DOI: 10.11817/j.ysxb.1004.0609.2020-39525

添加剂氧化钙对镍渣强化还原的影响

李小明,张馨艺,李 怡,邢相栋

(西安建筑科技大学 冶金工程学院,西安 710055)

摘 要:针对铁以铁橄榄石形式存在而难以直接还原磁选回收的问题,采用在镍渣中配加CaO提升镍渣碳热还原速率及铁金属化率的技术思路。将添加剂与镍渣按比例混合并配加适量还原剂后,在高温炉中进行还原,结合热力学计算及产物特征分析结果,研究添加剂强化还原的机理及还原效果。结果表明:CaO的加入有效促进了硅酸铁的解离,强化了还原过程,还原速率加快,金属相在渣相中的形态结构发生改变,金属铁的聚集长大明显,有利于后续分离回收。随着CaO添加量由0增加到10 %(质量分数),还原产物的金属化率和Fe颗粒平均粒径呈先增大后减小的趋势,FeO含量和残碳量变化规律相反。在CaO添加量为8 %时,还原产物中铁的金属化率和粒径达到峰值,分别为87.25%和41.3 μm。

关键词:镍渣;氧化钙;碳热还原;添加剂

文章编号:1004-0609(2020)-04-0887-09 中图分类号:TF111 文献标志码:A

镍渣是闪速炉或富氧顶吹炉冶炼镍过程中排出的废渣,含有铁、铬、镍等有价金属且铁品位较高,是重要的含铁二次资源,其长期堆存占用土地,污染环境,对其进行资源化利用具有重要的经济价值和社会效益[1-3]。

针对镍渣的回收利用,已开展了湿法浸出有价金属[4-5]、熔融还原提铁[6-7]、直接还原-磁选制备精矿粉或铁合金[8]等研究。其中直接还原-磁选技术因工艺简单借鉴性高,在实现复杂含铁二次资源中有价元素的高效分离方面受到研究者广泛关注[9]。但镍渣中铁以橄榄石形式存在导致其还原难度较大,需深入研究还原强化的工艺原理及技术措施[10-13]。

添加剂能在不改变还原产物的物相组成的条件下加快反应速率,是较为理想的还原强化方式。近年来对深度还原回收铁工艺中添加剂的选择,学者们进行了积极研究。曹羽鑫等[14]以铁品位70.25%、SiO2含量1.86%的铁精矿为原料,选取CaO、Na2CO3及Na2SO4为添加剂,得出CaO促进Fe2SiO4与C还原反应的热力学最佳条件,其次是Na2CO3,Na2SO4效果最差。孙体昌等[15]研究了Na2SO4、Na2CO3、CaCO3和CaSO4等添加剂对红土镍矿中镍铁选择性还原的影响规律,得出Na2SO4作用效果明显,获得镍铁产品中镍的品位较高。王爽等[16]研究了炉渣中铁、镍、铜的回收特点,发现添加CaO提高碱度可促进金属相的还原生长,改善金属相在渣相中的形态结构。耿超等[17]分析了以萤石和硫酸钠为添加剂对海滨钛磁铁矿直接还原磁选钛铁分离的影响,发现添加Na2SO4在还原提铁的同时可获得高品位钛产品。刘志国等[18]指出在直接还原焙烧过程中,CaO能够与硅酸盐矿物反应生成辉石,提高反应活性,促进镍的还原并且提高镍的回收率。在前人的研究中发现相比于其他添加剂,CaO促进还原的效果显著,且价格低廉产物无磁性,可通过磁选分离。针对镍渣强化还原的相关研究尚未积极开展,以上在复杂难选矿物方面开展的还原强化成果对镍渣的强化还原具有重要的参考价值。

本文以CaO作为添加剂,将其与镍渣按比例混配,在高温炉中进行还原,借助XRD、SEM、EDS等分析表征手段,研究添加剂对镍渣碳热还原的影响,为CaO作添加剂进行镍渣直接还原-磁选回收高品位铁产品提供理论依据和实验数据支撑。

