DOI:10.19476/j.ysxb.1004.0609.2017.08.03

GH696合金动态再结晶模型

许赵华,李 宏,李淼泉

(西北工业大学 材料学院,西安 710072)

摘 要:采用热模拟压缩试验研究GH696合金在变形温度为880~1020 ℃、应变速率为0.01~10.0 s-1、变形程度为30%~60%条件下的高温变形行为。采用金相显微镜对GH696合金高温压缩变形后的显微组织进行观察。结果表明:较高的变形温度和较低的应变速率有利于GH696合金的动态再结晶。采用加工硬化率-流动应力曲线确定GH696合金的动态再结晶临界应变,应用Avrami方程建立GH696合金的动态再结晶体积分数模型,并根据合金的金相定量试验结果建立GH696合金的动态再结晶晶粒尺寸模型。

关键词:GH696合金;热模拟压缩;动态再结晶;晶粒尺寸

文章编号:1004-0609(2017)-08-1551-12 中图分类号:TG319 文献标志码:A

动态再结晶是金属和合金高温变形过程中一种非常重要的显微组织演化机制。一方面,动态再结晶可以使因变形硬化的合金发生软化,修复其塑性和延展性,提高材料的塑性加工性能;另一方面,动态再结晶可以细化晶粒,控制最终产品的显微组织。以铜、镍、铝为基体的合金和以铁为基体的高温合金在高温变形过程中不发生相变,因而动态再结晶是控制锻件晶粒尺寸、形貌、平均取向及织构的唯一方法[1]。

动态再结晶过程是众多学者在研究金属和合金高温变形行为时关注的焦点。SELLARS等[2-3]在Avrami方程的基础上,通过大量显微组织演变试验研究建立了动态再结晶(DRX)、静态再结晶(SRX)和晶粒长大模型。MCQUEEN等[4]建立了考虑时间效应的动态再结晶分数模型。YADA等[5]、KOPP等[6]、LAASRAOUI等[7]、KIM等[8]分别提出了用应变表示的不同形式的动态再结晶分数模型,其中应用较为广泛的是与峰值应变 和动态再结晶临界应变

和动态再结晶临界应变 相关的动态再结晶分数模型[7]。MEDEIROS等[9]建立了IN718合金的亚动态再结晶晶粒尺寸与工艺参数间的关系模型。PARK等[10]采用双道次热模拟压缩确定了某镍基高温合金动态再结晶过程以及最终再结晶晶粒尺寸的影响。WANG等[11]发现GH718合金的再结晶晶粒尺寸随变形温度的升高、应变速率的减小和应变的减小而增大,建立了再结晶晶粒尺寸与变形参数间的关系模型。LIU等[12]根据动态再结晶进行速度的特征在Avrami方程的基础上提出了一种新的再结晶体积分数模型。刘东等[13]建立GH4169合金的动态再结晶模型。姚志浩等[14]建立GH738合金的动态再结晶、亚动态再结晶和晶粒长大模型。张云等[15]研究了GH4742合金的动态再结晶行为,并建立了合金的动态再结晶模型。郭海龙等[16]基于Yada模型通过统计回归建立了挤压态7075铝合金的动态再结晶经验模型并进行验证,结果表明所建立的模型误差平均值为5%。蔡志伟等[17]建立了AZ41M镁合金的动态再结晶临界应变模型。杨胜利等[18]引入了最大软化率应变(

相关的动态再结晶分数模型[7]。MEDEIROS等[9]建立了IN718合金的亚动态再结晶晶粒尺寸与工艺参数间的关系模型。PARK等[10]采用双道次热模拟压缩确定了某镍基高温合金动态再结晶过程以及最终再结晶晶粒尺寸的影响。WANG等[11]发现GH718合金的再结晶晶粒尺寸随变形温度的升高、应变速率的减小和应变的减小而增大,建立了再结晶晶粒尺寸与变形参数间的关系模型。LIU等[12]根据动态再结晶进行速度的特征在Avrami方程的基础上提出了一种新的再结晶体积分数模型。刘东等[13]建立GH4169合金的动态再结晶模型。姚志浩等[14]建立GH738合金的动态再结晶、亚动态再结晶和晶粒长大模型。张云等[15]研究了GH4742合金的动态再结晶行为,并建立了合金的动态再结晶模型。郭海龙等[16]基于Yada模型通过统计回归建立了挤压态7075铝合金的动态再结晶经验模型并进行验证,结果表明所建立的模型误差平均值为5%。蔡志伟等[17]建立了AZ41M镁合金的动态再结晶临界应变模型。杨胜利等[18]引入了最大软化率应变( )和中间变量Z/A,并建立

)和中间变量Z/A,并建立 和

和 与Z/A的关系表达式,建立了Al-Cu-Li合金的动态再结晶模型。NIE等[19]建立了FGH96合金的动态再结晶体积分数模型。MATSUI等[20]研究了Alloy718合金的动态再结晶体积分数模型,其中发生50%动态再结晶的应变与原始晶粒尺寸和Zener-Hollomon参数有关。LIU等[21-22]建立了300号钢的动态再结晶体积分数模型和亚动态再结晶体积分数模型。CHEN等[23]建立了某镍基高温合金的动态再结晶体积分数模型。

与Z/A的关系表达式,建立了Al-Cu-Li合金的动态再结晶模型。NIE等[19]建立了FGH96合金的动态再结晶体积分数模型。MATSUI等[20]研究了Alloy718合金的动态再结晶体积分数模型,其中发生50%动态再结晶的应变与原始晶粒尺寸和Zener-Hollomon参数有关。LIU等[21-22]建立了300号钢的动态再结晶体积分数模型和亚动态再结晶体积分数模型。CHEN等[23]建立了某镍基高温合金的动态再结晶体积分数模型。

