文章编号:1004-0609(2016)02-0261-11

包套在铝合金粉末热等静压成形中的屏蔽效应及其对性能的影响

郎利辉,王 刚,黄西娜,喻 思,段 文,续秋玉

(北京航空航天大学 机械工程及自动化学院 航空宇航制造工程系,北京 100191)

摘 要:通过数值模拟和热等静压实验,研究包套在铝合金粉末热等静压成形过程的屏蔽效应及其对性能的影响,建立包套对等静压力屏蔽效应的关系公式。结果表明:包套对等静压力的屏蔽效应与包套的几何尺寸、壁厚、屈服强度有关系,包套越厚,其屏蔽效应越显著,降低热等静压过程中粉末颗粒重排阶段的致密化程度。由于包套的屏蔽,对于二元共晶和三元共晶的液相没有实现完全挤出,在粉末颗粒与颗粒交界处残留有没有被液相填充完全的孔隙,降低粉末件最终的致密度。当包套厚度较大时,降低了粉末铝合金材料的抗拉强度和屈服强度,而对材料塑性的影响不明显。

关键词:铝合金粉末;热等静压;屏蔽效应

中图分类号:TF124 文献标志码:A

铝及其铝合金材料因具有质量轻、强度高、热导率高以及腐蚀性良好等特点,而被广泛应用于汽车和飞机的制造业[1-2]。铝合金粉末冶金成形被认为是一种可靠的、低成本的材料成形技术,近几年来引起了国内外的广泛关注。

目前,国内外对于粉末铝合金材料的制备大多采用压制+烧结的成形工艺。SCHAFFR等[3]对Al-3.8Cu- 1Mg-0.7Si、Al-4Cu-0.6Si-0.1Mg、Al-4Cu-1.2Mg粉末在100~500 MPa下进行高压压制,然后在不同烧结的气氛中进行烧结,指出对于Al-Cu-Mg(-Si)粉末材料,最佳烧结气氛依次为氮气、真空、氩气。 等[4]研究了Al-Cu-Mg粉末经过400 MPa高压压制后,在590 ℃氮气氛围下烧结1.5 h的组织和力学性能,研究发现,经过烧结后材料的横向断裂强度从86 MPa提高到466 MPa,硬度提高了2倍。PADMAVATHI等[5]研究了2712铝合金粉末在200~400 MPa下压制,在570~630 ℃真空烧结的工艺性能,指出对于2712铝合金粉末最优的压制烧结工艺参数为400 MPa、590 ℃,并且后期的热处理(T4)能使材料的力学性能大幅提升。然而,通过传统的压制-烧结技术制备铝合金时,烧结气氛、保温时间、压制压力、压制时间等众多因素都会对铝合金材料的性能产生影响,而且对于粉末中添加的粘结剂和润滑剂,需要在烧结过程中脱除,导致工艺较繁琐,残留的粘结剂可能形成杂质,大大降低铝合金的性能,采用热等静压工艺对铝合金粉末直接进行固结成形,不需要添加粘结剂,通过高温高压将粉末的压制和烧结过程合二为一,简化了粉末铝合金的制备工艺,特别是对于具有复杂内腔结构的构件,利用热等静压工艺可实现一次整体制备,大大提高了原材料的利用率,节省了加工成本,陆恒等[6]和WU等[7]分别利用热等静压技术实现了具有复杂型面的高温合金粉末叶盘和钛合金粉末叶盘的一次整体制备。但是国内外针对铝合金粉末热等静压制备及成形研究报道还较少,BALOG等[8]发现采用热等静压工艺可以使铝粉末表面的氧化膜破裂,成为单独的纳米级析出物分布在晶界上,提高了材料的伸长率。本文作者采用热等静压工艺将压制和烧结工艺合二为一,实现粉末铝合金材料的一步制备。

等[4]研究了Al-Cu-Mg粉末经过400 MPa高压压制后,在590 ℃氮气氛围下烧结1.5 h的组织和力学性能,研究发现,经过烧结后材料的横向断裂强度从86 MPa提高到466 MPa,硬度提高了2倍。PADMAVATHI等[5]研究了2712铝合金粉末在200~400 MPa下压制,在570~630 ℃真空烧结的工艺性能,指出对于2712铝合金粉末最优的压制烧结工艺参数为400 MPa、590 ℃,并且后期的热处理(T4)能使材料的力学性能大幅提升。然而,通过传统的压制-烧结技术制备铝合金时,烧结气氛、保温时间、压制压力、压制时间等众多因素都会对铝合金材料的性能产生影响,而且对于粉末中添加的粘结剂和润滑剂,需要在烧结过程中脱除,导致工艺较繁琐,残留的粘结剂可能形成杂质,大大降低铝合金的性能,采用热等静压工艺对铝合金粉末直接进行固结成形,不需要添加粘结剂,通过高温高压将粉末的压制和烧结过程合二为一,简化了粉末铝合金的制备工艺,特别是对于具有复杂内腔结构的构件,利用热等静压工艺可实现一次整体制备,大大提高了原材料的利用率,节省了加工成本,陆恒等[6]和WU等[7]分别利用热等静压技术实现了具有复杂型面的高温合金粉末叶盘和钛合金粉末叶盘的一次整体制备。但是国内外针对铝合金粉末热等静压制备及成形研究报道还较少,BALOG等[8]发现采用热等静压工艺可以使铝粉末表面的氧化膜破裂,成为单独的纳米级析出物分布在晶界上,提高了材料的伸长率。本文作者采用热等静压工艺将压制和烧结工艺合二为一,实现粉末铝合金材料的一步制备。

