文章编号:1004-0609(2010)08-1539-06

TA15钛合金β区变形动态再结晶的临界条件

欧阳德来1, 2,鲁世强1,黄 旭3,雷力明3

(1. 南昌航空大学 材料科学与工程学院,南昌 330063;

2. 南京航空航天大学 材料科学与技术学院,南京 210016;

3. 北京航空材料研究院 钛合金研究室,北京100095)

摘 要:采用Thermecmaster-Z热模拟试验机在变形温度1 050~1 100 ℃,应变速率10-3~1 s-1的条件下进行热模拟压缩试验。采用加工硬化率处理方法对应力-应变数据进行处理,结合ln θ —ε曲线的拐点及-?(ln θ)/?ε —ε曲线最小值的判据,研究TA15钛合金β区变形时的动态再结晶临界条件。结果表明:在本实验条件下,TA15钛合金的ln θ —ε曲线均出现拐点及-?(ln θ)/?ε —ε曲线均出现最小值;临界应变随应变速率的增大及变形温度的降低而增加,且临界应变与峰值应变之间基本保持恒定值εc/εp=0.62;临界应变预测模型函数关系可以表示为εc= 0.92×10-2Z 0.0843。

关键词:加工硬化率;动态再结晶;临界条件;TA15钛合金

中图分类号:TG306 文献标志码:A

Critical conditions of dynamic recrystallization

during deformation of β area in TA15 titanium alloy

OUYANG De-lai1, 2, LU Shi-qiang1, HUANG Xu3, LEI Li-ming3

(1. School of Materials Science and Engineering, Nanchang Hangkong University, Nanchang 330063, China;

2. College of Materials Science and Technology, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

3. Titanium Alloys Laboratory, Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The hot simulation compression tests of titanium alloy TA15 were conducted at deformation temperature of 1 050-1 100 ℃ and strain rate of 10-3-1 s-1 with the Thermecmaster-Z hot simulation test machine. The critical conditions of dynamic recrystallization for onset of DRX during deformation of β area were obtained by computation of the work hardening rate θ from initial stress—stain data and introduction of the inflection point criterion of lnθ —ε curves and the minimum value criterion of -?(lnθ)/?ε —ε curves. The results indicate that an inflection point in the ln θ —ε curve appears and a minimum value of -?(lnθ)/?ε —ε curve is presented when the critical state is attained for this alloy. The critical strain increases with increasing the strain rate and decreasing the deformation temperature. There is linear relationship between critical strain and peak strain, i.e. εc/εp=0.65. The predicting model of critical strain is described by the function of εc=0.92×10-2Z0.0843.

Key words: work hardening rate; dynamic recrystallization; critical condition; TA15 titanium alloy

TA15合金是一种通用型高铝含量近α合金,名义成分为Ti-6Al-2Zr-1Mo-1V,β相变温度为970~1 010 ℃。该合金为中等强度级别钛合金,具有良好的塑性,在高温下具有较高的抗蠕变强度和持久强度,并具有优良的焊接和热稳定性能。合金在500 ℃下的工作寿命可达3 000 h,而在450 ℃下的工作寿命长达6 000h。TA15合金主要用于制造500 ℃以下长时间工作的结构零件、承力结构件和一些温度较高、受力较复杂的重要结构零件,例如发动机的各种叶片、机匣、飞机的各种钣金件、梁、接头、大型壁板以及焊接承力框等。在我国引进的某型号歼击机上,其飞机隔框、壁板等重要结构零件也是由TA15钛合金制造的,且该合金单机毛坯用量占整个钛合金用量的70%左右,为此该合金成为我国某型号歼击机的关键结构的 用材[1-4]。