1 实验

1.1 实验原料

实验所用镍渣由国内某镍冶炼厂提供,为大块片状,将其粉碎至粒径小于0.074 mm后进行化学分析,其成分列于表1。由表1可知,原料中全铁含量为39.40%,FeO、SiO2含量分别达到49.68%和32.50%,镍渣中还伴有少量Ni、Cu等金属元素,具有回收利用价值。此外,原料中S含量较高,还原过程中S元素的变化亦需要关注。

表1 镍渣的化学成分

Table 1 Chemical composition of nickel slag (mass fraction, %)

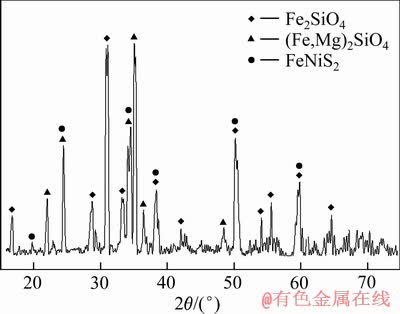

镍渣的XRD谱如图1所示。由图1可见,镍渣中的主要物相为Fe2SiO4 和 (MgFe)2SiO4,并存在少量FeNiS2。

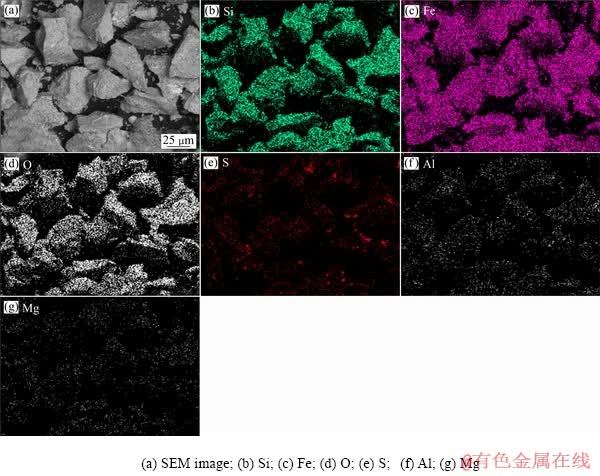

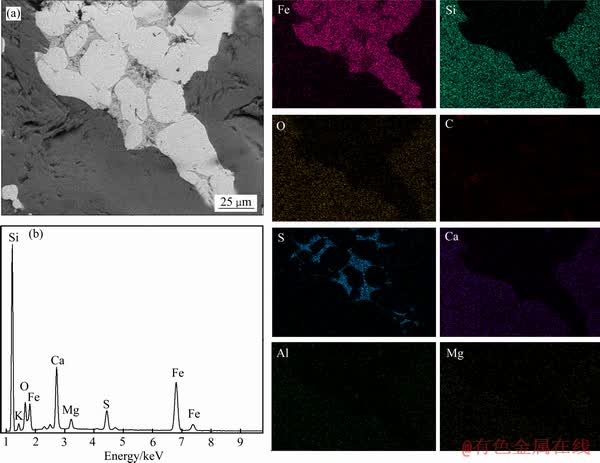

镍渣的SEM像如图2所示。由图2可知,镍渣颗粒较大,呈黑灰色,结构致密,分布较为均匀,小颗粒附着于大颗粒之间或表面。镍渣中含大量的Fe、O和Si元素,并伴有少量的S、Mg和Al元素。结合图1可知,Fe以Fe2SiO4形式大量存在,并伴有少量含铁、镍、铜的硫化物。

图1 镍渣的XRD谱

Fig. 1 XRD pattern of nickel slag

1.2 实验方法及装置

首先使用震荡破碎机将镍渣样品破碎至粒度<0.074 mm。加入的实际碳含量与还原镍渣中铁、铜、镍的氧化物理论最大需碳量之比为1.2:1。将镍渣和石墨粉按质量比准确称量后置于混料机中混合均匀,充分混匀后配加CaO、粘结剂(羧甲基酸钠)和水再次混匀,其中CaO用量分别取镍渣质量的0%、2%、4%、6%、8%和10%,粘结剂占镍渣质量的1%,水占镍渣质量的8%。接着将混合料放入模具用模压机压块,制成每块5 g,直径约10 mm、高10 mm的圆柱状样品,并将样品放于干燥箱中,于120 ℃干燥2 h。最后,升高还原炉温度至1200 ℃时,在氩气气氛(0.8 L/min)下将盛放有干燥样品的刚玉坩埚置于立式管式炉内,并保温一定时间。实验结束后,快速取出坩埚,在氩气气氛中冷却至室温之后,制样,进行检测分析。

