文章编号:1004-0609(2010)11-2101-05

2D70耐热铝合金显微组织均匀化热处理

李培跃1, 熊柏青1, 张永安1, 李志辉1, 王国军1, 2, 王 锋1, 朱宝宏1

(1. 北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京100088;

2. 东北轻合金有限责任公司,黑龙江哈尔滨150060)

摘 要:利用光学显微镜、扫描电子显微镜、能谱分析、差示扫描量热、X射线物相分析研究2D70耐热铝合金半连续铸锭的结晶相及合理的均匀化热处理制度。结果表明:合金半连续铸锭中枝晶偏析严重,存在大量非平衡共晶相,其成分为α(Al)+θ(Al2Cu)+S(Al2CuMg),其初始熔化温度为505.4 ℃;在530 ℃温度以下进行均匀化时,合金中的难溶相Al7Cu2Fe、Al7Cu4Ni、Al9FeNi含量基本没有变化;合金合理的均匀化热处理制度为(490 ℃, 16 h)+(520 ℃, 16 h)。

关键词:耐热铝合金,均匀化热处理,共晶相

中图分类号:TG146.21 文献标志码:A

Homogenization treatment and microstructure of semicontinous casting ingot of 2D70 heat-resistance aluminum alloy

LI Pei-yue1, XIONG Bai-qing1, ZHANG Yong-an1, LI Zhi-hui1,WANG Guo-jun1, 2, WANG Feng1, ZHU Bao-hong1

(1. State Key Laboratory of Nonferrous Metals and Processes,

General Research Institute for Nonferrous Metals,Beijing 100088, China;

2. Northeast Light Alloy Co., Ltd., Harbin 150060, China)

Abstract:The constituents of the semicontinuous casting ingot of 2D70 heat-resistance aluminum alloy and homogenization treatment were studied by optical microscopy (OM), scanning electron microscopy with energy dispersive X-ray spectroscopy (SEM-EDX),differential scanning calorimetry(DSC) and X-ray diffraction analysis (XRD). The results indicate that the semicontinuous casting ingot of 2D70 aluminum alloy presents a dendritic microstructure with severe segregation. The phases of the nonequilibrium eutectic are α(Al)+ θ(Al2Cu) +S(Al2CuMg) whose overheating temperature is 505.4 ℃. The volume fraction of hard dissolve phases such as Al7Cu2Fe, Al7Cu4Ni and Al9FeNi changes a little below 530 ℃. The reasonable homogenization treatment process of the alloy is (490 ℃, 16 h) +(520 ℃, 16 h).

Key words: heat-resistance aluminum alloy; homogenization treatment; eutectic

2D70铝合金为高纯、可热处理强化的Al-Cu-Mg-Fe-Ni系铝合金[1],该合金在飞行器发动机和汽车工业中有着广泛的应用[2]。它与欧美的2618A以及俄罗斯的AK4–1铝合金成分接近[3-4],以俄罗斯AK4–1铝合金为基础,通过严格控制杂质元素Mn、Si等含量,调整合金元素Cu、Fe、Ni含量,使得合金的综合性能得到了改善。该合金在高温长时间加热过程中软化速度慢,有良好的耐热性能,可用于150 ℃下长时间工作的受力结构零件[5-6],该合金淬火敏感性小,适合做大尺寸构件[7]。近年来,随着航空、国防工业的快速发展,对耐热铝合金性能提出了更高要 求[8-9],因此,有必要对该合金进行更为深入的研究。

