难选高硅型氧化锌矿机械活化碱法浸出研究

赵中伟1, 2,龙双1, 2,陈爱良1, 2,霍广生1, 2,贾希俊1, 2,李洪桂1, 2,阎海泉3

(1. 中南大学 冶金科学与工程学院,湖南 长沙,410083;

2. 中南大学 稀有金属冶金与材料制备湖南省重点实验室,湖南 长沙,410083;

3. 白银有色金属公司,甘肃 白银,730900)

摘 要:针对氧化锌矿综合利用工艺的现状和不足,将处理氧化铝矿物的拜耳法移植于氧化锌矿的湿法处理过程而形成“锌拜耳法”,提出氧化锌矿机械活化碱法浸出的新工艺。实验结果表明:当NaOH的用量为理论用量的3.5倍,温度为140 ℃,浸出时间2 h,液固比为10?1(mL/g)时,锌的浸出率达到95.1%,硅的浸出率为45.5%。氧化锌矿在高温、长时间和强机械活化作用下生成难溶产物Na2ZnSiO4是导致锌浸出率降低的主要原因。

关键词:拜耳法;浸出;机械活化;浸出率

中图分类号:TF813 文献标志码:A 文章编号:1672-7207(2010)04-1246-05

Alkali leaching of refractory high silica zinc oxide ore by mechanical activation

ZHAO Zhong-wei1, 2, LONG Shuang1, 2, CHEN Ai-liang1, 2, HUO Guang-sheng1, 2,

JIA Xi-jun1, 2, LI Hong-gui1, 2, YAN Hai-quan3

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Hunan Province for Metallurgy and Material Processing of Rare Metals, Changsha 410083, China;

3. Baiyin Nonferrous Ltd., Baiyin 730900, China)

Abstract: The present state and shortages comprehensive utilization of zinc oxide ores were described in this paper, and the Bayer process used to treat bauxite was transplanted to treat zinc oxide ores. So, this process can be regarded as “zinc Bayer process”. And a new method for alkaline leaching of refractory hemimorphite by mechanical activation was put forward. Optimized leaching parameters are obtained through experiments, as follows: the sodium hydroxide dosage = 3.5 times as much as the theoretical quantity, the leaching time = 2 h, temperature = 140 ℃ and ratio of leaching liquid to leaching solid (L/S) =10?1. Under these conditions, the leaching rate of zinc and silicon can reach 95.1% and 45.5%. Overlong leaching time and intense mechanical activation will deteriorate the zinc leachability and thus accelerate the Na2ZnSiO4 formation.

Key words: Bayer process; leaching; mechanical activation; leaching rate

氧化锌矿在国外被称为“非硫化锌矿”[1]。氧化锌矿主要包括:硅酸锌矿(Zn2SiO4),菱锌矿(ZnCO3)和异极矿[Zn4(Si2O7)2(OH)2·H2O]等[2-3]。目前,氧化锌矿石的处理方式有2种:(1) 氧化锌矿石经选矿富集后进入冶炼程序得金属锌,但由于氧化锌矿的自身特点(难选、高硅和高铁) 决定了选冶技术的难度;(2) 氧化锌矿石直接入冶炼程序。直接冶锌法又分为火法和湿法2类。尽管氧化锌矿易于用火法处理,但是该工艺环节多,流程长,设备庞大,能耗高,而且环境条件差。因此,一般都采用湿法(包括酸法和碱法两种)浸出[4]。但对于含有大量二氧化硅的氧化锌矿来说,二氧化硅在酸法浸出过程中生成的硅酸将产生凝胶[5],它将阻止硫酸锌溶液和泥浆的分离。目前冶金工作者已经尝试着用各种絮凝剂来凝聚硅酸,但结果使得在生产过程中酸耗增加,而且还必需配备复杂的净化过 程[6]。为了解决上述问题,近年来越来越多的研究者开始从事氧化锌矿的碱浸出研究。