图2 镍渣的SEM像及元素面扫描分析

Fig. 2 SEM image and element map distribution of nickel slag

实验装置如图3所示,立式管式炉配有温度控制装置,温度测量精度为±1 ℃,热电偶检测炉内温度并连接到计算机进行实验数据采集。保护气体(氩气)调节流量后,由炉底进气管通入炉内,穿过炉管后由上部出气管流出。

图3 实验装置示意图

Fig. 3 Schematic diagram of experimental apparatus

1.3 产物分析表征

将焙烧团块沿径向分割,一半保持团块状态不变,直接制成光片,采用Nova400Nano扫描电子显微镜(SEM)和能谱仪(EDS)观察样品的微观结构变化;另一半用RIGAKU的DMAX-RB12kW型旋转阳极衍射仪(XRD)进行矿相检测。使用化学分析法分析样品中Fem和Fet的含量。

还原产物金属化率( )通过式(1)计算:

)通过式(1)计算:

(1)

(1)

式中: Fem和Fet分别为还原产物中金属铁和全铁的含量,%。

2 结果与讨论

2.1 机理分析

XRD分析表明样品中的Fe元素主要以Fe2SiO4形式存在。在还原过程中,C难以直接与铁橄榄石反应。加入CaO后,Ca2+可作为Fe2SiO4中 的载体,反应机理如图4所示。

的载体,反应机理如图4所示。

图4 CaO催化镍渣碳热还原机理

Fig. 4 Mechanism of acceleration of iron reduction from nickel slag by CaO

当CaO与铁橄榄石接触时,Ca2+的存在削弱了 和Fe2+之间的键能。由于键能减弱且Ca2+和

和Fe2+之间的键能。由于键能减弱且Ca2+和 的结合能力更强,因此,在还原条件下化学键断裂,形成FeO和Ca2SiO4。随着反应温度的升高,镍渣在还原过程中发生一定的烧结行为,还原后的FeO将与SiO2重新结合,形成液相物质FeO·SiO2,恶化还原动力学条件阻碍还原反应的进行。适度增加CaO含量后,由于CaO活性较高,其与SiO2的结合能力强于FeO,CaO将与SiO2结合形成更为稳定的2CaO·SiO2,阻碍液相2FeO·SiO2的生成,改善还原条件,促进反应正向进行[14]。

的结合能力更强,因此,在还原条件下化学键断裂,形成FeO和Ca2SiO4。随着反应温度的升高,镍渣在还原过程中发生一定的烧结行为,还原后的FeO将与SiO2重新结合,形成液相物质FeO·SiO2,恶化还原动力学条件阻碍还原反应的进行。适度增加CaO含量后,由于CaO活性较高,其与SiO2的结合能力强于FeO,CaO将与SiO2结合形成更为稳定的2CaO·SiO2,阻碍液相2FeO·SiO2的生成,改善还原条件,促进反应正向进行[14]。

2.2 CaO添加量对镍渣还原产物金属化率及残余组分的影响

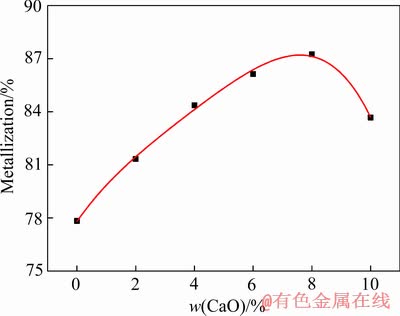

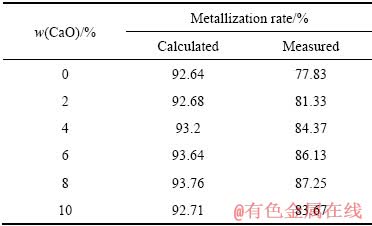

镍渣在1200℃下还原35min后的产物金属化率如图5所示。从图5中可以看出,当CaO含量低于8%时,还原球团的金属化率随CaO质量分数的增加而升高。CaO含量为8%时,产物中金属化率达到87.25%。进一步增加CaO含量到10%,产物金属化率略有减小,降至85.62%。在添加量为8%条件下,CaO能够明显改善镍渣的还原。