近年来,关于该合金的研究主要集中在合金成分、热加工工艺、淬透性能[7]等方面,而对合金显微组织及在均匀化热处理过程中的组织变化研究较少[10-11]。半连续铸造工艺冷却速度较大,为非平衡凝固,合金在凝固过程中会发生严重的枝晶偏析。合金在枝晶间最后结晶,形成非平衡凝固共晶相。这些相的熔化温度较低,在热处理过程中首先发生溶解或熔化,当热处理温度高于它们的熔化温度时,则造成合金的过烧。它们的存在降低了合金的塑性,影响合金热变形加工和使用性能,严重影响了合金性能的进一步提高,必须通过合理后续热处理加以消除[12-14]。为此,本文作者在探明铸锭铸态组织中的第二相种类的基础上,针对以往2D70耐热铝合金均匀化热处理第二相回溶不彻底的问题,开展2D70耐热铝合金半连续铸锭的均匀化工艺研究,以期为优化工艺参数提供实验基础及理论依据。

1 实验

实验铸锭采用半连续铸造,铸造过程中用精炼剂、氩气对熔体进行精炼,添加Al-Ti-B丝细化晶粒,铸造温度为740~750 ℃,铸造速度为35~40 mm/min,铸锭直径为400 mm。其成分如表1所列。均匀化实验试样均取自铸锭1/2半径处,试样尺寸为12 mm×12 mm × 15 mm。实验在马弗炉中进行,单级均匀化工艺选择(490 ℃, 16 h)和(520 ℃, 16 h),双级均匀化制度选择(490 ℃, 16 h)+(520 ℃, 16 h)和(490 ℃, 16 h)+(530 ℃, 16 h)。为保留均匀化态合金的显微组织,均匀化后试样均采用自来水冷却。

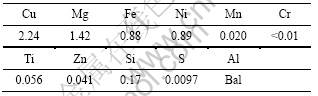

表1 合金的化学成分

Table 1 Chemical composition of alloy (mass fraction, /%)

显微组织观察样品经初磨、细磨、机械抛光后,经Kellers腐蚀剂腐蚀。采用Zeiss Axiovert 200MAT光学金相显微镜(OM)直接观察合金的金相组织,采用HITACHI S4800扫描电子显微镜(SEM)观察合金的显微组织,采用EMAX能谱分析仪(EDS)分析合金的微区和第二相粒子化学成分。利用Universal V4.1DTA2010 instruments型差示扫描量热仪(DSC)对合金进行热分析,升温速率为10 ℃/min,整个实验过程在氩气保护中进行。X射线物相分析在Rigaku DMAX-RB12KW旋转阳极衍射仪上进行,实验采用Cu靶,电压为40 kV,电流为150 mA,扫描速度为10 (?)/min。

2 结果与分析

2.1合金铸态显微组织

合金半连续铸锭金相组织如图1所示。合金铸态组织为典型的枝晶组织,晶粒尺寸为100~500 μm,枝晶间存在低熔点非平衡共晶相[15],在晶界和晶内还存在大量形状不规则的灰色相和黑色相,同时存在大量羽毛状相(如图1(b)中箭头所指),它们是高熔点金属间化合物,这类相的尺寸较大,对合金的塑性有较大影响。

图1 合金半连续铸锭的金相组织

Fig.1 Microstructures of as-cast alloy: (a) Low magnitude; (b) High magnitude

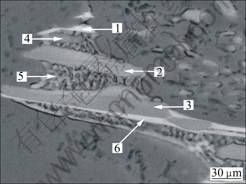

图2所示为合金典型的扫描电镜相片,表2所列为图2中各箭头所指相的能谱分析结果。由图2可见,合金铸态组织较为复杂,组织中存在大量不同类型粗大第二相。铸态合金中共晶相呈蜂窝状,伴生大量条状富Cu、Ni相,块状、条状富Fe、Ni相,各种第二相相互重叠交错。

图2 合金半连续铸锭扫描电镜相片

Fig.2 SEM image of as-cast alloy

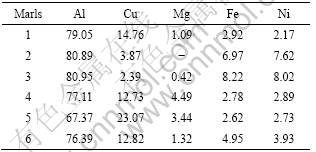

表2 图2中点的能谱分析结果

Table 2 Composition of second phases marked in Fig.2 measured by EDS (mole fraction, %)