在进行热等静压压制时,要将粉末装入包套之中,等静压压力通过包套传递,实现粉末致密化。由于包套具有一定的厚度和刚性,包套传递到工件上的压力就必然与压缸内的气体压力不相等,包套对等静压压力就产生了屏蔽效应[9-10],从而导致粉末致密化或者工件变形的不均匀。目前,国内外对包套在热等静压过程中的蔽作用的研究报道有限,董平等[11]采用解析法推导了球形和柱形包套对等静压力的屏蔽作用,指出对于同样厚度的包套,球形包套屏蔽的压力是柱形包套屏蔽压力的 倍。徐磊等[12]研究了包套对Ti-5Al-2.5Sn粉末热等静压过程中致密化的影响,当包套厚度超过5 mm,粉末压坯不能完全致密化。并且在致密化初期,样品致密度受包套壁厚影响很大,但是并没有给出定量的计算。程文祥[13]通过不同包套壁厚对Ti-5Al-2.5Sn ELI预合金粉末致密化行为的研究表明,在保温保压过程中,包套壁厚的屏蔽作用会导致不同区域粉末致密化进程不同,但对最终致密度的影响可忽略不计。

倍。徐磊等[12]研究了包套对Ti-5Al-2.5Sn粉末热等静压过程中致密化的影响,当包套厚度超过5 mm,粉末压坯不能完全致密化。并且在致密化初期,样品致密度受包套壁厚影响很大,但是并没有给出定量的计算。程文祥[13]通过不同包套壁厚对Ti-5Al-2.5Sn ELI预合金粉末致密化行为的研究表明,在保温保压过程中,包套壁厚的屏蔽作用会导致不同区域粉末致密化进程不同,但对最终致密度的影响可忽略不计。

本文作者针对广泛使用的2A12铝合金粉末,采用3种不同壁厚的包套对其进行热等静压成形,结合数值模拟,定量分析包套壁厚对于等静压力的屏蔽作用,建立了包套材料参数与所屏蔽压力之间的关系公式。并分析了显微组织和元素的扩散规律,研究了包套厚度对于铝合金粉末热等静压成形性能的影响。

1 实验

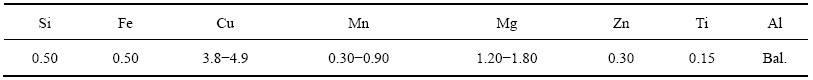

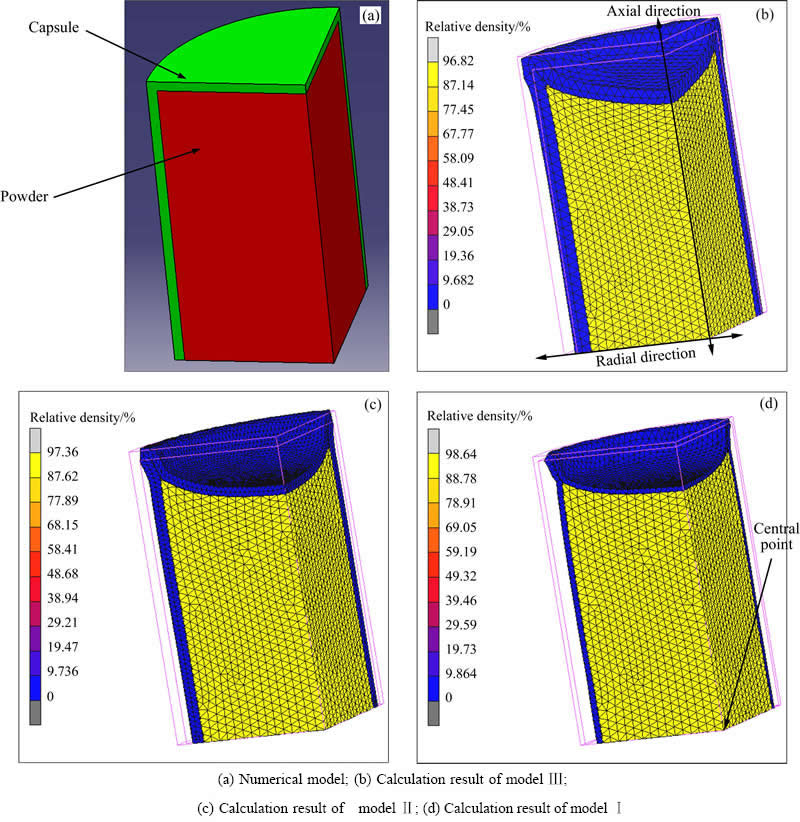

本实验中采用的2A12铝合金粉末由北京艾瑞福斯特技术开发有限公司提供,该粉末通过等离子旋转电极雾化法(PREP)制备,粉末的化学成分和基本特征如表1和表2所列。包套采用1060纯铝,厚度分别为3、2和1 mm(编号为Ⅲ、Ⅱ、Ⅰ),内径为60 mm,高度为120 mm,使用丙酮进行化学清理,去除因机械加工残留在包套内壁上的油污。粉末的装填过程在VSR-200时效振动系统上完成,振动频率为30 Hz,振动时间为45 min,振动后使粉末充填的松装密度达到1.76~1.89 g/cm3。包套焊封后,在400 ℃下,将包套内的真空度抽至1×10-4 Pa。

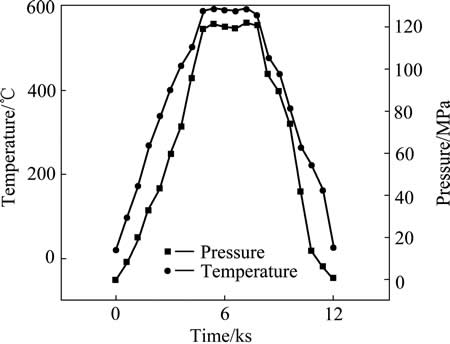

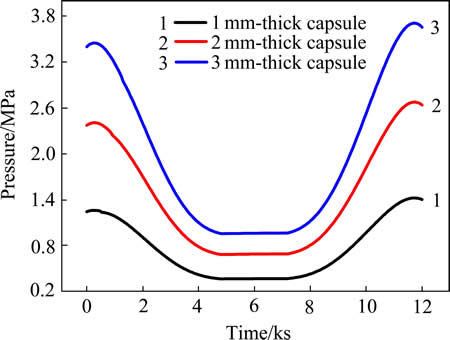

试验所用的热等静压设备为ABB公司生产的QIH-15型热等静压机,其最高温度可达2000 ℃,最高压力可达200 MPa,炉膛最大装料尺寸为d 150 mm×170 mm。本实验中用于压制的最高温度和压力分别为590 ℃、120 MPa,考虑到先升压的方式可能引起包套的破裂,若先升温可能引起液相的沉降,在本实验中采用温度和压力同步升高的配合机制,具体热等静压工艺如图1所示。

