文章编号:1004-0609(2015)10-2745-07

热等静压制备CF/Al复合材料的微观结构及性能

喻 思1,郎利辉1,姚 松2,王 刚1,黄西娜1,续秋玉1

(1. 北京航空航天大学 机械工程及自动化学院,北京 100191;

2. 中国工程物理研究院 化工材料研究所,绵阳 621900)

摘 要:采用热等静压(HIP)工艺制备连续碳纤维(CF)增强Al基复合材料。利用扫描电镜、粒度仪和X射线衍射仪表征2A12铝合金粉末形貌、粒度分布和相组成;利用光学显微镜、扫描电镜和能谱仪观察复合材料的显微组织、断口形貌和界面扩散反应特征,并对其主要力学性能进行测试。结果表明:粉末形貌呈球形,粒度主要分布在150~180 μm;复合材料致密,界面连接紧密无孔洞缺陷;与基体铝合金材料相比,复合材料的拉伸强度和断后伸长率分别提高5%和54%,断裂方式为脆性断裂;Al基体裂纹起源于粉末颗粒界面,CF/Al界面断口呈现CF拔出和断裂失效形式;CF/Al界面发生元素扩散,界面反应生成Al4C3金属间化合物。

关键词:CF/Al复合材料;热等静压;失效形式;界面反应

中图分类号:TG146.2 文献标志码:A

Microstructure and properties of CF/Al composite manufactured by hot isostatic pressing

YU Si1, LANG Li-hui1, YAO Song2, WANG Gang1, HUANG Xi-na1, XU Qiu-yu1

(1. School of Mechanical Engineering and Automation, Beihang University, Beijing 100191, China;

2. Institute of Chemical Materials, China Academy of Engineering Physics, Mianyang 621900, China)

Abstract: Aluminum matrix composite reinforced with continuous carbon fiber (CF) was manufactured by hot isostatic pressing (HIP). The morphology, grain size distribution and phase of the powders were investigated by scanning electron microscope (SEM), particle analyzer and X-ray diffraction (XRD). The microstructure, fracture surface morphologies and CF/Al interface reaction characteristic were observed by optical microscope (OM), scanning electron microscope (SEM) and energy dispersive spectrometer (EDS). The mechanical properties of the composites were also tested. The results indicate that, the powders are nearly spherical, the particle size is mainly 150-180 μm; the composites are compact and the interface bonding is tight without porosity defect; compared with the aluminum matrix alloy, the tensile strength and elongation of the composites increase by above 5% and 54%, respectively, and the fracture mechanism is brittle fracture; the fracture of the Al matrix is along the powder interface, carbon fibers are pulled out and fractured in the CF/Al interface zone; the interface of the CF/Al appears element diffusion, and the interfacial reaction product is Al4C3 intermetallic compound.

Key words: CF/Al composite; hot isostatic pressing; failure mode; interfacial reaction

随着航空航天器件向着复杂化、轻量化、高性能和高可靠性方向的发展,对宇航材料的综合性能提出了更高要求。以航天器结构件为例,新型材料必须具有高强度、低密度、高导热、低膨胀以及良好的机加工能力,上述要求推动着航空材料向高性能化、结构功能一体化和复合化的方向发展[1-3]。铝基碳纤维(CF/Al)复合材料就是一种典型的轻质多功能材料,具有密度小、比强度高、比模量高、导热、电性能优异和高温性能稳定等优点,目前,主要应用于航空航天领域。同时,与其他连续纤维复合材料相比,CF/Al复合材料具有低成本与易成形的优点,在很大程度上也促进了它的研究与发展[4-7]。

采用常规方法制备CF/Al复合材料时,如挤压铸造法和真空压力浸透法,主要存在以下问题:低温条件下碳纤维和铝的润湿性很差,界面连接强度较低,复合材料的性能差;高温条件下碳纤维和液态铝发生剧烈反应生成脆性化合物Al4C3,使碳纤维结构和性能受损,复合材料的性能下降;碳和铝的热膨胀系数相差很大,在成形和冷却过程中连接界面处容易产生应力集中和分离现象[8-12]。目前,纤维表面涂层技术可以发送纤维和基体的润湿性提高界面连接强度,以及减少界面反应和界面应力集中现象,从而制备出性能优异的复合材料,因此涂层技术已成为国内外的研究热点。但是,液态铸造过程中出现的基体晶粒粗大、成分偏析、致密度低、纤维分布不均匀等缺陷,会导致复合材料的性能下降;同时,涂层技术对复合材料界面反应和力学性能的影响仍然存在着很大的争论[13-14]。采用粉末冶金热等静压(HIP)技术制备的材料晶粒细小,无宏观偏析,完全致密,还能制备出形状复杂、采用常规加工方法难以加工的结构件[15-16]。另外,Al粉末在HIP高温高压过程中始终处于固态,可以减少界面反应和对碳纤维性能的损害,使得粉末和纤维的界面连接较好,复合材料的性能优异。