该铝合金在Al-Cu-Mg系中位于Al+Al2CuMg两相区内,一般来说,Fe和Ni元素含量比例为1?1时,生成三元Al9FeNi相,当Fe和Ni存在过剩时,则相应形成Al7Cu2Fe和Al7Cu4Ni,这两相的存在降低合金的力学性能。结合图2所示不同相的形态特征和对应的能谱分析,可知图2中的1、6为Al2Cu相,2、3为Al9FeNi相,4、5可能为Al2CuMg+Al2Cu共晶相。

2.2均匀化热处理

图3所示为合金不同状态的差示扫描量热(DSC)分析曲线。该合金在505.4~508.9 ℃处出现第一个明显的吸热效应,且为不定温热效应。根据该热效应的变温吸热性质,可知它是该合金组织中非平衡低熔点共晶相的熔化转变。文献[3, 16]提到该峰为Al2CuMg(S相)溶解吸热峰,图2及表2中的铸态组织能谱分析也证实了这个结论。在534.5~540.4 ℃处出现第二次吸热反应,该吸热峰对应共晶相中θ(Al2Cu)相的溶解。合金经(490 ℃, 16 h)均匀化后,曲线上505.4~508.9 ℃吸热峰消失, 530~540 ℃吸热峰依然存在,但峰值明显变小,表明合金中S(Al2CuMg)低熔点相发生了溶解,但θ(Al2Cu)相回溶不彻底。合金经(490 ℃, 16 h)+(520 ℃, 16 h)均匀化后两个低熔点峰基本消失,表明合金经(490 ℃, 16 h)+(520 ℃, 16 h)均匀化后,合金中Al2Cu(θ)+Al2CuMg(S)低熔点相已基本回溶到基体,合金组织变得均匀。

图3 不同状态合金DSC曲线

Fig.3 DSC thermogram of alloy at different tempers

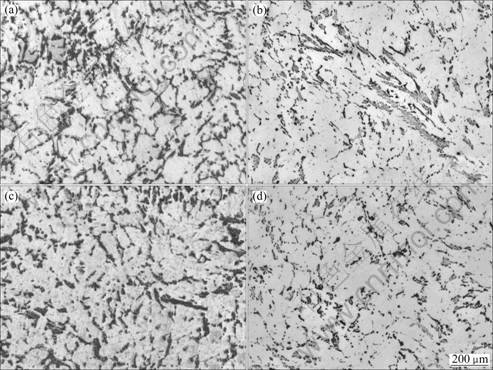

图4所示为合金经不同均匀化热处理制度后的金相照片。对比观察合金铸态及经不同制度均匀化后的组织,发现合金经(490 ℃, 16 h)单级均匀化后,枝晶网络变得稀疏,晶界和枝晶间共晶相数量已有所减少。进一步提高均匀化温度,合金经过(520 ℃, 16 h)均匀化后,合金出现复熔球,表明合金已经过烧。采用(490 ℃, 16 h)+(520 ℃, 16 h)双级均匀化,共晶相大量回溶,且无过烧出现,这与DSC分析结果相符合。进一步提高第二级均匀化温度,采用(490 ℃, 16 h)+(530 ℃, 16 h)均匀化时,由于温度过高,出现大量复熔球,表明合金已经严重过烧。

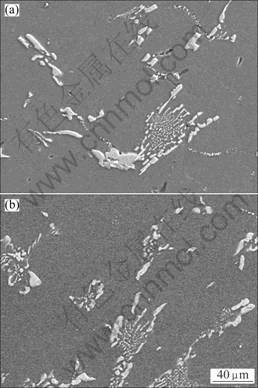

图5所示为合金均匀化后的扫描电镜相片。由图5可见,与(490 ℃, 16 h)均匀化相比,合金经(490 ℃, 16 h)+(520 ℃, 16 h)均匀化后,合金中仍残留大量难溶析出相(Al7Cu2Fe、Al7Cu4Ni、Al9FeNi相),且整个均匀化过程中,难溶相形貌、数量没有明显变化。

