DOI: 10.11817/j.ysxb.1004.0609.202037589

Fe-Mn-Si记忆合金的疲劳特性

孙德平1,鞠 恒2,苑海超1

(1. 大连海事大学 轮机工程学院,大连 116026;

2. 大连海洋大学 机械与动力工程学院,大连 116023)

摘 要:为分析Fe-Mn-Si记忆合金的疲劳特性,采用与该材料具有相同母相的304不锈钢作为对比材料,通过弯曲疲劳试验法测量两者在应变幅值为±3.5%时的疲劳断裂次数,并利用X射线衍射法(XRD)和场发射扫描电镜(SEM)分析试样相组成和断口形貌。结果表明:Fe-Mn-Si记忆合金和304不锈钢的弯曲疲劳断裂次数分别为1159次和63次,断口形貌依次为韧窝和撕裂棱。前者断裂时的物相基本为ε马氏体,而后者几乎全部由α′马氏体组成,表明应力诱发Fe-Mn-Si记忆合金发生γ→ε马氏体相变。相变过程中,应力集中程度和裂纹扩展速度降低是Fe-Mn-Si记忆合金疲劳强度提高的机理。

关键词:Fe-Mn-Si记忆合金;疲劳特性;γ→ε马氏体相变

文章编号:1004-0609(2020)-07-1620-06 中图分类号:TU973+.254 文献标志码:A

金属在循环载荷作用下,即使所受的应力低于屈服强度,亦会发生断裂,这种现象称为疲劳[1]。在材料疲劳断裂过程中,一般不会发生明显的塑性变形现象,故很难检测和预防,导致高危险性[2]。因此工程设备中需应用高疲劳强度的金属材料,并且研究其疲劳特性具有实际意义[3-4]。

Fe-Mn-Si记忆合金具有“应力自适应特性”,即合金在循环应变作用下可发生可逆的γ→ε马氏体相变,该过程中往复变形可吸收能量和减少应力集中来提高合金的疲劳特性[5]。目前,科研人员主要研究Fe-Mn-Si记忆合金的形状记忆效应机理及提高方法[6-8],关于合金承受循环应变时疲劳特性研究较少。

本文通过弯曲疲劳试验方法分析Fe-Mn-Si记忆合金的疲劳特性,并采用X射线衍射法(XRD)和场发射扫描电镜(SEM)观察分析Fe-Mn-Si记忆合金的物相组成以及断口形貌。

1 实验

本弯曲疲劳试验选用的材料为Fe-17Mn-5Si-10Cr-5Ni记忆合金,为对比研究试验材料的疲劳特性,采用同为奥氏体母相的304不锈钢作为对比材料,两者的化学成分如表1所示。利用SDS-100型电液伺服疲劳试验机进行室温条件下的Fe-Mn-Si记忆合金和304不锈钢的循环疲劳试验。图1所示为弯曲疲劳试验的试样形状及尺寸。利用线切割机将材料加工完成后,在热处理炉内进行(1000 ℃,1 h)固溶处理,消除试样在加工过程中产生的马氏体,使其完全由奥氏体相组成。

弯曲疲劳试验中,对试样加载交变对称循环应力,加载的应变-时间波形如图2所示。循环最大应变εmax和循环最小应变εmin分别为3.5%和-3.5%;平均应变εm=(εmax+εmin)/2=0;应变比R=εmax/εmin=-1;加载频率为3 Hz。

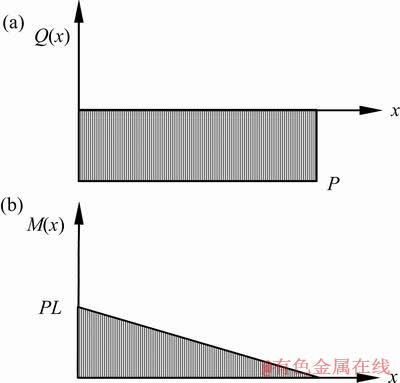

为保证弯曲疲劳试样承受等强度应力,采用自制的弯曲疲劳夹具上下弯曲试样,弯曲过程的简化力学模型如图3(a)和(b)所示。其中,向下弯曲过程的内力图和弯矩图如4(a)和(b)所示。同理,向上弯曲过程的内力图和弯矩图如5(a)和(b)所示。

