纵截面上,呈完全再结晶状态,但粗晶和细晶之间有分层,原因是在变形过程中,外侧金属与模具内壁存在较大的摩擦变形,达到再结晶晶粒的晶体长大的临界变形度,导致部分再结晶晶粒长大粗化。c区中组织基本都呈等轴晶分布,晶粒比较均匀,尺寸约为10~20 μm,说明心部肋板成形质量良好。d区中沿ED横截面上,都为等轴晶分布,晶粒较为均匀,尺寸为15~35 μm左右;沿ED纵截面上,和b区中结构类似,粗晶和细晶有明显分层,且粗晶的晶粒更大,分析原因是模具内壁产生的摩擦变形促进了再结晶晶粒的异常长大,同时d区的挤压变形比b区的小,摩擦变形产生的变形度对晶体长大的作用更大。4个不同位置的晶粒大小,均匀度等微观组织信息与上文HyperXtrude软件模拟的结果一致,变形程度大及变形速率快的区域,微观组织更加细小均匀。

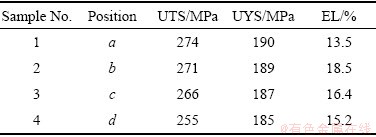

3.3 力学性能测试

按图9所示a、b、c、d四个位置取样,进行拉伸试验,测试宽幅型材的力学性能,测试结果如表3所列。4个位置的抗拉强度(UTS)在250 MPa以上,断后伸长率(EL)在15%以上,力学性能差异不明显。其中a区的抗拉强度最高,为274 MPa,超过国内AZ31镁合金一般挤压型材(T型材255 MPa[20]、中空型材256 MPa、宽幅板材270 MPa[21]、薄壁中空型材257 MPa[22]等)的最好抗拉强度,原因是挤压比大,则变形量大,使得晶粒再结晶程度提高,晶粒更加致密细小和均匀,最终大幅提升了抗拉强度;b区的综合力学性能最好,抗拉强度达到271 MPa,断后伸长率超过18%,其晶粒细小且更加均匀所致;而d区的综合力学性能相对较差,分析原因是其微观组织不均匀,再结晶晶粒异常粗大。这4个位置的力学性能与上文HyperXtrude软件的模拟结果及微观组织观察结果一致,变形程度大及变形速率快的区域,微观组织更细小均匀,综合力学性能更优异。

表3 宽幅型材不同位置的力学性能

Table 3 Mechanical properties of wide profile in different locations

4 结论

1) 超大规格宽幅薄壁中空镁合金型材在挤压成形过程中,结构优化前等效应变在分流时心部大于两侧,在成形时两侧大于心部;两侧速度值明显大于心部,导致充填不足、扭拧卷曲问题的出现,最终无法成形。结构优化后速度两侧略微大于心部,差值在4~8 mm/s左右,型材截面成形速度较为均匀,规避了充填不足、扭拧卷曲问题,能顺利成形。

2) 确定出了超大规格宽幅薄壁中空镁合金型材的优选工艺,即坯料温度400 ℃,模具温度450 ℃,挤压速度5 mm/s,该工艺下具有一定成形速度及最小的速度均方差,各部分成形更为均匀。

3) 结构优化后,在优选工艺下,成功制备了光亮平直、尺寸正常、表面质量良好的超大规格宽幅薄壁中空镁合金型材,验证了模拟结果的正确性;该型材截面尺寸为502 mm×60 mm,壁厚2~5 mm,是目前世界上规格最大的宽幅薄壁中空镁合金型材。

4) 型材各区域组织均匀细小,平均晶粒尺寸约为10~30 μm,抗拉强度在250 MPa以上,断后伸长率在15%以上,最高抗拉强度达到274 MPa。模拟结果中变形程度大及变形速率快的区域,实验结果中该区域微观组织更细小均匀,综合力学性能更优异,二者之间显出良好的一致性。

REFERENCES

[1] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[2] FRIEDRICH H, SCHUMANN S. Research for a “new age of magnesium” in the automobile industry[J]. Journal of Materials Processing Technology, 2001, 117(3): 276-281.

[3] 余 琨, 黎文献, 王日初. 镁合金塑性变形机制[J]. 中国有色金属学报, 2005, 15(7): 1081-1086.

YU Kun, LI Wen-xian, WANG Ri-chu. Plastic deformation mechanism of magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 1081-1086.

[4] KOJIMA Y, AIZAWA T, KAMADO S, HIGASHI K. Progressive steps in the platform science and technology for advanced magnesium alloys[J]. Mater Sci Forum, 2000, 350/351(7): 3-18.

