机械活化对磁黄铁矿浸出动力学的影响

张有新,何利华,刘旭恒

(中南大学 冶金科学与工程学院,湖南 长沙,410083)

摘 要:利用X线衍射仪、比表面积测试仪、扫描电镜和粒径分析仪对未机械活化和经振动磨机械活化后的磁黄铁矿进行分析和表征。在FeCl3-HCl体系中对未机械活化和经机械活化后的磁黄铁矿的浸出动力学进行研究。研究结果表明:机械活化增加磁黄铁矿的微观结构缺陷和比表面积,粉末粒度减小,形成的团聚体非常明显;与未活化的磁黄铁矿相比较,经机械活化10,20和40 min后的磁黄铁矿化学反应活性提高,反应速度加快,表观活化能降低,其中表观活化能由未活化时的150 kJ/mol分别降至58,49和45 kJ/mol。

关键词:机械活化;反应动力学;浸出率

中图分类号:TQ021.2 文献标志码:A 文章编号:1672-7207(2010)06-2085-06

Effect of mechanical activation on leaching kinetics of pyrrhotite

ZHANG You-xin, HE Li-hua, LIU Xu-heng

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The methods of X-ray diffractrometry, BET, scanning electron microscope and particle size analysis were used for studying the nonactivated and mechanical activated pyrrhotite in a vibrating mill. The influence of mechanical activation on leaching kinetics of pyrrhotite by FeCl3-HCl solutions was investigated. The results show that mechanical activation increases microstructure defects and specific surface area of pyrrhotite and decreases powder particle size. And the formation of aggregates is very obvious. Compared with the nonactivated pyrrhotite, the chemical activity of pyrrhotite mechanical activated for 10, 20 and 40 min is improved respectively, and its apparent activation energy is reduced from 150 kJ/mol to 58, 49 and 45 kJ/mol, respectively. So the chemical reaction speed is accelerated markedly.

Key words: mechanical activation; reaction kinetics; leaching rate

镍资源主要以硫化矿和红土矿存在,不管硫化矿造硫熔炼还是红土矿还原造锍熔炼产出的低冰镍,低冰镍传统处理工艺是经转炉吹炼生产高冰镍,投资大,能耗高,引起二氧化硫的污染和铁资源的浪费。湿法冶金有利于实现有价金属的综合回收,具有成本较低、环境友好等优点,已在金属的提取、材料的制备方面得到广泛应用。选择HCl-FeCl3体系对低冰镍进行氧化浸出,使硫以单质形式存在,镍和铁进入溶液,为提高金属的综合利用,例如将浸出的镍和铁混合液直接进行喷雾热解制备镍铁氧体(NiFe2O4)的预焼粉,盐酸可以回收利用,是一种有应用前景的方法。湿法冶金缺点是温度较低时,反应速度较慢。机械活化由于能够使矿物粒度变细,晶格缺陷增加, 能储量增高, 反应活性增强, 因而能加快矿物的分解速度, 降低分解反应对温度、浸出剂浓度等条件的依赖程度, 使浸出过程大大加强[1-6]。机械活化技术在冶金、材料、化工领域日益引起人们注意并获得成功应用[7-14]。在低冰镍中,镍主要以固溶体的形式与磁黄铁矿共存,并占据磁黄铁矿中铁的晶格。为加速低冰镍的浸出过程,了解低冰镍的浸出机理,选择磁黄铁矿进行动力学的研究就显得十分重要。Filippou等[15]进行了磁黄铁矿加压酸浸出的动力学研究;Droppert等[16]进行了镍磁黄铁矿在热硝酸中的浸出研究;Pratt等[17]在稀硫酸中进行了磁黄铁矿的氧化浸出研究。本文作者采用纯的磁黄铁矿为原料,同时引入机械活化,考察机械活化对其结构、形态和浸出动力学的影响,以期为从低冰镍中提取金属镍的湿法冶金过程强化提供理论支持。

1 实验

1.1 实验原材料

实验所用磁黄铁矿是纯矿物,尽可能避免过程中产生机械活化效应,矿石被粉碎和筛选到粒度小于45 μm。样品的化学成分(质量分数)为:58.20% Fe, 37.23% S, 0.61% SiO2。

1.2 机械活化

采用振动磨对磁黄铁矿矿进行机械活化,对于每个活化实验,每批样品(约15 g)在室温环境下进行活化,所有批次研磨转速为960 r/min,没有任何添加剂被用于研磨过程。样本在振动磨中被激活的时间分别为10,20和40 min。在完成研磨后,振动磨被彻底清洗和干燥,以便下次使用。

