热变形条件下V-10Cr-5Ti合金动态再结晶行为的元胞自动机模拟

来源期刊:中国有色金属学报(英文版)2019年第1期

论文作者:曹倬菡 孙宇 周琛 万志鹏 杨文华 任丽丽 胡连喜

文章页码:98 - 111

关键词:V-10Cr-5Ti合金;热变形;动态再结晶;元胞自动机;显微组织;数值模拟;晶粒细化

Key words:V-10Cr-5Ti alloy; hot deformation; dynamic recrystallization; cellular automaton; microstructure; numerical simulation; grain refinement

摘 要:通过在Gleeble-1500热模拟压缩机上对V-10Cr-5Ti合金进行温度为950~1350 °C、应变速率为0.01~ 10 s-1的热模拟压缩实验,并基于Arrhenius模型、位错密度模型、形核模型和晶粒长大模型,建立一种元胞自动机(CA)模型来模拟和表征动态再结晶过程中的组织演变。结果表明:流动应力对变形速率和变形温度具有强烈的依赖性,利用Arrhenius模型预测的应力值与实际测量值的误差小于8%。CA模型计算得到的初始平均晶粒尺寸为86.25 μm,与试验测量得到的85.63 μm相近。模拟表明:初始晶粒尺寸对动态再结晶组织演化影响并不显著,而提高应变速率或降低变形温度均可细化再结晶晶粒。

Abstract: The deformation behavior of V-10Cr-5Ti alloy was studied on the Gleeble-1500 thermomechanical simulator at the temperatures of 950-1350 °C, and the strain rates of 0.01-10 s-1. Based on the Arrhenius model, dislocation density model, nucleation model and grain growth model, a numerical cellular automaton (CA) model coupling simulation of hot deformation is established to simulate and characterize the microstructural evolution during DRX. The results show that the flow stress is fairly sensitive to the strain rate and deformation temperature. The error between the predicted stress by the Arrhenius model and the actual measured value is less than 8%. The initial average grain size calculated by the CA model is 86.25 μm, which is close to the experimental result (85.63 μm). The simulations show that the effect of initial grain size on the dynamic recrystallization microstructure evolution is not significant, while increasing the strain rate or reducing the temperature can refine the recrystallized grains.

Trans. Nonferrous Met. Soc. China 29(2019) 98-111

Zhuo-han CAO1, Yu SUN1, Chen ZHOU1, Zhi-peng WAN1, Wen-hua YANG2, Li-li REN3, Lian-xi HU1

1. National Key Laboratory for Precision Hot Processing of Metals, Harbin Institute of Technology, Harbin 150001, China;

2. Institute of Machinery Manufacturing Technology, China Academy of Engineering Physics, Mianyang 621900, China;

3. China Nuclear Industry No. 23 Construction Co., Ltd., Beijing 101300, China

Received 14 December 2017; accepted 13 August 2018

Abstract: The deformation behavior of V-10Cr-5Ti alloy was studied on the Gleeble-1500 thermomechanical simulator at the temperatures of 950-1350 °C, and the strain rates of 0.01-10 s-1. Based on the Arrhenius model, dislocation density model, nucleation model and grain growth model, a numerical cellular automaton (CA) model coupling simulation of hot deformation is established to simulate and characterize the microstructural evolution during DRX. The results show that the flow stress is fairly sensitive to the strain rate and deformation temperature. The error between the predicted stress by the Arrhenius model and the actual measured value is less than 8%. The initial average grain size calculated by the CA model is 86.25 μm, which is close to the experimental result (85.63 μm). The simulations show that the effect of initial grain size on the dynamic recrystallization microstructure evolution is not significant, while increasing the strain rate or reducing the temperature can refine the recrystallized grains.

Key words: V-10Cr-5Ti alloy; hot deformation; dynamic recrystallization; cellular automaton; microstructure; numerical simulation; grain refinement

1 Introduction

Dynamic recrystallization (DRX) plays an important role in controlling final microstructure morphology and refining grain through thermo- mechanical processing (TMP) to obtain excellent material properties [1]. Therefore, it is of great significance to reveal the microstructural evolution for predicting the microstructure characterization and mechanical properties of metallic materials during plastic deformation [2].

Cellular automaton (CA) approach is available to present the growth kinetics and texture evolution in the time and space scale [3]. At present, CA method provides a possibility to simulate microstructural evolution in the processing of both static and dynamic recrystallization due to its high flexibility, high efficiency and simple mapping between the CA time and the real time [4]. More importantly, the evolution of presented microstructure parameters and their interactions can also be monitored undergoing each CA simulation [5]. Additionally, CA modeling consists of state variables such as dislocation density and crystallographic orientation, which create more realistic representations of recrystallization kinetics. Therefore, predicting of the texture evolution of metallic materials by CA has become a heated issue of the international frontier research [3]. GOETZ and SEETHARAMAN [6] assumed that the nucleation rate is a linear function of dislocation growth rate. DING and GUO [7] developed a cellular automaton DRX (CA-DRX) model to simulate DRX behavior of pure copper during high-temperature deformation, which simulated the plastic flow behavior and the macroscopic stress-strain relationship successfully. Combined with metallurgical principles of DRX, KUGLER and TURK [8] developed a CA model to reproduce the microstructure changes undergoing multistage high-temperature deformation. Recently, LI et al [9] have established a CA model with the topological deformation of grains to characterize the DRX of the TA15 titanium alloy. The simulation results present a good agreement with experimental flow stress curve and microstructural evolution.