GH696合金是一种以Fe-25Ni-12Cr为基体的时效硬化型铁基高温合金,由Fe、Ni、Cr组成稳定的奥氏体,以金属间化合物 (Ni3AlTi)相时效析出强化,并辅以Mo的固溶强化和B的晶界强化。在高温下GH696合金具有较高的屈服强度和持久、蠕变强度以及良好的高温弹性性能、抗燃气腐蚀性能和加工塑性,可用于制造在650 ℃以下长期工作的涡轮、压气机紧固件、盘件、弹簧、工作叶片、涡轮壳体、环形零件[24]。由于GH696合金含Ni量较少,成本低,高温性能与部分镍基高温合金相当,因此具有极大的应用前景。GH696合金的基体为单相奥氏体组织,不存在同素异构转变,变形和热处理过程中不会发生相变重结晶,不能通过热处理来细化晶粒。因此,通过调节变形工艺参数控制其动态再结晶过程和晶粒尺寸对于得到具有优良性能的合金制件有着十分重要的意义。

(Ni3AlTi)相时效析出强化,并辅以Mo的固溶强化和B的晶界强化。在高温下GH696合金具有较高的屈服强度和持久、蠕变强度以及良好的高温弹性性能、抗燃气腐蚀性能和加工塑性,可用于制造在650 ℃以下长期工作的涡轮、压气机紧固件、盘件、弹簧、工作叶片、涡轮壳体、环形零件[24]。由于GH696合金含Ni量较少,成本低,高温性能与部分镍基高温合金相当,因此具有极大的应用前景。GH696合金的基体为单相奥氏体组织,不存在同素异构转变,变形和热处理过程中不会发生相变重结晶,不能通过热处理来细化晶粒。因此,通过调节变形工艺参数控制其动态再结晶过程和晶粒尺寸对于得到具有优良性能的合金制件有着十分重要的意义。

本文作者将在GH696合金热模拟压缩试验的基础上,研究GH696合金的动态再结晶过程,分析变形温度、应变速率和应变对显微组织演变影响。在此基础上,计算动态再结晶发生的临界应变,研究GH696合金的动态再结晶分数模型和晶粒尺寸模型,可对GH696合金热变形过程中的显微组织进行预测与控制。

1 实验

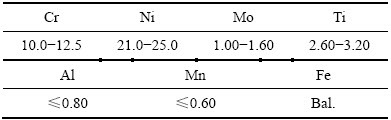

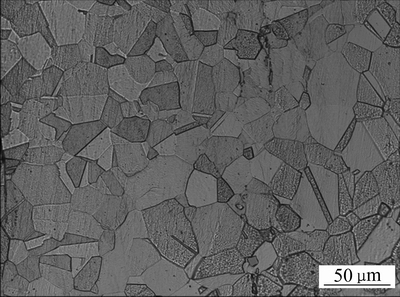

试验材料为d 60 mm的GH696合金棒材,其化学成分如表1所列,原始显微组织形貌如图1所示。由图1可以看出,GH696合金的原始显微组织为单相奥氏体组织,奥氏体晶粒大部分为等轴晶粒,存在少量孪晶,奥氏体晶粒尺寸大约为35 μm。

表1 GH696合金的化学成分

Table 1 Chemical composition of GH696 superalloy (mass fraction, %)

图1 供应态GH696合金的显微组织形貌

Fig. 1 Optical micrograph of as-received GH696 superalloy

GH696合金的热模拟压缩试验在Gleeble-3500型热模拟压缩试验机上进行,变形温度为880、910、940、970、1000、1030、1060、1090和1120 ℃,应变速率为0.01、0.1、1.0和10.0 s-1,变形程度为30%、40%、50%和60%。压缩试样为d 8 mm×12 mm的圆柱体,压缩前在试样上下两端面涂石墨膏并垫上钽片以减小摩擦力。试验采取电阻加热,将试样以10 ℃/s的加热速度加热至变形温度后保温5 min,然后以恒定应变速率压缩,压缩后立即水冷。将压缩后的试样沿轴线进行线切割,取一半进行镶嵌,然后将镶好的试样采用砂纸逐次打磨,直至试样上的划痕方向一致,且表面较光亮。随后,采用研磨膏抛光试样,完成抛光后使用成分配比为m(FeCl3):V(C2H5OH):V(HCl)=15 g:50 mL:50 mL的腐蚀剂进行腐蚀。在Leica DMI 3000M型倒置金相显微镜上对压缩变形后的组织进行观察,采用Image Pro-plus 6.0专业图像分析软件对部分试样的动态再结晶体积分数和动态再结晶晶粒尺寸进行定量。

2 结果与分析

2.1 流动应力

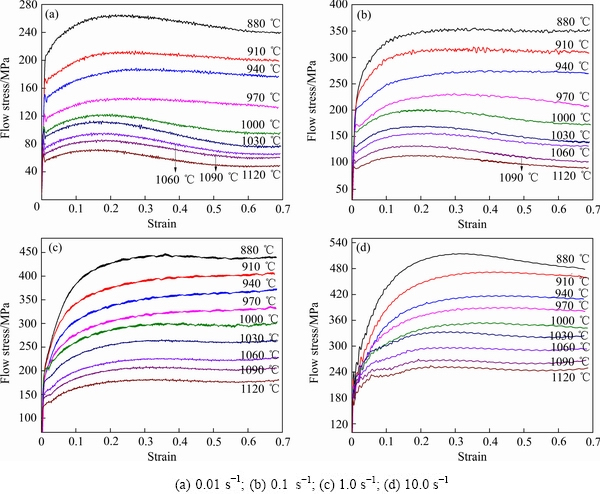

GH696合金在各变形温度和应变速率下压缩变形时的流动应力-应变曲线如图2所示。由图2可以看出,流动应力对变形温度和应变速率比较敏感。由图2中的GH696合金流动应力-应变曲线特征可知,在变形过程中在较低的变形温度和较高的应变速率下,GH696合金的主要软化机制为动态回复,而在较高的变形温度和较低的应变速率下,GH696合金的主要软化机制为动态再结晶。由图2可以看出,随着变形温度的升高和应变速率的降低,GH696合金流动应力逐渐减小。峰值应力σp在变形温度1120 ℃,应变速率0.01 s-1时达到最小值,峰值应变εp随变形温度的升高而减小,随应变速率的增大而增大。