利用阿基米德原理测量粉末铝合金试件密度,分别测量粉末铝合金试件径向和轴向的尺寸变化,并与数值模拟的结果相对比。利用D/max-2000型X射线衍射仪(XRD)分析粉末物相,利用环氧树脂对原始粉末和热等静压后的铝合金试样冷镶,试样经过打磨抛光后,在Keller试剂(V(HF):V(HCI):V(HNO3):V(H2O)= 1:1.5:2.5:95)中腐蚀40 s,采用OLYMPUSB×51M型金相显微镜和CS3400型钨灯丝扫描电子显微镜对显微组织进行观察,对元素分布进行能谱分析。拉伸试验采用QJ210型电子拉伸试验机,按照《GB/T 228-2002 金属材料室温拉伸试验方法》进行,分别测试材料的抗拉强度、屈服强度、断后伸长率,并分析断口的形貌。

图1 热等静压压制曲线

Fig. 1 Technology curves of HIP

表1 2A12铝合金粉末的化学成分

Table 1 Chemical composition of 2A12 aluminum alloy powder (mass fraction, %)

表2 2A12铝合金粉末的基本特征

Table 2 Basic characteristics of 2A12 aluminum alloy powder

图2 热等静压试件

Fig. 2 Photos of HIP specimens

2 结果与分析

2.1 数值模拟及验证

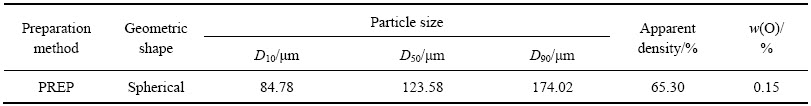

由于铝合金粉末试件为轴对称的圆柱模型,所以选取模型的1/8作为计算单元,利用大型的有限元软件MSC.MARC进行模拟计算,该软件对于粉末热等静压成形具有较好的预测性[14-15]。数值模型及计算结果如图3所示。

图3 数值模型及计算结果

Fig. 3 Numerical model and calculation result

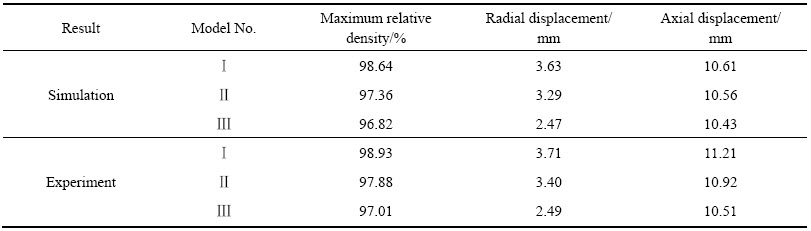

从图3可以看出,随着包厚度的不断减小,铝合金粉末经过热等静压后的相对致密度由96.82%升高到98.64%,径向位移由2.47 mm升高到3.63 mm,轴向位移由10.43 mm升高到10.61 mm。可见,随着包套厚度的减薄,粉末体的整体收缩逐渐变大,致密化程度提高,包套对于铝合金粉末在热等静压过程中的屏蔽作用变小。表3所列为3种不同包套厚度的热等静压试件的最高相对密度、径向位移和轴向位移的数值模拟结果和试验结果的对比。

从表3中可以看出,试验数据和数值模拟的结果相吻合,最大误差不超过5%,在工程允许的误差范围之内,说明数值模拟能在一定程度上反映铝合金粉末的热等静压过程,在分析包套对于粉末成形的屏蔽作用时,可以以数值模拟的分析过程为参考。

2.2 包套屏蔽效应的理论分析

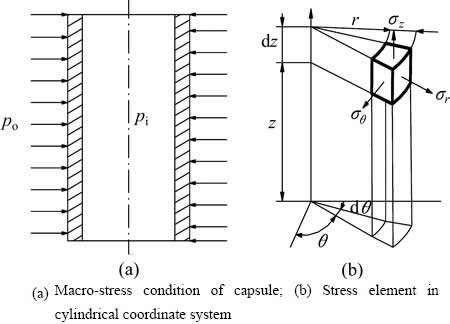

对于包套的简化模型及受力状态如图4所示,包套的内径为a,外径为b,壁厚为t,包套内部所受压力为pi,外部所受压力为po(po>pi)。包套为旋转体,承受的外力相对于旋转轴对称分布, 整个包套处于轴对称状态,在热等静压条件下包套材料作为理想的弹塑性材料而不考虑加工硬化,在圆柱坐标系下的应力张量 为

为

(1)

(1)

由径向的应力平衡可得微分方程:

(2)

(2)

式中: 为径向应力;

为径向应力; 为周向应力。

为周向应力。

几何方程(径向位移为u)[16]如下:

图4 包套受力示意图

Fig. 4 Schematic diagrams showing stress in capsule

(3)

(3)

(4)

(4)

式中:u为径向位移。

当载荷较小时,包套处于弹性状态,广义的虎克定律[17]为

(5)

(5)

式中:G为剪切模量。其中,

(6)

(6)

由式(3)~(5)可得

(7)

(7)

(8)

(8)

表3 试件参数数值模拟结果与试验结果对比

Table 3 Comparison of results of simulation and experiment

将式(7)、(8)代入式(2)得到求解该问题的拉梅方程,即

(9)

(9)

对式(9)进行积分求解得:

(10)

(10)

将式(10)代入式(3)、(4)可得:

(11)

(11)

式中: 为径向应变;

为径向应变; 为周向应变。

为周向应变。

将式(11)代入广义的虎克定律式(5),并结合

(12)

(12)

得到

(13)

(13)

式中:r为拉梅常数。

其中

由于包套的长度远大于包套的厚度,假设包套处于平面应变状态,z向的应变为0,即:

(14)

(14)

将式(14)代入式(13),可得:

(15)

(15)

利用边界条件:

(16)

(16)

将式(16)代入式(15)可以求得常数A和B:

(17)

(17)

发生塑形变形时使 [11],使式(15)中的

[11],使式(15)中的 进一步得到简化:

进一步得到简化:

(18)

(18)

在热等静压的过程中,四周等静压力作用在包套的外表面上,必须使包套发生塑性变形,之后才能使等静压力传递到包套内部的粉末体上,运用米塞斯屈服准则有:

(19)

(19)

将式(15)、(16)、(17)、(18)代入式(19)可以得到po和pi的关系,即

(20)

(20)

等静压力作用在包套的外表面,包套的外表面首先产生屈服,然后向内层扩展,当包套的内表面也产生屈服时,整个包套就开始塑形变形,令r=a,结合b-a=t,式(20)可简化为

(21)

(21)

由式(21)可以看出,包套对于等静压力的屏蔽作用与包套的内径a、外径b、包套壁厚t以及包套材料的屈服强度 均有关系,其屏蔽力的大小与包套厚度t和屈服强度

均有关系,其屏蔽力的大小与包套厚度t和屈服强度 成正比。

成正比。

根据式(21),并结合数值模拟过程,在热等静压过程中包套所屏蔽等静压力的大小如图5所示。由图5可以看出,包套屏蔽的压力呈现先减小后增大的U形曲线,包套越厚,对于粉末致密化的屏蔽压力越大,屏蔽效应越明显。包套对于内部粉末的“保护”主要集中在热等静压开始和结束两个阶段,在热等静压保温保压阶段其屏蔽作用相对较小。这主要是由于在热等静压的初期和后期,温度和压力均比较低,包套的屈服强度较大,外界的压力还不足以克服包套的保护作用而作用在粉末上。随着温度和压力的升高,包套迅速进入塑形状态,对内部粉末的屏蔽作用迅速减小,当热等静压进入保温保压的稳定阶段时,此时温度和压力均达到最大,包套对等静压力的屏蔽最小。

图5 包套对于等静压力的屏蔽

Fig. 5 Shielding effect of capsules for isostatic pressure

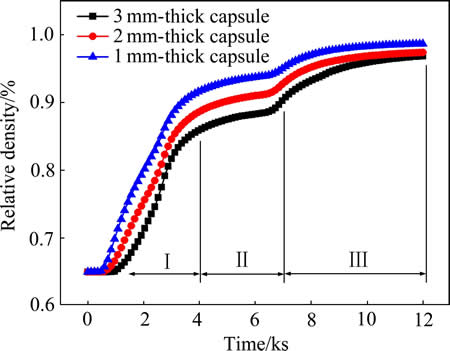

根据数值模拟可知,对于3种铝合金粉末试件的致密化过程如图6所示,对于粉末在热等静压中的致密化过程可以分为粉末的靠近及重排阶段(Ⅰ)、塑形变形阶段(Ⅱ)、扩散蠕变阶段(Ⅲ)[18]。其中,第一阶段的粉末颗粒重排对于粉末的最终致密化起了重要作用[19-20],从图6可以看出,包套越厚,粉末在第一阶段的致密的程度和速率越低,包套对于粉末重排的屏蔽作用越明显。在第一阶段,由于温度和压力均较低,还不足以达到粉末颗粒的屈服强度使其发生塑性变形,仅仅通过包套传递的压力发生类似于刚体的刚性运动使粉末颗粒产生平移或转动,使较大的搭桥孔洞坍塌或将某些粉末粒子挤入临近的空隙。由于在粉末致密化的初期阶段,空隙率较大,在35%左右,粉末粒子间的有效接触面积很小,变形阻力很低,致密化速率和程度对于包套所传递压力的依赖度较高。由图5可知,在热等静压的初始阶段,包套对于等静压力的屏蔽作用比较明显,所屏蔽的压力值分别达到3.6、2.5和1.3 MPa。由图1可知,在第一阶段最高压力约为60 MPa,3mm包套对于等静压力的屏蔽达到压力值的6%;所以,在该阶段,由于包套对等静压力的屏蔽作用较大并且压力对于致密化程度起主导作用,导致粉末初期的致密化程度较低,影响了试件在热等静压后的最终致密度。

图6 热等静压试件的致密化过程

Fig. 6 Densification process of HIP specimens

2.3 包套厚度对铝合金粉末热等静压的微观特征影响

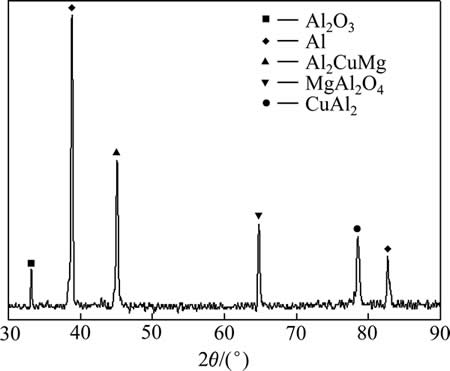

由图7铝合金粉末的XRD谱可以看出,在原始粉末中存在α(Al)、θ-CuAl2相、S-Al2CuMg相,还检测到了氧化相Al2O3和MgAl2O4,氧化相的存在主要由于在粉末的制备、运输、充填过程中接触到空气而出现了氧化现象,α(Al)、θ-CuAl2、S-Al2CuMg相之间主要有以下共晶反应生成[21]:

L  α(Al)+θ-CuAl2 (22)

α(Al)+θ-CuAl2 (22)

L  α(Al)+θ-CuAl2+S-Al2CuMg (23)

α(Al)+θ-CuAl2+S-Al2CuMg (23)

其中二元相θ-CuAl2的共晶温度为548 ℃,三元相S-Al2CuMg的共晶温度507 ℃,本试验中热等静压最高温度为590 ℃,可知在热等静压的过程中,粉末内部的二元相和三元相均已熔化,以液相的形式存在。

