文章编号:1004-0609(2013)S1-s0746-05

原位热等静压法制备Ti2AlN/Al2O3复合材料的微观结构及性能

郑 卓,崔玉友,杨 锐

(中国科学院金属研究所,沈阳 110016)

摘 要:采用原位热等静压法制备Ti2AlN/Al2O3复合材料,利用SEM和TEM研究Ti2AlN/Al2O3材料的微观结构及第二相颗粒Al2O3对复合材料的线性膨胀系数、热导率和硬度的影响。结果表明:Ti2AlN/Al2O3复合材料由片层状块体Ti2AlN相和弥散分布在基体内的近球形Al2O3颗粒组成。Ti2AlN/Al2O3复合材料的平均线性膨胀系数为9.86×10-6 ℃-1,热扩散率随着温度的升高而降低,比热容随着温度的升高而缓慢地增大,热导率随温度的升高而线性下降。Ti2AlN/Al2O3复合材料的强化机制主要为第二相粒子强化,Al2O3颗粒可以明显提高复合材料的硬度。室温下复合材料的维氏硬度为9 GPa,是单相Ti2AlN硬度的2.25倍。

关键词:Ti2AlN/Al2O3;复合材料;热等静压

中图分类号:TG148 文献标志码:A

Microstructure and properties of Ti2AlN/Al2O3 composite prepared by in-situ hot isostatic pressing process

ZHENG Zhuo, CUI Yu-you, YANG Rui

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The microstructure of Ti2AlN/Al2O3 composite fabricated by in-situ hot isostatic pressing was investigated by SEM and TEM and influence of Al2O3 particles on linear expansion coefficient, thermal conductivity and hardness of Ti2AlN/Al2O3 composite. The results show that the matrix Ti2AlN phase grains are plate-like, the strengthen Al2O3 particles are near spherical and disperse in matrix homogeneously. The average linear expansion coefficient of Ti2AlN/Al2O3 composite is 9.86×10-6 ℃-1. Thermal diffusivity decreases with the increase of the temperature, the specific heat capacity increases slowly with the increase of the temperature. The thermal conductivity of Ti2AlN/Al2O3 composite material decreases linearly with the increase of the temperature. The strengthening mechanism of composite is the second phase strengthen. Al2O3 particles can significantly improve the hardness of the composite. The Vickers hardness of Ti2AlN/Al2O3 is 9 GPa and 2.25 times as that of Ti2AlN at room temperature.

Key words:Ti2AlN/Al2O3; composite; hot isostatic pressing

近年来,一种被称为Mn+1AXn相的三元层状陶瓷得到了研究者极大的关注。其中M代表近过渡族金属,A代表主族金属(包括第3主族和第4主族),X代表C或者N,而n=1,2,3。Ti2AlN是研究Ti-Al-N系MAX相材料的重点,受到了广泛的关注。该材料具有金属和陶瓷的性能,具备金属的导热导电性,高温下具有良好的塑性,易于切削加工的特点。同时该材料具有陶瓷的高强度、高熔点、低密度,良好的热稳定性和抗氧化性能[1-6]。但是Ti2AlN与其他MAX相材料一样,其硬度和抗蠕变强度普遍较低,耐磨性较差,这样严重地限制了它的应用。近年来国内外对MAX相的研究有较大的进展,研究对象不再局限于单相MAX。通过加入第二相颗粒来提高MAX相的强度,硬度和抗氧化性能的研究渐多[7-11]。通过改变预备粉体的成分和配比可以在生成Ti2AlN相材料的同时引入原位生成的Al2O3增强相,制备出Ti2AlN/Al2O3复合材料,从而大幅度提高材料的显微硬度[12]。本文作者进一步研究Ti2AlN/Al2O3复合材料中Al2O3颗粒对材料的线性膨胀系数、热导率和不同载荷下硬度性能的影响。

1 实验

将Al3Ti,TiN和TiO2粉末按质量比2.07:1.68:1混合均匀。反应方程式为:

7Al3Ti+13TiN+6TiO2=13Ti2AlN+4Al2O3 (1)

将上述混合好的粉末经过冷压成型装入纯钛包套。利用热等加压,在1 300 ℃、150 MPa下经过2 h后,将压制好的样品用线切割除掉包套。所有样品经过预磨、抛光后,浸入氢氟酸溶液腐蚀。实验表明该条件下制备出的Ti2AlN/Al2O3复合材料含Al2O3颗粒的体积分数约为25%,孔隙率为4%。该复合材料具有杂质少、第二相颗粒分散均匀优点[12]。

