文章编号:1004-0609(2013)S1-s0787-06

钙热还原TiO2制备钛粉过程中还原产物的酸浸工艺

王东生1, 2, 3,徐宝强1, 2, 3,戴永年1, 2, 3,任新林1, 2, 3,杨 斌1, 2, 3

(1. 真空冶金国家工程实验室,昆明 650093;

2. 云南省有色金属真空冶金重点实验室,昆明 650093;

3. 昆明理工大学 冶金与能源工程学院,昆明 650093)

摘 要: 钙热还原TiO2制备金属钛粉是一种新的钛粉生产方法,在整个流程中,还原产物的酸浸工艺是一个很重要的环节。通过单因素实验考察搅拌速度、反应温度、氢/钙离子摩尔比、液固比和反应时间等因素对钙浸出率和钛浸出率的影响。结果表明:在搅拌速度 500 r/min、温度 25 ℃、氢/钙离子摩尔比2.25:1、液固比30:1和酸浸时间15 min的条件下,钙的浸出率可达到99.18%,钛溶出率下降到0.143%。对钛粉(浸出渣)进行的XRD、SEM、EDS等分析检测表明:通过酸浸可将氧化钙等还原副产物有效去除;实验扩大后产品钛粉中氧含量高的主要原因是Ti-O固溶体彻底脱氧困难,其次是中间产物CaTiO3没有被充分还原。

关键词:钙热还原;酸浸;氧化钙;钛

中图分类号:TF823 文献标志码:A

Acid leaching of reduction products in process of calciothermic reduction of TiO2

WANG Dong-sheng1, 2, 3, XU Bao-qiang1, 2, 3, DAI Yong-nian1, 2, 3, REN Xin-lin1, 2, 3, YANG Bin1, 2, 3

(1. National Engineering Laboratory for Vacuum Metallurgy, Kunming 650093, China;

2. Key Laboratory for Nonferrous Metals Vacuum Metallurgy of Yunnan Province, Kunming 650093, China;

3. Faculty of Metallurgy and Energy Engineering, Kunming University of Science and Technology, Kunming 650093, China)

Abstract: Preparation of titanium powders from TiO2 by calcium vapor reduction is one of the most active new methods of titanium production, and in this procedure the acid leaching process of reduction products plays an important role. With single-factor experiment method, the influences of agitation speed, temperature, mole ratio of hydrogen/calcium ions, liquid-to-solid ratio and leaching time on the leaching rate of calcium and titanium were studied. It shows that under the conditions of agitation speed 500 r/min, temperature 25 ℃, mole ratio of hydrogen/calcium ions 2.25:1, liquid-to-solid ratio 30:1 and leaching time 15 min, the leaching rates of calcium and titanium are about 99.18% and 0.143%, respectively. The titanium powder (leaching residues) was detected by means of XRD, SEM and EDS. It is proved that calcium oxide and other impurities can be effectively removed by acid leaching. Higher oxygen content is mainly caused by difficult deoxidization of Ti-O solid solution, as well as the inadequate reduction of intermediate products calcium titanate.

Key words: calciothermic reduction; acid leaching; calcium oxide; titanium

钛具有密度低、比强度高、耐热、耐腐蚀、无毒无磁等优异性能,在航空航天、交通运输、石油化工、能源等领域得到越来越广泛的应用,需求量逐年上升[1]。目前,Kroll法[2]是工业生产海绵钛的主要工艺。但是该工艺为半连续生产,生产效率低,氯化过程对设备的要求较高,环境污染严重,导致钛的生产成本较高,限制了金属钛的大规模应用[3-5]。科研工作者致力于寻求一种更高效的新工艺。目前发展了很多制备钛的方法,如FFC法[6]、OS法[7]、ESR法[8]、EMR/MSE法[9]、SOM法[10]、PRP法 [11]、USTB法[12]等。其中典型的是FFC法和PRP法。

OKABE等[11]于2004年提出的PRP工艺是一种清洁高效的钛粉制备工艺。在这个工艺过程中,还原剂钙和预还原块没有直接接触,因而能有效避免还原剂中杂质对产品的污染。另外,与FFC法相比,该工艺熔盐的使用量大幅度减少,还原过程在几个小时内就能完成。在PRP工艺原理的基础上,WAN等[13]对其做了改进,省去了预烧结和加入海绵钛去除反应器中O2和N2的步骤,并且重新设计了反应器,进行了千克级的扩大实验。其工艺流程如图1所示。本文作者通过单因素实验研究了钙热还原二氧化钛制备金属钛粉过程中还原产物的酸浸工艺,讨论了搅拌速度、反应温度、氢/钙离子摩尔比、液固比和反应时间等工艺条件对钙浸出率和钛浸出率的影响,寻求既能促进还原副产物CaO的浸出,同时又能抑制钛浸出的有效措施,为扩大实验中酸浸效率打下理论基础。