[5] 王祝堂. 镁及镁合金型材的挤压[J]. 有色金属加工, 2004, 33(1): 31-36.

WANG Zhu-tang. Extrusion of magnesium and magnesium alloy profiles[J]. Non-ferrous Metal Processing, 2004, 33(1): 31-36.

[6] 王 锐. AZ31镁合金型材宽展挤压工艺参数研究[J]. 热加工工艺, 2012, 41(13): 95-97.

WANG Rui. Study on process parameters of wide extrusion of AZ31 magnesium alloy profiles[J]. Thermal Processing, 2012, 41(13): 95-97.

[7] STONE R B, WOOD K L, CRAWFORD R H. Using quantitative functional models to develop product architecture[J]. Design Studies, 2000, 21(3): 239-260.

[8] KURT. Extrusion: Processes, machinery, tooling[M]. Ohio: American Society for Metals, Metals Park, 1976: 152-153.

[9] TANG J, WU W T, WALTERS J. Recent development and application of finite element method in metal forming[J]. Journal of Materials Processing Technology, 1994, 46(1/): 117-126.

[10] 周 飞, 彭颖红, 阮雪榆. 铝型材挤压过程有限元数值模拟[J]. 中国有色金属学报, 1998, 8(4): 637-642.

ZHOU Fei, PENG Ying-hong, RUAN Xue-yu. Finite element numerical simulation of aluminum profiles extrusion process[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(4): 637-642.

[11] 苌群峰, 李大永, 彭颖红, 曾小勤. AZ31镁合金板材温热冲压数值模拟与实验研究[J]. 中国有色金属学报, 2006, 16(4): 580-585.

CHANG Qun-feng, LI Da-yong, PENG Ying-hong, ZENG Xiao-qin. Numerical simulation and experimental study on warm stamping of AZ31 magnesium alloy sheets[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(4): 580-585.

[12] 张保军, 杨 合, 郭良刚, 石 磊, 郑文达, 谷瑞杰, 寇永乐. AZ31镁合金薄壁管挤压分流孔轴向倾角影响规律的仿真模拟[J]. 中国有色金属学报, 2012, 22(10): 2713-2719.

ZHANG Bao-jun, YANG He, GUO Liang-gang, SHI Lei, ZHENG Wen-da, GU Rui-jie, KOU Yong-le. Simulation simulation of influence law of axial inclination angle of AZ31 magnesium alloy thin wall tube extrusion shaft[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2713-2719.

[13] 刘 筱, 朱必武, 李落星, 唐昌平. 挤压态AZ31镁合金热变形过程中的孪生和织构演变[J]. 中国有色金属学报, 2016, 26(2): 288-295.

LIU Xiao, ZHU Bi-wu, LI Luo-xing, TANG Chang-ping. Twinning and texture evolution of AZ31 magnesium alloy during hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 288-295.

[14] 孟帅举, 余 晖, 崔红卫, 张 静, 赵维民, 王志峰, 秦春玲. 新型Mg-Bi-Al-Zn变形镁合金的微观组织与力学性能[J]. 中国有色金属学报, 2017, 27(5): 894-901.

MENG Shuai-ju, YU Hui, CUI Hong-wei, ZHANG Jing, ZHAO Wei-min, WANG Zhi-feng, QIN Chun-ling. Microstructure and mechanical properties of a novel Mg-Bi-Al-Zn wrought magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(5): 894-901.

[15] 胡忠举, 刘雁峰, 卢立伟, 伍贤鹏, 刘楚明. 镁合金正挤压-弯曲剪切复合连续变形工艺及挤压力计算[J]. 中国有色金属学报, 2018, 28(5): 923-930.

HU Zhong-ju, LIU Yan-feng, LU Li-wei, WU Xian-peng, LIU Chu-ming. Positive extrusion-bending shear composite continuous deformation process and extrusion force calculation of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(5): 923-930.

[16] 李琳琳, 张治民, 薛 勇. AZ31镁合金管材挤压成形数值模拟研究[J]. 锻压装备与制造技术, 2006, 41(2): 70-72.

LI Lin-lin, ZHANG Zhi-min, XUE Yong. Numerical simulation study on extrusion forming of AZ31 magnesium alloy tubes[J]. Forging Equipment and Manufacturing Technology, 2006, 41(2): 70-72.