本文作者采用HIP技术制备出CF/Al复合材料,分别测试2A12 Al粉末件和CF/Al复合材料的拉伸性能,对复合材料的拉伸断口形貌进行分析,确定其失效机理;并研究Al/CF界面结合情况对复合材料力学性能的影响,为进一步采用HIP制备CF/Al复合材料提供理论依据。

1 实验

1.1 实验材料

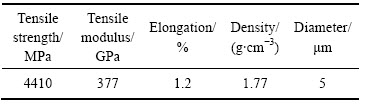

实验采用日本东丽公司生产的M40JB-3K-50长碳纤维,其性能参数列于表1;所用2A12 Al预合金粉末为北京有色金属研究总院提供;包套材料为工业纯铝1060A。

1.2 制备过程

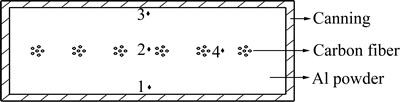

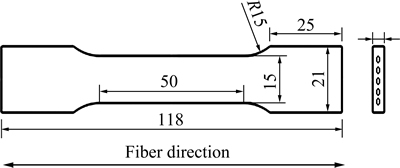

碳纤维表面的油污和杂质元素会阻碍元素的相互扩散,降低界面结合能力。实验前采用超声波清洗机和酒精清洗碳纤维,去除杂质和油污。图1所示为实验方案示意图。其中1~4点为测量相对密度的取样点。将Al粉末和CF(体积分数为1%)进行初装、振实,通过FJ-620分子泵进行抽真空除气处理后焊合包套。采用RD-450型热等静压机进行热等静压处理,工艺参数如下:温度为470 ℃,压力为120 MPa,保温保压时间为2 h。图2所示为拉伸试样尺寸,将HIP后的材料进行机械加工得到拉伸试样。

表1 M40JB碳纤维的性能参数

Table 1 Performance parameters of M40JB carbon fiber

图1 实验方案示意图

Fig. 1 Schematic diagram of experimental program

图2 标准拉伸试样尺寸示意图

Fig. 2 Schematic diagram of standard specimens for tensile tests (Unit: mm)

1.3 性能检测

采用CS3400型扫描电镜(SEM) 观察Al粉末形貌;采用SA-CP3型岛津离心沉降式粒度分布仪表征Al粉末粒度分布;采用D/max-2000型X射线衍射仪(XRD)分析Al粉末物相;通过排水法测定材料在图1所示的1~4点处的相对密度,每处取样3个求平均值;采用FPZ100型万能力学试验机测试抗拉强度;采用DM4000M型金相显微镜观察粉末的显微组织;通过扫描电镜(SEM)对复合材料的断口形貌和界面区域的元素扩散进行观察和分析。

2 结果与分析

2.1 粉末表征

2.1.1 粉末的形貌

图3所示为预合金2A12 Al粉末的表面形貌。从图3可以看出,粉末以球形或近球形为主。球形粉末的松装密度比异性粉末的大,可以减小试样变形,提高成品率;同时,球形粉末比表面积小,吸附的气体和杂质较少,在前期的抽真空除气处理中有助于提高产品质量;球形粉末的流动性好,有利于热等静压的致密化,因此,这种粉末形貌有利于复合材料的成形。

图3 2A12Al粉末表面形貌

Fig. 3 Surface morphology of 2A12 Al powder

2.1.2 粉末的粒度

图4所示为2A12 Al粉末的粒度分布。由图4可以看出,粒度分布区间为45~250 μm,其中70%粉末粒度分布在150~180 μm。这种具有一定分布区间的粉末在装填和HIP过程中,粒径较小的粉末能够进入大粉末的间隙中,从而提高粉末致密度,有利于材料性能的提高。