图1 钛粉生产工艺图

Fig. 1 Experimental procedure of titanium powder production

1 实验

1.1 实验原料

酸浸实验采用的物料是钙热还原TiO2制备钛粉扩大实验过程中产生的还原产物。还原反应的原料钛白粉来自四川攀枝花地区,成分为TiO2 99.2%,P2O5 0.36%,K2O 0.3%,还有其他一些杂质。首先将钛白粉1.67 kg和相应量的CaCl2 0.835 kg以质量比2:1混合均匀,在2 MPa的压力下保压30 s,制成尺寸为d 30 mm×7 mm圆柱形的预还原块。再把预还原块和一定量的金属钙粒(3.34 kg)装入特制的不锈钢反应器内,将反应器密封放入真空炉内加热还原。还原反应在1 100 ℃的条件下保温8 h,还原反应结束后打开反应器得到还原产物。将还原产物进行机械粉碎,粉碎时间为30 s。测得粒度<80 μm的大于98%,满足浸出实验要求。然后把粉碎好的物料放入真空干燥箱内,在60 ℃干燥24 h。还原产物的XRD分析结果如图2所示。由图2分析可知,还原产物中的主要物质是CaO和Ti,还有少量Ca(OH)2(检测过程中CaO吸水)。对还原产物进行化学成分分析,其含钛17.27%,含钙44.24%。实验中用到的其他试剂均为分析纯。

图2 还原产物的XRD谱

Fig. 2 XRD pattern of reduction product

1.2 实验方法

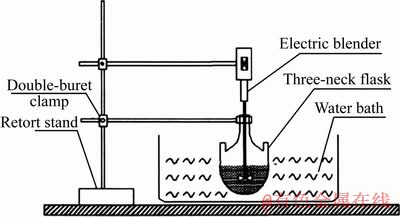

反应装置如图3所示。首先在500 mL的三口瓶中加入配制好的盐酸,把三口瓶放入水浴锅内,达到指定温度后,再加入5 g物料进行浸出实验。反应完成后迅速将浸出液进行过滤,测得母液中钙和钛的含量,以确定还原产物中钙和钛的浸出率。浸出液中钙的含量用EDTA滴定分析方法测定[14],钛的含量用电感耦合等离子发射光谱(ICP-AES,OPTIMA8000,PerkinElmer)分析测定;用日本理学公司生产的X射线衍射仪(XRD,D/max-3B)分析还原产物的物相组成;用装有能谱仪的扫描电镜(SEM-EDS;FEI QUANTA 600)观察浸出渣即钛粉的形貌,并检测不同区域的元素分布;钛粉中的氧、氮含量用美国立可公司的氮氧分析仪(LECO TC400)测定,检测依据参考Q/GYB 10.3—2002。

图3 反应装置简图

Fig. 3 Equipment sketchmap

2 结果和讨论

2.1 搅拌速度对钙和钛浸出率的影响

在反应温度25 ℃、溶液中氢/钙离子摩尔比2.25:1、液固比20:1和反应时间10 min的条件下,研究搅拌速度对钙浸出率和钛浸出率的影响,结果如图4所示。

由图4可知:在一定范围内,钙和钛的浸出率都随着搅拌速度的增大而提高;当搅拌速度达到350r/min后继续增大搅拌速度,钙和钛的浸出率无明显变化,同时观察到还原产物较均匀地悬浮于溶液中。当搅拌速度超过350 r/min时,搅拌速度可以作为浸出过程中的不变因素不予考虑,因此后续的实验将搅拌速度设定为500 r/min,以消除搅拌速度对浸出过程的影响。