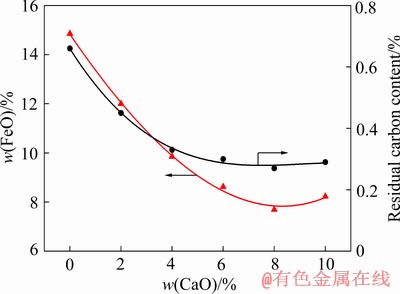

还原产物中FeO和残碳量如图6所示。由图6可得:未添加CaO时,还原产物中FeO含量为14.8%;随着CaO含量的增加,FeO含量从14.8%(CaO为0%)降至7.6%(CaO为8%),且变化趋势趋于平坦;当CaO含量增加至10%时,FeO含量上升至8.23%;残碳量与FeO含量具有相似的趋势;当CaO含量由0%增加到8%时,残碳量下降幅度较大,由0.66%减小到0.27%;当CaO含量为10%时,残碳量微增至0.29%;当CaO含量超过8%时,还原产物的金属化率和FeO含量趋于稳定。

图5 CaO添加量对镍渣碳热还原金属化率的影响

Fig. 5 Effect of CaO addition on metallization rate of reduced nickel slag

图6 CaO添加量对FeO和残碳的影响

Fig. 6 Effect of CaO addition on FeO and residual carbon

2.3 CaO添加量对镍渣还原产物组成的影响

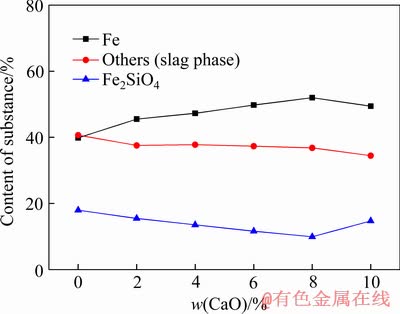

在不同CaO添加量条件下,镍渣碳热还原产物的组成计算(采用FactSage热力学软件计算)结果分别如图7和表3所示。计算主要关注Fe2SiO4和CaO的反应过程,图7中Others为CaSiO3和SiO2的含量。由图7可得:随着CaO添加量的增加(0%~8%),Fe含量变化幅度明显,由39%迅速增到52%以上;Fe2SiO4的变化呈相反趋势,当CaO含量由2%增至8%时,Fe2SiO4含量由17%快速降至9%以下;当CaO含量由8%增至10%时,Fe2SiO4含量开始增加。此时渣相中CaSiO3含量明显下降,由9.29%降为2.17%;渣相量呈下降趋势,由40%逐步降至34%。

由表3可知,渣相中主要成分为SiO2和CaSiO3,气体主要为CO。由Fe含量计算得出还原产物的金属化率,如表4所列。将计算结果与实验结果进行比较,结果表明,样品金属化率计算结果与实验结果不完全一致,但其变化趋势相同,即铁的金属化率先增加,而当CaO含量大于8%后铁的金属化率略有减少。

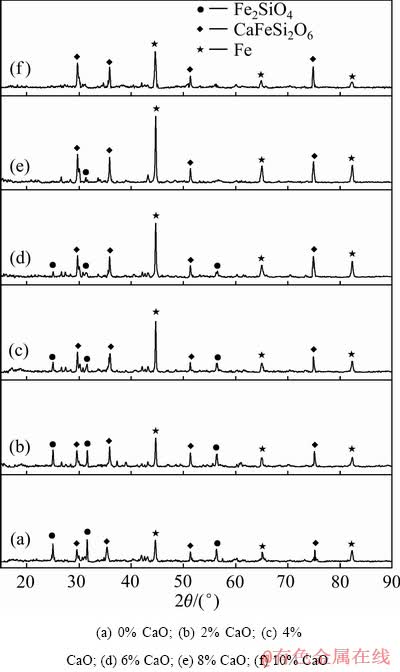

不同CaO添加量下镍渣样品在1200 ℃还原35 min所得产物的XRD谱如图8所示。由图8可得,在不同的CaO添加量下,还原产物的物相相似,主要物相均是金属铁、Fe2SiO4和CaFeSi2O6,其中CaFeSi2O6为反应的过程产物。