氧化锌矿的碱浸出主要是以氢氧化钠或氨水作碱性浸出剂来处理ZnCO3含量高的氧化锌矿。刘三军[7]研究了氨法处理高ZnCO3含量的氧化锌矿,使锌与氨水生成锌氨络离子进入溶液,然后再将浸出液送去电积沉锌。而Frenay[8]则进行了氧化锌矿在不同碱性介质中的溶解实验,他认为在较高的温度下用氢氧化钠作浸出剂来浸出菱锌矿和氧化锌矿中锌的效果较 好。然而国内外冶金工作者对高硅型氧化锌矿[Zn4(Si2O7)2(OH)2·H2O]的研究甚少。为了充分利用高硅型氧化锌矿的资源以及简化现有生产流程[9],本研究利用热球磨来对高硅型氧化锌矿进行机械活化浸 出[10],以图强化高硅型氧化锌矿的碱分解过程。

1 实验

1.1 实验原料及设备

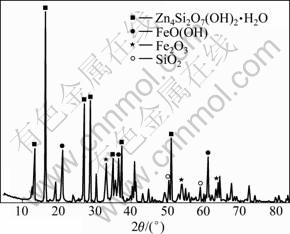

本研究所用的实验原料为云南兰坪的氧化锌矿,其XRD光谱图和主要元素的化学成分(质量分数)分别如图1和表1所示。

从图1可知:氧化锌矿中主要含有异极矿[Zn4Si2O7(OH)2?H2O]、石英[SiO2]、赤铁矿[Fe2O3]和针铁矿[FeO(OH)]等物质。

图1 氧化锌矿的XRD光谱

Fig.1 Results of XRD analysis of zinc oxide ores

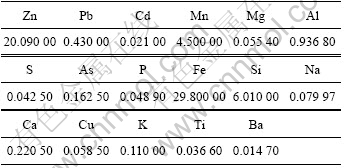

表1 氧化锌矿化学成分

Table 1 Chemical composition of zinc oxide ores %

机械活化设备为固速装置上放置的特殊材料制成的滚筒磨,滚筒尺寸为580 mm×120 mm;加热设备由3个电阻炉组成;温度由KSY-18温度控制仪通过E型(镍铬-康铜)铠装热电偶控制;活化介质由不同大小按一定比例组成的钢球组成;分离设备为L-600型台式低速自动平衡离心机。

1.2 实验方法

将矿石细磨,称取25 g 氧化锌矿粉末与一定体积和浓度的NaOH溶液同时加入已装有活化介质的滚筒中。然后调节温度控制仪至预定值,当温度升高至预定值时开始计时。达到预定时间后停止加热,及时使用离心机进行分离,滤液用络合滴定法分析其中Zn含量ρ(Zn),用硅钼蓝光度法分析其中Si质量浓度ρ(Si),然后按照式(1)分别计算氧化锌矿中Zn和Si的浸出率。

(1)

(1)

其中:R为Zn和Si的浸出率,%;ρ为浸出液中Zn和Si的质量浓度,g/L;V为浸出液的体积,L;w为氧化锌矿中Zn和Si的质量分数,%。

2 实验结果与讨论

2.1 温度对锌和硅浸出的影响

在液固比为10?1,NaOH浓度为5 mol/L,浸出时间为2 h的条件下,考察温度对锌和硅浸出率的影响,结果如图2所示。

从图2可知:锌和硅具有相同的浸出特性。在温度低于140 ℃时,锌和硅的浸出率随温度升高急剧增加,这是由于在碱性溶液中,氧化锌矿中锌和硅发生如下反应[11-13]:

ZnO+2NaOH+H2O→Na2Zn(OH)4 (2)

Zn4(OH)2Si2O7·H2O+12NaOH→Na2Zn(OH)4+Na2SiO3 (3)

SiO2+2NaOH→Na2SiO3+H2O (4)