传统的物理冶金学观点认为钛合金具有较高的层错能(纯钛的约为0.31 J/m2,Ti-3Al的约为0.208 J/m2),位错的攀移和交滑移过程容易进行,在热加工过程中动态再结晶难于进行[5]。近年来,针对TA15钛合金的β相区变形研究发现[6],在某些合适的热变形工艺条件下,该合金是可以发生动态再结晶的。动态再结晶临界应变是材料刚发生动态再结晶时对应的应变值,通常认为在应变到达峰值应变(εp),即对应峰值应力前动态再结晶就已经发生。准确找到材料热变形条件下的临界应变量是建立临界应变预测模型的关键。近年来,一些学者采用加工硬化率方法对应力—应变数据进行判断钢铁材料[7-9]及镁合金[10]的动态再结晶临界应变时表现出较高的适应性及精度。本文作者也曾基于位错理论,探讨材料大应变条件下的加工硬化率曲线及动态再结晶的拐点判据,并采用θ —σ曲线上的拐点判据研究TA15钛合金动态再结晶的临界条 件[11]。这种方法是对应力—应变曲线数据进行适当的加工硬化率处理,得到θ —σ曲线及–?θ/?σ —σ曲线,再采用–?θ/?σ—σ曲线上的最小值判据来得到临界应变εc。但原始采集的应力—应变数据本身存在一定的实验误差,这种实验误差在θ和–?θ/?σ的计算过程中两次被放大[12]。

本研究采用对TA15钛合金等温恒应变速率压缩试验,利用所得数据进行加工硬化率处理,并采用 lnθ—ε曲线上的拐点判据及–?(lnθ)/?ε —ε曲线上的最小值,直接确定动态再结晶临界应变,建立该合金的临界条件。该方法与文献[11]中的方法相比,仅在θ计算过程中放大实验误差,在–?(lnθ)/?ε的计算中不涉及到应力误差的放大,从而增加临界应变确定值的准确性[12]。

1 实验

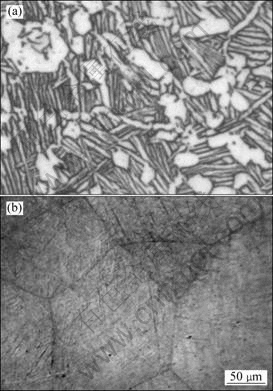

实验材料为TA15钛合金棒材,加工成d 8 mm× 12 mm的标准圆柱压缩试样。热分析法测定该合金的(α+β)/β转变温度为982 ℃。棒材原始组织是双态组织,加热至β相区保温210 s后组织全部由β晶粒组成,如图1所示。

图1 TA15钛合金的显微组织

Fig.1 Microstructures of TA15 titanium alloys: (a) Received bar; (b) Holded for 210 s at 1 050 ℃

在Thermecmaster-Z型热模拟试验机上对实验材料快速加热至β相区,保温210 s后进行等温恒应变速率热压缩至应变0.92,变形温度为1 050、1 075、1 100 ℃,应变速率为10-3、10-2、10-1和1 s-1。

2 结果与分析

2.1 流变曲线

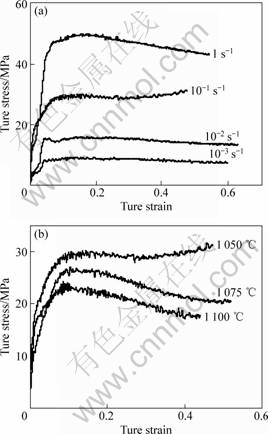

图2所示为TA15钛合金在β相区变形时不同应变速率及变形温度下的真应力—真应变曲线。由图2可看出,在变形开始时,应力随应变的增加而快速增加,发生加工硬化后应力达到峰值。当继续变形时,应力随应变的增加出现缓慢下降。在较高变形温度或较低应变速率下,峰值应力过后,随应变的增加,应力下降幅度相对较大,应力—应变曲线呈现动态再结晶型曲线。而在较低变形温度或较高应变速率下,峰值应力过后,随应变的增加,应力下降幅度相对平缓,应力—应变曲线呈现动态回复型曲线。

图2 TA15合金的真应力—真应变曲线

Fig.2 True stress—true strain cures of TA15 alloy: (a) t= 1 050 ℃; (b)  =10-1 s-1