表1 Fe-17Mn-5Si-10Cr-5Ni合金和304不锈钢的化学成分

Table 1 Chemistry compositions of Fe-17Mn-5Si-10Cr-5Ni alloy and 304 stainless steel

图1 弯曲疲劳试验试样

Fig. 1 Specimen of bending fatigue test (Unit: mm)

图2 应变-时间波形图

Fig. 2 Oscillogram of strain and time

图3 向下、向上弯曲过程的简化力学模型

Fig. 3 Simplify mechanical model of bending process

图4 向下弯曲过程中试样的内力图和弯矩图

Fig. 4 Internal force diagram(a) and bending moment diagram(b) of downward bending process

图5 向上弯曲过程中试样的内力图和弯矩图

Fig. 5 Internal force diagram(a) and bending moment diagram(b) of upward bending process

循环疲劳过程中,利用D/max-3B型X射线衍射仪对Fe-Mn-Si记忆合金和304不锈钢表层进行相组成分析。其主要技术参数如下:Cu Kα辐射,加速电压40 kV,电流150 mA,扫描速度0.02 (°)/s,扫描角度为30°~75°。循环疲劳断裂后,通过SUPRA 55 SAPPHIR型场发射扫描电镜分析断口形貌。

2 结果与讨论

2.1 疲劳断裂次数及相组成

在应变幅值在±3.5%的情况下,Fe-Mn-Si记忆合金和304不锈钢的弯曲循环断裂次数分别为1159次和63次,前者的弯曲疲劳次数明显高于后者。图6 所示为不同循环弯曲次数下的304不锈钢的XRD谱。

为更精确地了解弯曲疲劳试样相体积变化规律,通过直接比较法定量计算XRD谱中各相含量[9]。根据图6得到不同弯曲次数条件下的304不锈钢中γ和α′相的体积分数,如表2所示。

图6 不同循环弯曲次数下的304不锈钢XRD谱

Fig. 6 XRD patterns of 304 stainless steel under different bending cycles

表2 在不同循环弯曲次数下的304不锈钢试样相体积分数

Table 2 Phase constitution of 304 stainless steel specimens with different bending cycles

由图6可知,经循环弯曲后的304不锈钢的相组成为γ+α′。与弯曲前由单一奥氏体组织(γ)组成的304不锈钢相比,新增了α′马氏体相,表明304不锈钢试样发生了不可逆的γ→α′马氏体相变[10]。在XRD谱中,衍射峰的面积大小实际上反应该衍射峰所代表相在试样中的体积分数。故由循环弯曲次数的增加,(110)α′和(200)α′马氏体相的衍射峰面积不断增加,(111)γ、(200)γ及(220)γ奥氏体相的衍射峰面积不断减小这一现象可知,在循环弯曲疲劳过程中,304不锈钢的母相γ奥氏体随循环次数的增加而逐渐减少,新增相α′马氏体相随循环次数的增加而逐渐增加。

由表2可知,经1次循环弯曲后,γ奥氏体含量从100%降为42.3%,α′马氏体含量从0%增加到57.7%;经10次循环弯曲后,γ奥氏体含量降为16.4%,α′马氏体含量增加为83.6%。在循环弯曲前期,γ→α′马氏体相变迅速产生,且几乎与循环次数呈线性关系。从第31次到63次循环弯曲过程中,α′奥氏体含量虽然继续增加,但增速相对放缓。究其原因在于,304不锈钢在弯曲疲劳前期基本由奥氏体相组成,可进行γ→α′相变的母相含量较高,故产生的α′相较多,其含量增加较快。疲劳试验后期,α′相增加速度随着母相γ的减小而降低。当304不锈钢最终断裂时,其γ奥氏体含量仅为3.7%,α′马氏体含量为96.3%,说明在弯曲过程中,绝大多数母相奥氏体发生了γ→α′马氏体相变。同理,测量不同循环次数下Fe-Mn-Si记忆合金的XRD谱如图7所示。