图2 温度对锌和硅浸出率的影响

Fig.2 Effect of temperature on leaching rate of zinc and silicon

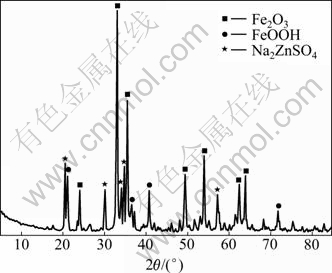

而且,在机械搅拌下通过高硅型氧化锌矿动力学研究发现:反应活化能E=45.7 kJ/mol处于受化学反应控制动力学区间,随着温度的升高上述反应将愈加剧烈,锌和硅的浸出率随之增加。但是当温度超过140 ℃,锌和硅的浸出率又同时急剧减小。通过氧化锌矿在165℃下浸出渣的XRD光谱图(图3)可知:由于强机械活化作用,反应得到一种胶状Na2ZnSiO4产物,该产物温度越高对其生成越有利[14-15],这将导致渣中含锌和硅不断增加,从而导致锌和硅的浸出率降低。为了最大程度浸出氧化锌矿中的锌并尽可能减少锌在浸出过程中的损失,实验选取最佳浸出温度为140 ℃。

图3 浸出渣的XRD光谱图

Fig.3 Results of XRD analysis of leaching slag

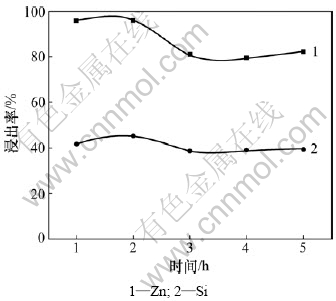

2.2 浸出时间对锌和硅浸出的影响

在液固比为10?1,NaOH浓度为5 mol/L,浸出温度140 ℃的条件下,考察浸出时间对锌和硅浸出率的影响,结果如图4 所示。

图4 时间对锌和硅浸出率的影响

Fig.4 Effect of time on leaching rate of zinc and silicon

从图4可知:反应时间对锌和硅浸出具有几乎相同的影响,当反应时间小于2 h时,随着反应时间的延长,锌和硅的浸出率基本不变;但当反应时间超过2 h时,锌和硅的浸出率不断降低,最后趋于不变,这是因为在强机械活化的作用下,反应时间对Na2ZnSiO4的生成起到推动作用,导致渣中含锌和硅不断增多,锌和硅的浸出率则不断降低,最后趋于平衡。故选最佳浸出时间2 h。

2.3 碱浓度对锌、硅浸出的影响

根据热力学平衡计算,碱浓度越大,锌的溶解度越大[12],对浸出越有利,结合碱的溶解度综合考虑,试验选取NaOH用量为理论用量(12.8 g)的1,2,3,4和5倍,温度为140 ℃,液固比为10?1,浸出时间为2 h。试验结果如图5所示。

从图5可知,锌和硅的浸出率随浸出液NaOH用量的增加而增加,但当NaOH用量达到理论用量的3.5倍以后锌的浸出率增加变得缓慢,当NaOH用量达到理论用量的4倍以后硅的浸出率增加变得缓慢,这是因为在浸出过程中Zn的氧化物将与NaOH分别发生(2)和(3)式反应,生成可溶性的Na2Zn(OH)4(aq.)(或Na2ZnO2)产物,在一定范围内增加NaOH 的浓度对反应(2)和(3)的发生起正向推动作用,但由于过程受化学反应步骤控制,在温度一定的前提下,随着NaOH 浓度的增加,其正向推动力将随之减小,最后趋于零。故当NaOH用量超过理论用量的3.5倍时,Zn的浸出率基本趋于不变。故确定最佳浸出条件NaOH的用量为理论用量的3.5倍。

图5 NaOH用量对锌和硅浸出率的影响

Fig.5 Effect of sodium hydroxide concentration on leaching rate of zinc and silicon