=10-1 s-1

2.2 基于加工硬化率的临界应变分析

材料加工硬化率(θ=?σ/?ε)是表征流变应力随应变速率变化的一个变量。通常,流变曲线是形变时材料微观组织的外在表现,难于直接从流变曲线中确定动态再结晶临界应变。而采用应力—应变曲线上信息得到的加工硬化率曲线则能反映材料内部组织的变化特征[13-14]。POLIAK和JONAS[15]认为材料发生动态再结晶时,其θ —σ曲线呈现拐点特征,即–?2θ/?σ=0。利用偏导数的关系可以推导出如下关系:-?(lnθ)/?ε=?θ/?σ,说明不仅θ —σ曲线呈现拐点特征,而且lnθ —ε曲线也必然出现相应的拐点特征[12]。这样,根据TA15钛合金应力—应变曲线数据绘制 lnθ —ε及-?(lnθ)/?ε—ε曲线图,再采用-?2(lnθ)/?ε=0判据即可直接得到相应的临界应变值εc。

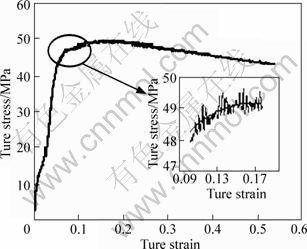

图3所示为TA15钛合金在变形温度1 050 ℃、应变速率1 s-1时的应力—应变曲线。由图3中的局部放大图可见,试验所得到的应力—应变曲线是不光滑的而呈波浪型的。实际上难于直接从其测量或计算出加工硬化率(斜率)。本文作者曾对应力—应变曲线先进行拟合,获得拟合方程,再对拟合方程求导,得到各应变条件下的斜率的方法,效果较好。本研究也采用此方法先对图3中的应力—应变曲线进行拟合,再对拟合方程求导,得到各应变条件下的斜率,最后绘制 lnθ —ε曲线,确定临界条件。通过对图3所示的应 力—应变曲线进行拟合得到拟合方程:

(1)

(1)

图3 变形温度1 050 ℃、应变速率1 s-1时的应力—应变曲线拟合

Fig.3 True stress—strain curve of TA15 titanium alloy deformed at temperature of 1 050 ℃ and strain rate of 1 s-1

根据拟合方程(1)及?σ/?ε≈Δσ/Δε关系,绘制 lnθ —ε及-?(lnθ)/?ε—ε曲线,如图4所示。

由图4(a)可见,lnθ —ε曲线中在应变0.12附近出现拐点,为了确定拐点的具体位置,对图4中曲线进行三次方拟合,拟合方程为

(2)

(2)

对方程(2)进行求导得,

(3)

(3)

根据方程(3)绘制-?(lnθ)/?ε—ε的关系曲线,如图4(b)所示。当-?2(lnθ)/?ε=0时对应的应变即为临界应变,εc=0.11。

2.3 临界条件的确定

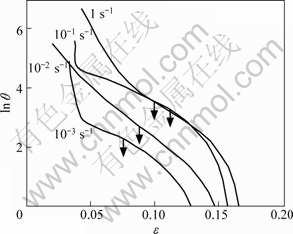

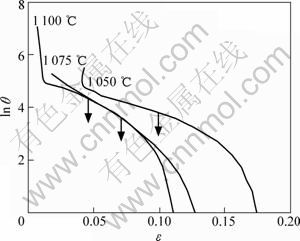

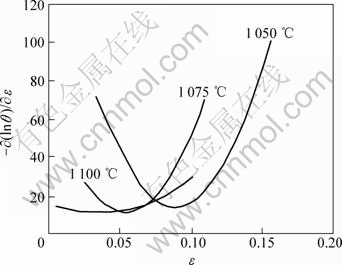

采用以上相同方法,绘制其它热变形条件下的 lnθ —ε关系曲线,如图5和6所示。

由图5和6可见,不同应变速率及不同变形温度下的lnθ—ε曲线变化规律相似。随应变的增加,加工硬化率开始快速降低,后进入一个缓慢降低阶段,最后又快速降低,在缓慢降低阶段的某个应变对应处出现拐点。

