文章编号:1004-0609(2010)S1-s0280-04

热等静压制备Al2O3增强Ti2AlN金属陶瓷

郑 卓,崔玉友,杨 锐

(中国科学院 金属研究所,沈阳 110016)

摘 要:采用热等静压工艺,在1 000 ℃、100 MPa条件下,选择混合粉末Al3Ti+TiN+TiO2和Al3Ti+TiN,调整各粉末中不同成分的比例,找到性能合适的合金配比,利用XRD和扫描电镜研究压制后的样品的相组成和组织形貌。结果表明:粉末经热等静压后均可生成Ti2AlN相,但是生成物相比例不同;其中Al3Ti、TiN和TiO2的质量比为2.07?1.68?1的粉末压制出来的样品是完整的Ti2AlN基体,同时生成的Al2O3均匀弥散分布在基体中,对基体具有强化作用。

关键词:金属陶瓷;Ti2AlN;热等静压

中图分类号:TG 1482 文献标志码:A

Ti2AlN cermet enhanced by Al2O3 prepared by

hot isostatic pressing

ZHENG Zhuo, CUI Yu-you, YANG Rui

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The bulk intermetallic-ceramic composites in Ti-Al-N system was fabricated by reactive hot isostatic pressing (hipping) of two kinds of powder mixtures TiAl3+TiN+TiO2 and TiAl3+TiN at 1 000 ℃ and 100 MPa for different times. To find the best rate of components to fabricate the Ti2AlN, different rates in each kind of powders were operated. The chemical phase and microscopy was characterized by X-ray diffractometry and scanning electron microscopy. The results show that Ti2AlN and Al2O3 phases form in both two mixtures of powders, but the content of phase is different. TiAl3+TiN+TiO2 mixture is the better, which can make perfect base of Ti2AlN, simultaneity Al2O3 is formed , it disperses in the base homogeneously and strengthens the base metal.

Key words: metal ceramic; Ti2AlN; hot isostatic pressing

1963年,JEITSCHKO等[1]发现Ti2AlN的六面体结构。1984年,SCHUSTER和BAUER[2]又发现在Ti-Al-N三元体系中存在Ti3AlN和Ti3Al2N2结构。此后,BARSOUN等[3]和EL-RAGHY等[4]分别对TiAlN和具有类似结构的Ti-Si-C三元体系进行了细致的研究,发现许多其他的分子及结构排列。2000年,BARSOUN[5]将Ti2AlN和其他体系中具有类似结构和性质的三元体系进行比较,列出他们的一些共性,称为Mn+1AXn相(其中M代表近过渡族金属,A代表族金属(包括第3主族和第4主族),X代表C或者N,而N为1,2,3)。MAX相的层状晶体结构和微观结构,使它同时具有金属和陶瓷的性质:良好的导热性和导电性,较低的硬度和较高的弹性模量和剪切模量,良好的机械加工性能和耐磨性。在高温下具有一定的塑性,良好的热稳定性和高温抗氧化性。也正因为此类合金具有这些优良的性能,所以,它至今仍然是许多实验室研究的热点[6-12]。本文作者试图在Ti2AlN基体中引入与之同时生成的Al2O3作为增强相,来提高材料的高温抗氧化性能和耐磨性能。

1 实验

实验材料为Al3Ti微米粉末(74 μm),TiN纳米粉末和TiO2粉末。首先按质量比2?1混合Al3Ti和TiN粉末,标识为样品a;将Al3Ti、TiN和TiO2粉末分别按质量比1.88?1.68?1和2.07?1.68?1混合,标识为样品b和c。样品b与样品c的不同在于,样品c多10%的Al3Ti,期望的反应方程式分别为

2Al3Ti+2TiN+3O2=2Ti2AlN+2Al2O3 (1)

7Al3Ti+13TiN+6TiO2=13Ti2AlN+4Al2O3 (2)

将上述混合好的粉末先经过冷压成型,然后装入纯钛包套,利用热等加压,在100 MPa下经1 000 ℃ 加压2 h后,将压制好的样品用线切割除掉纯钛包套,所有样品经过预磨、抛光后,浸入氢氟酸溶液腐蚀,腐蚀好的样品利用Rigaku D/max-2400PC XRD衍射仪进行物相分析,利用ZEISS-Axiovert200 MAT金相显微镜观察显微组织进行金相分析,利用日本Hitachi 公司装有Oxford能谱系统的S-4300N扫描电子显微镜观察材料的组织形貌和分析能谱,利用Tester FM-700E显微硬度计测试样品的硬度。