图7 不同CaO添加量时FactSage计算的产物组成

Fig. 7 Product composition calculated by FactSage under different addition amounts of CaO

表3 CaO添加量对产物物相组成的影响

Table 3 Composition of slag phase with different CaO additions

表4 产物金属化率的计算值与实验值

Table 4 Calculated and experimental values of metallization rate of reduced samples

在不添加CaO的情况下,样品中Fe2SiO4的质量分数较大,峰值明显较高,其原因是Fe2SiO4碳还原较困难。随着CaO含量从2%增加到8%,XRD谱中Fe的衍射峰显著增加,同时镍渣中Fe2SiO4的特征峰逐渐变小。当CaO含量增加到10%时,基本观察不到Fe2SiO4的衍射峰,而此时CaFeSi2O6峰略微增高。表明添加适量CaO能够有效促进Fe2SiO4的分解,从而促进还原反应进行,提高还原产物的金属化率。还原过程的主要反应如式(2)、(3)和(4)所示,式(5)为总反应。

Fe2SiO4+2CaO=Ca2SiO4+2FeO (2)

FeO+C=Fe+CO (3)

CaO+2Fe2SiO4+3C=CaFeSi2O6+3Fe+3CO (4)

2CaO+Fe2SiO4+2C=Ca2SiO4+2Fe+2CO (5)

2.4 CaO添加量对镍渣还原产物形貌及铁粒大小的影响

图8 还原产物的XRD谱

Fig. 8 XRD patterns of reduced nickel slag added with different amounts of CaO

图9 添加不同量CaO镍渣经1200 ℃还原35 min后产物的SEM像

Fig. 9 SEM images of reduced nickel slag added with different amounts of CaO reduced at 1200 ℃ for 35 min

镍渣添加不同含量的CaO后,在1200 ℃还原35min,还原产物的SEM像如图9所示。图中白点是金属铁。随着CaO含量从0%增加到8%,金属铁颗粒尺寸逐渐增大;当CaO含量超过4%时,部分铁相聚集成面域的形式存在;当CaO含量大于8%时,继续增加CaO含量金属铁平均粒径增加不明显。不添加CaO时(见图9(a)),还原后的金属铁在氧化物表面形成少量且较小的聚集体。添加CaO后(见图9(b)~(f)),还原产物中金属铁颗粒或近似为球形,或聚集成条带形,颗粒表面变得光滑。表明适量的CaO可以促进还原,相同的还原温度和还原时间内,铁相聚集,铁颗粒粒径增大。实验温度和还原时间条件下,CaO含量控制在8%可以使镍渣达到较好的还原效果。

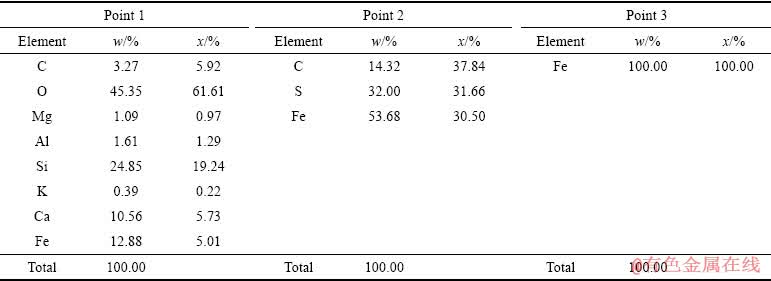

图9(e)中不同区域的EDS分析结果如表5所示。镍渣在1200 ℃、CaO含量为8%条件下还原35 min所得产物的SEM像及分析结果图10所示,对扫描电镜图10(a)进行能谱分析,结果见图10(b),从能谱图中可看出还原产物有O、Fe、Ca、Mg、S等元素,其分布见矩形区域的面扫描结果。