图7 不同循环弯曲次数下的Fe-Mn-Si记忆合金XRD谱

Fig. 7 XRD patterns of Fe-Mn-Si memory alloy under different bending cycles

由图7可知,循环弯曲后期Fe-Mn-Si记忆合金的相组成为γ+ε+α′,与弯曲前由单一奥氏体组织组成的记忆合金相比,新增了ε和α′马氏体相,试样发生了记忆合金典型的γ→ε马氏体相变及不可逆的γ→α′马氏体相变。与304不锈钢不同的是,Fe-Mn-Si记忆合金弯曲疲劳试验初期,仅存在(100)ε和(110)ε马氏体相的衍射峰。并且马氏体峰面积随着循环弯曲次数的增加而不断增加,(111)γ、(200)γ及(220)γ奥氏体相的衍射峰面积不断减小。在循环弯曲后期,试样中才出现(110)α′和(200)α′马氏体相的衍射峰。通过直接比较法对Fe-Mn-Si记忆合金的XRD谱进行定量计算,得到不同弯曲次数条件下的记忆合金中γ、ε和α′相的体积分数如表3所示。

表3 不同循环弯曲次数下的Fe-Mn-Si记忆合金试样相体积分数

Table 3 Phase constitution of Fe-Mn-Si memory alloy specimens with different bending cycles

由表3可知,经1次循环弯曲后,Fe-Mn-Si记忆合金γ奥氏体含量从100%降为52.6%,ε马氏体含量从0增加为47.4%,α′马氏体含量为0%;经100次次循环弯曲后,γ奥氏体含量降为4.5%,ε马氏体含量增加为95.5%,α′马氏体含量依旧为0。在循环弯曲前期(0次→100次),ε马氏体含量由0%增加至95.5%,表明ε马氏体快速形核和长大的特点。从第100次到500次循环弯曲过程中,γ奥氏体含量继续减少,ε马氏体含量增加,但两者变化放缓,ε马氏体的增加速度降低是由于母相γ含量的降低所致。该过程中,α′马氏体含量由0%增加至0.1%,其成因是应力诱发ε马氏体的量随着弯曲循环次数的增加而增加,ε马氏体大量的产生使其由定向分布逐渐转变为交叉分布,交叉部位的马氏体随着循环次数持续增加(500次~ 1159次),相互作用诱发出α′马氏体,使得α′马氏体含量缓慢增加到0.3%[11]。Fe-Mn-Si记忆合金最终弯曲疲劳断裂时,γ奥氏体含量仅为1.3%,ε马氏体含量为98.4%;α′马氏体含量为0.3%,说明在弯曲过程中绝大多数的母相奥氏体发生的相变是γ→ε马氏体相变。

2.2 弯曲疲劳断口形貌

图8 Fe-Mn-Si记忆合金和304不锈钢疲劳断口的微观形貌

Fig. 8 Microstructure of fatigue fracture inside Fe-Mn-Si alloy(a) and 304 stainless steel(b)

为进一步分析试样弯曲疲劳断裂特性,采用场发射扫描电子显微镜观测到Fe-Mn-Si记忆合金和304不锈钢的疲劳断口形貌如图8所示。Fe-Mn-Si记忆合金的断口由大小不一的韧窝组成(见图8(a)),该种断裂形式属于塑性断裂,体现其较好的疲劳特性[12-13]。这种断裂形式的形成是由于Fe-Mn-Si记忆合金在承受循环应变时,产生了γ→ε马氏体相变,减缓了应力集中[14]。另外,由于裂纹尖端的应力较大,导致Fe-Mn-Si记忆合金在裂纹扩展方向产生马氏体,抑制该裂纹扩展。随着弯曲次数增加,合金在局部区域产生的颈缩横截面尺寸将减小到一定程度发生断裂,形成大小不一的韧窝状结构。