2 结果与讨论

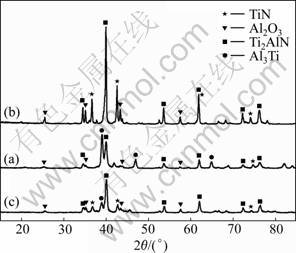

样品a、b和c的XRD谱如图1所示。由图1可看出,样品a、b和c均在热等静压条件下反应生成Ti2AlN,且Ti2AlN的峰非常明显,都同时生成Al2O3增强相。样品a中存在较多的Al3Ti,说明反应不充分,有Al3Ti剩余;样品b的Ti2AlN相的衍射峰最为明显,未发现 Al3Ti相,但是有TiN相残留,这也是反应不够充分的结果。相对而言,样品c中Ti2AlN峰位明显,虽然其中残留的TiN比样品a的要多些,但残留TiN和Al3Ti的总量相对于其他样品少了许多。

图1 样品a、b和c的XRD谱

Fig.1 XRD patterns of samples a (a), b (b) and c (c)

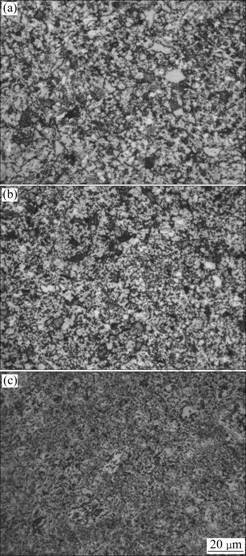

图2所示为样品a、b和c的光学显微组织。由图2可以看出,样品a中有若干较大的颗粒,在大的颗粒边缘有明显的边界,分布不均匀;样品b中虽没有大的颗粒,但是较大颗粒还是能够明显的辨别出来;样品c的表面形貌均匀,没有较大的颗粒,颗粒间也很少有明显的边界。

图2 样品a、b和c的光学显微组织

Fig.2 Optical microstructures of samples a (a), b (b) and c (c)

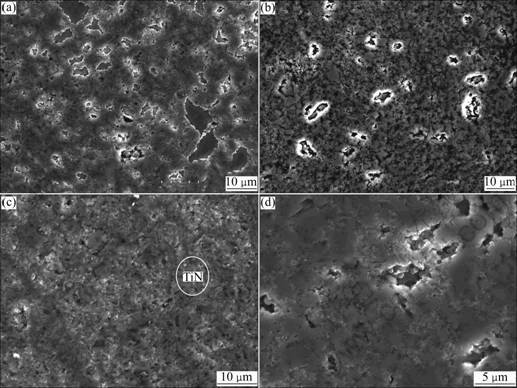

图3所示为样品a、b和c的SEM像及样品中白色区域的显微组织。图3中白色亮点部位经过能谱测定是Al2O3,深灰色的区域是Ti2AlN,被白色包围的深色的部位是Al3Ti(见图3(a)),图3(c)中标出颜色较浅的灰色区域是TiN。由图3可见,作为基体的Ti2AlN形成连续的和较均匀的分布,作为增强相Al2O3在基体中分布也比较均匀。图3(d)所示为白色亮点区域的放大,可以清楚看到白色区域中间是孔洞,这样的孔洞出现在各个样品中,说明制备工艺还需进一步优化。

图3 样品a、b和c的SEM像以及样品b中白色区域的显微组织

Fig.3 SEM images of samples a (a), b (b) and c (c), and microstructure of white lights in sample b (d)

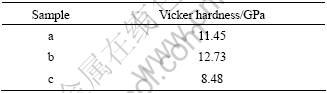

对样品a、b和c分别进行了维氏硬度测试,每个样品测试11个点,载荷2 N,统计平均值列于表1。

从表1看出,样品b的维氏硬度最高,样品a的次之,样品c的最低。这样的结果从XRD谱中能够得到解释,在样品b中含有较多的Al2O3,所以硬度较高;样品a中的Al2O3虽然没有样品b中的多,但是其中含有一定量的TiN,而TiN也属于陶瓷相,起到一定的增加强度的作用;样品c中的Al2O3相虽然细小,且分布比较均匀,但与样品a和b相比,硬度较小。关于Ti2AlN的硬度值,BARSOUM等[5]在1997年做过报道,测定为3.5 GPa,从表1中看出,3个样品的硬度值均超过文献中相Ti2AlN硬度,可见强化作用较明显。