图4 2A12 Al粉末的粒度分布

Fig. 4 Particle size distribution of 2A12 Al powder

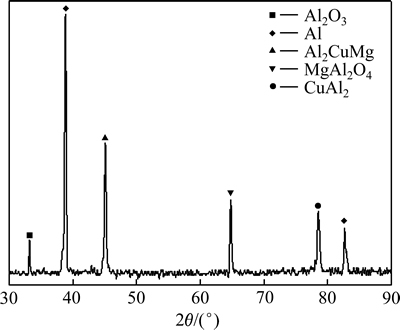

2.1.3 粉末的物相分析

图5所示为2A12 Al粉末的XRD谱。由图5可以看出,在原始粉末中不仅存在α(Al)、θ(CuAl2)和S(Al2CuMg)相,还检测到了氧化相Al2O3和MgAl2O4。由此可以判断,HIP前粉末在储运、填装和除气等工艺流程中,与空气进行接触而出现了氧化现象。

图5 2A12 Al粉末的XRD谱

Fig. 5 XRD pattern of 2A12 Al powder

2.2 材料的致密度和显微组织

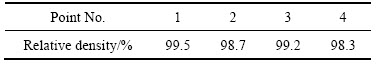

图6所示为复合材料的金相显微组织。图6(a)所示为碳纤维在铝基体中的分布,其中黑色的为碳纤维,其余部位是 Al基体;图6(b)所示为2A12 Al粉末的显微组织。由图6可以看出,复合材料表面没有孔洞和裂纹缺陷出现。表2所列为图1中4点位置处的相对密度值。由表2可知,2A12 Al粉末试样的相对密度在99%以上,复合材料的相对密度在98%以上,表明材料基本完全致密。而复合材料的相对密度略低于粉末试样的,这是由包套结构所致,导致热等静压过程中不同部位的塑性变形程度不一致,存在表面相对密度高、中心相对密度低的现象,所以不同部位的相对密度不一样。

由图6(a)可以看出,纤维与2A12 Al粉末之间不存在间隙,纤维出现团簇现象。纤维强度高于Al粉末强度,随着Al粉末的致密化,位于外侧的碳纤维使粉末表面破裂,Al粉末在达到致密化的同时,纤维也与Al基体紧密连接;中部纤维受到阻碍作用,和Al粉末的接触面积较少。由图6(b)可以发现,在HIP过程中,粉末颗粒除了以靠近及重排机制收缩外,还以滑移的方式产生塑性变形,球形粉末成为较规则的多面体形状而达到整体的致密化。同时连接界面清晰可见,界面处弥散着大量的θ(CuAl2)相和S(Al2CuMg)相(见箭头A所示)。超塑性材料和热轧制状态合金的扩散连接界面消失机理是不同的[17]。对于后者,连接界面的消失和高的连接强度是通过界面区域晶粒的再结晶而实现的;对于超塑性材料2A12铝合金粉末,实现方式主要是通过界面区域晶粒的长大。晶粒长大和再结晶都是通过晶界迁移实现的,晶界迁移的过程就是原子的扩散过程。致密化过程中,原始Al粉末界面处的第二相质点θ相和S相阻碍了原子的扩散,降低了界面能而导致晶界迁移困难,连接界面清晰可见。

图6 复合材料的金相显微

Fig. 6 Metallographic micrograph of composite

表2 图1中拉伸试样1~4点处的相对密度

Table 2 Relative density of points 1-4 in tensile sample shown in Fig. 1

2.3 材料的力学性能

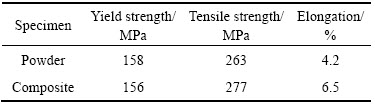

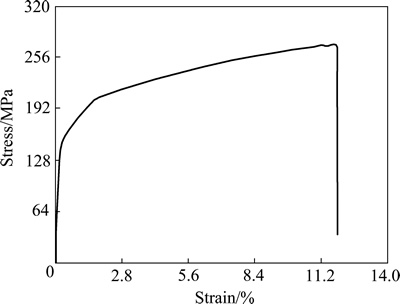

表3所列为基体铝合金粉末试样和复合材料试样的力学性能。由表3可知,复合材料与粉末材料相比,其抗拉强度和断后伸长率分别提高5%和54%,规定塑性延伸强度相当。连续碳纤维通过载荷传递使复合材料的强度提高。图7所示为复合材料的应力-应变曲线。由图7可知,复合材料的失效方式为没有明显屈服阶段的脆性断裂。

“混合定律”表明复合材料的力学性能取决于基体强度和增强体强度。复合材料“混合定律”为

(1)

(1)

式中:Ec为复合材料的拉伸模量;Ef为纤维的拉伸模量;Em为基体的拉伸模量; 为纤维的体积分数。

为纤维的体积分数。

(2)