1.3 浸出实验

在1 L多口烧瓶中进行浸出反应。反应瓶配有温度计和回流冷凝器,在恒温水浴锅中进行加热,搅拌方式采用磁力搅拌。首先将装有800 mL浸出液(包括实验所需的盐酸和三氯化铁)的烧瓶加热到实验所需温度(±0.5 ℃)。大约加入10 g样品,并被充分搅拌。在每一步操作中,在适当时候将2 mL溶液样品取出,使用重铬酸钾滴定法分析二价铁的含量。

1.4 表征

X线衍射表征采用西门子D-500衍射仪,使用Co Kα辐射(λ=0.179 026 nm),扫描速度为8 (°)/min;显微结构采用JXA-8800R电子探针进行分析;BET测量使用ASAP2010 快速比表面和孔径分布测定仪;激光粒径应用Mastersizer 2000G型激光粒度仪进行分析;以二苯胺磺酸钠为指示剂,重铬酸钾滴定法分析浸出液中二价铁的含量。

2 分析讨论

2.1 结构和形态分析

2.1.1 样品的XRD分析

图1所示为未经机械活化的磁黄铁矿和经不同时间机械激活的磁黄铁矿的XRD谱。从图1可以看出:所有峰值与标准的磁黄铁矿的XRD谱相吻合,没有发现新的晶相,表明没有形成新的物质。经机械活化磁黄铁矿的与未活化样品的衍射峰相比,衍射峰的强度减弱和宽化,最主要的原因是机械活化使磁黄铁矿的晶体结构发生紊乱。

图1 未活化和经不同时间机械活化后磁黄铁矿的XRD谱

Fig.1 XRD patterns of nonactivated pyrrhotite and samples activated for different time

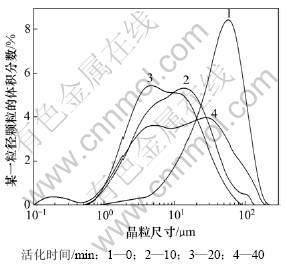

2.1.2 粉末粒度分析

图2所示为未活化和不同时间机械活化的磁黄铁矿的粒径分布。从图2可以看出:未活化的磁黄铁矿D50为44.625 ?m左右,经10和20 min研磨后,D50从44.623 ?m减少到9.784 ?m 和6.925 ?m。机械活化40 min的磁黄铁矿D50缓慢增加至11.670 ?m。粒径分布的变化结果表明:粒度减小在20 min內基本完成,活化20 min后,粉末的团聚速率超过粉末的破损速率。

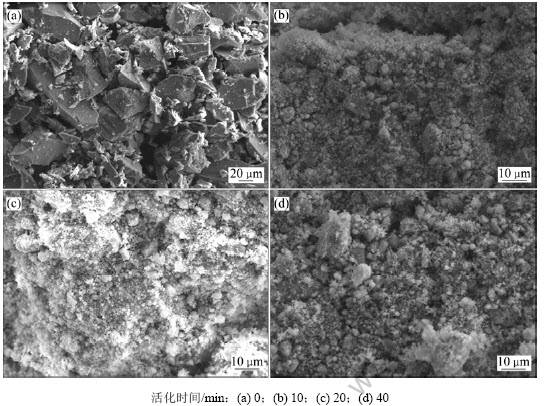

2.1.3 SEM分析

图3所示为未活化和不同时间机械活化的磁黄铁矿的SEM照片。从图3可以看出:经活化磁黄铁矿晶粒尺寸减小至1 ?m以下,形成的团聚体清晰可见。

图2 未活化和经不同时间机械活化的磁黄铁矿的粒径分布

Fig.2 Particle size distributions of nonactivated pyrrhotite and samples activated for different time

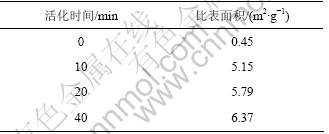

2.1.4 比表面积分析

表1所示为未活化和不同时间机械活化的磁黄铁矿的比表面积。未活化样品的比表面积为0.45 m2/g,经10 min活化后,样品的比表面积增大到 5.15 m2/g;经机械活化20和40 min的样品,比表面积分别增加到5.79 m2/g 和6.37 m2/g;活化10 min以后,再进一步增加研磨时间,比表面积变化不明显。

表1 未活化和不同时间机械活化的磁黄铁矿的比表面积

Table 1 BET surface area of unmilled pyrrhotite and sample milled for different time