图2 GH696合金高温压缩变形时的流动应力-应变曲线

Fig. 2 Flow stress-strain curves of GH696 superalloy during isothermal compression at different strain rates

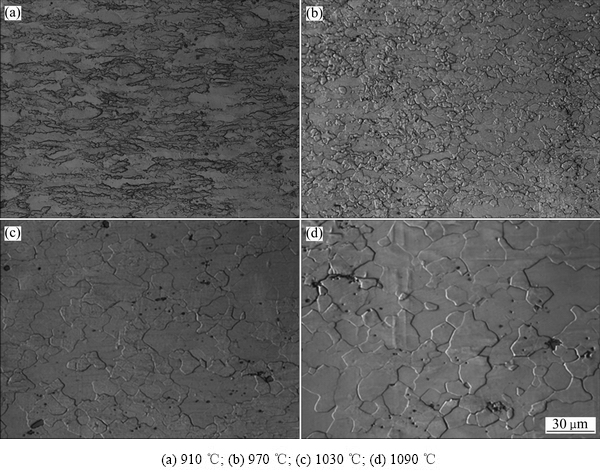

图3 变形温度对GH696合金压缩变形时显微组织的影响( = 0.01 s-1, △H/H0=50%)

= 0.01 s-1, △H/H0=50%)

Fig. 3 Effect of deformation temperature on microstructure of isothermally compressed GH696 superalloy ( =0.01 s-1, △H/H0=50%)

=0.01 s-1, △H/H0=50%)

2.2 显微组织演变

图3所示是变形程度(△H/H0)为50%、应变速率 ( )为0.01 s-1时,变形温度对GH696合金高温压缩变形后显微组织形貌的影响。由图3可以看出,在变形温度为910 ℃时,GH696合金奥氏体晶粒被压扁,呈长条状。同时,在大部分被拉长的原始奥氏体晶粒的晶界处都出现了少量细小的动态再结晶晶粒。随着变形温度的增加,动态再结晶晶粒越来越多,逐渐取代被拉长的原始奥氏体晶粒,当变形温度为970 ℃时,GH696合金基本完成动态再结晶。随着变形温度的继续升高,细小的再结晶晶粒开始长大。综上所述,变形温度对GH696合金的显微组织演变有明显影响,再结晶晶粒尺寸随着GH696合金变形温度的升高而增大,动态再结晶程度提高。

)为0.01 s-1时,变形温度对GH696合金高温压缩变形后显微组织形貌的影响。由图3可以看出,在变形温度为910 ℃时,GH696合金奥氏体晶粒被压扁,呈长条状。同时,在大部分被拉长的原始奥氏体晶粒的晶界处都出现了少量细小的动态再结晶晶粒。随着变形温度的增加,动态再结晶晶粒越来越多,逐渐取代被拉长的原始奥氏体晶粒,当变形温度为970 ℃时,GH696合金基本完成动态再结晶。随着变形温度的继续升高,细小的再结晶晶粒开始长大。综上所述,变形温度对GH696合金的显微组织演变有明显影响,再结晶晶粒尺寸随着GH696合金变形温度的升高而增大,动态再结晶程度提高。

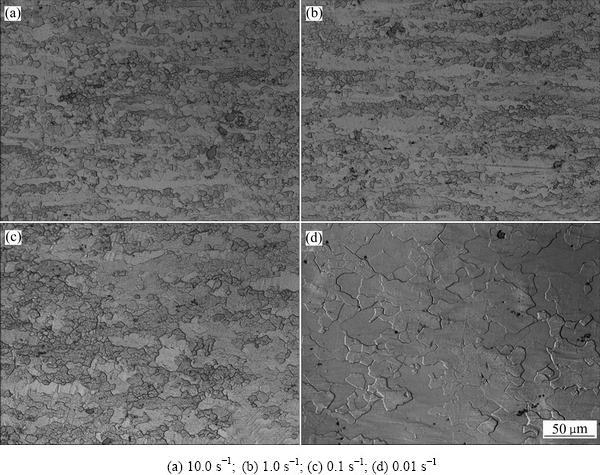

图4所示是变形温度为1060 ℃、变形程度为50%时应变速率对GH696合金高温压缩变形后显微组织的影响。由图4可以看出,在应变速率为0.1~10.0 s-1时,大部分变形晶粒均发生了动态再结晶;当应变速率0.01 s-1时,GH696合金发生了完全动态再结晶。综上所述,应变速率对GH696合金变形过程中的显微组织演变也有明显影响,随着变形应变速率的增大,合金GH696再结晶晶粒尺寸变小,再结晶程度稍有降低。

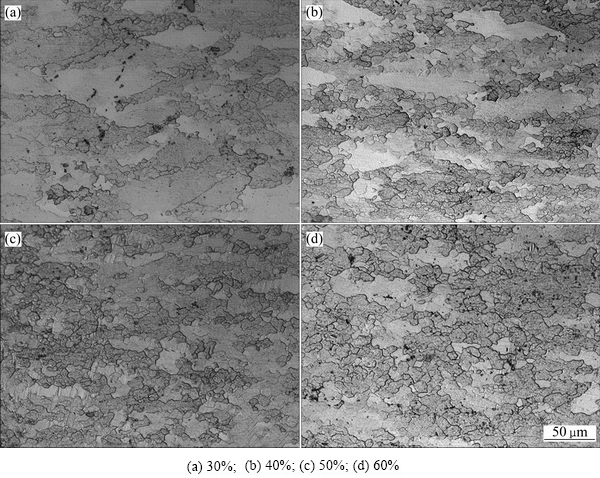

图5所示是变形温度为1060 ℃、应变速率为0.1 s-1时变形程度对GH696合金高温压缩变形后显微组织的影响。由图5可以看出,在变形程度为30%时,在被拉长的奥氏体晶粒的晶界附近,只有很少量的动态再结晶晶粒,随着GH696合金变形程度的不断增大,动态再结晶分数增大,在变形程度为50%时,基本完成动态再结晶。