利用Philips公司装有Oxford能谱系统的XL-30FEG扫描电子显微镜观察材料的组织形貌和分析能谱。利用美国Anter公司生产UnithermTM-1252 Ultra High Temperature Dilatometer超高温热膨胀计研究材料的线性热膨胀系及平均膨胀系数,样品为d6×50 mm柱状样品。利用美国Anter公司生产FlashlineTM-5000 Thermal Properties Analyzer热分析仪研究材料热扩散率、比热容及热导率。样品尺寸为d(12.7±0.02)×15 mm。利用Tester FM-700E硬度计测试样品的硬度。

2 结果与讨论

图1所示为Ti2AlN/Al2O3复合材料的显微结构照片。从图1中可以看到:复合材料包含有近球形颗粒和块状基体。近球形颗粒尺寸在1~3 μm之间,弥散分布在复合材料内部。近球形颗粒与块体间的界面明显。块状基体内部有明显的分层。不同块体内的分层方向不同,说明块体间的取向不同。

图1 Ti2AlN/Al2O3复合材料的SEM像

Fig.1 SEM image of Ti2AlN/Al2O3 composite

图2 Ti2AlN/Al2O3复合材料TEM明场像及相应位置选区电子衍射花样和EDS谱

Fig.2 TEM bright field image of Ti2AlN/Al2O3 composite (a) and selected-area electron diffraction (SAED) pattern of Ti2AlN in zone A (b), Al2O3 (c) in zone B and EDS spectra from A (d) and B (e) in Fig. 2(a)

图2(a)所示为Ti2AlN/Al2O3复合材料的透射电镜明场像照片和对应A、B两点的选区电子衍射。由图2(a)可见:近球形颗粒间彼此分开。基体相是块状晶粒。图2(d)和(e)所示为A、B两点的能谱曲线,通过定量计算得出A点处含有49.81%Ti、30.23%Al和19.95%的N(摩尔分数)。而在B点处含有39.33%的Al和60.67%的O。由此可见,两点处的成分明显不同。结合图2(b)和(c)中的选区电子衍射可以判断,A点处是基体相Ti2AlN,而B点处是原位反应得到的加强相α-Al2O3相。

对于复合材料而言,两相的界面对材料的性能有很大的影响。界面是基体和增强材料之间传递载荷的媒体。材料的硬化与强化取决于跨越界面的载荷传递。界面的多少随着第二相增强颗粒体积分数的增加而增加。由图2(a)透射照片可以看出:在制备的Ti2AlN/Al2O3复合材料中Al2O3颗粒与基体相Ti2AlN之间没有形成过渡的晶面相,界面清楚、干净。Ti2AlN单晶体结构为六方结构,空间群为P63/mmc,各向异性。但由于复合材料内各个晶体间取向不同,所以整体材料为各向同性。

图3所示为Ti2AlN/Al2O3复合材料的线膨胀曲线,复合材料在从500~1 000 ℃时的平均线性膨胀系数为9.86×10-6 ℃-1。Ti2AlN的体膨胀系数[13]为8.8×10-6 ℃-1,Al2O3的线性膨胀系数[14]为9.6×10-6 ℃-1。复合材料的膨胀系数大于Ti2AlN和Al2O3的膨胀系数,主要是因为制备的复合材料中含有4%(体积分数)闭合孔隙。孔隙对于材料膨胀系数影响较为复杂[15],复合材料加热时,内部孔隙中的封闭的气相,同时与Al2O3相和Ti2AlN相发生膨胀。由于各相膨胀系数存在的差异,产生热失配应力的,从而影响复合材料的热膨胀系数,导致材料的膨胀系数增大。Al2O3/Ti2AlN复合材料可以通过热处理的方法减少内部的孔隙,从而降低复合材料的膨胀系数。纯钛的膨胀系数[16]为10.1×10-6 ℃-1,与制备的复合材料较为接近。因此,该材料可能会与纯钛材料结合制备出具有特殊功能的工程材料。

图3 Ti2AlN/Al2O3复合材料的线性膨胀曲线

Fig.3 Linear thermal expansion curve of Ti2AlN/Al2O3 composite

从图4可以看出:Ti2AlN/Al2O3复合材料的热扩散率随着温度的升高而降低,并且在500 ℃之前下降速度较快,在500~1 000 ℃时下降速度较慢。说明Ti2AlN/Al2O3复合材料在高温区域具有一定的阻热的性能,有可能成为一种高温阻热材料。Al2O3/Ti2AlN复合材料的比热容随着温度的升高而缓慢地增大。这与Al2O3材料的增长趋势相同[14]。在相同温度下,复合材料的比热容小于Al2O3的比热容。

图4 Ti2AlN/Al2O3复合材料热扩散率和比热容随温度变化的曲线(Al2O3材料的数据来自文献[14])

Fig.4 Temperature dependence of thermal diffusivity and specific heat capacity curves of Ti2AlN/Al2O3 composite and Al2O3[14]