(2)

式中: 为复合材料的拉伸强度;

为复合材料的拉伸强度; 为纤维拉伸强度;

为纤维拉伸强度; 为基体拉伸强度。

为基体拉伸强度。

表4所列为复合材料的拉伸强度和拉伸模量的理论值与实验值。由表4可知,复合材料的理论值与实验值相符合,表明碳纤维与基体铝有较好的界面结合,HIP过程没有损伤碳纤维的性能。

表3 2A12铝粉末材料和复合材料的力学性能

Table 3 Mechanical properties of 2A12 Al alloy powder and composite

图7 复合材料应力-应变曲线

Fig. 7 Stress-strain curve of composites

表4 复合材料的理论值和实验值

Table 4 Theoretical and experimental values of composites

2.4 材料的断口分析

图8所示为铝基体处断口形貌的SEM像。由图8(a)可看出,该区域没有出现夹杂和孔洞等缺陷,粉末呈现规则的多面体形状,与图6(b)所示形貌一致。由图8(b)所示的高倍断口形貌可看出,Al-Al界面发生脱粘现象,铝粉末没有发生断裂;断口整体表现为脆性断裂;颗粒界面处存在明显的裂缝,粉末表面也出现裂纹。对图8(b)中粉末裂纹处(见箭头所指)进行能谱分析,其主要化学元素含量列于表5。由表5可知,氧元素含量达到7.15%,结合图5可知,其主要存在于氧化物中。在此次HIP工艺条件下,粉末表面的氧化物没有发生破裂,而是完整地存在于界面处,阻止粉末基体的扩散连接,扩散程度较低。界面连接强度的高低取决于原始连接界面扩散程度的大小,导致粉末界面连接强度低于基体Al粉末的强度,试样裂纹起源于粉末界面连接处,粉末颗粒本身没有发生断裂。所以试样断口没有明显的缩颈和屈服现象出现,表现为脆性断裂,这与图7中的应力-应变曲线结果一致。本文作者认为,在不同HIP工艺条件下,Al粉末表面氧化物对扩散连接的影响有待更深入的研究。

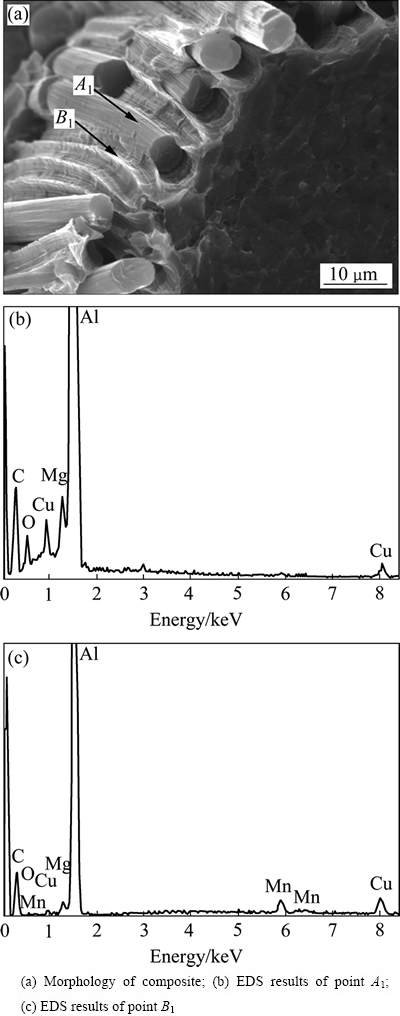

图9所示为碳纤维处断口形貌的SEM像和能谱分析结果。图9(a)为断口形貌的SEM像,图9(b)和(c)所示分别为图9(a)界面区域铝基体和纤维(见箭头A1、B1处)的EDS谱。复合材料的断裂机理主要有3种:1) 如果基体-增强体的界面连接强度较弱,那么裂纹会在界面区域产生和扩张,失效形式表现为增强体的拔出;2) 如果界面连接强度和基体强度都很高,那么当载荷强度达到增强体的断裂应力时,增强体会发生断裂;3) 如果基体的强度低于界面连接强度和增强体强度时,断裂会伴随基体中孔隙的形成和长大而发生[18]。由图9(a)可以看出,CF/Al复合材料的断裂机理很复杂,碳纤维呈现出不同的失效方式;CF/Al界面区域存在光亮物质;部分碳纤维的中部出现断裂现象。大部分纤维保持着其完整从铝基体中拔出或剥离的形貌,而与纤维连接的Al粉末并没有发生破裂。这是由于界面连接强度低于粉末断裂强度,载荷沿着界面从基体传递到纤维,使纤维与基体脱粘,纤维产生大量拔出和相互摩擦,提高了塑性能量的吸收,从而使复合材料的塑性提高;而剩余少数纤维则呈现断裂分离的形貌,这是由于界面连接强度高于纤维的断裂强度,轴向载荷先达到了纤维的断裂应力,使材料从纤维处断裂而分离。纤维的断裂强度远远高于Al粉末基体,这种失效形式提高了复合材料的拉伸强度。