[17] 吴桂敏, 高 飞, 符 蓉. AZ31镁合金连续挤压过程数值模拟[J]. 热加工工艺, 2009, 38(17): 39-41.

WU Gui-min, GAO Fei, FU Rong. Numerical simulation of continuous extrusion process of AZ31 magnesium alloys[J]. Thermal Processing, 2009, 38(17): 39-41.

[18] 郭丽丽, 李永兵, 裴久杨. 基于HyperXtrude的ZK60镁合金型材挤压成形数值模拟和实验验证[J]. 锻压技术, 2015, 40(6): 138-144.

GUO Li-li, LI Yong-bin, PEI Yong-yang. Numerical simulation and experimental verification of extrusion forming of ZK60 magnesium alloy Profiles based on HyperXtrude[J]. Forging Technology, 2015, 40(6): 138-144.

[19] 管仁国, 赵占勇, 陈礼清, 王付兴. AZ31镁合金型材连续流变挤压成形过程的数值模拟[J]. 中国有色金属学报, 2010, 20(5): 923-929.

GUAN Ren-guo, ZHAO Zhan-yong, CHEN Li-qing, WANG Fu-xing. Numerical simulation of continuous rheological extrusion process of AZ31 magnesium alloy profiles[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 923-929.

[20] 周海涛, 曾小勤, 王渠东, 丁文江. AZ31镁合金型材挤压工艺和组织性能分析[J]. 轻合金加工技术, 2003, 31(9): 28-30.

ZHOU Hai-tao, ZENG Xiao-qin, WANG Qu-dong, DING Wen-jiang. Extrusion process and microstructure analysis of AZ31 magnesium alloy profiles[J]. Light Alloy Processing Technology, 2003, 31(9): 28-30.

[21] 王 赛. 高塑性AZ31镁合金薄板成形工艺及组织性能[D]. 沈阳: 沈阳工业大学, 2015: 65-66.

WANG Sai. Forming process and microstructure of high plasticity AZ31 magnesium alloy sheets[D]. Shenyang: Shenyang University of Technology, 2015: 65-66.

[22] 高天娇. 超细晶镁合金型材成型工艺及组织性能[D]. 沈阳: 沈阳工业大学, 2014: 57-58.

GAO Tian-jiao. Molding process and microstructure of ultrafine magnesium alloy profiles[D]. Shenyang: Shenyang University of Technology, 2015: 57-58.

Numerical simulation and experimental study on extrusion forming of ultra-large size wide thin-walled hollow magnesium alloy profiles

WANG Jing-feng1, 2, PENG Xing1, 2, WANG Kui1, 2, WANG Qing1, 2, GAO Shi-qing1, 2, HU Hao1, 2, PAN Fu-sheng2

(1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400044, China)

Abstract: The structure of the wide-format thin-walled hollow profile of the large size was optimized by the DEFORM-3D numerical simulation software, and the extrusion process of the profile was optimized by HyperXtrude numerical simulation software. After the optimization of profile structure, the phenomenon of uneven velocity distribution was obviously improved, and the problem of insufficient filling and twisting curl was avoided, and a preferred process with a certain forming speed and minimum average velocity variance was determined. A bright and straight large-size wide-walled hollow magnesium alloy profile was successfully prepared, the profile cross-section size was 502 mm×60 mm, which was currently the world’s largest wide-walled thin-walled hollow magnesium alloy profile. The microstructures observation and mechanical performance testing were carried out on the regions of the profile, the regional tissues are uniform lyson, the average grain size is about 10-30 μm, the tensile strength is above 250 MPa, and the elongation is more than 15%.

Key words: magnesium alloy; wide thin-walled hollow profile; large size; extrusion; numeric simulation; microstructure; mechanical properties

Foundation item: Project(2016YFB0301102) supported by the National Basic Research Development Program of China; Project(51874062) supported by the General Project of National Natural Science Foundation of China; Project(2018CDGFCL0005) supported by the Fundamental Research Funds for the Central Universities, China

Received date: 2018-12-07; Accepted date: 2020-12-04

Corresponding author: WANG Jing-feng; Tel: +86-23-65112153; E-mail: jingfengwang@163.com

(编辑 王 超)

基金项目:国家重点研发计划资助项目(2016YFB0301102);国家自然科学基金面上资助项目(51874062);中央高校基本科研业务费专项项目(2018CDGFCL0005)

收稿日期:2018-12-07;修订日期:2020-12-04

通信作者:王敬丰,教授,博士;电话:023-65112153;E-mail:jingfengwang@163.com