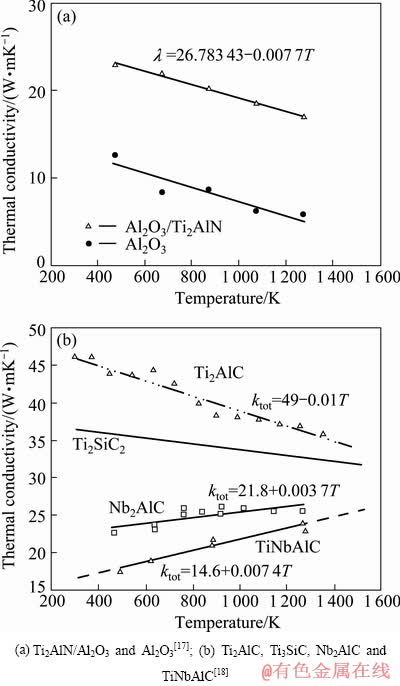

复合材料的热导率随温度变化曲线如图5所示。测量结果表明,Ti2AlN/Al2O3复合材料的热导率和温度之间存在着线性关系:

λ=26.783 43-0.0077T (2)

式(2)的拟合系数r2>0.98。随着温度的升高,Ti2AlN/Al2O3复合材料的热导率呈现出线性下降。从473 K升至1 273 K,其热导率从22.8 W·m-1·K-1下降到16.9 W·m-1·K-1,这个现象与Ti2AlC,Ti3SiC2相似,而与Nb2AlC和TiNbAlC的现象正好相反,如图5(b)所示。另外,Ti2AlN/Al2O3复合材料的热导率的值要比Ti2AlC,Ti3SiC2的值要小,这是受复合材料中有Al2O3颗粒和孔隙中的影响。从图5(a)可以看出:Al2O3的热导率随温度的增加而减少,从而降低了复合材料的热导率。对于热导率而言,复合材料中孔隙可看做孤立的杂质,其传导性为0。因此孔隙的存在也导致热导率降低。

图5 材料的热导率随温度的变化曲线

Fig.5 Temperature dependence of thermal conductivity

图6所示为Ti2AlN/Al2O3复合材料的显微维氏硬度和载荷的对应关系图。对于单相Ti2AlN材料随着载荷的增加,硬度值逐渐下降,并趋向于4 GPa[13]。在Ti3SiC2、Ti4AlN3和Ti3AlC2的硬度测试中也观察到这种变化的趋势。这种现象被称为压痕的尺寸效应。即在较低载荷下,测定样品的维氏硬度相对较高。但是这种压痕尺寸效应对Ti2AlN/Al2O3复合材料来说,影响不大。从图6可以看出:样品随着载荷的增加,材料的显微硬度变化不大。Al2O3/Ti2AlN复合材料硬度在9 GPa左右,远大于单相Ti2AlN材料4 GPa,说明Al2O3颗粒能够有效提高基体材料Ti2AlN相的显微硬度。复合材料的强化机制主要为颗粒强化。

图6 Ti2AlN/Al2O3复合材料与Ti2AlN[13]的维氏硬度与不同载荷之间的关系

Fig.6 Relationship between Vickers hardness of Ti2AlN/Al2O3 and Ti2AlN[13] composite versus indentation load

3 结论

1) 在Ti2AlN/Al2O3复合材料中主要由近球形的Al2O3颗粒与层状块体Ti2AlN相组成,两相间界面明显,无过渡相。增强相Al2O3为近球形颗粒,尺寸为1~3 μm,块体Ti2AlN相为层状结构,Ti2AlN块体间取向随机,整体材料为各向同性。

2) Ti2AlN/Al2O3复合材料的平均线性膨胀系数为9.86×10-6 ℃-1与纯钛较为接近。复合材料中存在的闭合孔隙,导致膨胀系数略大于Al2O3和Ti2AlN的膨胀系数。

3) 受Ti2AlN/Al2O3复合材料中Al2O3和空隙的影响,其热扩散率随着温度的升高而降低,比热容随着温度的升高而缓慢地增大,热导率随温度的升高而线性下降。

4) Ti2AlN/Al2O3复合材料的强化机制主要为第二相粒子强化。复合材料的维氏硬度对压痕的尺寸效应不敏感。Al2O3颗粒可以明显提高复合材料的硬度,其维氏硬度为9GPa是单相Ti2AlN材料(4GPa)的2.25倍。

REFERENCES

[1] JEITSCHKO W, NOWOTNY H, BENESOBSKY F. Ti2AlN, a nitrogen-containing H-phase[J]. Chemical Monthly, 1963, 94(6): 1198-1200.

[2] SCHUSTER J C, BAUER J. The ternary system titanium- aluminum-nitrogen[J]. Journal of Solid State Chemistry, 1984, 53(2): 260-265.