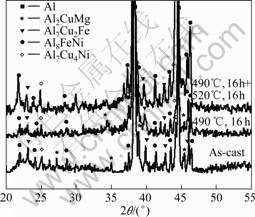

图6所示为合金铸锭及经不同均匀化工艺处理后的XRD谱。由图6可见,铸态合金主要相为α(Al)、S(Al2CuMg)、Al7Cu2Fe、Al7Cu4Ni、Al9FeNi相,这与前文关于铸态SEM组织及EDS分析结果相吻合;铸态合金经(490 ℃, 16 h)均匀化后,S(Al2CuMg)相发生回溶,其他相没有明显变化;合金经(490 ℃, 16 h)+(520 ℃, 16 h)均匀化后,Al9FeNi、Al7Cu2Fe、Al7Cu4Ni相对应的峰值更高,S相峰更低,几近消失,表明合金中共晶相已经基本回溶到基体。正是由于共晶相的回溶,Al7Cu2Fe、Al7Cu4Ni、Al9FeNi相相对含量升高,在图谱中峰值增高。对比单级均匀化和双级

图4 不同均匀化温度处理后合金的金相显微组织

Fig.4 Microstructures of alloys after different homogenization treatments: (a) 490 ℃, 16 h; (b) 520 ℃, 16 h; (c) (490 ℃, 16 h)+(520 ℃, 16 h); (d) (490 ℃, 16 h)+(530 ℃, 16 h)

图5 不同均匀化温度处理后合金的SEM像

Fig.5 SEM images of alloys after different homogenization treatments: (a) 490 ℃, 16 h; (b) (490 ℃, 16 h)+(520 ℃, 16 h)

图6 不同状态合金XRD谱

Fig.6 XRD patterns of alloys at different tempers

均匀化结果表明,双级均匀化工艺可以使得共晶相有效地回溶基体,一些第二相衍射峰基本保持不变,说明这些第二相在均匀化处理过程中不能有效回溶基体[17]。

3 结论

1) 合金铸态组织枝晶偏析严重,存在大量非平衡共晶相,其成分为α(Al)+θ(Al2Cu)+S(Al2CuMg)。

2) 经(490 ℃, 16 h)均匀化热处理后,共晶相部分回溶,经(490 ℃, 16 h)+(520 ℃, 16 h)双级均匀化后,共晶相基本回溶基体。合金中Al7Cu2Fe、Al7Cu4Ni、Al9FeNi难溶相,在530 ℃温度以下进行均匀化,含量基本没有变化。

3) 合金合理的均匀化热处理制度为(490 ℃, 16 h)+(520 ℃, 16 h)。

REFERENCES

[1] 陆海庆, 张思平. 2D70-T651铝合金预拉伸厚板生产工艺研究[J]. 铝加工, 2003(6): 14-16.

LU Hai-qing, ZHANG Si-ping. Study on production process of 2D70-T651 aluminum alloy plate[J]. Aluminum Fabrication, 2003(6): 14-16.

[2] WANG Jian-hua, YI Dan-qing, WANG Bin. Microstructure and properties of 2618-Ti heat resistant aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(3): 590-594.

[3] 王国军, 熊柏青, 张永安, 李志辉, 李培跃. 2D70铝合金铸态及均匀化态的显微组织演变[J]. 特种铸造及有色合金, 2009, 29(6): 560-564.

WANG Guo-jun, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui, LI Pei-yue. Microstructural evolution of as-cast and homogenized 2D70 aluminum alloy[J]. Special Casting & Nonferrous Alloys, 2009, 29(6): 560-564.

[4] AJDELSZTAJN L, ZUNIGA A, JODOIN B, LAVERNIA E J. Cold gas dynamic spraying of a high temperature Al alloy[J]. Surface & Coatings Technology, 2006, 201: 2109-2116.

[5] SOMI REDDY A. Fatigue and creep deformed microstructures of aged alloys based on Al–4%Cu–0.3%Mg[J]. Materials and Design, 2008, 29: 763-768.