图7 Al粉末的XRD谱

Fig. 7 XRD pattern of Al powder

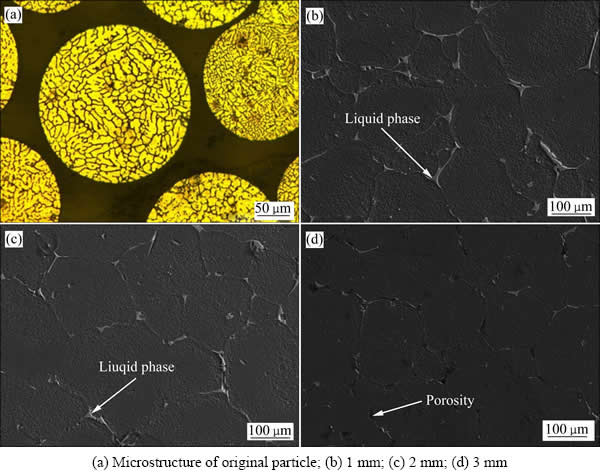

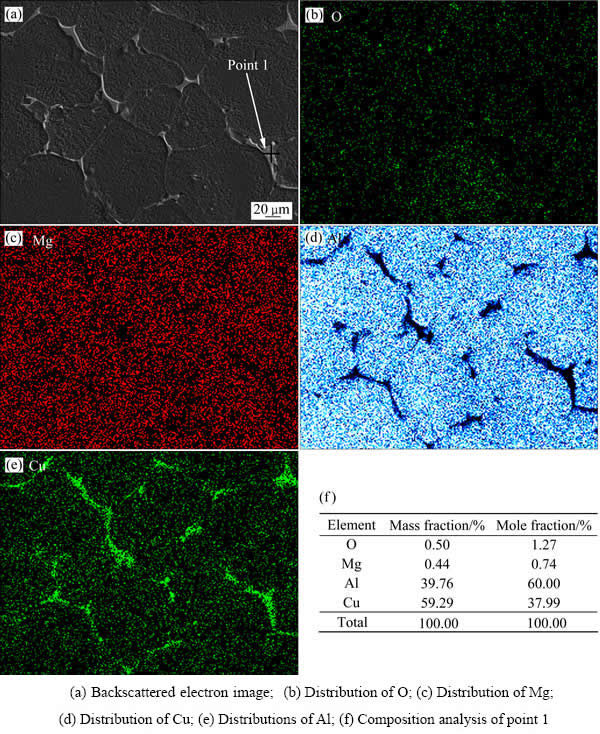

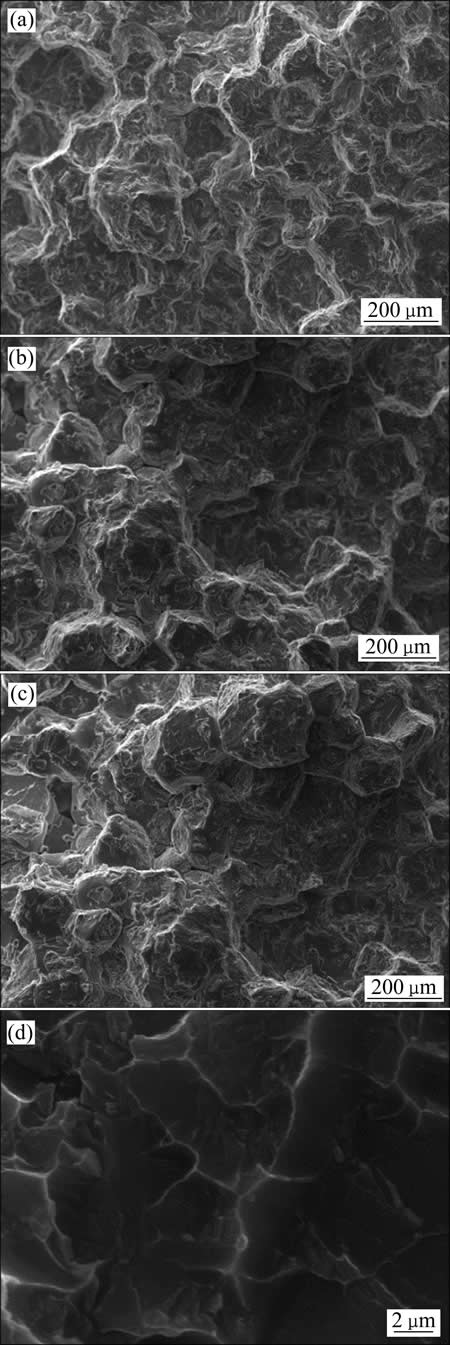

图8所示分别为包套厚度1、2和3 mm铝合金粉末试件的背散射衍射电子像。从图8可以看出,Cu、Mg等合金元素主要分布在粉末内部树枝晶的晶轴处(见图8(a)),粉末颗粒交界处的成分与粉末基体的成分明显不同。由图9的EDS分析可以看出,在粉末颗粒的交界处,Cu等元素大量富集,Al元素减少,对点1元素分析可知,Al和Cu的摩尔比接近2:1,通过之前的XRD分析及2系铝合金中相的组成[22],可以推断在粉末颗粒边界的相组成应该包括θ-CuAl2、S-Al2CuMg、MgAl2O4[23],即铝合金的共晶液相转移到粉末颗粒的交界处[24],如图8(b)和(c)中的箭头所示。由图8可以看出,液相随着包套厚度的变大而渐渐减少,在铝合金粉末固结成形的过程中,液相扮演类似粘结剂的角色,对于粉末的致密化具有促进作用[25-26],液相的减少影响了粉末的致密化进程,降低了粉末体的致密度。

图8 原始粉末显微组织及不同壁厚包套试件的背散射电子像

Fig. 8 Microstructure of original particle(a) and back-scattered electron images((b), (c), (d)) of HIP specimens with different thickness capsules