图4 在变形温度1 050 ℃、应变速率1 s-1时lnθ与应变ε及-?(lnθ)/?ε与应变ε之间的关系

Fig.4 Relationship between lnθ(a) and -?(lnθ)/?ε (b) and strain ε at temperature of 1 050 ℃ and strain rate of 1 s-1

图5 在变形温度1 050 ℃时不同应变速率下lnθ与应变ε之间的关系

Fig.5 Relationship between lnθ and ε at temperature of 1 050 ℃ and different strain rates

图6 在应变速率10-1 s-1时不同变形温度下lnθ与应变ε之间的关系

Fig.6 Relationship between lnθ and strain ε at strain rate of 10-1 s-1 and different temperatures

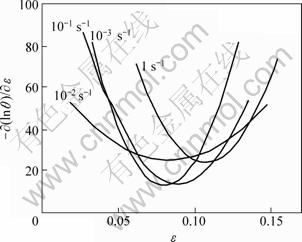

图7和8所示为对应于lnθ—ε曲线条件的 -?(lnθ)/?ε—ε关系曲线。由图7和8可见,-?(lnθ)/?ε—ε曲线均相应地出现最小值,曲线最小值处则对应于lnθ—ε曲线的拐点位置,曲线最小值处对应的应变值即为动态再结晶临界应变。

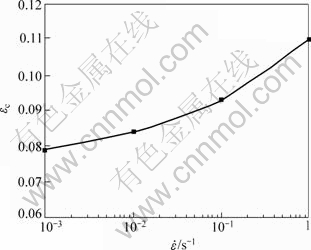

图9所示为应变速率对合金动态再结晶临界应变的影响规律。由图9可看出,应变速率对临界应变产生正的影响,即随应变速率的增加,临界应变得到相应的提高。这是由于不管动态再结晶是何种形核机制,动态再结晶新晶粒的形成都必须依靠位错的迁移、合并,促使某小角度晶界形成大角度晶界。当应变速率较小时,变形晶粒内部产生的位错有足够的时间进行迁移、合并,形成大角度晶界,这时变形至较小应变时就能发生动态再结晶。当变速率增大时,变形晶粒内部产生的位错没有足够的时间进行迁移。这时需要变形至更大的应变量来提高位错密度和位错迁移时间,从而动态再结晶临界应变增大。

图7 变形温度1 050 ℃时不同应变速率下的-?(lnθ)/?ε与应变之间的关系

Fig.7 Relationship between -?(lnθ)/?ε and ε of TA15 titanium alloy deformed at 1 050 ℃ and different strain rates

图8 在应变速率为10-1 s-1时不同变形温度下的-?(lnθ)/?ε与应变ε之间的关系

Fig.8 Relationship between -?(lnθ)/?ε and ε of TA15 titanium alloy deformed at 10-1 s-1 and different temperatures

图9 在变形温度为1 050 ℃时TA15钛合金应变速率对临界应变的影响

Fig.9 Effect of strain rate on critical strain of TA15 titanium alloy at 1 050 ℃

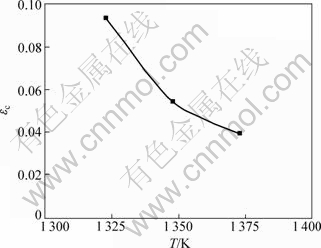

图10所示为变形温度对合金动态再结晶临界应变的影响。由图10可见,变形温度对临界应变的影响是负的,即升高变形温度,则降低临界应变。这是由于升高变形温度,则提高了位错迁移的驱动力,位错迁移更加容易。这样合金变形至较小的应变量就能生成动态再结晶新晶粒。

图10 在应变速率为10-1 s-1时TA15钛合金变形温度对临界应变的影响

Fig.10 Effect of deformation temperature on critical strain of TA15 titanium alloy at 10-1 s-1