[6] 黄 敏, 马春雨, 杨守杰, 戴圣龙. 2D70铝合金厚板热处理制度研究[C]// 2002年中国材料研讨会论文集: 2002年材料科学与工程新进展(下): 2002.

HUANG Min, MA Chun-yu, YANG Shou-jie, DAI Sheng-long. Heat treatment of thick plate of 2D70alloy[C]. The New Progress on Material Science and Engineering in 2002(Part ), 2002.

[7] 王国军, 熊柏青, 张永安, 李志辉, 李培跃. 2D70铝合金淬透性研究[J]. 稀有金属, 2009, 33(3): 304-308.

WANG Guo-jun, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui, LI Pei-yue. Hardenability of 2D70 aluminum alloy[J]. Chinese Journal of Rare Metals, 2009, 33(3): 304-308.

[8] WANG Jian-hua. Effect of melt over-heating and zirconium alloying in the morphology of Al9FeNi and mechanical properties of 2618 alloy[J]. Acta Metallurgica Sinica(English Letters), 2002. 15(06): 525-530.

[9] MAJIMEL J, CASANOVW M J, LAPASSET G. Dislocation mechanisms involved in at 150 ℃ creep test of an Al(CuMg) aluminum alloy[J]. Materials Science Forum, 2002, 396/402: 1383-1388.

[10] WANG Guo-jun, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui, LI Pei-yue. Microstructural characterization of as-cast and homogenized 2D70 aluminum alloy[J]. International Journal of Minerals Metallurgy and Materials, 2009, 16(4): 427-431.

[11] OGUOCHA I N A, YANNACOPOULOS S. Precipitation and dissolution kinetics in Al–Cu–Mg–Fe–Ni alloy 2618 and Al–alumina particle metal matrix composite[J]. Materials Science and Engineering A, 1997, 231: 25-33.

[12] ZUO Yu-bo, WANG Shuang, ZHAO Zhi-hao, CUI Jian-zhong, ZHANG Hai-tao, TU Gan-feng. Constituents evolution of LFEC 7050 aluminum alloy during processing[J]. Transactions Nonferrous Metals Society of China, 2007, 17(2): 249-253.

[13] FAN Xi-gang, JIANG Da-ming, MENG Qing-chang, ZHANG Bao-you, WANG Tao. Evolution of eutectic structures in Al-Zn-Mg-Cu alloys during heat treatment[J]. Transactions Nonferrous Metals Society of China, 2006,16(3): 577-581.

[14] 王建华. 2618耐热铝合金的组织与力学性能的研究[D]. 长沙: 中南大学, 2003.

WANG Jian-hua. Study on microstructures and mechanical properties of heat resistance aluminum alloy 2618[D]. Changsha: Central South University, 2003.

[15] BELOV N A, ESKIN D G,, AKSENOV A A. Multicomponent phase diagrams: applications for commercial aluminum alloys[M]. Oxford: Elsevier, 2005.

[16] 金相图谱编写组. 变形铝合金金相图谱[M]. 北京:冶金工业出版社, 1975.

Editorial Group of Metallography Atlas. Metallography atlas of deformable aluminum alloy[M]. Beijing: Metallurgical Industry Press, 1975.

[17] 纪艳丽, 潘琰峰, 郭富安. 6022铝合金铸态组织研究[J]. 金属热处理, 2008, 33(5): 31-34.

JI Yan-li, PAN Yan-feng. GUO Fu-an. Study on microstructure of as-cast 6022 aluminum alloy[J]. Heat Treatment of Metals, 2008, 33(5): 31-34.

(编辑 何学锋)

基金项目:科技部科技支撑计划资助项目(2007BAE38B06)

收稿日期:2009-08-13;修订日期:2010-02-28

通信作者:熊柏青,教授,博士;电话:010- 82241885;E-mail:xiongbq@grinm.com