V-Cr-Ti alloy has been considered as a potential constructive material for the first wall blanket of the fusion reactor [10]. The composition of V-(4-10)% Ti-(4-15)%Cr alloy has been developed actively through a series of systemic studies. It exhibits good resistance to irradiation damage and void swelling [11], especially at moderately high temperature. Moreover, this alloy possesses excellent mechanical properties coupled with low coefficient of thermal expansion, reduced activation, fast decay characteristics [12], stable fracture toughness and so forth. In recent years, some investigations have been carried out on the hot deformation behavior and mechanical properties of V-Cr-Ti type alloys. DONAHUE et al [13] evaluated a physically based constitutive model for the V-4Cr-4Ti alloy from 77 to 373 K. CAI et al [14] developed a Johnson-Cook model for the V-5Cr-5Ti alloy under high strain rate impact and quasi-static tensile state and investigated the studied material stain-rate sensitivity at room temperature. LI et al [15,16] calculated the activation energy, established an Arrhenius-type constitutive equation for the V-5Cr-5Ti alloy and found that both discontinuous dynamic recrystallization (DDRX) and continuous dynamic recrystallization (CDRX) mechanisms occurred. From the above- mentioned analysis, there are few reports of the deformation behavior of V-10Cr-5Ti alloy despite a lot of research on V-(4-5)Cr-(4-5)Ti alloys.

In this work, the DRX of V-10Cr-5Ti alloy was investigated by hot compression tests over large ranges of deformation temperature and strain rate. In addition, a CA model was established to simulate the DRX behaviors of the studied material. The microstructural evolution of recrystallization of V-10Cr-5Ti alloy was predicted quantitatively, including the grain shape, average size, volume fraction and kinetics analysis of dynamic recrystallization.

2 Experimental

The chemical composition of the studied V-10Cr-5Ti alloy is illustrated in Table 1. The cylindrical specimens with the diameter of 8 mm and the height of 12 mm were machined from the as-received alloy. Thin graphite flakes were placed between the dies and specimen in order to reduce the friction on the stress state. All the specimens were treated at 1400 °C for 1 min at an increasing rate of 10 °C/s to eliminate the unevenness. Subsequently, the samples were cooled to the designed deformation temperature at a cooling rate of 5 °C/s and soaked for 30 s to eliminate the temperature gradients. Furthermore, vacuum environment was provided to prevent from oxidation during hot single-compression tests on the Gleeble-1500 thermo-mechanical simulator under the deformation temperatures of 950-1350 °C, and the strain rates of 0.01-10 s-1. After that the deformed specimens were quenched with room temperature water immediately when the compression deformation degree reached 50%. The samples after deformation were sectioned parallel to the compressive axis, mechanically polished and chemically etched for microstructural analysis. The corrosive liquid is composed of 59% methanol + 35% ethanol + 6% perchloric acid. EBSD observation was performed on Quanta 200FEG.

Table 1 Chemical compositions of V-10Cr-5Ti alloy (mass fraction, %)

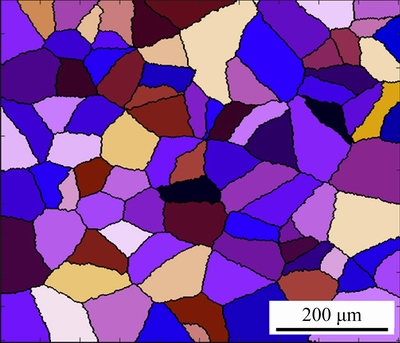

Figure 1 shows the microstructure of the studied V-10Cr-5Ti alloy before hot compression deformation. It can be observed from this figure that the initial microstructure consists of equiaxed grains with an average grain size of 85.63 um, which was measured based on the linear intercept method.

Fig. 1 Initial microstructure of V-10Cr-5Ti alloy before hot deformation

The flow curves derived from hot compression tests under various deformation conditions on Gleeble 1500D thermal simulation test machine are depicted in Fig. 2. Typically, the true stress-true strain curves exhibit DRX characteristics with a peak stress followed by gradual fall toward a continuous increase at a decreasing rate till the maximum strain. In work hardening (WH) stage, the primary rapid rise in stress is attributed to the large number of proliferation and tangles of dislocations and the increase in the formation of poorly developed subgrain boundaries [17], so the effect of work hardening is distinct. In softening stage, the dislocation density reaches a critical point, correspondingly at a variation in driving force, and DRX occurs at the original grain boundaries [18]. With further deformation, a lot of potential nuclei were activated and new DRX grains appeared. The decrease in flow stress is caused by the intensive effect of the dynamic softening mechanism such as DRX and dynamic recovery (DRV). When the work hardening and dynamic softening arrive at a dynamic equilibrium, a steady state flow stress is obtained. Meanwhile, it is noted that the stress-strain curves of V-10Cr-5Ti alloy are fairly sensitive to the hot processing parameters of strain rates and deformation temperatures. Specifically, the decrease of deformation temperature or the increase of strain rate would significantly improve the flow stress of the studied material, indicating that the alloy possesses negative sensitivity and positive strain rate sensitivity [18]. For instance, the peak stress can be up to 380.5 MPa under 950 °C and 10 s-1. Whereas, the peak stress is only 240.9 MPa when the sample is deformed at 1150 °C and 1 s-1. The former is about 1.5 times that of the latter. This is because on one hand, the lower strain rate provides more time for the sample to promote dynamic recovery and dynamic recrystallization, resulting in greater softening than work hardening; on the other hand, under high temperature, there will be higher mobility at boundaries for nucleation and growth of DRX grains and dislocation annihilation, which will promote occurrence of the dynamically recrystallized behavior [18]. Besides, the high deformation temperature is beneficial for reducing the dislocation slip resistance and generating more slip systems, which strengthens the softening effect during the deformation process [17]. Therefore, the peak stress decreased with increasing temperature and falling strain rate. However, the steady state does not explicitly appear in the experimental curves due to the small deformation.

