Ti-25V-15Cr-0.2Si阻燃钛合金的动态再结晶行为

来源期刊:中国有色金属学报(英文版)2016年第4期

论文作者:鲁世强 欧阳德来 崔霞 王克鲁

文章页码:1003 - 1010

关键词:阻燃钛合金;变形组织;变形机制;动态再结晶预测模型

Key words:burn resistant titanium alloy; deformed microstructure; deformation mechanism; dynamic recrystallization prediction models

摘 要:对Ti-25V-15Cr-0.2Si阻燃钛合金在温度为950~1100 °C,应变速率为0.001~1 s-1条件下进行热压缩试验,研究了该合金在β相区变形时的动态再结晶行为。结果表明,该合金的热变形机制主要是由动态再结晶支配的,而动态再结晶新晶粒主要是通过弓弯形核机制来形成的。当应变速率降低和变形温度升高时动态再结晶易于发生;当应变速率为0.01~0.1 s-1,变形温度为950~1050 °C时,动态再结晶使晶粒细化;当变形温度高于1100 °C,应变速率低于0.001 s-1时,动态再结晶晶粒粗化。为了确定在不同变形条件下的动态再结晶体积分数和动态再结晶晶粒尺寸,分别建立了该合金动态再结晶动力学和动态再结晶晶粒尺寸预测模型。

Abstract: Dynamic recrystallization (DRX) behavior in β phase region for the burn resistant titanium alloy Ti-25V-15Cr-0.2Si was investigated with a compression test in the temperature range of 950-1100 °C and the strain rate of 0.001-1 s-1. The results show that deformation mechanism of this alloy in hot deformation is dominated by DRX, and new grains of DRX are evolved by bulging nucleation mechanism as a predominant mechanism. DRX occurs more easily with the decrease of strain rate and the increase of deformation temperature. Grain refinement is achieved due to DRX during the hot deformation at strain rate range of 0.01-0.1 s-1 and temperature range of 950-1050 °C. DRX grain coarsening is observed for the alloy deformed at the higher temperatures of 1100 °C and the lower strain rates of 0.001 s-1. Finally, in order to determine the recrystallized fraction and DRX grain size under different deformation conditions, the prediction models of recrystallization kinetics and recrystallized grain sizes were established.

Trans. Nonferrous Met. Soc. China 26(2016) 1003-1010

Shi-qiang LU1, De-lai OUYANG2, Xia CUI2, Ke-lu WANG1

1. School of Aeronautical Manufacturing Engineering, Nanchang Hangkong University, Nanchang 330063, China;

2. School of Materials Science and Engineering, Nanchang Hangkong University, Nanchang 330063, China

Received 14 April 2015; accepted 12 October 2015

Abstract: Dynamic recrystallization (DRX) behavior in β phase region for the burn resistant titanium alloy Ti-25V-15Cr-0.2Si was investigated with a compression test in the temperature range of 950-1100 °C and the strain rate of 0.001-1 s-1. The results show that deformation mechanism of this alloy in hot deformation is dominated by DRX, and new grains of DRX are evolved by bulging nucleation mechanism as a predominant mechanism. DRX occurs more easily with the decrease of strain rate and the increase of deformation temperature. Grain refinement is achieved due to DRX during the hot deformation at strain rate range of 0.01-0.1 s-1 and temperature range of 950-1050 °C. DRX grain coarsening is observed for the alloy deformed at the higher temperatures of 1100 °C and the lower strain rates of 0.001 s-1. Finally, in order to determine the recrystallized fraction and DRX grain size under different deformation conditions, the prediction models of recrystallization kinetics and recrystallized grain sizes were established.

Key words: burn resistant titanium alloy; deformed microstructure; deformation mechanism; dynamic recrystallization prediction models

1 Introduction

Ti-25V-15Cr-0.2Si alloy, as a highly-β stabilised titanium alloy (Ti-alloy) developed by Northwest Institute for Nonferrous Metal Research of China in 1996, has extensive application prospects to an aerospace area due to their excellent combination of better burn resistance and application properties compared with other burn resistant Ti-alloys such as Ti-Nb series and Ti-Al-Cu series [1,2]. Unfortunately, its poor workability make it fairly difficult to control its hot working process [3], which limits the application of the alloy. Therefore, it is necessary and significative to improve the ductility performance of the alloy so that the poor workability of the alloy can be overcome in hot working.

Recently, it has been extensively accepted that dynamic recrystallization is a powerful mechanism for grain refinement in hot working process of alloys and plays an important role in improving the ductility performance of materials, such as steels [4,5], magnesium alloys [6-8], and titanium alloys [9-11]. DRX has been observed in Ti-25V-15Cr-0.2Si alloy during hot working by some researchers. SUN et al [12] researched the hot deformation behavior of Ti-25V- 15Cr-0.2Si alloy by processing map technology and microstructure observation, and reported that DRX occurred at temperature of 1050-1100 °C and strain rate of 0.01-0.1 s-1. ZHAO et al [13] proposed subgrain rotating and grain boundary bulging as the predominant nucleation mechanism for DRX of Ti-25V-15Cr-0.2Si alloy. The deformation activation energy of Ti-25V- 15Cr-0.2Si alloy deformed at temperature of 950-1000 °C was calculated to be 276.7 kJ/mol by ZHAO et al [14]. They also suggested that DRX was an important deformation mechanism during the current high- temperature deformation conditions. ZHANG et al [15] studied the coarse grain superplastic deformation of Ti-25V-15Cr-0.2Si alloy and suggested that the superplastic behavior of large-grained Ti-25V- 15Cr-0.2Si alloy could be explained by DRX and dynamic recovery (DRV). However, little research work was focused on DRX behavior of Ti-25V-15Cr-0.2Si alloy, such as DRX kinetics and evolution of microstructure associated with DRX in hot working.