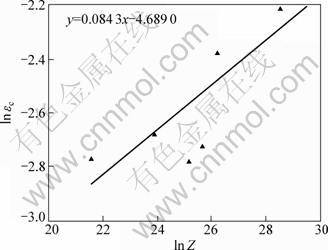

为了构建合金β区变形过程中临界应变预测模型,采用目前应用最广泛的Sellars模型结构,即:  。其中:a1、a2均为常数;Z为Zener- Hollomon参数,

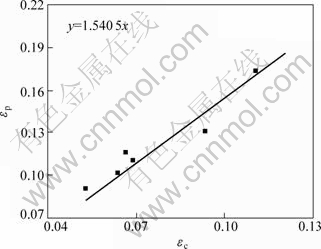

。其中:a1、a2均为常数;Z为Zener- Hollomon参数, ,其中Q为热变形激活能,本实验条件下的激活能约为313.442 kJ/mol[11]。这样,根据所得到的各热变形条件下的临界应变值及相对应的Z值,绘制lnεc与lnZ及临界应变(εc)与峰值应变(εp)的关系曲线,如图11和12所示。由图11可见,lnεc与lnZ之间呈较好的线性关系,对其进行线性拟合,得到拟合方程:lnεc= 0.084 3lnZ-4.689,也即临界应变预测模型可以表示为εc=0.92×10-2Z 0.084 3。由图12可见,临界应变与峰值应变也呈现较好的线性关系,进一步对其进行线性拟合,可知临界应变与峰值应变的关系为εc=0.65εp。

,其中Q为热变形激活能,本实验条件下的激活能约为313.442 kJ/mol[11]。这样,根据所得到的各热变形条件下的临界应变值及相对应的Z值,绘制lnεc与lnZ及临界应变(εc)与峰值应变(εp)的关系曲线,如图11和12所示。由图11可见,lnεc与lnZ之间呈较好的线性关系,对其进行线性拟合,得到拟合方程:lnεc= 0.084 3lnZ-4.689,也即临界应变预测模型可以表示为εc=0.92×10-2Z 0.084 3。由图12可见,临界应变与峰值应变也呈现较好的线性关系,进一步对其进行线性拟合,可知临界应变与峰值应变的关系为εc=0.65εp。

图11 lnεc与lnZ之间的关系

Fig.11 Relationship between lnεc and lnZ

图12 临界应变与峰值应变的关系

Fig.12 Relationship between critical strain and peak strain

3 结论

1) TA15钛合金发生动态再结晶时,其lnθ —ε曲线出现拐点,并且在-?(lnθ)/?ε —ε曲线上出现最小值。利用此拐点判据,可以确定材料的动态再结晶临界条件。

2) 动态再结晶临界应变随应变速率的增大及变形温度的降低而增加,且临界应变与峰值应变之间具有一定的相关性,即εc=0.65εp。

3) 在本实验条件下,合金动态再结晶临界应变预测模型函数关系可以表示为εc=0.92×10-2Z0.084 3。

REFERENCES

[1] 王 斌, 郭鸿镇, 姚泽坤, 陈金科, 李蓬川. 热压参数对TA15合金流动应力及显微组织的影响[J]. 锻压技术, 2006, 31(6): 106-109.

WANG Bin, GUO Hong-zhen, YAO, Ze-kun, CHEN Jin-ke, LI Peng-chuan. Influence of hot compression parameters on flow stress and microstructure of TA15 alloy[J]. Forging & Stamping Technology, 2006, 31(6): 106-109.

[2] 王 洋, 尤逢海, 朱景川, 来忠红, 刘 勇. TA15合金热变形行为研究[J]. 机械工程材料, 2006, 30(11): 63-65.

WANG Yang, YOU Feng-hai, ZHU Jing-chuan, LAI Zhong-hong, LIU Yong. Study on hot deformation behavior of TA15 alloy[J]. Materials for Mechanical Engineering, 2006, 31(6): 106-109.

[3] 李兴无, 沙爱学, 张旺峰, 储俊鹏, 马济民. TA15合金及其在飞机结构中的应用前景[J]. 钛工业进展, 2003, 20(4/5): 90-94.