Fig. 2 Flow curves of V-10Cr-5Ti alloy under various deformation conditions

3 Simulating dynamic recrystallization behavior by CA method

3.1 Modeling Arrhenius constitutive equation

The flow stress of the alloy under high temperature plastic deformation can be expressed by the Arrhenius constitutive equation as follows:

(1)

(1)

where T is the thermodynamic temperature (K); R is the gas mole constant (8.314 J/mol); Q is the thermal activation energy (kJ/mol); A, α, and n are material constants.

In addition, the Zener-Hollomon parameter (Z parameter) is usually used to describe the effect of temperature and strain rate on the hot deformation flow behavior, as shown in Eq. (2):

(2)

(2)

Therefore, the Arrhenius equation containing the Z parameter can be expressed as

(3)

(3)

3.2 Development of dynamic recrystallization model

3.2.1 Modeling dislocation density

During hot deformation of metals, the magnitudes of WH, DRV and DRX are the main influential factors in determining the magnitude of dislocation density (ρ). It is well known that dynamic recrystallization commences during the compressive deformation when ρ reaches its critical value (ρc). In the present research, the modified Kocks and Mecking model was employed to illustrate the evolution of ρ during plastic deformation:

(4)

(4)

where  expresses the work hardening; k1 is the work hardening parameter which can be determined by Eq. (5); k2ρ is the dynamic softening; k2 is the recovery coefficient parameter which can be determined by Eq. (6).

expresses the work hardening; k1 is the work hardening parameter which can be determined by Eq. (5); k2ρ is the dynamic softening; k2 is the recovery coefficient parameter which can be determined by Eq. (6).

k1=2θ/αGb (5)

k2=2θ/σs (6)

Among them, G is the shear modulus (MPa); σs is the steady-state stress (MPa) and α is the interaction coefficient of dislocation density, usually taken as 0.5; b is the Burgers vector; θ is the work hardening rate (MPa). Therefore, the values of k1 and k2 are calculated as 10.23 and 0.2. The true stress is relevant to dislocation density as

(7)

(7)

where  is the average dislocation density for all cells (cm-1).

is the average dislocation density for all cells (cm-1).

3.2.2 Modeling DRX nucleation

The nucleation of recrystallized grains during hot deformation conditions can be simulated based on the presented two stages of the DRX model involving generation of initial microstructure and distribution of dislocations. According to previous studies [12], the first part of nucleation model assumes that the nucleation rate is a function of strain rate and deformation temperature and can be described as [17]

(8)

(8)

where C is model constant which can be determined by experimental results; Qact is the activation energy for nucleation; m is the exponent which was set to be 1 in the simulation.

The other part, DRX is driven by a decreasing of the Gibbs energy and the nucleation of new grains principally appears at pre-existing grain boundaries at sites of sufficient stored energy [19]. As is commonly accepted, the critical value of dislocation density that can be calculated by Eq. (9) is used to judge whether or not DRX occurs [20].

(9)

(9)

where M is the mobility of grain boundary; γi is the energy of grain boundary; l is the dislocation mean free path; τ is the dislocation line energy, and can be calculated by [21]

τ=c2Gb2 (10)

where c2 is a constant of the order of 0.5. The dislocation mean free path l can be taken as the subgrain size and calculated from Eq. (11) [21]:

(11)

(11)

where σ is the flow stress; K1 is a constant which is about 10 for most metals [21].

Furthermore, to take into account stochastic aspects of nucleation, particularly CA cell (i, j) is described by a pseudorandom value rand (0, 1). The CA cell changes its state when the dislocation density reaches the critical value, as well as, probability criterion is satisfied rand< P1 [20]:

(12)

(12)

where A is the constant of materials, and the value of Qb can be calculated by the Arrhenius constitutive equation as 425 kJ/mol [16].

3.2.3 Modeling DRX growth

The difference between the dislocation densities of the matrix and the recrystallized grain provides the driving force for growth of recrystallized grain.

The growth velocity (vi) for the (ith) recrystallized grain is proportional to the driving force per cell area as

v(i,j)=Mf(i,j) (13)

where fi is the driving force for the ith recrystallized grain with the per unit area. The mobility of grain boundary (M) can be expressed as [20]

(14)

(14)

where  , δ is the mean thickness of the grain boundary thickness, Dob is the boundary self-diffusion coefficient, Qb is the boundary diffusion activation energy, and k is the Boltzmann’s constant.