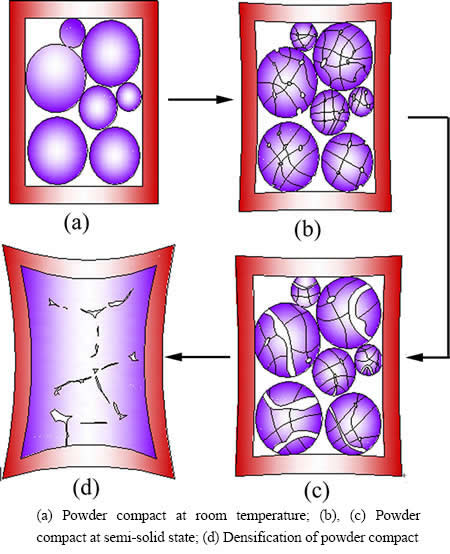

在热等静压过程中随着温度和压力的升高,熔点较低的三元共晶相首先开始团聚并熔化,随后二元共晶相开始在铝合金粉末表面和内部大量团聚并熔化,此时,会形成类似“口袋”状的液相聚集区和液相通道[27],固相的形状会变得不规则,随着热等静压温度和压力升高以及保温保压时间的延长,包套内的铝合金粉末以固液混合的半固态形式存在,液相的体积分数随着温度的升高逐渐变大[28],作用在粉末体的等静压力会将粉末颗粒内部的液相“挤出”,不规则的固相相互“挤压自锁”[27]。当包套较薄时,施加到粉末体的力较大,可以将粉末颗粒内的液相充分“挤出”,充填到粉末颗粒与颗粒的交界处,实现粉末体的致密化,其过程如图10所示。当包套壁厚较大时,屏蔽的压力较大,施加到粉末体的压力不足以将液相完全挤出到粉末颗粒之间的孔隙处,所以包套为3 mm的铝合金粉末经过热等静压后的致密度较低(见图8(d)中箭头所示),粉末颗粒之间还存在孔洞。

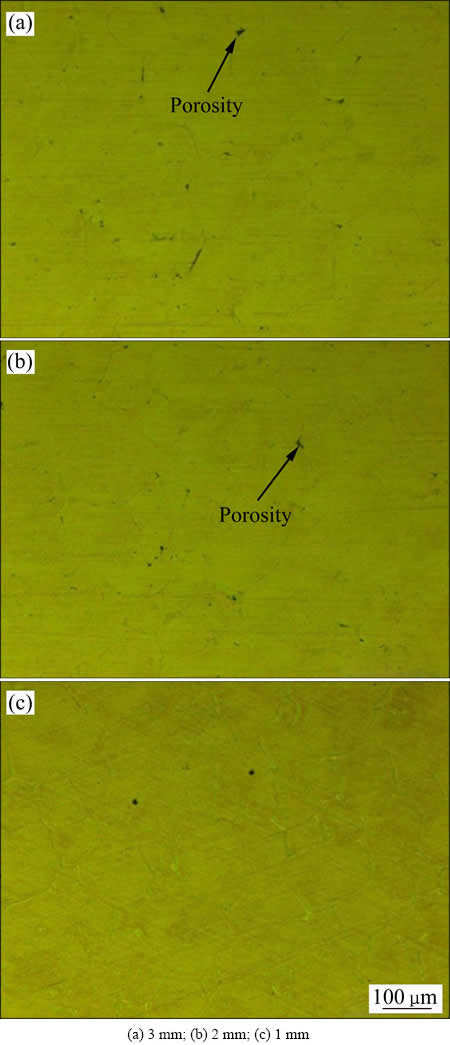

通过金相组织照片(见图11)可以进一步看出,当包套较厚时,铝合金粉末经过高温高压固结后,内部存在孔洞,随着包套厚度变薄,内部孔洞逐渐减少,当包套厚度为1mm时,材料的内部孔洞基本消失,达到致密的状态。

2.4 拉伸性能及断口分析

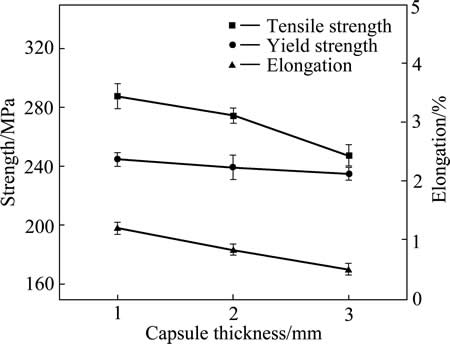

对3种包套厚度的铝合金粉末热等静压试样进行拉伸性能测量,抗拉强度、屈服强度及断后伸长率如图12所示。

从图12可以看出,随着包套厚度的减小,热等静压成形的铝合金粉末材料的抗拉强度和屈服强度逐步提高,包套厚度越小,对外界的压力的屏蔽作用越小,施加到粉末体上的压力就越大,促进了热等静压初期粉末颗粒之间的重排和对液相的“挤压”,使粉末体的致密化程度升高,液相的“粘结”作用加强,增强了粉末之间的“焊合”程度。但是材料塑性较低,拉断试件没有发生明显的宏观塑性变形。从图13断口形貌可以进一步看出包套厚度的不同对于铝合金粉末热等静压材料性能的影响。

从图13拉伸断口形貌中可以看出,3种不同包套厚度的铝合金粉末试件基本沿着颗粒的交界处断裂,属于脆性断裂。由前面的分析可知,在热等静压成形的过程中,合金元素向粉末颗粒交界处聚集,改变了此处的成分,使液相在此聚集,将粉末颗粒“粘结”在一起,成为断裂的“薄弱区”。包套厚度越大,粉末颗粒交界处的结合越薄弱,由包套厚度为3 mm的试件断口可以看出,未结合的粉末颗粒原始表面和液相未能充填孔隙,表明部分粉末之间未能形成扩散粘结,导致强度较低。从图12(d)局部放大图可以看出,断口以小平面为断裂单元,河流花样较短且不连续,汇合特征不明显,呈现解理脆性断裂的断口形貌,综合来看,热等静压成形的铝合金粉末材料在拉伸过程中呈现脆性断裂的特征,所以材料的塑性偏低,虽然随着包套厚度的减小,伸长率有一定程度的增高,但整体而言,包套厚度对于塑性的影响不大。