Li Xing-wu, Sha Ai-xue, Zhang Wang-feng, CHU Jun-peng, MA Ji-min. TA15 titanium alloy and its applying prospects on airframe[J]. Titanium Industry Progress, 2003, 20(4/5): 90-94.

[4] 徐文臣, 单德彬, 李春峰, 吕 炎. TA15钛合金的动态热压缩行为及其机理研究[J]. 航空材料学报, 2005, 25(4): 10-15.

XU Wen-chen, SHAN De-bin, LI Chun-feng, L? Yan. Study on the dynamic hot compression behavior and deform action mechanism of TA15 titanium alloy[J]. Journal of Aeronautical Materials, 2005, 25(4): 10-15.

[5] GUO Z, MIODOWNIK A P, SAUNDERS N, SCHILLE J P. Influence of stacking-fault energy on high temperature creep of alpha titanium alloys[J]. Scripta Materialia, 2006, 54(12): 2175-2178.

[6] 张旺峰, 李兴无, 马济民, 朱知寿. TA15钛合金β热变形对组织特征参数的影响规律研究[J]. 材料工程, 2006(10): 10.

ZHANG Wang-feng, LI Xing-wu, MA Ji-min, ZHU Zhi-shou. Effect of β hot process on structure parameters for TA15 titanium alloy[J]. Materials Engineering, 2006(10): 10.

[7] GOTTSTEIN G, BRUNGER E, FROMMERT M, GOERDELER M, ZENG M. Prediction of the critical conditions for dynamic recrystallization in metals[J]. Zeitschrift fur Metallkunde, 2003, 94(5): 628-635.

[8] POLIAK E I, JONAS J. Critical strain for dynamic recrystallization in variable strain rate hot deformation[J]. ISIJ International, 2003, 43(5): 692-700.

[9] NAJAFIZADEH A, JONAS J J. Predicting the critical stress for initiation of dynamic recrystallization[J]. ISIJ International. 2006, 46(11): 1679-1684.

[10] 黄光杰, 钱宝华, 汪凌云, JONAS J. AZ31镁合金初始动态再结晶的临界条件研究[J]. 稀有金属材料与工程, 2007, 36(12): 2080-2083.

HUANG Guang-jie, QIAN Bao-hua, WANG Ling-yun, Jonas J. Study on the critical conditions for initial dynamic recrystallization of AZ31 magnesium alloy[J]. Rare Metal Materials and Engineering, 2007, 36(12): 2080-2083.

[11] 欧阳德来, 鲁世强. 应用加工硬化率研究TA15钛合金β区变形的动态再结晶临界条件[J]. 航空材料学报, 2010, 30(2): 17-23.

OUYang De-lai, LU Shi-qiang. Study on critical strains of dynamic recrystallization during β process in TA15 titanium alloy using working hardening rate[J]. Journal of Aeronautical Materials, 2010, 30(2): 17-23.

[12] POLIAK E I, JONAS J J. Initiation of dynamic recrystallization in constant strain rate hot deformation[J]. ISIJ International, 2003, 43(5): 684-691.

[13] PRASAD G V, GOERDELER M, GOTTSTEIN G. Work hardening model based on multiple dislocation densities[J]. Materials Science and Engineering A, 2005, 400/401: 231-233.

[14] ROLLETT A D, KOCKS U F. A review of the stages of work hardening[J]. Solid State Phenomena, 1993, 35/36: 1-9.

[15] POLIAK E I, JONAS J J. A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization[J]. Acta Materialia, 1996, 44(1): 127-136.

(编辑 李艳红)

基金项目:国家重点基础研究发展计划资助项目(2007CB613803);航空科学基金资助项目(2009ZE56014);江西省自然科学基金资助项目(2008GZC0041);江西省教育厅科技资助项目(GJJ08203)

收稿日期:2009-10-09;修订日期:2010-01-20

通信作者:鲁世强,教授,博士;电话:0791-3863039;E-mail:niatlusq@126.com