图4 搅拌速度对钙和钛浸出率的影响

Fig. 4 Effect of stirring speed on leaching rate of calcium and titanium

2.2 温度对钙和钛浸出率的影响

在搅拌速度500 r/min、氢/钙离子摩尔比2.25:1、液固比20:1和反应时间10 min的条件下,考察了温度对钙和钛浸出率的影响,结果如图5所示。

图5 温度对钙浸出率和钛浸出率的影响

Fig. 5 Effect of temperature on leaching rate of calcium and titanium

由图5可知:随着酸浸温度的升高,钙和钛的浸出率都有所增加。当温度从25 ℃升高到45 ℃时,钙的浸出率从97.87%增加到98.23%,温度对钙的浸出率影响不大;钛的浸出率从0.709%增加到1.514%,增加了一倍多。可见,低温能有效地降低钛粉在酸浸工艺中的损失,增大钛粉的收得率,而较高的酸浸温度反而会造成生产环境的恶化和能耗的增加。综合考虑,浸出温度选择为25 ℃为宜。

2.3 氢/钙离子摩尔比对钙和钛浸出率的影响

在搅拌速度500 r/min、反应温度25 ℃、液固比20:1和反应时间10 min的条件下,考察了氢/钙离子摩尔比对钙浸出率和钛浸出率的影响,结果如图6所示。

由图6可以看出,在相同时间内,钙和钛的浸出率都随着氢/钙离子的摩尔比增加而增大,即随着初始盐酸浓度的增加而增加。这主要是因为氢/钙离子摩尔比增加,相应地增大了H+向固体表面扩散的速率。当氢/钙离子的摩尔比由2:1增大到3:1时,反应10 min后钙离子的浸出率由97.56%增大到98.47%,钛的浸出率却由0.646%增加到1.314%,可见酸浓度对钛浸出率的影响较钙更加明显。增大酸浓度,一方面增加了生产成本,另一方面增加了钛粉在酸浸工艺中的损失,但要保证Ca2+的完全溶出又需要盐酸适当过量,因此在本实验条件下氢/钙离子的摩尔比选择为2.25:1。

图6 氢/钙离子摩尔比对钛和钙浸出率的影响

Fig. 6 Effect of HCl concentration on leaching rate of titanium and calcium

2.4 液固比对钙和钛浸出率的影响

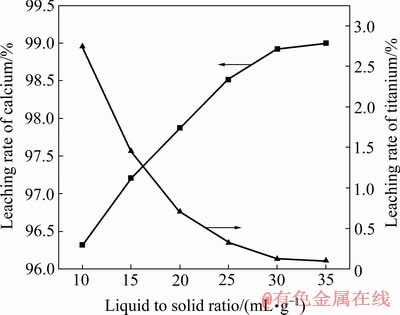

在搅拌速度500 r/min、反应温度25 ℃、氢/钙离子摩尔比2.25:1(HCl总量不变)和反应时间10 min的条件下,考察液固比对钙浸出率和钛浸出率的影响,结果如图7所示。

图7 液固比对钛和钙浸出率的影响

Fig. 7 Effect of liquid-to-solid ratio on leaching rate of titanium and calcium

从图7可以看出,钙的浸出率随着液固比的增加而增大,从96.32%增大到99%;钛的浸出率随着液固比的增大而减小,从2.741%减小到10.6%。这主要是因为增大液固比后,相应地降低了H+浓度。在实验条件下,钙的浸出受H+浓度的影响较小,而钛的浸出受H+浓度影响大,H+浓度降低直接导致钛的浸出率下降。这对整个工艺来说十分有利,增大液固比,既有利于钙的浸出,还减小钛粉在酸浸工艺中的损失。当液固比增大到30:1时,继续增大液固比,钛的浸出率降低就不太明显了,因此在实验条件下,液固比取30:1为宜。

2.5 钙和钛的浸出率和反应时间的关系

在搅拌速度500 r/min、反应温度25 ℃、氢/钙离子摩尔比2.25:1、液固比30:1的条件下,研究钙浸出率和钛浸出率随时间的变化情况,结果如图8所示。

图8 钙浸出率和钛浸出率与反应时间的关系

Fig. 8 Relationship between leaching rate of calcium and titanium and leaching time

从图8可以看出:钙的浸出反应很快,浸出2 min后,钙的浸出率就达到了87.24%,随着浸出时间的延长,钙的浸出率先增大后减小。钛的浸出率随着反应时间的延长一直增大,反应30 min后,钛的浸出率为0.147%。这主要是因为随着反应的进行,溶液中H+浓度不断减小,使得H3PO4的电离程度加剧,释放出更多的PO43-;同时Ca2+不断溶出,溶液中Ca2+浓度增大,溶液中PO43-和Ca2+结合生成Ca3(PO4)2沉淀,最终导致溶液中的钙的浸出率下降,钛粉(浸出渣)中的杂质元素Ca含量增高,整个反应如式(1)~(5)所示。因此,为了防止溶液中Ca3(PO4)2的生成,盐酸也应适当过量。可见酸浸时间也是影响产品质量的一个重要因素,实验拟定的最佳浸出时间为15 min。