[3] 梅炳初, 徐学文, 朱教群, 刘 俊. 含铝Ti3SiC2在1 100 ℃和 1 200 ℃空气中的循环氧化行为[J]. 中国有色金属学报, 2004, 14(5): 772-776.

MEI Bing-chu, XU Xue-wen, ZHU Jiao-qun, LIU Jun. Cyclic oxidation behavior of ternary layered compound Ti3SiC2 with solute Al at 1 100 ℃ and 1 200 ℃ in air[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 772-776.

[4] 严 明, 梅炳初, 朱教群, 田晨光, 王 苹. 块体Ti2AlN多晶陶瓷的制备研究[J]. 武汉理工大学学报, 2007, 29(3): 20-22.

YAN Ming, MEI Bing-chu, ZHU Jiao-qun, TIAN Chen-guang, WANG Ping. Synthesis of bulk polycrystalline Ti2AlN cermic[J]. Journal of Wuhan University of Technology, 2007, 29(3): 20-22.

[5] 周卫兵, 梅炳初, 朱教群, 严 明. 三元层状化合物Ti2AlN在800 ℃, 900 ℃和1 000 ℃空气中的循环氧化行为[J]. 材料科学与工艺, 2010, 18(4): 584-587.

ZHOU Wei-bing, MEI Bing-chu, ZHU Jiao-qun, YAN Ming. Cyclic oxidation behavior of ternary layered compound Ti2AlN at 800 ℃, 900 ℃ and 1 000 ℃ in air[J]. Materials Science & Technology, 2010, 18(4): 584-587.

[6] 郑 卓, 崔玉友, 杨 锐. 热等静压制备Al2O3增强Ti2AlN金属陶瓷[J]. 中国有色金属学报, 2010, 20(S1): s280-s283.

ZHENG Zhuo, CUI Yu-you, YANG Rui. Ti2AlN cermet enhanced by Al2O3 prepared by hot isostatic pressing[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s280-s283.

[7] LUO Y M, LI S Q, CHEN J, WANG R G, LI J Q, PAN W. Effect of composition on properties of alumina/titanium silicon carbide composites[J]. Journal of the American Ceramic Society, 2002, 85: 3099-3101.

[8] WANG H J, JIN Z H, MIYAMOTO Y. Effect of Al2O3 on mechanical properties of Ti3SiC2/Al2O3 composite[J]. Ceramics International, 2002, 28(8): 931-934.

[9] CHEN J X, ZHOU Y C. Strengthening of Ti3AlC2 by incorporation of Al2O3[J]. Scripta Mater, 2004, 50(6): 897-901.

[10] WAN D T, ZHOU Y C, BAO Y W, YAN C K. In-situ reaction synthesisand characterization of Ti3Si(Al)C2/SiC composites[J]. Ceramics International, 2006, 32: 883-890.

[11] LI J Y, CUI Y Y, YANG R. Al2O3 dispersion-strengthened Ti2AlN composites and a method for producing the same: United States Patent, US7459408B2 [P]. 2008-12-02.

[12] ZHENG Z, WANG G, CUI Y Y, YANG R. Synthesis of Ti2AlN cermet strengthened by Al2O3[C]//Proceedings of the 12th World Conference on Titanium. Beijing, 2011: 1567-1570.

[13] BARSOUM M W, EL-RAGHY T, ALI M. Processing and characterization of Ti2AlC, Ti2AlN, and Ti2AlC0.5N0.5[J]. Metallurgical and Materials Transactions A, 2000, 31(7): 1857-1865.

[14] BAUCCIO M. ASM engineered materials reference book[M] 2nd ed. Materials Park, OH: ASM International, 1994: 193-229.

[15] TANE M, NAKAJIMA H. Effective-mean-field theory for electrical conductivity of multiphase composite materials [J]. Japanese Journal of Applied Physics, 2007, 46: 5221-5225.

[16] LIDE D R. CRC handbook of chemistry and physics[M]. 80th ed. Boca Raton, FL: CRC Press, 1999: 12-197.

[17] SHACKELFORD J, ALEXANDER W. CRC materials science and engineering handbook CRC[M]. 3rd ed. Washington, D.C.: CRC Press, 2001: 433-434.

[18] BARSOUM M W, SALAMA I, EL-RAGHY T, GOLCZEWSKI J, SEIFERT H, ALDINGER F, PORTER W, WANG H. Thermal and electrical properties of Nb2AlC, (Ti, Nb)2AlC and Ti2AlC[J]. Metallurgical and Materials Transactions A, 2002, 33: 2775-2779.

(编辑 杨幼平)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:崔玉友, 研究员, 博士; 电话: 024-23971961; E-mail: yycui@imr.ac.cn