, δ is the mean thickness of the grain boundary thickness, Dob is the boundary self-diffusion coefficient, Qb is the boundary diffusion activation energy, and k is the Boltzmann’s constant.

The driving force related to the stored energy can be expressed as differences in dislocation densities across the microstructure [19]:

(15)

(15)

where ρm is the dislocation density of the matrix; ρi is the dislocation density of the ith recrystallized grain; di is the diameter of the ith recrystallized grain; γi is the grain boundary energy which can be calculated from Eq. (16):

(16)

(16)

where θi is the grain boundary misorientation between the ith recrystallized grain and the matrix; γm is the boundary energy; θm is the misorientation of high angle boundary (taken as 15°).

3.3 Basic principle of topology deformation

When the cylindrical specimen is compressed, it will be still cylindrical if the effect of friction is neglected (Fig. 3). According to the principle of volume invariability, the following relationship can be established:

π(d0/2)2h0=π(d/2)2h (17)

Under the effect of compressive strain ε, the relationship between the height before and after deformation of the specimen can be expressed by Eq. (18):

ε=ln(h/h0) (18)

From this we can obtain the relationship between height and radius before (h0, r0) and after (h, r) deformation in terms of strain, that is, as shown in Eqs. (19) and (20):

h=h0exp ε (19)

(20)

(20)

3.4 Procedures of CA simulation

Fig. 3 Cylindrical specimen before and after deformation

Fig. 4 Flowchart of CA simulation

The flowchart of the CA model is presented in Fig. 4. The model mainly includes three main parts: inputting material basic parameters and simulated thermal deformation conditions, reading initialization microstructure, and dislocation proliferation. The detail determined material parameters of the V-10Cr-5Ti alloy used for the microstructure simulation are presented in Table 2. During the simulation, each cell possesses six state variables [22].

(1) The dislocation density variable was used to record the changes of dislocation density with increasing strain. The initial dislocation density of all the CA cells is equal to the same numerical value on the assumption that all primary grains are identical and uniform. The average value can be calculated by the Williamson-Hall (WH) method [23] to be 1×109 μm2. The increment of dislocation density (Δρ) is calculated by Kocks and Mecking model during the progress of DRX. The dislocation density of the cell is set to be ρc when DRX occurs, and then increases with increasing strain. Besides, it can also describe the deformation stored energy.

(2) The state variable of grain orientation of the matrix and recrystallized grains was set by random integer in the range of 0-180, which presents different grains. In addition, it can be used to evaluate the grain boundary energy. When the CA cell becomes a nucleon, it is fully recrystallized and assigned with a new value of crystallographic orientation.

(3) The grain boundary variable is performed to differentiate whether the cells are at grain boundaries.

(4) The state variable of colors is set by 0-255 for visualization.

(5) The grain label variable that distinguishes different grains by an integer in the range of 0-N, where N is the total number of the grains.

(6) The recrystallization time variable was introduced to track the recrystallization process.

Table 2 Detailed material parameters for V-10Cr-5Ti alloy

The principles of physical metallurgy and CA models were implemented on the MATLAB platform to predict the dynamic recrystallization. The evolution of grain morphology and other local information related to dislocation density changes can be traced at different instants of time. The fraction of dynamic recrystallization (Xdrx) can be calculated by

(21)

(21)

where Nr is the number of recrystallized cells; Nc represents the total number of cells in the cellular space.

Each grain diameter of the recrystallization grain in the simulation can be counted and computed according to the area number of multiple cells in each grain. Additionally, the average diameter of dynamically recrystallized grain can be calculated by [24]

(22)

(22)

where Ai is the area of the ith grain i; Ng is the number of recrystallized grains.

3.5 Generation of initial microstructure

The first step for the simulation is to generate the initial microstructure prior to deformation. The size of CA space was evaluated based on the image of actual microstructure and recorded mean grain sizes. Based on the average grain size, the CA space size as well as amount of initial grains can be easily linked to provide statistically representative digital microstructure on account of normal isotropic grain growth algorithm. The computational domain composed of CA cells is 502×502 square lattices and periodic boundary conditions, which will be considered as a representative volume element (RVE). The size of each cell is set as 2 μm to the actual dimension of the material, and the simulation area corresponds to 1024 μm × 1024 μm in the real specimen. The evolution of cell array is characterized by the state of cell determined by the neighborhood and the transformation rule [25].

In order to reproduce the DRX behaviors of the V-10Cr-5Ti alloy, a numerical model is established by coupling the CA method with unconstrained grain growth, microstructure morphology and the physical principles of discontinuous dynamic recrystallization (DDRX).

To generate the initial microstructure, a mean grain size measured by experiment is imputed, which will lead to a computation of texture close to the actual grain size. Figure 5 shows the initial microstructure with an average grain diameter approximately 86.254 μm.

Fig. 5 Microstructure of studied V-10Cr-5Ti alloy before hot deformation generated by CA simulation

4 Results and discussion

According to the parameters of single-pass compressive deformation, the DRX microstructure evolution and flow stress behavior of V-10Cr-5Ti alloy were simulated. The main results have been acquired and discussed as follows.