H3PO4=H++ H2PO4- (1)

H2PO4-=H++ HPO42- (2)

HPO42-=H++ PO43- (3)

CaO+2H+=Ca2++H2O (4)

3Ca2++2PO43-=Ca3(PO4)2↓ (5)

2.6 综合性实验及浸出渣分析

通过以上实验,得到的最佳酸浸工艺如下:搅拌速度500 r/min,反应温度25 ℃,氢/钙离子的摩尔比2.25:1,液固比30:1,浸出时间15 min。在最佳的酸浸工艺条件下,钙的浸出率为99.2%,钛的浸出率下降到0.143%。反应结束后,将浸出渣用蒸馏水洗涤3次,再用无水乙醇洗涤1次,然后经70 ℃真空干燥24 h后得到钛粉。对钛粉进行化学成分分析,钛粉中含钛91.64%,含钙1.61%,含氧4.38%,含氮2.16%。对钛粉(浸出渣)进行扫描电镜和能谱分析,结果如图9和表1所示。

从图9(a)可以看出,钛粉的粒度大部分在10~20 μm之间,图中浅色区域为金属钛。对区域3进行EDS分析,发现含氧5.7%和氮2.2%,没有发现钙元素的残留。图中暗色区域(区域4)含钙31.62%和氧29.43%。可见钛粉中残余的大部分钙元素都是由这部分带入的。经过计算发现,区域4中Ti、Ca和O的摩尔比为1:1:2.3,因此有理由推测区域4的主要物质为CaTiO3,另外还有一些钛的低价氧化物。残留物中没有发现K、P、Fe等杂质元素,可见酸浸过程中这些杂质能够被有效地去除。

在先前的实验中得到了含氧0.12%、含氮0.025%的钛粉[15]。然而实验扩大以后产品钛粉中的氧、氮含量却急剧升高。钛粉中氧的来源主要有3个:1) Ti—O固溶体本体中的残余O(区域3);2) 未被充分还原的中间产物CaTiO3中的O(区域4);3) 吸附在Ti颗粒边界上或者包裹于Ti颗粒内部的CaO中含有的O。文献报道在1 373 K温度下Ca-CaO体系中Ti-O固溶体被还原后Ti中的平衡氧浓度为0.049%[16]。然而在扩大实验中很难让Ti-O固溶体达到脱氧平衡状态,从图9也可以看出,要将Ti-O固溶体中的氧脱除至很低的水平也不是那么容易,因此还原过程中Ti-O固溶体还原不彻底是导致最终产品钛粉中氧含量偏高的主要原因。Ca则主要因为中间产物CaTiO3还原不彻底从而残留于钛粉中,因此在扩大实验中CaTiO3没有被充分还原是导致产品中氧含量偏高的另一个原因;尚未发现酸浸过程导致氧含量高的实验证据。氮含量升高是由于还原产物在后续的破碎和样品保存过程中钛粉与空气接触导致,近年来已通过氩气气氛保护手段使钛粉氮含量降至0.026%,表明酸浸过程也未对钛粉的氮含量造成严重影响。

图9 钛粉的SEM像及相应的EDS谱

Fig. 9 SEM image and EDS spectra of titanium powder

表1 钛粉的EDS元素分析结果(质量分数,%)

Table 1 EDS element analysis of titanium powder (mass fraction, %)

3 结论

1) 研究钙热还原TiO2制备金属钛粉过程中还原产物的酸浸工艺,得到了最佳酸浸工艺条件:搅拌速度 500 r/min,温度 25 ℃,氢/钙离子的摩尔比2.25:1,液固比30:1,酸浸时间15 min。此时Ca的浸出率达到99.18%,钛溶出率下降到0.143%。

2) 钛粉中氧含量高的主要原因是Ti-O固溶体彻底脱氧困难,其次是中间产物CaTiO3没有被充分还原;氮含量的控制能够通过在破碎过程中通入氩气气氛保护降至0.026%。

REFERENCES

[1] 王向东, 逯福生, 贾 翃, 郝 斌. 2012年中国钛工业发展报告[J]. 钛工业进展, 2013, 30(2): 1-6.