2.3 动态再结晶模型

2.3.1 动态再结晶临界应变

高温变形过程中,当内部位错密度达到临界值时,材料才会发生动态再结晶[25],此时所对应的应变就称为临界应变。动态再结晶临界应变是确定热变形过程中材料发生动态再结晶的重要参数,因此确定动态再结晶临界应变在预测和模拟微观组织演变过程中具有重要意义。

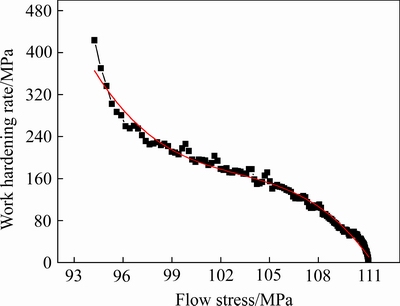

一般情况下,可以采用金相观察法和流动应力-应变曲线分析法确定动态再结晶临界应变。但是,金相观察法需要准备和分析大量不同应变量下的试样,工作量大且浪费材料。因此,一般采用流动应力-应变曲线分析方法确定临界应变。RYAN等[26]最先提出加工硬化率(θ=dσ/dε)的概念,指出加工硬化率-流动应力(θ-σ)曲线的拐点即为动态再结晶发生的临界条件,表达式如下:

(1)

(1)

式中:θ(θ=dσ/dε)为加工硬化率,MPa。

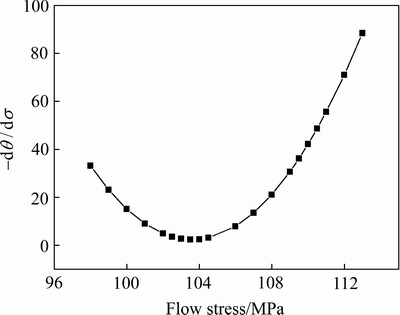

但是,很难在θ-σ曲线上直接准确的确定其拐点。NAJAFIZADEH等[27]在研究304H不锈钢发生动态再结晶的临界应力时指出,可以对θ-σ曲线进行三次多项式拟合,θ-σ曲线的拐点对应(dθ/dσ)-σ曲线的最低点,因此可由(dθ/dσ)-σ曲线的最低点代替θ-σ曲线的拐点准确的确定动态再结晶临界应变。

图4 应变速率对GH696合金压缩变形时显微组织的影响(t=1060 ℃, △H/H0=50%)

Fig. 4 Effect of strain rate on microstructure of isothermally compressed GH696 superalloy (t=1060 ℃, △H/H0=50%)

图5 变形程度对GH696合金压缩变形时显微组织的影响(t=1060℃,  =0.1 s-1)

=0.1 s-1)

Fig. 5 Effect of height reduction on microstructure of isothermally compressed GH696 superalloy (t=1060℃,  =0.1 s-1)

=0.1 s-1)

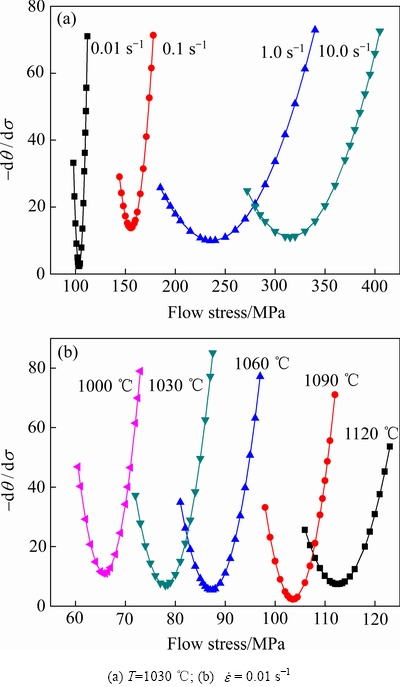

图6所示是变形温度为1030 ℃、应变速率为0.01 s-1时θ-σ曲线及其对应的三阶多项式拟合曲线,由图6可以看出,对于GH696合金,三次多项式可以很好的拟合θ-σ曲线。图7所示是变形温度为1030 ℃、应变速率为0.01 s-1时GH696合金的(dθ/dσ)-σ曲线。由图7可以看出最低点对应的应力为103.5 MPa,再由GH696合金的流动应力-应变曲线(σ-ε)可以得到对应的临界应变为0.07。

图6 GH696合金的加工硬化率与流动应力(t=1030℃,  = 0.01 s-1)

= 0.01 s-1)

Fig. 6 Work hardening rate versus flow stress of GH696 superalloy (t=1030℃,  = 0.01 s-1)

= 0.01 s-1)

图7 GH696合金加工硬化率的导数(dθ/dσ)与流动应力σ (t=1030℃,  = 0.01 s-1)

= 0.01 s-1)

Fig. 7 Derivative of strain hardening rate (dθ/dσ) of GH696 superalloy versus flow stress σ (t=1030℃,  = 0.01 s-1)

= 0.01 s-1)