4.1 Result verification of hot compression simulation

To verify the validity and applicability of the simulated stress-strain model, the strain was selected in the range from 0.05 to 0.65 with an interval of 0.05, and the simulated results are shown in Fig. 6. The simulated values of the model are in good agreement with the experimental values, indicating that the established Arrhenius constitutive model can better characterize the flow stress behavior of V-10Cr-5Ti alloy. Besides, it can be seen from Fig. 7(a) that most of the data points fall on the optimal regression line, and the correlation coefficient is 0.983. On this basis, the average relative error between the predicted and experimental values under different strains is calculated. The results in Fig. 7(b) show that the error is small and relatively uniform in the entire strain interval, mainly concentrated in -6% to 8%, indicating that the overall prediction accuracy is high. Therefore, the Arrhenius model can be used for the simulation of the microstructure evolution in the dynamic recrystallization of V-10Cr-5Ti alloy.

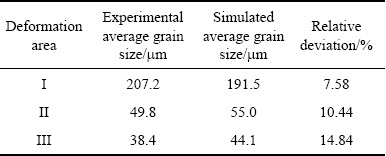

Figure 8 indicates the metallography observation of three typical deformation areas obtained from both experimental test and CA simulation at 1250 °C, 0.1 s-1 and 50% reduction. From the distribution of the effective strain in the compression specimen, it can be obviously seen that there is a conspicuous gap of the effective strain in different regions of the specimen, whose influence cannot be ignored. The first area I has a very small deformation due to the effect of three-dimensional compression stress, so the microstructure in Fig. 8(c) presents a more complete and original grain distribution. This nonuniform distribution of the original grain may cause some deviation in the simulation (Fig. 8(d)). While, the relative deviation of average grain size between the metallographic observation and the simulation results is 7.58% (Table 3). On the contrast, the third area III has the maximum deformation as a result of tensile stress, whose grains are squashed and elongated (Figs. 8(a) and (b)). The inhomogeneous phenomenon of strain can be attributed to the effect of the contact and friction behavior between specimen and die. The experimental average grain sizes in Figs. 8(a) and (e) are 38.4 μm and 49.8 μm, while the simulated ones are 44.1 μm and 55 μm, respectively. The relative deviations are 14.84% and 10.44%. It can be explicitly deduced that the simulation results are in accordance with the experimental results (Table 3).

Fig. 6 Comparison between predicted and experimental values of stress-strain curves at different strain rates

Fig. 7 Correlation coefficient between predicted and experimental values (a) and average relative error at different strains (b)

Fig. 8 Comparisons between experimental and simulated microstructure of three deformation areas of specimen treated at 1250 °C, 0.1 s-1 and 50%

Table 3 Experimental and simulated grain sizes after deformation

Figure 9 shows the electron backscatter diffraction (EBSD) image of microstructural evolution of V-10Cr-5Ti alloy during hot compression deformation at 1250 °C and 0.01 s-1 by CA simulation. It can be found that nearly all of the small DRX grain nuclei appear at grain boundaries, indicating a good agreement with the simulation. A more regular and equiaxed microstructure with a comparatively constant average grain size was also discussed in relation to experiments by HALLBERG et al [26]. Moreover, it can be figured out that the initial equiaxed grains are becoming elongated perpendicular to the compressive axis, which can also be supported by the EBSD and simulated results illustrated in Figs. 9(c) and (d), respectively.

Fig. 9 Experimental (a, c) and simulated (b, d) microstructures of V-10Cr-5Ti alloy treated at strain of 0.1 under different conditions

Fig. 10 Nucleation microstructure of triangular grain boundary at 1350 °C and 0.01 s-1

The TEM image (Fig. 10) shows that dynamic recrystallization nucleation occurs preferentially at the triangular grain boundaries formed by grains A, B, and C. This is due to the fact that the dislocations are more likely to be plugged and accumulated at the triangular grain boundaries than at the grain boundaries of the two grains. The degree is also greater, with a stronger nucleation advantage, which is in good agreement with the simulation results.

The final DRX grain size was measured through orientation distinction in the CA model through area method. In the verification stage, as observed in the final microstructures obtained from the experiments, the final texture showed that the CA model predicted microstructure accurately with the help of EBSD. In addition, the final textures were only 7.6% and 1.2% area recrystallized when the strain was 0.1 for the rate of strain and temperature considered here. By running the code under the same condition, similar results can be acquired, illustrating that the final microstructures are not fully recrystallized, and the DRX fractions are 7.9% and 1.3%, respectively. Relative errors are 3.9% and 8.3%, showing a good agreement between the experimental results and the predicted values.

4.2 Evolution of DRX microstructure

It is significant to visualize the behavior precisely during CA simulated results analysis. Much macroscopic quantitative information on the material behavior can be obtained in graphical form from the results of simulation, including recrystallization kinetics, stress-strain curves, grain size distributions. The basic process of DRX of V-10Cr-5Ti specimen subjected to hot compression deformation can be visualized as presented from Fig. 11. The process of DRX can be divided into three parts, including the nucleation, grain growth and grain impingement. Besides, the recrystallization fraction increases with the increase of strain, and reaches 100% at the strain of 0.8, as shown in Fig. 11(d).

Fig. 11 Predicted microstructures of V-10Cr-5Ti alloy heat treated at different strains

Generally, the recrystallized grains firstly nucleate at the primary grain boundaries subjected to a certain plastic deformation degree, and then they grow up with the increase in the strain.