WANG Xiang-dong, LU Fu-sheng, JIA Hong, HAO Bin. Report on China titanium industry progress in 2012[J]. Titanium Industry Progress, 2013, 30(2): 1-6.

[2] KROLL W. The production of ductile titanium[J]. Transactions of Electrochemical Society, 1940, 78: 35-47.

[3] 郑海燕, 卢金文, 沈峰满. TiO2直接制备金属钛技术进展[J]. 过程工程学报, 2009, 9: 448-452.

ZHENG Hai-yan, LU Jin-wen, SHEN Feng-man. New technologies on direct production of metallic titanium from TiO2[J]. The Chinese Journal of Process Engineering, 2009, 9: 448-452.

[4] FRAY D J. Novel methods for the production of titanium[J]. International Materials Reviews, 2008, 53(6): 317-324.

[5] 朱鸿民, 焦树强, 宁晓辉. 钛金属新型冶金技术[J]. 中国材料进展, 2011, 30(6): 37-43.

ZHU Hong-min, JIAO Shu-qiang, NING Xiao-hui. New metallurgical technologies of titanium metal[J]. Materials China, 2011, 30(6): 37-43.

[6] SCHWANDT C, DOUGHTY G R, FRAY D J. The FFC-Cambridge process for titanium metal winning[J]. Key Engineering Materials, 2010, 436: 13-25.

[7] ONO K, SUZUKI R O. A new concept for production Ti sponge: Calciothermic reduction[J]. JOM, 2002, 54: 59-61.

[8] TAKENAKA T, SUZUKI T, ISHIKAWA M. The new concept for electrowinning process of liquid titanium metal in molten salt[J]. Electrochemistry, 1999, 67: 66l-668.

[9] PARK I, ABIKO T, OKABE T H. Production of titanium powder directly from TiO2 in CaCl2 through an electronically mediated reaction (EMR)[J]. Physics and Chemistry of Solids, 2005, 66: 410-413.

[10] 赵志国, 鲁雄刚, 丁伟忠, 周国志. 利用固体透氧膜提取海绵钛的新技术[J]. 上海金属, 2005, 20(2): 40-43.

ZHAO Zhi-guo, LU Xiong-gang, DING Wei-zhong, ZHOU Guo-zhi. A new technology using SOM to produce titanium sponge[J]. Shanghai Metals, 2005, 20(2): 40-43.

[11] OKABE T H, ODA T, MITSUDA Y. Titanium powder production by preform reduction process(PRP)[J]. Journal of Alloys and Compounds, 2004, 364: 156-163.

[12] 黄珊艳, 侯 娜, 朱鸿民. TiCxOy固溶体的导电性能和物相研究[J]. 有色金属, 2011, 10: 43-46.

HUANG Shan-yan, HOU Na, ZHU Hong-min. Study on conductive properties and phases of TiCxOy solid solution[J]. Nonferrous Metals, 2011, 10: 43-46.

[13] WAN He-li, XU Bao-qiang, DAI Yong-nian. Preparation of titanium powders by calciothermic reduction of titanium dioxide[J]. Journal of Central South University, 2012, 19: 2434-2439

[14] 万贺利, 龙 萍, 徐宝强, 杨 斌, 刘大春, 戴永年. 测定钙热还原二氧化钛制备钛粉产物中氧化钙的含量[J]. 轻金属, 2012(1): 53-56.

WAN He-li, LONG Ping, XU Bao-qiang, YANG Bin, LIU Da-chun, DAI Yong-nian. Determination of calcium oxide in product of calciothermic reduction of titanium dioxide by EDTA titrimetry[J]. Light Metal, 2012(1): 53-56.

[15] JIA Jin-gang, XU Bao-qiang, YANG Bin, WANG Dong-sheng. Preparation of titanium powders from TiO2 by calcium vapor reduction[J]. JOM, 2013(3): 630-635.

[16] SUZUKI R O. Calciothermic reduction of TiO2 and in situ electrolysis of CaO in the molten CaCl2[J]. Journal of Physics and Chemistry of Solids, 2005, 66: 461-465.

(编辑 袁赛前)

基金项目:国家自然科学基金青年科学基金资助项目(51004058);云南省应用基础研究基金资助项目(2011FB039)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:徐宝强,副教授,博士;电话:0871-65161583;E-mail: kmxbq@126.com