图9 热等静压试件的背散射电子及元素面扫描分布

Fig. 9 Back-scattered electron images and elements map scanning distributions HIP specimens

图10 液相的挤出及致密化过程

Fig. 10 Process of liquid phase extrusion and densification

图11 热等静压后不同壁厚包套试件的显微组织

Fig. 11 Microstructures of specimens with different thick capsules after HIP

图12 热等静压粉末铝合金材料的拉伸性能

Fig. 12 Tensile property of P/M aluminium alloys by using HIP

图13 热等静压粉末铝合金拉伸断口形貌

Fig. 13 Tensile fracture morphologies of P/M aluminium alloys after HIP

3 结论

1) 对具有3种不同厚度包套的铝合金粉末试件进行热等静压试验及数值模拟,包套越薄,试件的尺寸收缩越大,致密化程度越高,对等静压力的屏蔽效应越小;建立热等静压过程中包套对粉末体屏蔽作用的关系公式 ,包套所屏蔽的等静压力呈U形分布,降低粉末颗粒重排阶段的致密化速率和程度,导致热等静压试件最终的致密化水平较低。

,包套所屏蔽的等静压力呈U形分布,降低粉末颗粒重排阶段的致密化速率和程度,导致热等静压试件最终的致密化水平较低。

2) 包套厚度越小,粉末体承受的压力越大,将粉末内部熔化的液相挤出,填充到粉末颗粒与颗粒的缝隙处,不规则的固相相互挤压自锁,充填到粉末颗粒交界处的液相促进了颗粒的粘结,提高颗粒之间的焊合程度和材料的致密化程度;包套厚度越大,其屏蔽的压力越大,使液相的挤出不充分,不能完全填充粉末颗粒之间的缝隙,使热等静压成形的粉末铝合金材料存在孔洞。

3) 包套厚度越小,其抗拉强度、屈服强度、断后伸长率均提高;从断口分析可知铝合金粉末材料呈现脆性断裂的特征,所以其塑性均较低,包套厚度对于粉末铝合金材料的塑性影响不大。

REFERENCES

[1] MILLER W S, ZHUANG L, BOTTEMA J, WITTEBROOD A J, de SMET P, HASZLER A, VIEREGGE A. Recent development in aluminium alloys for the automotive industry[J]. Materials Science and Engineering A, 2000, 280(1): 37-49.

[2] NAKAI M, ETO T. New aspect of development of high strength aluminum alloys for aerospace applications[J]. Materials Science and Engineering A, 2000, 285(1/2): 62-68.

[3] SCHAFFER G B, HALL B J, BONNER S J, HUO S H, SERCOMBE T B. The effect of the atmosphere and the role of pore filling on the sintering of aluminium[J]. Acta Materialia, 2006, 54(1): 131-138.

[4] AZIM G, FEHIM F, OSMAN KA. Microstructural examination and properties of premixed Al-Cu-Mg powder metallurgy alloy[J]. Materials Characterization, 2011, 62(7): 730-735.

[5] PADMAVATHI C, ANISH U. Sintering behaviour and mechanical properties of Al-Cu-Mg-Si-Sn aluminum alloy[J]. Transactions of the Indian Institute of Metals, 2011, 64(4/5): 345-357.

[6] 陆 恒, 魏青松, 薛鹏举, 王基维, 史玉升. Inconel625粉末盘热等静压近净成形过程模拟与验证[J]. 中国机械工程, 2013(19): 2675-2680.

LU Heng, WEI Qing-song, XUE Peng-ju, WANG Ji-wei, SHI Yu-sheng. Numerical simulation and verification of near-net-shaping Inconel625 powder disk under hot isostatic pressing[J]. China Mechanical Engineering, 2013(19): 2675-2680.

[7] WU Y, XUE P J, WEI Q S. Integrated forming process for manufacturing Ti6Al4V impeller with a functional coating layer using hot isostatic pressing[J]. Materials and Manufacturing Processes, 2015, 30(6): 756-765.

[8] BALOG M, POLETTI C, SIMANCIK F, WALCHER M, RAJNER W. The effect of native Al2O3 skin disruption on properties of fine Al powder compacts[J]. Journal of Alloys and Compounds, 2011, 509: S235-S238.

[9] BESSON J, ABOUAF M. Behaviour of cylindrical hip containers[J]. International Journal of Solids and Structures, 1991, 28(6): 691-702.

[10] SKOROKHOD V V, SHTERN M B, PANFILOV Y A. Effect of a shell on the change in shape of a porous billet during isostatic pressing. 1. Stress deviator with isostatic pressing[J]. Powder Metallurgy and Metal Ceramics, 1997, 36(1/2): 35-40.

[11] 董 平. 包套对等静压压力的屏蔽效应分析[J]. 金属成形工艺, 2002(3): 12-14.

DONG Ping. An analysis of the shielding effect of container on isocratic pressing[J]. Metal Forming Technology, 2002(3): 12-14.

[12] 徐 磊, 邬 军, 刘羽寅, 雷家峰, 杨 锐. Ti-5Al-2.5Sn合金粉末热等静压压坯的致密化行为及性能[J]. 钛工业进展, 2011(4): 19-23.

XU Lei, WU Jun, LIU Yu-yin, LEI Jia-feng, YANG Rui. Densification and properties of Ti-5Al-2.5Sn alloy prepared by using HIP[J]. Titanium Industry Progress, 2011(4): 19-23.

[13] 程文祥. Ti-5Al-2.5Sn ELI预合金粉末热等静压致密化行为与有限元模拟研究[D]. 沈阳: 中国科学院大学, 2013.

CHENG Wen-xiang. Investigation on densification behavior and finite element modeling of Ti-5Al-2.5Sn ELI pre-alloyed powders during HIPing[D]. Shenyang: University of Science and Technology of China, 2013.

[14] 郎利辉, 布国亮, 薛 勇, 张东星. 钛合金热等静压模拟本构关键参数确定及工艺优化[J]. 塑性工程学报, 2011(4): 34-38.