表5 图9(e)中不同区域的EDS分析结果

Table 5 EDS analysis results of points shown in Fig. 9

图10 还原产物的SEM像、EDS谱及区域元素面扫图

Fig. 10 SEM image(a), EDS spectrum(b) and element map scanning distribution of reduced nickel slag

由图9、10及表5可以看出还原产物区域1为剩余的渣相,区域2为FeS,区域3为Fe相。Fe元素与S元素重合较多,整个区域中均有C元素,Ca、Mg、Al、Si和O等元素存在于渣相中。Fe与S反应生成FeS,而FeS与Fe反应生成低熔点的共溶体Fe-FeS[20]导致还原体系的熔点降低。1200 ℃时,还原体系基本处于熔融状态,降低了渣相的黏度,提高了流动性,有利于金属相的扩散,从而促进了被还原出的金属铁聚集长大。

采用ImageJ软件分析图9中金属铁的粒径,结果如图11所示。由图11可见,随着CaO加入量的增加,产物中金属铁的平均粒径先增加后略微减少。当CaO添加量为2%时,铁的平均粒径相比不添加CaO时仅增加约2 μm,当CaO添加量由2%提高到8%时,铁的平均粒径由14.2 μm增至41.3 μm,增加量高达27.1 μm,并在8%时达到最大值。随着CaO含量继续增加,铁的平均粒径减小,当CaO含量为10%时,金属铁的平均粒径降至35.2 μm。其中CaO含量为6%~10%时,金属粒径大于30 μm。可知CaO可以加速还原产物中金属铁的迁移聚合,与图8所示的变化规律一致。

图11 还原产物中铁的平均粒径

Fig. 11 Average particle size of iron in reduced nickel slag

3 结论

1) 添加CaO能够有效解离铁橄榄石,促进还原反应进行,提高还原产物的金属化率。还原产物金属化率随着CaO含量的增加先逐渐增加,然后略有下降,FeO和残碳含量呈相反趋势。当CaO添加量为8%时,样品金属化率最高达到87.25%。

2) 添加不同含量的CaO后,还原产物的物相基本相似,主要物相是金属铁、CaFeSi2O6和Fe2SiO4。

3) 还原产物中铁的粒径随着CaO含量的增加先增加,然后略有下降。当CaO添加量由2%提高到8%时,金属铁的平均粒径由14.2 μm增至41.3 μm。

REFERENCES

[1] 李小明, 谢 庚, 赵俊学, 崔雅茹. 镍渣直接还原提铁及同时制备胶凝材料的研究[J]. 有色金属(冶炼部分), 2015(12): 51-55.

LI Xiao-ming, XIE Geng, ZHAO Jun-xue, CUI Ya-ru. Study on direct reduction of iron from nickel slag and preparation of cementitious materials at the same time[J]. Nonferrous Metals (Smelting), 2015(12): 51-55.

[2] ALTER H. The composition and environmental hazard of copper slag in the context of the basel convention[J]. Resources, Conservation and Recycling, 2005, 43(4): 353-360.

[3] 李小明, 沈 苗, 王 翀, 崔雅茹, 赵俊学. 镍渣资源化利用现状及发展趋势分析[J]. 材料导报, 2017,31(5): 100-105.

LI Xiao-ming, SHEN Miao, WANG Wei, CUI Ya-ru, ZHAO Jun-xue. Analysis of the status quo and development trend of nickel slag resource utilization[J]. Material Guide, 2017,31 (5): 100-105.

[4] 龚竹青, 李景升, 郑雅杰, 杨兴文. 全湿法处理回收银锌渣中有价金属[J]. 中南工业大学学报(自然科学版), 2003, 34(5): 506-509.

GONG Zhu-qing, LI Jing-sheng, ZHENG Ya-jie, YANG Xing-wen. Treatment of valuable metals in silver-zinc slag by total wet process[J]. Journal of Central South University of Technology (Natural Science Edition), 2003, 34(5): 506-509.

[5] 郭学益, 许志鹏, 李 栋, 田庆华. 基于AOP协同氧化浸出碲渣中的碲和有价金属[J]. 中国有色金属学报, 2018, 28(1): 173-180.