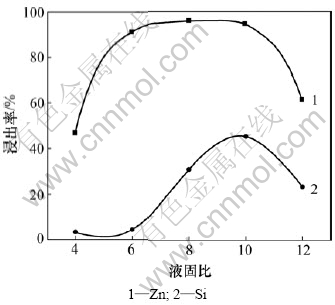

2.4 液固比对锌和硅浸出的影响

在碱矿比为2?1,温度为140 ℃,浸出时间2 h的条件下,考察液固比对锌和硅浸出率的影响,结果如图6所示。

图6 液固比对锌、硅浸出率的影响

Fig.6 Effect of ratio of leaching liquid to leaching solid on leaching rate of zinc and silicon

从图6可知,液固比对锌和硅浸出率的影响较大,当液固比小于10?1时,锌和硅的浸出率随液固比的增加而增加,只是当液固比达到6?1以后锌的浸出率增加变得比校缓慢。这主要是因为液固比在一定程度上增加将有利于离子间的扩散,并且羟合锌配离子在溶液中也有一定的溶解度,液固比小会限制锌的浸出程度。但当液固比大于10?1以后,锌和硅的浸出率随液固比的增加反而减小,这是因为液固比太大会使得热球磨的活化效果变差,且碱的浓度变得太低也将导致锌和硅的浸出率降低。综合考虑确定最佳浸出液固比为10?1。

3 结论

(1) 当温度超过140 ℃时氧化锌矿在强机械活化作用下将生成难溶产物Na2ZnSiO4,导致锌在渣中损失从而浸出率降低。

(2) 氧化锌矿在长的浸出时间、强机械活化作用下将生成难溶产物Na2ZnSiO4,导致锌的浸出率降低。

(3) 当NaOH的用量为理论用量的3.5倍,温度为140 ℃,浸出时间2 h,液固为10?1时,氧化锌矿机械活化碱法浸出锌的浸出率达到95.1%,硅的浸出率为45.5%。

参考文献:

[1] 刘亚川, 刘述平, 李博, 等. 低品位氧化锌矿的氨-铵盐浸出研究[J]. 矿产综合利用, 2008(2): 3-5.

LIU Ya-chuan, LIU Shu-ping, LI Bo, et al. Research on ammonia-ammonium chloride leaching of a low-grode zinc oxide ore[J]. Multipurpose Utilization of Mineral Resources, 2008(2): 3-5.

[2] 刘三军, 欧乐明, 冯其明, 等. 低品位氧化锌矿石的碱法浸出[J]. 湿法冶金, 2005, 24(1): 23-25.

LIU San-jun, OU Le-ming, FENG Qi-ming, et al. Alkaline leaching of Zn from zinc oxide ore[J]. Hydrometallurgy of China, 2005, 24(1): 23-25.

[3] 姚耀春, 朱云, 王平. 难选氧化锌矿氨浸的动力学研究[J]. 有色金属, 2004, 53(3): 49-51.

YAO Yao-chun, ZHU Yun, WANG Ping. Kingetic study on ammonia leaching of refractory minerals of zinc oxide[J]. Nonferrous Metals, 2004, 53(3): 49-51.

[4] 蓝卓越, 胡岳华, 黎维中. 低品位氧化锌矿硫酸浸出工艺研究[J]. 矿冶工程, 2002, 22(3): 63-65.

LAN Zhuo-yue, HU Yue-hua, LI Wei-zhong. Sulfuric acid leaching of low-grade zinc oxide ore—A study[J]. Mining and Metallurgical Engineering, 2002, 22(3): 63-65.

[5] 李锋, 垒作姜, 王励生. 浸出高硅锌焙砂中硅胶聚沉的规律[J]. 中国有色金属学报, 2003, 13(6): 1114-1117.

LI Feng, JIN Zuo-mei, WANG Li-sheng. Silica gel aggregation under acidic leaching of high-silica containing zinc calcine[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1114-1117.

[6] 陈永海, 覃文庆, 黄红军. 高硅氧化锌矿酸浸脱硅过程研究进展[J]. 湖南有色金属, 2005(2): 14-16.