The volume fraction of DRX and average grain size of DRX are presented in Fig. 12. At the initial stage of deformation, there is no occurrence of DRX. DRX grain nuclei start to commence with low DRX fraction when the strain reaches a critical value. Besides, the DRX exerts a slight effect on the properties at this stage because the DRX grain nuclei take up only a small fraction of the recrystallized area due to their small sizes. Subsequently, there is a slow increase in the DRX fraction, while the average grain size decreases gradually. Additionally, the size of primary grain is fairly bigger than that of the DRX grain nuclei. Accordingly, the microstructure becomes inhomogeneous, and the average grain size drops down. Therefore, the evolution rule of volume mean grain size exhibited by simulation can well reflect the microstructure evolution of DRX.

With the progression of the plastic deformation, the DRX grains grow up at the expense of primary grains. In the meantime, the size differences between the primary grains and DRX grains start to decrease. Furthermore, there is a steep drop in the average grain size, while the fraction of DRX rapidly rises to a peak.

With the further increase of strain, the average grain size drops down slowly due to the growth of the DRX grain. In addition, the size difference between the DRX and initial grains decreases gradually. However, when the DRX is nearly completed, the average grain size grows at a relatively low rate, which is in that the primary grains are almost entirely depleted. Figure 12 also presents the graphic illustration of change of the average grain size, volume fraction and the simulation of microstructure evolution on DRX in detail. Moreover, the processing of DRX can be separated into three stages, including nucleation, nucleus growth and grain contact [27]. It can be distinctly figured out that the average grain size keeps dropping before the onset of steady state during the whole processing of DRX.

Fig. 12 Influence of strain on DRX volume fraction and mean grain size at 1250 °C and 0.1 s-1

4.3 Effect of deformation parameters on dynamic recrystallization

4.3.1 Effect of initial grain size

Figure 13 illustrates primary microstructures with different mean grain sizes (d0=40, 60, 80 and 100 μm) and the corresponding DRX microstructures obtained by CA simulation at 1250 °C and 0.1 s-1 up to a total strain of 0.8. It is interesting to figure out that although significant differences exist in the initial microstructure, these differences do not result in a severe gap in the recrystallized texture, given the same deformation conditions and sufficient time for full recrystallization. The phenomenon agrees well with the simulated results obtained by ZHANG et al [28]. Despite the four DRX microstructures are almost similar, the volume fraction of DRX is bigger for small initial grain sizes, which is because the nucleation rate of the DRX grain increases for a small initial grain size owing to the high area fraction of the grain boundary. Hence, the number of possible nuclei sites in the texture increases. Conversely, if larger primary grain sizes are considered, the number of possible nucleation sites is reduced, which slows down the process of DRX.

4.3.2 Effect of strain rate

It is well known that the deformation temperature and the strain rate have significant effects on the processing of DRX. Based on the CA simulation, the influence of the strain rate on the microstructure is simulated, as demonstrated in Fig. 14. As seen in the final textures obtained from the simulations, the final microstructures were not fully recrystallized when the strain was 0.3 at different temperatures. Figure 14 also illustrates that the more recrystallized grains are generated with the increase of strain rate. In contrast, the smaller the average recrystallized grain size is generated at the same time. The volume fraction of DRX decreases with the increase of hot strain under the same strain.

Besides, as demonstrated in Fig. 15, the grain sizes corresponding to the four strain rates are 51.24, 45.61, 26.47 and 18.35 μm, respectively. It is supposed to be noted that the mean grain size decreases with the increase in the strain rate under the condition of complete DRX at the same deformation condition, whose evolution trend is similar to that in Ref. [28].

4.3.3 Effect of deformation temperature

Fig. 13 Microstructure evolution of V-10Cr-5Ti samples with different initial grain sizes treated at 1350 °C and 1 s-1

Fig. 14 Microstructures of V-10Cr-5Ti alloy treated at deformation temperature of 1250 °C and strain of 0.3 using CA simulation at different strain rates

Fig. 15 Microstructures of fully recrystallized V-10Cr-5Ti alloy treated at deformation temperature of 1250 °C and strain of 0.8 using CA simulation at different strain rates

Figure 16 presents the influences of deformation temperature on the predicted volume fraction of DRX under the same hot compression strain rate 1 s-1 at different deformation temperatures. The DRX kinetic curves are characterized by an S-shape. It is apparent that only when the density of dislocation reaches the critical value, can DRX occur at a certain strain rate and deformation temperature during hot deformation. Additionally, the volume fraction of DRX remains zero when the dislocation density is below the same criteria. This phenomenon is tightly relevant to the dislocation accumulation rate and the critical dislocation density for the initiation of DRX [29]. It can be figured out that increasing the deformation temperature possesses the capability to decrease the incubation period. The higher the critical strain and the slower the rate of dislocation accumulation, the longer the incubation period will be.

Fig. 16 Influence of deformation temperature on volume fraction of DRX at strain rate of 1 s-1

Fig. 17 Relationship between deformation temperature and DRX grain size of fully recrystallized V-10Cr-5Ti alloy

Figure 17 summarizes the relationship between DRX grain size and deformation temperature at the same deformation. It is apparently demonstrated that the microstructure consists of fine equiaxed DRX grains. It can be seen from the figure that when the deformation temperature increases from 950 to 1350 °C, the average grain size also increases from 27.31 to 53.45 μm, indicating that increasing the deformation temperature promotes the coarsening of recrystallized grains. This is the result of increased slip activity and grain boundary sliding alone [29].