表1 样品a、b和c的维氏硬度

Table 1 Vickers hardness of samples a, b and c

3 结论

1) 利用微米级的TiAl3粉末和纳米级的TiN粉末混合,或者在其中加入TiO2,两种方法都可以在热等静压的条件下制备出Ti2AlN基体和Al2O3增强相。

2) 单纯加入Al3Ti和TiN会导致Al3Ti剩余,Al2O3量相对不足,这是因为反应物中氧含量不足;而加入TiO2后, 增加了反应物中的氧含量,使Al2O3生成量增加,Al3Ti相完全反应,但TiN剩余。

3) 通过减少TiN的比例,加入适量的TiO2可以有效降低TiN在生成物中的比例。在不影响Ti2AlN基体的前提下,提高增强相Al2O3的含量。

4) 与Ti2AlN同时生成的Al2O3可以提高基体的硬度。所有样品的硬度值比较高,说明弥散分布在Ti2AlN基体中Al2O3起到强化作用。

REFERENCES

[1] JEITSCHKO W, NOWOTNY H, BENESOBSKY F. Ti2AlN, eine stickstoffhaltige H-phase [EB/OL]. http://www.springer- link.com/content/k368x7218q2hor47/Chemie/Chemical Monthly, 1963, 94(6): 1198-1200.

[2] SCHUSTER J C, BAUER J. The ternary system titanium- aluminum-nitrogen [J]. Journal of Solid State Chemistry, 1984, 53(2): 260-265.

[3] BARSOUM M W, FARBER L, LEVIN I, PROCOPIO A, El-RAGHY T, BERNER A. High-resolution transmission electron microscopy of Ti4AlN3 or Ti3Al2N2 revisited [J]. Journal of the American Ceramic Society, 1999, 82(9): 2545-2547.

[4] El-RAGHY T, BARSOUM M W, ZAVALIANGOS A, KALIDINDI S R. Processing and mechanical properties of Ti3SiC2: II. Effect of grain size and deformation temperature [J]. Journal of the American Ceramic Society, 1999, 82(10): 2855-2860.

[5] BARSOUM M W. The MN+1AXN phases: A new class of solids [J]. Thermodynamically Stable Chemistry, 2000, 28(1/4): 201-208.

[6] HOLM B, AHUJA R, LI S, JOHANSSON B. Theory of the ternary layered system Ti-Al-N [J]. Journal of Applied Physics, 2002, 91(12): 9874-9877.

[7] WANG X H, ZHOU Y C. Microstructure and properties of Ti3AlC2 prepared by the solid–liquid reaction synthesis and simultaneous in-situ hot pressing process [J]. Acta Materialia, 2002, 50(12): 3143-3151.

[8] LEE Y J, KANG S W. Ti-Al-N thin films prepared by the combination of metallorganic plasma-enhanced atomic layer deposition of Al and TiN [J]. Electrochemical and Solid-State Letters, 2003, 6(5): C70-C72.

[9] JOELSSON T, HORLING A, BIRCH J, HULTMAN L. Single-crystal Ti2AlN thin films [J]. Applied Physics Letters, 2005, 86(11): 111913-111913.

[10] GAO J, LI C, WANG N, DU Z. Thermodynamic analysis of the Ti-Al-N system [J]. International Journal of Mineral, Metallurgy, Material, 2008, 15(4): 420-424.

[11] YAN M, CHEN Y L, MEI B C, ZHU J Q. Synthesis of high-purity Ti2AlN ceramic by hot pressing [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(1): 82-85.

[12] EKLUND P, BECKERS M, JANSSON U, HOGBERG H, HULTMAN L. The M(n+1)AX(n) phases: Materials science and thin-film processing [J]. Thin Solid Films, 2010, 518(8): 1851-1878.

(编辑 李艳红)

通信作者:郑 卓; 电话: 024-23971962; E-mail: zzheng@imr.ac.cn