图8 铝基体处的断口形貌

Fig. 8 Fracture morphologies of Al matrix

表5 裂纹处的主要化学元素的含量

Table 5 Mass fraction of main chemical element in crack (mass fraction, %)

复合材料界面反应程度对其性能产生很大影响。适量的界面反应可以提高界面结合强度,进而提高复合材料的力学性能;过量的界面反应将会生成大量的金属间化合物,严重损伤复合材料的力学性能。由图9(b)和(c)可看出,界面区域的Al基体和纤维表面都含有的C元素和Al元素。由此可以判断,在HIP过程中,CF/Al界面区域的化学元素发生了扩散。碳原子在铝中的溶解度几乎为0,高温下碳纤维和铝基体发生化学反应生成了Al4C3金属间化合物。

结合图6(a)和图9(a)分析可知,纤维的分布和拔出都具有明显的方向性,这是由于HIP过程中,固态铝粉末的流动性较差,远低于液态铝的,纤维的方向主要取决于实验前的排布,成形过程中基本不会改变。随着粉末的致密化,纤维出现的团簇现象导致中间分布的纤维与粉末的扩散连接面积的减少,同时由于固态下元素的扩散速度较低,界面反应不激烈,粉末表面的Al2O3在也抑制CF/Al的界面反应,这些因素都导致CF/Al界面连接强度不高,中间部位的纤维整体呈现沿轴向拔出的失效方式。而断裂的纤维主要位于团簇的外层,这是由于界面处的铝粉末致密化过程中发生破裂,纤维与铝粉末完全接触,更容易发生界面扩散反应,导致界面连接强度高于内部。另外,在铝粉末破裂的部位会出现应力集中现象,成形过程中这些部位的纤维由于受压应力过大而从中部断裂;同时,断口处纤维断裂的部位不平整,也说明了不同部位纤维所受力的大小不一样。但是本实验中,关于碳纤维含量和复合材料断裂方式及力学性能的关系并没有说明。

图9 复合材料的断口形貌和能谱分析结果

Fig. 9 Fracture morphology and EDS results of composite

3 结论

1) 通过HIP工艺成功制备出CF/Al复合材料。复合材料的微观结构显示Al/C和Al/Al界面连接紧密,不存在孔洞和裂纹缺陷,Al粉末试样的致密度在99%以上,复合材料的致密度在98%以上。

2) CF/Al复合材料的屈服强度、抗拉强度和断后伸长率分别为156 MPa、277 MPa和6.5%。复合材料的力学性能与铝粉末试样相比有了很大的提高,其抗拉强度和断后伸长率分别提高5%和54%,屈服强度基本相当;断口形貌表现为脆性断裂。

3) 铝粉末表面的氧化物阻碍了扩散连接,界面连接强度低于粉末强度,材料断裂起源于扩散连接界面,粉末基体没有发生破裂。CF/Al界面发生了元素扩散现象,反应生成Al4C3金属间化合物。碳纤维呈现拔出和断裂两种不同的失效形式,存在强界面连接强度和适中界面连接强度,纤维的失效方式说明了复合材料力学性能提高的原因。

REFERENCES

[1] 刘孝飞, 刘彦强, 樊建中, 魏少华, 马自力, 左 涛. 热等静压制备Sip/Al-Cu复合材料的组织与性能[J]. 中国有色金属学报, 2012, 22(11): 3059-3065.

LIU Xiao-fei, LIU Yan-qiang, FAN Jian-zhong, WEI Shao-hua, MA Zi-li, ZUO Tao. Microstructure and properties of Sip/Al-Cu composites fabricated by hot isostatic pressing[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3059-3065.

[2] 唐见茂. 航空航天材料发展现状及前景[J]. 航天器环境工程, 2013, 30(2): 115-121.

TANG Jian-mao. A review of aerospace materials[J]. Spacecraft Environment Engineering, 2013, 30(2): 115-121.