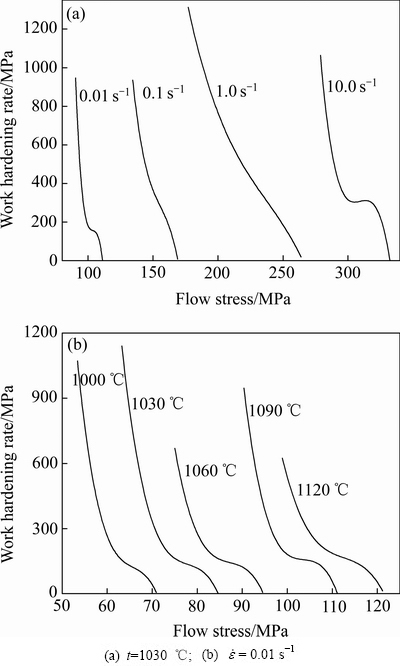

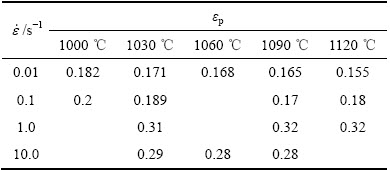

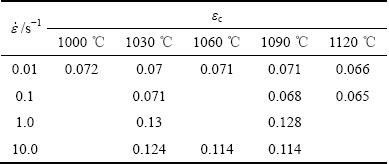

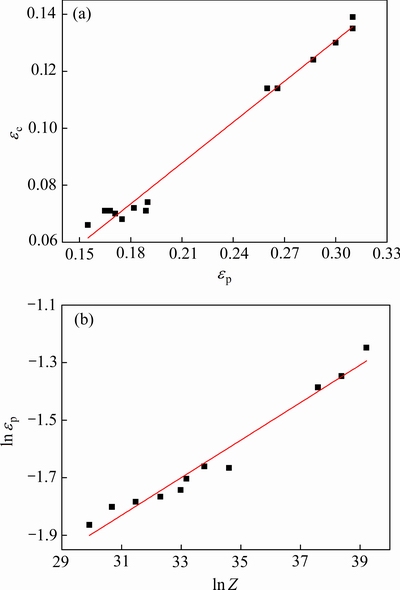

在不同的变形温度和应变速率下,GH696合金的θ-σ曲线对应的三阶多项式拟合曲线如图8所示,(-dθ/dσ)-σ曲线如图9所示,由此结合对应的σ-ε曲线可以确定各变形条件下的临界应变值。部分变形条件下的峰值应变εp和临界应变εc如表2和表3所列。

图8 GH696合金的加工硬化率与流动应力的三次多项式拟合曲线

Fig. 8 Three order polynomials equation of work hardening rate versus flow stress of GH696 superalloy

图9 GH696合金加工硬化率的导数(dθ/dσ)与流动应力σ

Fig. 9 Derivative of strain hardening rate (dθ/dσ) of GH696 superalloy versus flow stress σ

表2 GH696合金在各变形条件下的εp

Table 2 Values of εp of GH696 superalloy under different deformation conditions

表3 GH696合金在各变形条件下的εc值

Table 3 Values of εc of GH696 superalloy under different deformation conditions

图10 GH696合金临界应变随峰值应变的变化和峰值应变随Z-H参数的变化

Fig. 10 Variation of critical strain with peak strain(a) and peak strain with Z-H parameter(b) of GH696 superalloy

图10(a)所示为部分变形参数下的临界应变εc随峰值应变εp的变化情况。由图10(a)可以看出,临界应变εc随峰值应变εp呈近似线性变化,对其进行线性拟合可得:

(2)

(2)

由GH696合金的流动应力-应变曲线可知,当应变速率大于0.1 s-1时,GH696合金在各变形条件下的峰值应变平均值为0.3,而当应变速率小于等于0.1 s-1时,峰值应变εp与Z-H参数之间存在如图10(b)所示的关系,由图10(b)可知 随

随 参数的增加近似线性增加,因此可得峰值应变的表达式:

参数的增加近似线性增加,因此可得峰值应变的表达式:

(3)

(3)

2.3.2 体积分数模型

目前,动态再结晶分数与变形工艺参数的关系一般采用如下形式的Avrami方程:

(4)

(4)

式中:Xdrx为再结晶体积分数,%;k和m为材料参数; 为应变;εp为峰值应变;εc为临界应变。

为应变;εp为峰值应变;εc为临界应变。

一般情况下,动态再结晶体积分数可以由动态再结晶软化程度来表示[28],如式(5)所示。

(5)

(5)

式中: 和

和 分别为变形过程中软化机制只有动态回复时的流动应力和稳态应力,MPa;

分别为变形过程中软化机制只有动态回复时的流动应力和稳态应力,MPa; 和

和 为试验得到的流动应力和稳态应力,MPa。其中,σsat可由外延法求得。

为试验得到的流动应力和稳态应力,MPa。其中,σsat可由外延法求得。

本文作者在外延流动应力-应变曲线以得到仅有动态回复时的流动应力-应变曲线时所用的数学模型为 模型[29]。因此,动态回复流动应力

模型[29]。因此,动态回复流动应力 可由式(6)表示:

可由式(6)表示:

(6)

(6)

式中: 为屈服应力,MPa;

为屈服应力,MPa; 为动态回复系数;

为动态回复系数; 为累积应变。

为累积应变。

由式(4)可知,确定GH696合金的动态再结晶体积分数模型需要确定材料参数k和m。对式(4)两边取两次自然对数并整理可得式(7):

(7)

(7)

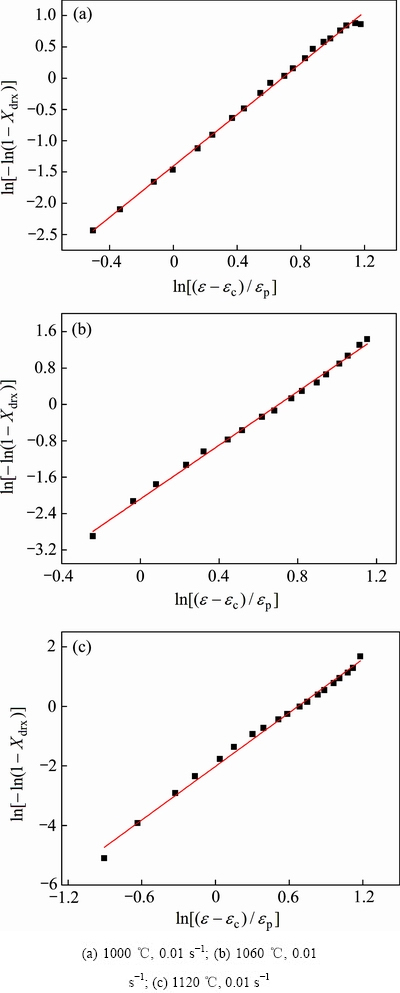

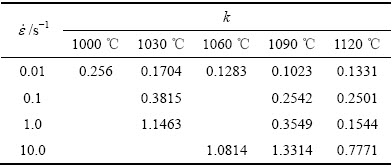

将由式(5)计算得到的Xdrx代入式(7)进行线性回归可得k和m的值,GH696合金的ln[-(1-Xdrx)]与ln[(ε-εc)/εp]的关系曲线如图11所示,k和m的值如表4和表5所列。经分析各变形条件下的k和m的值的特点,可知k和m均与 呈线性关系,如图12所示,由此可得k和m的表达式如下:

呈线性关系,如图12所示,由此可得k和m的表达式如下:

(8)

(8)

(9)

(9)

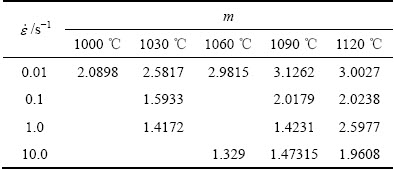

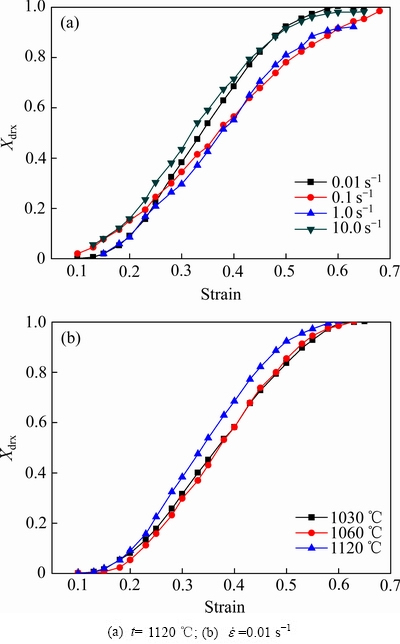

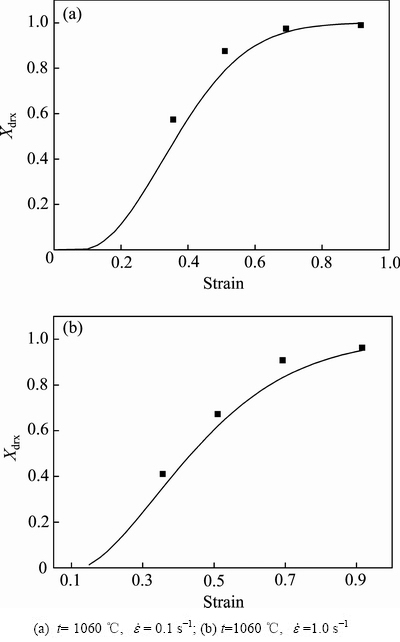

图13所示为GH696合金由式(5)计算的动态再结晶体积分数随应变的变化情况。由图13可以看出,随着应变的增加,GH696合金的动态再结晶体积分数先缓慢增大,再快速增大,然后又缓慢增大并趋于平稳。由图13(a)可以看出,在相同的变形温度和应变下,应变速率为0.01 s-1和10.0 s-1时,GH696合金的动态再结晶体积分数大于应变速率为0.1 s-1和1.0 s-1时的动态再结晶体积分数,原因在于:应变速率为0.01 s-1时,达到相同应变所用的时间比0.1 s-1和1.0 s-1长,因此动态再结晶进行的时间比较长;而应变速率为10.0 s-1时,虽然达到相同应变的时间变短,但是应变速率较高,变形比较剧烈,位错增殖、运动速率很快,合金内部畸变能比较高,动态再结晶驱动力大,动态再结晶过程进行的比较迅速,因此其动态再结晶体积分数也比较高。由图13(b)可以看出,应变速率为0.01 s-1时,变形温度对动态再结晶体积分数的影响不明显,原因有两方面:一方面由于变形速率很低,各变形温度下的动态再结晶都有较充足的时间进行;另一方面,变形温度都比较高并且差距不大,温度对合金动态再结晶的激活作用已达到一定程度,不再随变形温度的升高而明显增大。

综上所述,GH696合金的动态再结晶体积分数模型为

(10)

(10)

式中: ;

;

;

; ;

; 。

。

在不同的变形工艺参数下,采用上述模型计算GH696合金动态再结晶分数的结果与试验测量结果对比情况如图14所示。由图14可以看出,模型在两组变形工艺参数下的平均相对误差分别为7.34%和7.85%,平均误差为7.6%。由图14可以看出,因此,本文作者建立的模型能够较好地预测GH696合金的动态再结晶体积分数。

图11 GH696合金的ln[-ln(1-Xdrx)]与ln[(ε-εc)/εp]的关系曲线

Fig. 11 Relationships between ln[-ln(1-Xdrx)] and ln[(ε-εc)/εp] of GH696 superalloy

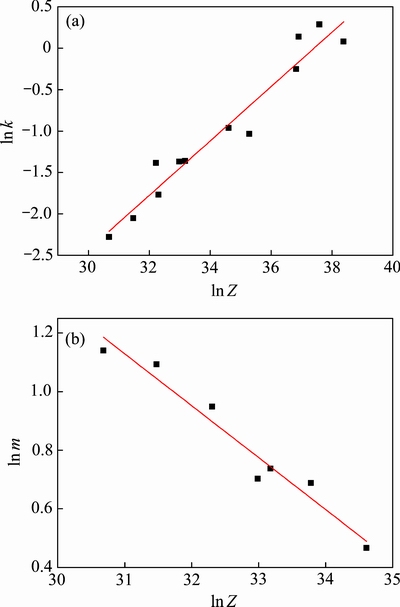

表4 GH696合金各变形条件下的k值

Table 4 Values of k under different deformation conditions of GH696 superalloy

表5 GH696合金各变形条件下的m值

Table 5 Values of m under different deformation conditions of GH696 superalloy

图12 GH696合金的材料常数k和m与Z-H参数的关系曲线

Fig. 12 Relationships between Z-H parameter and k(a) and m(b) of GH696 superalloy