LANG Li-hui, BU Guo-liang, XUE Yong, ZHANG Dong-xing. Determine key parameters of simulation constitutive and process optimization for titanium alloy (Ti-6Al-4V) hot isostatic pressing[J]. Journal of Plasticity Engineering, 2011(4): 34-38.

[15] 姚 松, 郎利辉, 布国亮, 张东星, 王 刚. 基于Ti-6Al-4V的热等静压与温压成形数值模拟对比研究[J]. 锻压技术, 2013(3): 156-160.

YAO Song, LANG Li-hui, BU Guo-liang, ZHANG Dong-xing, WANG Gang. Comparison of numerical simulation between hot isostatic pressing and warm compaction on Ti-6Al-4V[J]. Forging & Stamping Technology, 2013(3): 156-160.

[16] 陈金德, 俞汉清. 金属塑性成形原理[M]. 北京: 机械工业出版社, 2001: 104-105.

CHEN Jin-de, YU Han-qing. Fundamental of metal plastic forming[M]. Beijing: China Machine Press, 2001: 104-105.

[17] 杨桂通. 弹性力学[M]. 北京: 高等教育出版社, 2011: 46-47.

YANG Gui-tong. Theory of elastic mechanics[M]. Beijing: Higher Education Press, 2011: 46-47.

[18] 马福康. 等静压技术[M]. 北京: 冶金工业出版社, 1992: 175-177.

MA Fu-kang. Isostatic pressing technology[M]. Beijing: Metallurgical Industry Press, 1992: 175-177.

[19] 肖志瑜, 陈维平, 温利平, 李元元. 温压动态压制曲线及颗粒重排贡献率的探讨[J]. 粉末冶金材料科学与工程, 2005(2): 96-99.

XIAO Zhi-yu, CHEN Wei-ping, WEN Li-ping, LI Yuan-yuan. Exploration on dynamic compaction curves and contribution of particle re-arrangement during warm compaction[J]. Materials Science and Engineering of Powder Metallurgy, 2005(2): 96-99.

[20] KIM J C, MARTIN D M, LIM C S. Effect of rearrangement on simulated particle packing[J]. Powder Technology, 2002, 126(3): 211-216.

[21] 郎利辉, 王 刚, 布国亮, 姚 松, 续秋玉. 热等静压工艺参数对2A12粉末铝合金性能的影响研究[J]. 粉末冶金工业, 2014(5): 19-23.

LANG Li-hui, WANG Gang, BU Guo-liang, YAO Song, XU Qiu-yu. Study on the effect of hot isostatic pressing process parameters on the properties of 2A12 aluminum alloy powder[J]. Powder Metallurgy Industry, 2014(5): 19-23.

[22] 张丁菲, 潘复生. 铝合金及应用[M]. 北京: 化学工业出版社, 2007: 120-121.

ZHANG Ding-fei, PAN Fu-sheng. Aluminum alloy and its application[M]. Beijing: Chemical Industry Press, 2007: 120-121.

[23] PAI B C, RAMANI G, PILLAI R M, SATYANARAYANA K G. Role of magnesium in cast aluminium alloy matrix composites[J]. Journal of Materials Science, 1995, 30(8): 1903-1911.

[24] SCHAFFER G B, HALL B J, BONNER S J, HUO S H, SERCOMBE T B. The effect of the atmosphere and the role of pore filling on the sintering of aluminium[J]. Acta Materialia, 2006, 54(1): 131-138.

[25] ARRIBAS I,  J M, CASTRO F. The initial stage of liquid phase sintering for an Al-14Si-2.5Cu-0.5Mg (wt%) P/M alloy[J]. Materials Science and Engineering A, 2010, 527(16/17): 3949-3966.

J M, CASTRO F. The initial stage of liquid phase sintering for an Al-14Si-2.5Cu-0.5Mg (wt%) P/M alloy[J]. Materials Science and Engineering A, 2010, 527(16/17): 3949-3966.

[26] LIU Y, LUO X, LI Z. Microstructure evolution during semi- solid powder rolling and post-treatment of 7050 aluminum alloy strips[J]. Journal of Materials Processing Technology, 2014, 214(2): 165-174.

[27] WU Y F, KIM G. Compaction behavior of Al6061 powder in the semi-solid state[J]. Powder Technology, 2011, 214(2): 252-258.

[28] SERCOMBE T B. On the sintering of uncompacted, pre-alloyed Al powder alloys[J]. Materials Science and Engineering A, 2003, 341(1): 163-168.

Shielding effect of capsules and its impact on mechanical properties of P/M aluminium alloys fabricated by hot isostatic pressing

LANG Li-hui, WANG Gang, HUANG Xi-na, YU Si, DUAN Wen, XU Qiu-yu

(Manufacture Engineering of Aerospace Vehicle, School of Mechanical Engineering and Automation,

Beihang University, Beijing 100191, China)

Abstract: By numerical simulation and hot isostatic pressing (HIP) tests of aluminum alloy powders, the shielding effect of capsules and its impact on the mechanical properties of P/M aluminium alloys were studied during the processes of HIP. In addition, the experimental equations about the shielding effect of capsules were established. The results show that the shielding effect of capsules depends on geometry size of capsule, wall thickness and yield strength. The thicker the capsule, the greater the shielding effect of capsule, which reduces densification during grains rearrangement stage in the processes of HIP. Binary eutectic liquid phase and ternary eutectic liquid phase would not be squeezed out and the pores among powder particles are not filled by the liquid phase because of the shielding effect of capsule. Besides, through tensile mechanical properties tests, the tensile strength and yield strength of P/M aluminium alloys increase when the capsule becomes thin but the effect on the metal plastic is insignificant.

Key words: aluminum alloy powder; hot isostatic pressing; shielding effect

Received date: 2015-05-06; Accepted date: 2015-11-23

Corresponding author: WANG Gang; Tel: +86-18911241921; E-mail: wanggang198733673@126.com

(编辑 龙怀中)

收稿日期:2015-05-06;修订日期:2015-11-23

通信作者:王 刚,博士;电话:18911241921;E-mail: wanggang198733673@126.com