由图8(b)可知,大量撕裂棱构成304不锈钢的断口,这是准解理断裂(脆性断裂)的典型形貌[15]。准解理断裂是由于解理断裂核产生于304不锈钢的不同位置,断裂核逐渐扩散断裂面,进而产生断裂。由于没有抑制作用,304不锈钢的裂纹迅速扩展,故其疲劳特性较差。与304不锈钢相比,Fe-Mn-Si记忆合金由于存在应力诱发的γ→ε马氏体相变,其应力集中程度降低,裂纹的扩展速度降低,故弯曲疲劳强度高。

3 结论

1) 在应变幅值在±3.5%的情况下,Fe-Mn-Si记忆合金和304不锈钢的弯曲循环断裂次数分别为1159次和63次。

2) Fe-Mn-Si记忆合金和304不锈钢的疲劳断口形貌依次为韧窝和撕裂棱,分别属于塑性断裂和脆性断裂。

3) 随着疲劳次数的增加,304不锈钢的绝大多数母相发生了γ→α′马氏体相变,断口基本由α′马氏体组成。相同试验条件,断裂后的Fe-Mn-Si记忆合金断口主要由ε马氏体组成。

4) Fe-Mn-Si记忆合金疲劳强度高的机理是由于其存在应力诱发γ→ε马氏体相变。在相变过程中,合金的应力集中程度降低,裂纹扩展被抑制。

REFERENCES

[1] 姚卫星. 结构疲劳寿命分析[M]. 北京: 国防工业出版社, 2003: 1.

YAO Wei-xing. Fatigue life prediction of structures[M]. Beijing: National Defence Industry Press, 2003: 1.

[2] 钟群鹏, 赵子华. 断口学[M]. 北京: 高等教育出版社, 2006: 243.

ZHONG Qun-peng, ZHAO Zi-Hua. Fractography[M]. Beijing: High Education Press, 2006: 243.

[3] SEIFI M, SALEM A, SATKO D, SHAFFER J, LEWANDOWSKI J. Defect distribution and microstructure heterogeneity effects on fracture resistance and fatigue behavior of EBM Ti-6Al-4V[J]. International Journal of Fatigue, 2017, 94(1): 263-287.

[4] 马 权, 黄朝文. Ti-55531合金的高周疲劳断口形貌分析[J]. 中国有色金属学报, 2018, 28(12): 2467-2475.

MA Quan, HUANG Chao-wen. Fracture surface analysis of high-cycle fatigue for Ti-55531 alloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(12): 2467-2475.

[5] 王金刚. Fe-Mn-Si形状记忆合金的应力自适应特性和力学行为[D]. 天津: 河北工业大学, 2006: 26-27.

WANG Jin-gang. The stress self-accommodation characteristic and mechanics behavior of Fe-Mn-Si shape memory alloy[D]. Tianjin: Hebei University of Technology, 2006: 26-27.

[6] LAI M J, LI Y J, LILLPOPP L, PONGE D, WILL S, RAABE D. On the origin of the improvement of shape memory effect by precipitating VC in Fe-Mn-Si-based shape memory alloys[J]. Acta Materialia, 2018, 155: 222-235.

[7] PENG Hua-bei, CHEN Jie, WANG Yong-ning, WEN Yu-hua. Key factors achieving large recovery strains in polycrystalline Fe-Mn-Si-based shape memory alloys: A review[J]. Advanced Engineering Materials, 2017, 20(3): 1700741.

[8] LIU Wen-bo, LI Ning, WEN Yu-hua, ZHANG Shi-chao, YANG Shi-zhou. Effects of amount of pre-deformation on precipitation of NbC particles and shape memory effect of Fe17Mn5Si8Cr5Ni0.5NbC alloy during electropulsing treatment[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S1): 193-197.