图13 GH696合金的动态再结晶体积分数的计算结果

Fig. 13 Calculated consequence of dynamic recrystallization volume of isothermal compressed GH696 superalloy

图14 GH696合金高温变形过程中的动态再结晶体积分数计算值与试验值的对比

Fig. 14 Comparison of calculated Xdrx with experimental Xdrx during isothermal compression of GH696 superalloy

2.3.3 晶粒尺寸模型

动态再结晶晶粒尺寸是指金属或者合金的再结晶过程达到稳态时晶粒的尺寸。当变形达到稳态时,动态再结晶晶粒尺寸随着应变量的增加基本保持不变,并且晶粒尺寸与Zener-Holloman参数存在一定的函数关系:

(11)

(11)

式中:C和a为材料参数。

对式(11)两边取自然对数,可得:

(12)

(12)

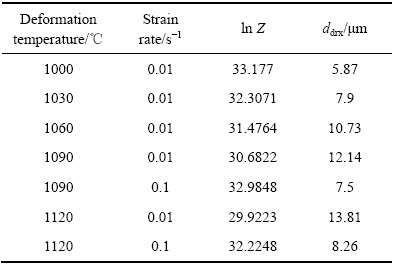

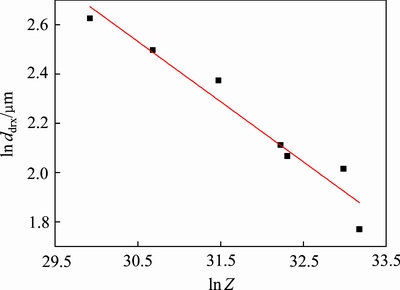

采用截线法在Image-Pro Plus软件上对完成动态再结晶的试样进行晶粒尺寸定量试验,试验结果如表6所列。将测得的ddrx按照式(12)进行线性回归,结果如图15所示,可得材料参数C=3.69×104,a=-0.2616。因此,GH696合金的动态再结晶晶粒尺寸模型为

(13)

(13)

表6 GH696合金不同变形工艺参数下的ddrx和ln Z值

Table 6 Values of ddrx and ln Z under different deformation conditions of GH696 superalloy

图15 GH696合金的ddrx与Z-H参数的关系曲线

Fig. 15 Relationship between ddrx and Z-H parameter of GH696 superalloy

3 结论

1) GH696合金高温变形时发生了动态回复和动态再结晶行为。随着合金应变速率的减小,变形温度的升高,变形程度的增大,合金动态再结晶程度增加,再结晶晶粒长大。

2) 根据热模拟压缩试验和定量金相试验结果,由加工硬化率-流动应力曲线确定了GH696合金高温变形时发生动态再结晶的临界应变。

3) 应用Avrami方程建立了GH696合金的动态再结晶体积分数模型,模型表达式如下:

式中: ;

;

;

; ;

; 。

。

4) 建立了GH696合金的动态再结晶晶粒尺寸模型,表达式如下:

REFERENCES

[1] DOHERTY R D, HUGHES D A, HUMPHREYS F J, JONAS J J, JUUL J D, KASSNER M E, KING W E, MCNELLEY T R, MCQUEEN H J, ROLLETT A D. Current issues in recrystallization: A review[J]. Materials Science and Engineering A, 1997, 238: 219-274.

[2] SELLARS C M, WHITEMAN J A. Recrystallization and grain growth in hot rolling[J]. Metal Science, 1979, 13: 187-194.

[3] SELLARS C M. Modelling microstructural development during hot rolling[J]. Materials Science and Technology, 1990, 6: 1072-1081.

[4] MCQUEEN H J, YUE S, RYAN N D, FRY E. Hot working characteristics of steels in austenitic state[J]. Journal of Materials Processing Technology, 1995, 53: 293-310.

[5] YADA H, In: RUDDLE G E, CRAWLEY A F, (Eds.), Proc. Int. Symp. Accelerated cooling of Rolled Steel, Conf. of Metallurgists, CIM, Winnipeg, MB, Canada: Pergamon Press, 1987: 105-120.

[6] KOPP R, CAO M L, SOUZA M M D. Proceedings of the Second International Conference on Technology of Plasticity, 1987: 1129-1134.

[7] LAASRAOUI A, JONAS J J. Recrystallization of austenite after deformation at high temperature and strain rates—Analysis and modeling[J]. Metallurgical Transactions A, 1991, 22: 151-160.

[8] KIM S I, LEE Y, LEE D L, YOO Y C. Modeling of AGS and recrystallized fraction of microalloyed medium carbon steel during hot deformation[J]. Materials Science and Engineering A, 2003, 355: 384-393.

[9] Medeiros S C, Prasad Y V R K, Frazier W G, Srinivasan R. Microstructural modeling of metadynamic recrystallization in hot working of IN718 superalloy[J]. Materials Science and Engineering A, 2000, 293: 198-207.

[10] Park N K, Kim I S, Na Y S, Yeom J T. Hot forging of a nickel-base superalloy[J]. Journal of Materials Processing Technology, 2001, 111: 98-102.

[11] Wang Y, Shao W Z, Zhen L, Yang L, Zhang X M. Flow behavior and microstructures of superalloy 718 during high temperature deformation[J]. Materials Science and Engineering A, 2008, 497: 479-486.

[12] Liu J, Cui Z, Ruan L. A new kinetics model of dynamic recrystallization for magnsium alloy AZ31B[J]. Materials Science and Engineering A, 2011, 529: 300-310.

[13] 刘 东, 罗子健. GH4169合金热加工过程中的显微组织演化数学模型[J]. 中国有色金属学报, 2003, 5(13): 1211-1218.

LIU Dong, LUO Zi-jian. Mathematical model for microstructure evolution of GH4169 alloy during hot working process[J]. The Chinese Journal of Nonferrous Metals, 2003, 5(13): 1211-1218.