CHEN Yong-hai, TAN wen-qing, HUANG Hong-jun. Development of silica-removal study on leaching high-grade silico zinc oxide ore with sulfuric acid[J]. Hunan Nonferrous Metals, 2005(2): 14-16.

[7] 刘三军, 欧乐明, 冯其明. 氧化锌矿的碱法浸出研究[J]. 矿产保护与利用, 2004(4): 39-43.

LIU San-jun, OU Le-ming, FENG Qi-ming. Alkaline leaching of a zinc oxide ore[J]. Conservation And Utilization of Mineral Resources, 2004(4): 39-43.

[8] Frenay J. Leaching of oxided zinc ores in various media[J]. Hydrometallurgy, 1985(15): 243-253.

[9] 刘桂华, 刘云峰, 李小斌, 等. 拜耳法溶出过程降低赤泥碱耗[J]. 中国有色金属学报, 2006, 16(3): 555-559.

LIU Gui-hua, LIU Yun-feng, LI Xiao-bin, et al. Reducing loss of soda in red mud in process of Bayer digestion[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 555-559.

[10] 顾珩, 李洪桂, 刘茂盛. 热球磨苏打法处理钼渣新工艺研究[J]. 中国钼业, 1997, 21(4): 16-18.

GU Heng, LI Hong-gui, LIU Mao-sheng. Study on the new technology for treatment of the molybdenum residue of ammonia-leaching with sodium carbonat in a heat ball-millreactor[J]. China Molybdenum Industry, 1997, 21(4): 16-18.

[11] 林祚彦, 华一新. 高硅氧化锌矿硫酸浸出的工艺及机理研究[J]. 有色金属: 冶炼部分, 2003(5): 9-11..

LIN Zuo-yan, HUA Yi-xin. Technology and mechanism study on leaching high silicon zinc oxide ore with sulfuric acid[J]. Nonferrous Metals: Smelting, 2003(5): 9-11.

[12] 张承龙, 邱媛媛, 黄希, 等. 含锌危险废物的碱法浸出研究[J]. 有色冶金设计与研究, 2007, 28(23): 88-90, 102.

ZHANG Cheng-long, QIU Yuan-yuan, HUANG Xi, et al. Research on alkaine leaching of hazardous waste bearing Zn[J]. Nonferrous Metals Engineering and Research, 2007, 28(23): 88-90, 102.

[13] 李小斌, 任万能, 刘桂华, 等. NaOH-NaAl(OH)4-H2O体系活度系数的计算模型[J]. 中南大学学报: 自然科学版, 2006, 37(3): 493-497.

LI Xiao-bin, REN Wan-neng, LIU Gui-hua, et al. Activity coefficient calculation model for NaAl(OH)4-NaOH-H2O system[J]. Journal of Central South University: Science and Technology, 2006, 37(3): 493-497.

[14] Malavasi G, Lusvardi G, Pedone A, et al. Crystallization kinetics of bioactive glasses in the ZnO-Na2O-CaO-SiO2 system[J]. J Phys Chem, 2007, 111: 8401-8408.

[15] 付戈妍, 包玉敏, 付克. Na2ZnSiO4的微波合成及离子导电性质的研究[J]. 内蒙古民族大学学报: 自然科学版, 2004, 19(5): 511-513.

FU Ge-yan, BAO Yu-min, FU Ke. Microwave synthesize of Na2ZnSiO4 and study of its electric conductivity[J]. Journal of Inner Mongolia University for Nationalities, 2004, 19(5): 511-513.

收稿日期:2009-08-22;修回日期:2009-11-30

基金项目:“973”国家重点基础研究发展计划支持项目(2007CB613603);教育部“新世纪优秀人才支持计划”(NCET-05-0692)

通信作者:赵中伟(1966-),男,河北永年人,教授,博士生导师,从事有色金属冶金提取及冶金材料的制备研究;电话:0731-88830476;E-mail: zhaozw@mail.csu.edu.cn

(编辑 任楚威)