[9] YU Qing-chun, ZHANG Shi-chao, YANG Bin. Dispersion of copper oxide supported on γ-alumina and its sulfation properties[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(11): 2644-2648.

[10] LI Xi-feng, DING Wei, CAO Jian, YE Li-yan, CHEN Jun. In situ TEM observation on martensitic transformation during tensile deformation on SUS304 metastable austenitic stainless steel[J]. Acta Metallurgica Sinica (English Letters), 2015, 28(3): 302-306.

[11] 林成新, 谷南驹, 张建军, 刘庆锁. Fe-Mn-Si 形状记忆合金的应力诱发马氏体相变的X射线分析[J]. 材料热处理学报, 2004, 25(3): 1-4.

LIN Cheng-xin, GU Nan-ju, ZHANG Jian-jun, LIU Qing-suo. X-ray analysis for stress-induced martensitic transformation in Fe-Mn-Si based shape memory alloy[J]. Transactions of Materials and Heat Treatment, 2004, 25(3): 1-4.

[12] FU Jian-xin, CAO Cheng-ming, TONG Wei, PENG Liang-ming. Effect of thermomechanical processing on microstructure and mechanical properties of CoCrFeNiMn high entropy alloy[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(5): 931-938.

[13] MORIN David, HOPPERSTAD Odd Sture, BENALLAL Ahmed. On the description of ductile fracture in metals by the strain localization theory[J]. International Journal of Fracture, 2018, 209(1): 1-25.

[14] JU Heng, LIN Cheng-xin, YUN Tian, LIU Zhi-jie, JIANG Hui-ling, SUN De-ping. Mechanical properties study of Fe-Mn-Si shape memory alloy welding seam formed by laser welding with filler powder[J]. Materials, 2018, 11(8): 1454-1469.

[15] 李培友, 王永善. 热处理温度对Zr44Co56合金显微组织和力学性能影响[J]. 中国有色金属学报, 2017, 27(11): 2299-2306.

LI Pei-you, WANG Yong-shan. Effect of heat treatment temperature on microstructure and mechanical properties of Zr44Co56 alloy [J]. The Chinese Journal of Nonferrous Metals, , 2017, 27(11): 2299-2306.

Fatigue properties of Fe-Mn-Si memory alloy

SUN De-ping1, JU Heng2, YUAN Hai-chao1

(1. College of Marine Engineering, Dalian Maritime University, Dalian 116026, China;

2. Mechanical and Power Engineering College, Dalian Ocean University, Dalian 116023,China)

Abstract:In order to analyze the fatigue properties of Fe-Mn-Si memory alloy, the 304 stainless steel that had the same parent phase was chosen as contrast material. The fatigue cycles were measured by bending fatigue test under the ±3.5% strain amplitudes, and the phase compositions and fractures appearances of specimens were observed with X-ray diffraction (XRD) and field emission scanning electron microscope (SEM). The experimental results show that the bending fatigue break cycles of Fe-Mn-Si memory alloy and 304 stain steel is 1159 and 63, respectively, their fracture appearances are dimples and tearing ridges in turn. When the specimens break, the former phase compositions are almost ε-martensite, while the latter were basically composed by α′-martensite. The phenomenon indicates that the bending stress induces the γ→ε martensite phase transformation of Fe-Mn-Si memory alloy, and the mechanism of fatigue strength improvement inside Fe-Mn-Si memory alloy is that stress concentration and crack speed reduce in the phase transition process.

Key words: Fe-Mn-Si memory alloy; fatigue properties; γ→ε martensite phase transformatio

Foundation item: Project(51879026) supported by the National Natural Science Foundation of China

Received date: 2019-07-26; Accepted date: 2020-04-28

Corresponding author: SUN De-ping; Tel: +86-1398448819; E-mail: sdpdmu@163.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51879026)

收稿日期:2019-07-26;修订日期:2020-04-28

通信作者:孙德平,副教授,硕士;电话:13998448819;E-mail:sdpdmu@163.com