GUO Xue-yi, XU Zhi-peng, LI Dong, TIAN Qing-hua. The ruthenium and valuable metals in the leaching residue based on AOP[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(1): 173-180.

[6] 孙长余, 郭兴敏, 李 菲. 非接触式熔融还原法制备金属镍[J]. 中国有色金属学报, 2010, 20(10): 2045-2050.

SUN Chang-yu, GUO Xing-min, LI Fei. Preparation of metallic nickel by non-contact smelting reduction method[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 2045-2050.

[7] 朱茂兰, 王俊娥, 陈 杭, 傅皓柯, 高浩菡, 胡志彪. 铜渣熔融还原回收铁试验研究[J]. 有色金属(冶炼部分), 2019(1): 21-23.

ZHU Mao-lan, WANG Jun-xi, CHEN Hang, FU Yu-ke, GAO Hao-zhen, HU Zhi-wei. Experimental study on smelting reduction and recovery of iron from copper slag[J]. Nonferrous Metals (Smelting), 2019(1): 21-23.

[8] 李东升, 春铁军, 王 臻, 宁 超, 穆固天, 朱梦飞, 龙红明. 高磷铁矿含碳团块直接还原-磁选提铁[J]. 过程工程学报, 2018, 18(2): 375-381.

LI Dong-sheng, CHUN Tie-jun, WANG Wei, NING Chao, MU Gu-tian, ZHU Meng-fei, LONG Hong-ming. Direct reduction-magnetic separation of iron-bearing agglomerates in high-phosphorus iron ore[J]. The Chinese Journal of Process Engineering, 2018, 18 (2): 375-381.

[9] 陈伟鹏, 张天睿, 李光卫, 赵增武, 李保卫, 武文斐. 添加剂对褐铁矿煤基直接还原强化作用研究[J]. 矿冶工程, 2018, 38(1): 76-80.

CHEN Wei-peng, ZHANG Tian-rui, LI Guang-wei, ZHAO Zeng-wu, LI Bao-wei, WU Wen-fei. Strengthening effects of different additives on coal-based direct reduction of limonite [J]. Mining and Metallurgical Engineering, 2018, 38 (1): 76-80.

[10] ZHAO Long-sheng, WANG Li-na, CHEN De-sheng, ZHAO Hong-xin, LIU Ya-hui, QI Tao. The behavior of vanadium and chromium in the direct reduction-magnetic separation process of high-chromium vanadium-titanium magnet concentrate[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1325-1333.

[11] 倪 文, 贾 岩, 郑 斐, 王中杰, 郑美娟. 金川镍弃渣铁资源回收综合利用[J]. 北京科技大学学报, 2010, 32(8): 975-980.

Ni Wen, Jia Yan, Zheng Fei, Wang Zhong-jie, Zheng Mei-juan. Comprehensive utilization of iron recovery from Jinchuan nickelresidue[J]. Journal of University of Science and Technology Beijing, 2010, 32(8): 975-980.

[12] 白彦贵, 朱果灵, 张柏汀. 金川提镍弃渣提铁基础研究[J]. 钢铁研究学报, 1994(S1): 163-168.

Bai Yan-gui, Zhu Guo-ling, Zhang Bai-ting. Research on the basics of lifting nickel from Jinchuan nickel slag[J]. Journal of Iron and Steel Research, 1994(S1): 163-168.

[13] Fedorova N A,Tsymbulov L B, Tsemekhman L S. Distribution of copper, nickel, cobalt and iron between products of smelting of copper concentrate obtained by flotation of converter matte[J]. Russian Journal of Applied Chemistry, 2003, 76(2): 175-179.

[14] 曹羽鑫, 王恒辉, 马江华, 赵 栋, 李光强. 添加剂对铁精矿制备还原铁粉的影响[J]. 过程工程学报, 2018, 18(1): 133-139.

Cao Yu-xin, Wang Heng-hui, Ma Jiang-hua, Zhao Dong, Li Guang-qiang. Effect of additives on the preparation of reduced iron powder from iron concentrate [J]. The Chinese Journal of Process Engineering, 2018, 18(1): 133-139.