5 Conclusions

1) The flow stress of V-10Cr-5Ti alloy has a strong dependence on the deformation rate and deformation temperature. Both the increase of strain rate and the decrease of deformation temperature can promote the increase of flow stress. Based on the stress and working parameters, the Arrhenius equation containing the Z parameter can be expressed as

2) The established CA model reveals the influence of the hot deformation parameters on the dislocation density and the DRX microstructural evolution. The parameters alter the accumulation rate of dislocation density through work hardening and dynamic recovery, and further affect the onset and the nucleation and growth of DRX. The simulation results of the mechanical response and DRX evolution are verified by hot compression experiments. The characteristics of deformed and recrystallized grains are checked by EBSD.

3) The non-uniform nucleation at the grain boundaries, especially prior nucleation at triple junctions, was captured and analyzed. The final grain size distribution, microstructural evolution and DRX fraction were well quantitatively predicted with the developed model at various temperatures and different initial grain sizes.

4) Additional simulations were performed to further demonstrate the capabilities of the established model. It is found that the simulation presents a good agreement with the experimental results over a wide range of temperature and strain rate combinations. Therefore, the simulation results can also provide a theoretical reference for the control of the microstructure and properties of V-10Cr-5Ti alloy during hot deformation.

References

[1] ZHOU Guo-wei, LI Zi-han, LI Da-yong, PENG Ying-hong, ZUROB H S, WU Pei-dong. A polycrystal plasticity based discontinuous dynamic recrystallization simulation method and its application to copper [J]. International Journal of Plasticity, 2017, 91: 48-76.

[2] CHEN Ming-song, LIN Y C, LI Kuo-kuo, ZHOU Ying. A new method to establish dynamic recrystallization kinetics model of a typical solution-treated Ni-based superalloy [J]. Computational Materials Science, 2016, 122: 150-158.

[3] ZHANG Tao, LU Shi-hong, WU Yun-xin, GONG Hai. Optimization of deformation parameters of dynamic recrystallization for 7055 aluminum alloy by cellular automaton [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(6): 1327-1337.

[4] LIU Yan-xing, LIN Y C, ZHOU Ying. 2D cellular automaton simulation of hot deformation behavior in a Ni-based superalloy under varying thermal-mechanical conditions [J]. Materials Science and Engineering A, 2017, 691: 88-99.

[5] LIN Y C, HE Dao-guang, CHEN Ming-song, CHEN Xiao-min, ZHAO Chun-yang, MA Xiang, LONG Zhi-li. EBSD analysis of evolution of dynamic recrystallization grains and δ phase in a nickel-based superalloy during hot compressive deformation [J]. Materials & Design, 2017, 97: 13-24.

[6] GOETZ R L, SEETHARAMAN V. Modeling dynamic recrystallization using cellular automata[J]. Scripta Materials, 1998, 38: 405-413.

[7] DING R, GUO Z X. Coupled quantitative simulation of microstructural evolution and plastic flow during dynamic recrystallization [J]. Acta Materialia, 2001, 49: 3163-3175.

[8] KUGLER G, TURK R. Modeling the dynamic recrystallization under multi-stage hot deformation [J]. Acta Materials, 2004, 52: 4659-4668.

[9] LI Hong-wei, SUN Xin-xin, YANG He. A three-dimensional cellular automata-crystal plasticity finite element model for predicting the multiscale interaction among heterogeneous deformation, DRX microstructural evolution and mechanical responses in titanium alloys [J]. International Journal of Plasticity, 2016, 87: 154-180.

[10] MUROGA T, NAGASAKA T, ABE K, CHERNOV V M, MATSUI M, SMITH D L, XU D L, ZINKLLE S J. Vanadium alloys—Overview and recent results [J]. Journal of Nuclear Materials, 2002, 307-311: 547-554.

[11] GHOSH C, BASU J, RAMACHANDRAN D, MOHANDAS E. Alloy design and microstructural evolution in V-Ti-Cr alloys [J]. Materials Characterization, 2015, 106: 292-301.

[12] KURTZ R J, ABE K, CHERNOV V M, HOELZER D T, MATSUI H, MUROGA T, ODETTE G R. Recent progress on development of vanadium alloys for fusion [J]. Journal of Nuclear Materials, 2004, 329-333: 47-55.

[13] DONAHUE E G, ODETTE G R, LUCAS G E. A physically based constitutive model for a V-4Cr-4Ti alloy [J]. Journal of Nuclear Materials, 2000, 283-587: 637-641.

[14] CAI C M, ZHANG J T, NIU L S, SHI H J. Strain-rate sensitivity and fracture mode of V-5Cr-5Ti alloy [J]. Scripta Materials, 2010, 62: 524-527.

[15] LI Yu-fei, WANG Zhen-hong, ZHANG Lin-ying, LUO Chao, LAI Xin-chun. Arrhenius-type constitutive model and dynamic recrystallization behavior of V-5Cr-5Ti alloy during hot compression [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(6): 1889-1900.

