冷轧Fe-Mn-Si合金的形状记忆效应与淬火温度的关系

来源期刊:中南大学学报(自然科学版)1990年第3期

论文作者:谭树松 赵清华

文章页码:272 - 276

关键词:铁; 锰; 硅; 合金/ε-马氏体; 不全位错; 堆垛层错

Key words:iron; manganese; silicon; alloys/ε-martensite; partial dislocation; stacking fault; shapes memory effect(SME)

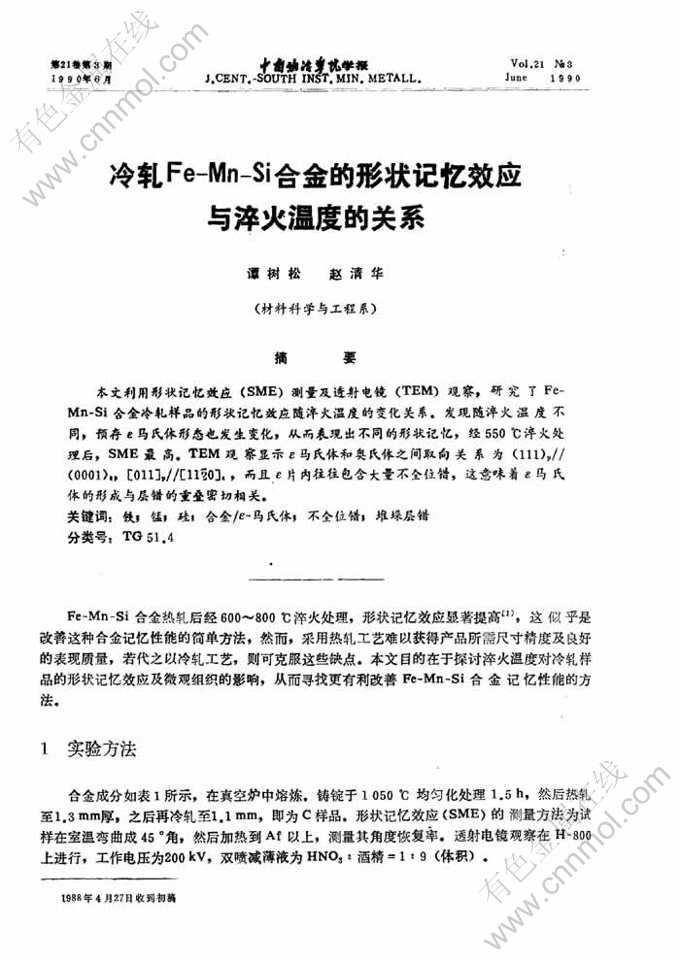

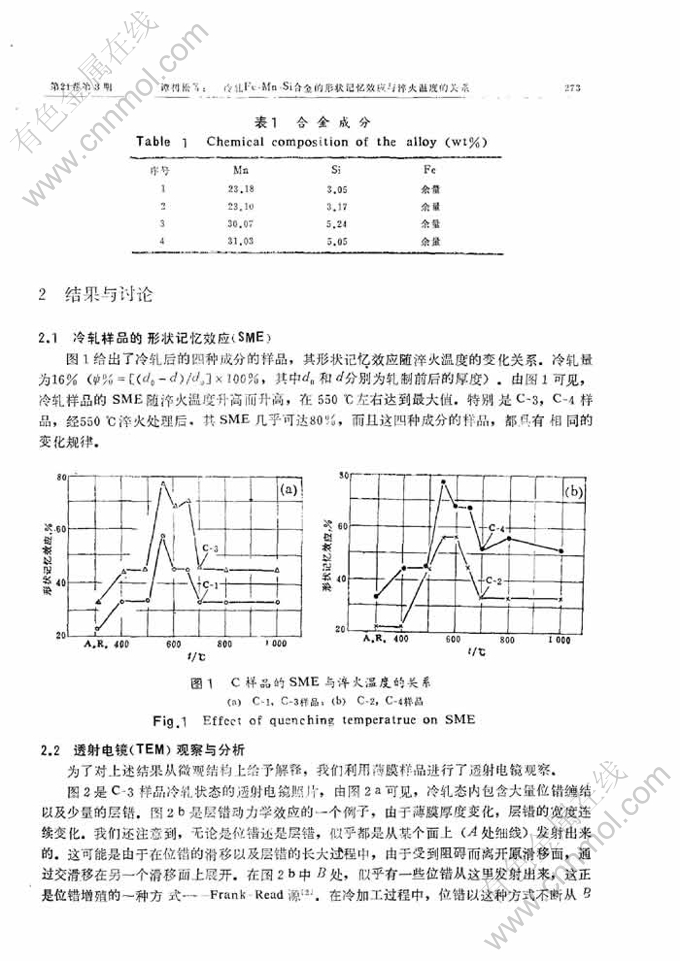

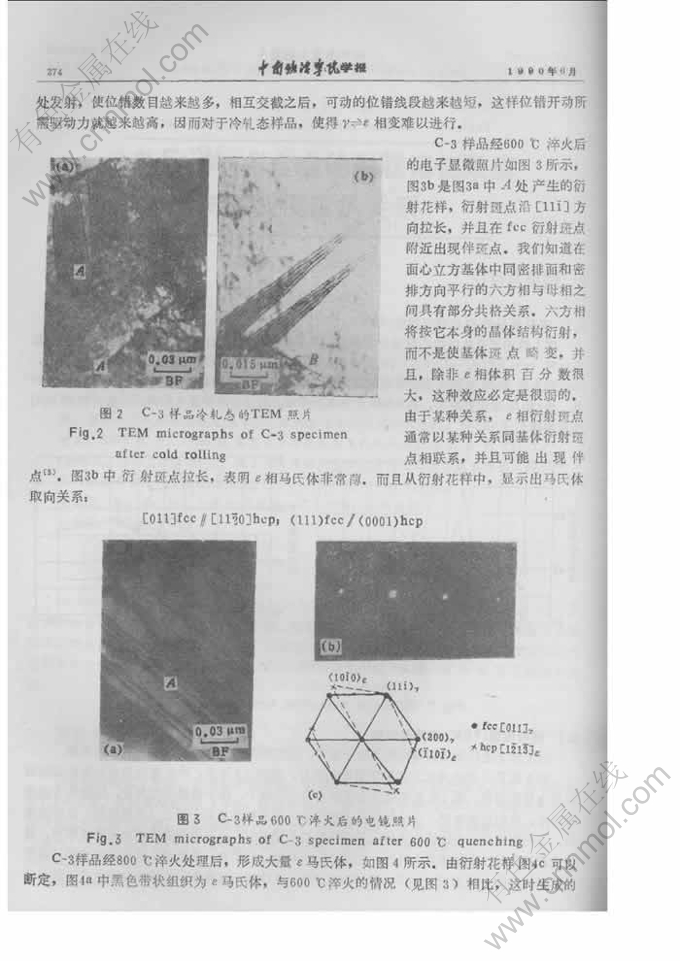