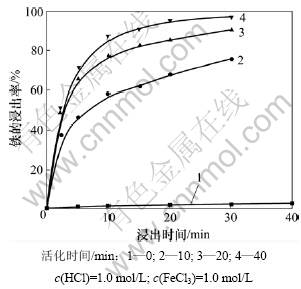

2.2 活化时间对浸出率的影响

图4所示为活化时间对磁黄铁矿浸出率的影响。试验结果表明:磁黄铁矿经活化后,铁的浸出速率有明显的提高,从而证实了机械活化可以改善磁黄铁矿的浸出性能;此外,活化矿的初期浸出反应比后期快得多。这主要归于机械活化引起磁黄铁矿的晶面缺陷、细颗粒,并增加其比表面积和反应性能;随着活化时间的增加,铁的浸出速率增幅逐渐减弱,而活化时消耗的机械能会越来越多,因此,活化时间并非越长越好。从本实验看,选择活化时间在20 min 左右比较合适。

图3 未活化和不同时间机械活化的磁黄铁矿的SEM照片

Fig.3 SEM photographs of nonactivated pyrrhotite and samples activated for different time

图4 活化时间对磁黄铁矿浸出率的影响

Fig.4 Effects of activation time on leaching of pyrrhotite at 50 ℃

2.3 浸出动力学分析

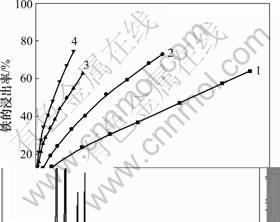

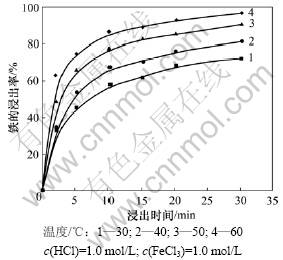

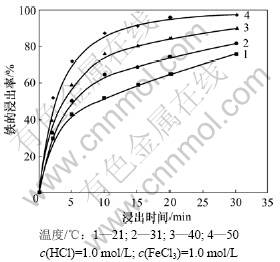

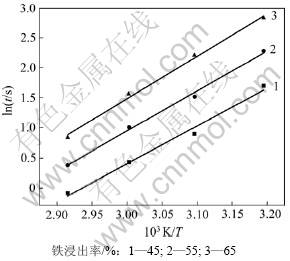

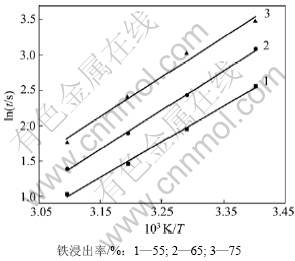

未机械活化和机械活化10,20和40 min 后磁黄铁矿的浸出过程的动力学曲线和相应的Arrhenius图,分别如图5~8和图9~12所示(其中:t为达到某浸出率所需时间)。从图5~8可以看出:机械活化后,在浸出剂浓度相同的条件下,浸出性能大幅度提高。未活化的磁黄铁矿活化能为150 kJ/mol,随着机械活化的时间延长,其反应的表观活化能逐渐减小,分别为58,49和45 kJ/mol。机械活化使磁黄铁矿浸出的表观反应活化能降低,使浸出反应对温度的依赖性降低。

温度/℃:1—70; 2—75; 3—80; 4—85

c(HCl)=1.0 mol/L; c(FeCl3)=1.0 mol/L

图5 温度对未活化磁黄铁矿浸出率的影响

Fig.5 Effects of temperature on leaching of nonactivated pyrrhotite

温度/℃:1—40; 2—50; 3—60; 4—70

c(HCl)=1.0 mol/L; c(FeCl3)=1.0 mol/L

图6 温度对活化10 min的磁黄铁矿浸出率的影响

Fig.6 Effects of temperature on leaching of activated pyrrhotite for 10 min

图7 温度对活化20 min的磁黄铁矿浸出率的影响

Fig.7 Effects of temperature on leaching of activated pyrrhotite for 20 min

图8 温度对活化40 min的磁黄铁矿浸出率的影响

Fig.8 Effects of temperature on leaching of activated pyrrhotite for 40 min

图9 未活化磁黄铁矿浸出反应的Arrhenius图

Fig.9 Arrhenius plots for reactions on leaching of nonactivated pyrrhotite

图10 活化10 min磁黄铁矿浸出反应的Arrhenius图

Fig.10 Arrhenius plots for reactions on leaching of pyrrhotite activated for 10 min

图11 活化20 min磁黄铁矿浸出反应的Arrhenius 图

Fig.11 Arrhenius plots for reactions on leaching of pyrrhotite activated for 20 min

图12 活化40 min磁黄铁矿浸出反应的Arrhenius图

Fig.12 Arrhenius plots for reactions on leaching of pyrrhotite activated for 40 min