[16] LI Yu-fei, WANG Zhen-hong, ZHOU Yun-hong, LUO Chao, LAI Xin-chun. Thermal activation parameters of V-5Cr-5Ti alloy under hot compression [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(8): 2564-2570.

[17] Alireza H, Maryam M, Seyed M, Hasan B. Constitutive modeling for high-temperature flow behavior of Ti-6242S alloy [J]. Materials Science and Engineering A, 2017, 681: 103-113.

[18] XU Zhao-hua, LI Miao-quan, LI Hong. Plastic flow behavior of superalloy GH696 during hot deformation [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(3): 712-721.

[19] Zhi Ying, Liu Xiang-hua, Yu Hai-liang. Cellular automaton simulation of hot deformation of TRIP steel [J]. Computational Materials Science, 2014, 81: 104-112.

[20] Ning Y Q, Wang T, Fu M W, Li M Z, Wang L, Zhao C D. Competition between work hardening effect and dynamic-softening behavior for processing as-cast GH4720Li superalloys with original dendrite microstructure during moderate-speed hot compression [J]. Materials Science and Engineering A 2015, 642: 187-193.

[21] Takaki T, Yoshimoto C, Yamanaka A, Tomita Y. Multiscale modeling of hot-working with dynamic recrystallization by coupling microstructure evolution and macroscopic mechanical behavior [J]. International Journal of Plasticity, 2014, 52: 105-116.

[22] Zhang Chi, Zhang Li-wen, Xu Qian-hong, Xia Ying-nan, Shen Wen-fei. The kinetics and cellular automaton modeling of dynamic recrystallization behavior of a medium carbon Cr-Ni-Mo alloyed steel in hot working process [J]. Materials Science and Engineering A, 2016, 678: 33-43.

[23] TAKWBAYASHI T K S, YOSHINAGA N, USHIODA K, OGATA S. Comparison of the dislocation density in martensite steels evaluated by some X-ray diffraction methods [J]. ISIJ International, 2010, 50, 875-882.

[24] Liu Yan-xing, Lin Y C, Li Hong-bin, Wen Dong-xu, Chen Xiao-min, Chen Ming-song. Study of dynamic recrystallization in a Ni-based superalloy by experiments and cellular automaton model [J]. Materials Science and Engineering A, 2015, 626: 432-440.

[25] Jin Zhao-yang, Cui Zhen-shan. Investigation on dynamic recrystallization using a modified cellular automaton [J]. Computational Materials Science, 2012,63: 249-255.

[26] Hallberg H, Wallin M, Ristinmaa M. Simulation of discontinuous dynamic recrystallization in pure Cu using a probabilistic cellular automaton [J]. Computational Materials Science, 2010, 49: 25-34.

[27] Wan Z P, Sun Y, Hu L X, Yu Huan. Experimental study and numerical simulation of dynamic recrystallization behavior of TiAl-based alloy [J]. Materials Design, 2017, 122: 11-20.

[28] Zhang Yan-qiu, Jiang Shu-yong, Liang Yu-long, Hu Li. Simulation of dynamic recrystallization of NiTi shape memory alloy during hot compression deformation based on cellular automaton [J]. Computational Materials Science, 2013, 71: 124-134.

[29] Popova E, Staraselski Y, Brahme A, Mishra R K, Inal K. Coupled crystal plasticity-Probabilistic cellular automata approach to model dynamic recrystallization in magnesium alloys [J]. International Journal of Plasticity, 2015, 66: 85-102.

曹倬菡1,孙 宇1,周 琛1,万志鹏1,杨文华2,任丽丽3,胡连喜1

1. 哈尔滨工业大学 金属精密加工国家级重点实验室,哈尔滨 150001;

2. 中国工程物理研究院 机械制造技术研究所,绵阳 621900;

3. 中国核工业集团 第23建设有限公司,北京 101300

摘 要:通过在Gleeble-1500热模拟压缩机上对V-10Cr-5Ti合金进行温度为950~1350 °C、应变速率为0.01~ 10 s-1的热模拟压缩实验,并基于Arrhenius模型、位错密度模型、形核模型和晶粒长大模型,建立一种元胞自动机(CA)模型来模拟和表征动态再结晶过程中的组织演变。结果表明:流动应力对变形速率和变形温度具有强烈的依赖性,利用Arrhenius模型预测的应力值与实际测量值的误差小于8%。CA模型计算得到的初始平均晶粒尺寸为86.25 μm,与试验测量得到的85.63 μm相近。模拟表明:初始晶粒尺寸对动态再结晶组织演化影响并不显著,而提高应变速率或降低变形温度均可细化再结晶晶粒。

关键词:V-10Cr-5Ti合金;热变形;动态再结晶;元胞自动机;显微组织;数值模拟;晶粒细化

(Edited by Xiang-qun LI)

Foundation item: Project (51405110) supported by the National Natural Science Foundation of China; Project (20132302120002) supported by the Specialized Research Fund for the Doctoral Program of Higher Education, China; Project (LBH-Z14096) supported by Heilongjiang Province Postdoctoral Fund, China

Corresponding author: Lian-xi HU; Tel: +86-13613603223; E-mail: hulx@hit.edu.cn

DOI: 10.1016/S1003-6326(18)64919-2