[3] 曾凡昌, 李成功, 于 翘. 航空航天材料[M]. 北京: 国防工业出版社, 2002: 23-25.

ZENG Fan-chang, LI Cheng-gong, YU Qiao. Aerospace materials[M]. Beijing: National Defense Industry Press, 2002: 23-25.

[4] LANCIN M, MARHIC C. TEM study of carbon fiber reinforced aluminum matrix composites: Influence of brittle phases and interface on mechanical properties[J]. Journal of the European Ceramic Society, 2000, 20(10): 1493-1503.

[5] 刘玫潭, 蔡旭升, 李国强. 高性能SiC增强Al基复合材料的纤维组织和热性能[J]. 中国有色金属学报, 2013, 23(4): 1040-1045.

LIU Mei-tan, CAI Xu-sheng, LI Guo-qiang. Microstructure and thermal properties of high-performance SiC reinforced Al matrix composite[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 1040-1045.

[6] 武高辉, 张云鹤, 康鹏超. Cf+SiCp/Al复合材料的微观组织与力学性能[J]. 稀有金属材料与工程, 2007, 36(3): 328-330.

WU Gao-hui, ZHANG Yun-he, KANG Peng-chao. The microstructure and mechanical properties of Cf+SiCp/Al composites[J]. Rare Metal Materials and Engineering, 2007, 36(3): 328-330.

[7] CHAND S. Review carbon fibers for composites[J]. Journal of Materials Science, 2000, 35(6): 1303-1313.

[8] LI S H, CHAO C G. Effects of carbon fiber/Al interface on mechanical properties of carbon-fiber-reinforced aluminum- matrix composites[J]. Metallurgical and Materials Transactions A, 2004, 35(7): 2153-2160.

[9] BUSHBY R S, SCOTT V D. Evaluation of aluminum-copper alloy reinforced with pitch-based carbon fibers[J]. Composites Science and Technology, 1997, 57(1): 119-128.

[10] KYONO T, HALL I W, TAYA M. The effect of isothermal exposure on the transverse properties of a continuous fiber metal-matrix composite[J]. Journal of Materials Science, 1986, 21(12): 4269-4280.

[11] DAOUD A. Microstructure and tensile properties of 2014 Al alloy reinforced with continuous carbon fibers manufactured by gas pressure infiltration[J]. Materials Science and Engineering A, 2005, 391(1): 114-120.

[12] LANG Li-hui, YU Si, WANG Gang, HUANG Xi-na, XU Qiu-yu. Microstructure and mechanical properties of 2A12 Al alloy powder reinforced with continuous carbon fibers manufactured by hot isostatic pressing[C]//2015 12th International Bhurban Conference on Applied Sciences and Technology (IBCAST). Islamabad: IEEE, 2015: 84-88.

[13] TANG Yi-ping, LIU Lei, LI Wei-wei, SHEN Bin, HU Wen-bin. Interface characteristics and mechanical properties of short carbon fibers/Al composites with different coatings[J]. Applied Surface Science, 2009, 255(8): 4393-4400.

[14] LIU Z G, MANG X B, CHAI L H, CHEN Y Y. Interface study of carbon fiber reinforced Al-Cu composites[J]. Journal of Alloys and Compounds, 2010, 504(10): 512-514.

[15] 黄培云. 粉末冶金原理[M]. 北京: 冶金工业出版社, 1997: 2-3.

HUANG Pei-yun. Theory of powder metallurgy[M]. Beijing: Metallurgical Industry Press, 1997: 2-3.

[16] 邬 军, 徐 磊, 雷家峰, 刘羽寅. 粉末冶金TA7 ELI合金的制备及其界面反应层[J]. 中国有色金属学报, 2010, 20(1): 299-302.

WU Jun, XU Lei, LEI Jia-feng, LIU Yu-yin. Preparation of powder metallurgy TA7 ELI alloy and its interface reaction layer[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 299-302.

[17] HUANG Y, RIDLEY N, HUMPHREYS F J, CUI J Z. Diffusion bonding of super plastic 7075 aluminum alloy[J]. Materials Science and Engineering A, 1999, 266(1): 295-302.

[18] HSIAO B S, CHEN E J, ISHIDA H. Controlled interphases in composite materials[M]. New York: Elsevier Science, 1990: 613-614.

(编辑 龙怀中)

收稿日期:2015-01-06;修订日期:2015-06-11

通信作者:喻 思;电话:18813165850;E-mail: yyuussii@163.com