[14] 姚志浩, 董建新, 张麦仓. GH738高温合金热变形过程显微组织控制与预测(Ⅰ. 组织演化模型的构建)[J]. 金属学报, 2011, 12(47): 1581-1590.

YAO Zhi-hao, DONG Jian-xin, ZHANG Mai-cang. Microstructure control and prediction of GH738 superalloy during hot deformation (Ⅰ. Construction of microstructure evolution model)[J]. Acta Metallurgical Sinica, 2011, 12(47): 1581-1590.

[15] 张 云, 曹富荣, 林开珍, 李宝绵, 周 舸, 丁 桦. GH4742高温合金的动态再结晶行为[J]. 中国有色金属学报, 2013, 11(23): 3091-3099.

ZHANG Yun, CAO Fu-rong, LIN Kai-zhen, LI Bao-mian, ZHOU Ge, DING Hua. Dynamic recrystallization behavior of GH4742 superalloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 11(23): 3091-3099.

[16] 郭海龙, 孙志超, 杨 合. 挤压态7075铝合金再结晶经验模型及应用[J]. 中国有色金属学报, 2013, 23(6): 1507-1515.

GUO Hai-long, SUN Zhi-chao, YANG He. Empirical recrystallization model and its application of as-extruded aluminum alloy 7075[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1507-1515.

[17] 蔡志伟, 陈拂晓, 郭俊卿. AZ41M镁合金动态再结晶临界条件[J]. 中国有色金属学报, 2015, 25(9): 2335-2341.

CAI Zhi-wei, CHEN Fu-xiao, GUO Jun-qing. Critical conditions of dynamic recrystallization for AZ41M magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9): 2335-2341.

[18] 杨胜利, 沈 健, 闫晓东, 李锡武, 孙宝庆, 毛柏平. 基于Al-Cu-Li合金流变行为的动态再结晶动力学与形核机制[J]. 中国有色金属学报, 2016, 26(2): 365-374.

YANG Sheng-li, SHE Jian, YAN Xiao-dong, LI Xi-wu, SUN Bao-qing, MAO Bai-ping. Dynamic recrystallization kinetics and nucleation mechanism of Al-Cu-Li alloy based on flow behavior[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 365-374.

[19] Nie L F, Zhang L W, Zhu Z, Xu W. Constitutive modeling of dynamic recrystallization kinetics and processing maps of solution and aging FGH96 superalloy[J]. Journal of Materials Engineering and Performance, 2013, 22(12): 3728-3734.

[20] Matsui T. High temperature deformation and dynamic recrystallization behavior of alloy718[J]. Materials Transactions, 2013, 54(4): 512-519.

[21] Liu Y G, Li M Q, Luo J. The modelling of dynamic recrystallization in the isothermal compression of 300M steel[J]. Materials Science and Engineering A, 2013, 574: 1-8.

[22] LIU J, LIU Y G, LIN H, LI M Q. The metadynamic recrystallization in the two-stage isothermal compression of 300M steel[J]. Materials Science and Engineering A, 2013, 565: 126-131.

[23] CHEN X M, LIN Y C, WEN D X, ZHANG J L, HE M. Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation[J]. Materials and Design, 2014, 57: 568-577.

[24] 中国航空材料手册编辑委员会. 中国航空材料手册[M]. 北京: 中国标准出版社, 2001: 141-155.

China Areonautical Materials Handbook Editorial Committee. China areonautical materials handbook[M]. Beijing: Standards Press of China, 2001: 141-155.

[25] 毛卫民, 赵新兵. 金属的再结晶与晶粒长大[M]. 北京: 冶金工业出版社, 1994: 197-216.

MAO Wei-min, ZHAO Xin-bing. The recrystallization and grain growth of metal[M]. Beijing: Metallurgical Industry Press, 1994: 197-216.

[26] RYAN N D, MCQUEEN H J. Flow stress, dynamic restoration, strain hardening and ductility in hot working of 316 steel [J]. Journal of Materials Processing Technology, 1990, 21: 177-199.

[27] NJAFIZADEH A, JONAS J J. Predicting the critical stress for initiation of dynamic recrystallization[J]. The Iron and Steel Institute, International, 2006, 46: 1679-1684.

[28] LAASRAOUI A, JONAS J J. Prediction of steel flow stresses at high temperatures and strain rates[J]. Metallurgical Transactions A, 1991, 22: 1545-1558.

[29]  Y. A dislocation model for the stress-strain behavior of polycrystalline α-Fe with special emphasis on the variation of the densities of mobile and immobile dislocations[J]. Materials Science and Engineering A, 1970, 5: 193-200.

Y. A dislocation model for the stress-strain behavior of polycrystalline α-Fe with special emphasis on the variation of the densities of mobile and immobile dislocations[J]. Materials Science and Engineering A, 1970, 5: 193-200.

Dynamic recrystallization model of GH696 superalloy

XU Zhao-hua, LI Hong, LI Miao-quan

(School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: The deformation behavior of GH696 superalloy was studied by isothermal compression experiments the deformation temperatures ranging from 880 to 1120 ℃, strain rates ranging from 0.01 to 10.0 s-1 and deformation degree ranging from 30% to 60%. The microstructure of GH696 superalloy after compression was observed on a microscope. The results show that dynamic recrystallization of GH696 superalloy occurs more easily at higher deformation temperature and lower strain rate. The critical strain of dynamic recrystallization of this alloy is identified based on the work hardening rate versus flow stress curves. The kinetics of dynamic recrystallization of GH696 superalloy is established based on Avrami equation. A model for DRX grain size is established based on OM experimental measurement results of GH696 superalloy.

Key words: GH696 superalloy; isothermal compression; dynamic recrystallization; grain size

Received date: 2016-06-28; Accepted date: 2016-11-11

Corresponding author: LI Miao-quan; Tel: +86-29-88460328; E-mail: honeymli@nwpu.edu.cn

(编辑 王 超)

收稿日期:2016-06-28;修订日期:2016-11-11

通信作者:李淼泉,教授,博士;电话:029-88460328;E-mail: honeymli@nwpu.edu.cn