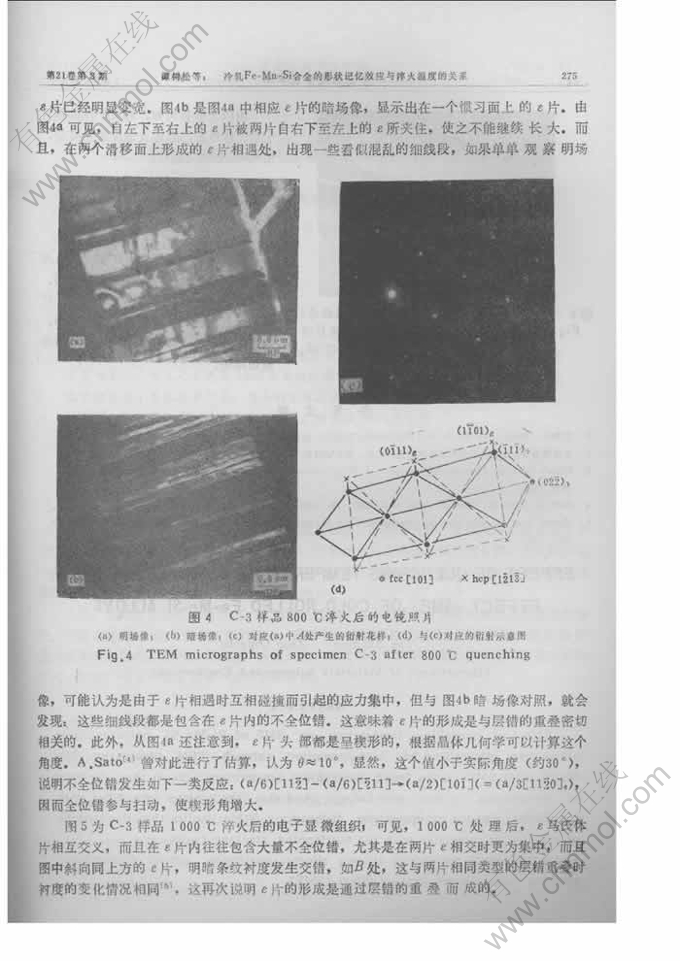

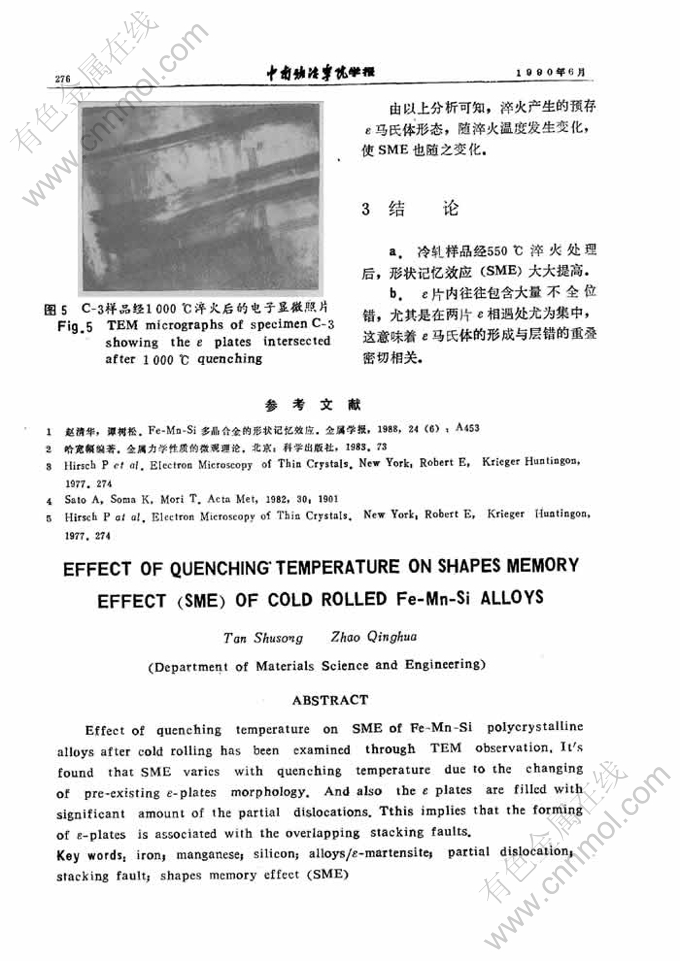

摘 要:本文利用形状记忆效应(SME)测量及透射电镜(TEM)观察,研究了Fe-Mn-Si合金冷轧样品的形状记忆效应随淬火温度的变化关系。发现随淬火温度不同,预存ε马氏体形态也发生变化,从而表现出不同的形状记忆,经550℃淬火处理后,SME最高。TEM观察显示ε马氏体和奥氏体之间取向关系为(111)γ//(0001)δ,[011]γ//[1120]e,而且ε片内往往包含大量不全位错,这意味着ε马氏体的形成与层错的重叠密切相关

Abstract: Effect of quenching temperature on SME of Fe-Mn-Si polycrystallinealloys after cold rolling has been examined through TEM observation.It′sfound that SME varies with quenching temperature due to the changingof pre-existing ε-plates morphology.And also the ε plates are filled withsignificant amount of the partial dislocations.Tthis implies that the formingof ε-plates is associated with the overlapping stacking faults.