[15] 孙体昌, 蒋 曼, 刘志国, 刘 娜, 张士元, 寇 珏, 徐承焱. 添加剂对低镍高铁红土镍矿选择性还原的影响[J].中国矿业大学学报, 2013, 42(5): 838-844.

SUN Ti-chang, JIANG Man, LIU Zhi-guo, LIU Na, ZHANG Shi-yuan, KOU Jue, XU Cheng-yu. Research on the effect of additive on selective reduction of the laterites ores with low nickel and high iron content[J]. Journal of China University of Mining & Technology, 2013, 42(5): 838-844.

[16] 王 爽, 倪 文, 李克庆, 李克庆, 王长龙, 王健月. 碱度对镍渣球团深度还原回收铁、镍和铜的影响[J]. 材料热处理学报, 2014, 35(9): 23-28.

WANG Shuang, NI Wen, LI Ke-qing, WANG Chang-long, WANG Jian-yue. Effect of basicity on recovering iron, nickel and copper by deep reduction process of nickel slag pellets[J]. Transactions of Materials and Heat Treatment, 2014, 35(9): 23-28.

[17] 耿 超, 孙体昌, 杨慧芬, 马友文, 胡天洋. 添加剂对海滨钛磁铁矿直接还原磁选钛铁分离的影响[J]. 中国有色金属学报, 2017, 27(8): 1720-1728.

GENG Chao, SUN Ti-chang, YANG Hui-fen, MA You-wen, HU Tian-yang. Effects of additives on the separation of ferrotitanium by direct reduction magnetic separation of titan magnetite[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(8): 1720-1728.

[18] 刘志国, 孙体昌, 蒋 曼, 高 恩. CaO在红土镍矿直接还原焙烧中的作用机理[J]. 中南大学学报(自然科学版), 2015, 46(10): 3566-3572.

LIU Zhi-guo, SUN Ti-chang, JIANG Man, GAO En, Mechanism of CaO in direct reduction roasting of nickel laterite ore[J]. Journal of Central South University (Science and Technology), 2015, 46(10): 3566-3572.

Effect of calcium oxide on carbothermal reduction of nickel slag

LI Xiao-ming, ZHANG Xin-yi, LI Yi, XING Xiang-dong

(School of Metallurgical Engineering, Xi’an University of Architecture and Technology, Xi’an 710055, China)

Abstract: Aiming at the problem that iron exists in the form of fayalite and the difficulty in direct reduction of the magnetic separation and recovery, the technical idea for adding CaO in nickel slag to improve the carbothermal reduction rate and iron metallization rate of nickel slag was used. The additive and the nickel slag were mixed in proportion and added with an appropriate amount of reducing agent, and they were reduced in a high temperature furnace. Combined with the thermodynamic calculation and product characteristic analysis results, the mechanism and the reduction effect of the additive strengthening reduction were studied. The results show that the addition of CaO can effectively promote the dissociation of iron silicate, strengthen the reduction process, accelerate the reduction rate, change the morphology of the metal phase in the slag phase, and increase the aggregation of metallic iron, which is beneficial for subsequent separation and recovery. As the amount of CaO increases from 0% to 10%, the metallization rate of the reduction product and the average particle size of Fe particles increases first and then decreases, with the changes of FeO content and residual carbon amount being opposite. The added amount of CaO being 8%, the metallization ratio and particle diameter of iron in the reduced product peak at 87.25% and 41.3 μm, respectively. With the added amount of CaO being 8%, the metallization rate and particle diameter of iron in the reduction products peak at 87.25% and 41.3 μm, respectively.

Key words: nickel slag; calcium oxide; carbothermal reduction; additive

Foundation item: Projects(51774224) supported by the National Natural Science Foundation of China

Received date: 2019-05-18; Accepted date: 2019-08-26

Corresponding author: LI Xiao-ming; Tel: +86-29-82202931; E-mail: xmli88@126.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51774224)

收稿日期:2019-05-18;修订日期:2019-08-26

通信作者:李小明,教授;电话:029-82202931;E-mail:xmli88@126.com