4 结论

(1) 机械活化增加了磁黄铁矿的比表面积和微观结构缺陷,粉末粒度减小,形成的团聚体清晰可见。

(2) 机械活化增强磁黄铁矿的浸出动力学性能,增大浸出率,使浸出反应温度降低,浸出时间缩短。

(3) 未活化的磁黄铁矿表观活化能为150 kJ/mol,随着机械活化时间的延长,其反应的表观活化能逐渐减小,分别为58,49和45 kJ/mol。

(4) 有关低冰镍中镍与磁黄铁矿的固溶体浸出行为有待于进一步研究。

参考文献:

[1] Bala? P. Extractive metallurgy of activated minerals[M]. Amsterdam: Elsevier, 2000: 25-56.

[2] Balá? P, Boldi?árová E, Achimovi?ová M, et al. Leaching and dissolution of a pentlandite concentrate pre-treated by mechanical activation[J]. Hydrometallurgy, 2000, 57(1): 85-96.

[3] Maurice D, Hawk J A. Ferric chloride leaching of mechanically activated chalcopiryte[J]. Hydrometallurgy, 1998, 49(1/2): 103-123.

[4] Welham N J. Mechanochemical processing of gold-bearing sulphides[J]. Miner Eng, 2001, 14(4): 341-347.

[5] Welham N J. Mechanochemical processing of enargite (Cu3AsS4)[J]. Hydrometallurgy, 2001, 62(3): 165-173.

[6] 孙培梅, 李洪桂, 李运娇, 等. 机械活化苛性钠分解柿竹园白钨矿的研究[J]. 中南工业大学学报: 自然科学版, 1999, 30(3): 248-251.

SUN Pei-mei, LI Hong-gui, LI Yun-jiao, et al. Study of the NaOH decomposition process of Shizhuyuan scheelite with mechanical activation method[J]. Journal of Central South University of Technology: Natural Science, 1999, 30(3): 248-251.

[7] Tká?ová K, Balá? P. Structural and temperature sensitivity of leaching of chalcopyrite with iron (Ⅲ) sulphate[J]. Hydrometallurgy, 1988, 21(1): 103-112.

[8] Balá? P, ?tevulová N, Kammel R, et al. Extraction of Ni, Cu and Co from mechanically activated pentlandite concentrate[J]. Metall, 1998, 52(10/11): 620-623.

[9] Amer A M. Hydrometallurgical processing of Egyptian black shale of the Quseier-Safaga region[J]. Hydrometallurgy, 1994, 36(1): 95-107.

[10] Amer A M. Investigation of the direct hydrometallurgical processing of mechanically activated complex sulphide ore, Akarem area, Egypt[J]. Hydrometallurgy, 1995, 38(3): 225-234.

[11] Welham N J. The effect of extended milling on minerals[J]. Canadian Institute of Metallurgy Bulletin, 1997, 90(1): 64-68.

[12] Welham N J. Enhancement of the dissolution of ilmenite (FeTiO3) by extended milling[J]. Transactions of Institution of Mining and Metallurgy (Section A): Mining Industry, 1997, 106: 135-144.

[13] ZHAO Zhong-wei, LONG Shuang, CHEN Ai-liang, et al. Mechanochemical leaching of refractory zinc silicate chemimorphites in alkaline solution[J]. Hydrometallurgy, 2009, 99(3): 255-258.

[14] ZHAO Zhong-wei, OUYANG King-sam, WANG Ming. Structural macrokinetics of synthesizing ZnFe2O4 by mechanical ball milling[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(6): 1131-1135.

[15] Filippou D, Konduru R, Demopoulos G P. A Kinetic study on the acid pressure leaching of pyrrhotite[J]. Hydromentallurgy, 1997, 47(1): 1-18.

[16] Droppert D J, Shang Y X. The leaching behaviour of nickeliferous pyrrhotite concentrate in hot nitric acid[J]. Hydromentallurgy, 1995, 39(1/3): 169-182.

[17] Pratt A R, Nesbitt H W, Muir I J. Generation of acids from mine waste: Oxidative leaching pyrrhotite in dilute H2SO4 solutions at pH 3.0[J]. Geochim Cosmochim, 1994, 58(23): 5147-5159.

(编辑 陈爱华)

收稿日期:2009-10-16;修回日期:2009-12-06

基金项目:国家重点基础研究发展计划项目(2007CB613603)

通信作者:刘旭恒(1981-),男,湖南涟源人,博士,从事功能材料和有色金属冶金研究;电话:0731-88830476;E-mail: hgli@mail.csu.edu.cn