The present work aims to investigate DRX behavior of burn resistant titanium alloy Ti-25V-15Cr-0.2Si under hot working with the help of hot compression tests on the Thermecmaster-Z hot simulator. The effects of deformation parameters on DRX evolution have been investigated. Deformation mechanism and DRX mechanism have been discussed, and the prediction models of DRX have been developed.

2 Experimental

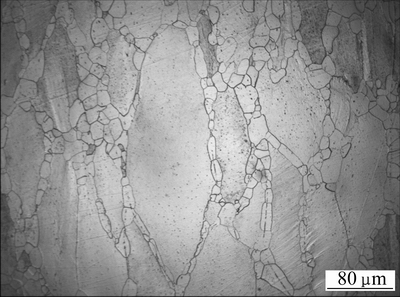

The as-received Ti alloy is the ingot forged above β-transus temperature, which consists of a single β phase (Fig. 1). It has the nominal chemical composition of Ti-25V-15Cr-0.2Si. The cylindrical specimens with the diameter of 8 mm and the height of 12 mm were machined with flat bottomed grooves on both end surfaces of the specimens for holding the lubricant in such a way to reduce the friction between die and specimen. The hot compression tests were conducted in the temperature range of 950-1100 °C, the strain rate range of 0.001-1.0 s-1 and the high reduction range of 10%-60% on a Thermecmaster-Z hot simulator. Specimens were heated to corresponding test temperatures at the rate of 5 °C/s and kept for 300 s before hot compression in order to obtain a uniform deformation temperature. After hot compression, the specimens were cooled in the air, followed by the sectioning along the longitudinal axis direction. The sectioned samples were finally prepared according to the standard metallographic procedure for microstructure examination by optical microscopy.

Fig. 1 Original microstructure of Ti-25V-15Cr-0.2Si alloy in as-received condition

3 Results and discussion

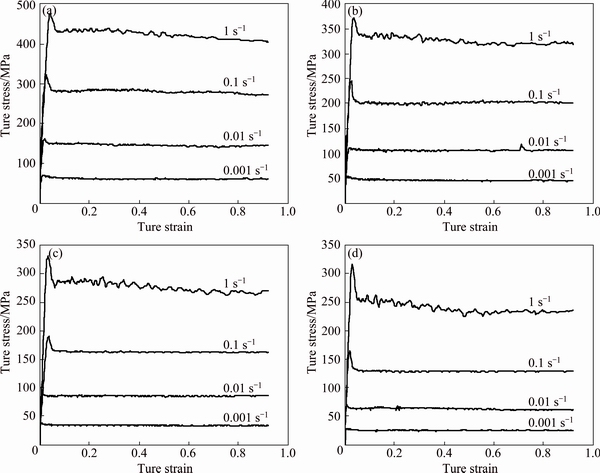

3.1 Flow stress behavior

Typical stress-strain curves of the alloy during the isothermal compression at different temperatures and strain rates are shown in Fig. 2. Generally, the shape of stress-strain curves of materials articulates the intrinsic relationship of flow stress with thermodynamic behavior, which helps in identifying the mechanism of hot deformation. As can be seen from Fig. 2, the stress-strain curves present the characteristics that the flow stress increases sharply to a maximum and decreases gradually to a steady-state with further straining. This suggests that the mechanism of work hardening is balanced by the softening process which may be associated with DRX or DRV in hot deformation.

3.2 Activation energy

The constitutive relationship between flow stress, temperature, and strain rate during hot working at a given strain can be described by an equation known as the Arrhenius-type relation as follows [16]:

(1)

(1)

where A1, α and n are material dependent constants, Q is the deformation activation energy (J/mol), R is the gas constant of 8.314 J/(mol·K), σp is the peak stress,  is the strain rate (s-1), T is the temperature (K).

is the strain rate (s-1), T is the temperature (K).

When ασp<0.8, Eq. (1) can be simplified as

(2)

(2)

When ασp>1.2, Eq. (1) can be simplified as

(3)

(3)

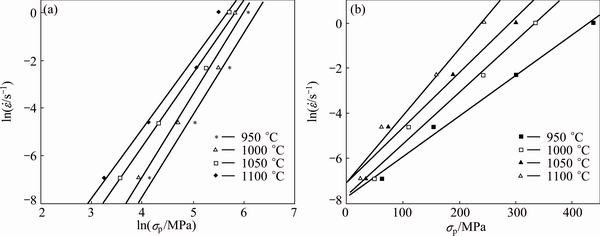

where A2, A3 and β are material dependent constants, and α=β/n. According to the peak stress of the stress-strain curves, the relationship curves of  and lnσp , and the relationship curves of

and lnσp , and the relationship curves of  and σp are determined, as shown in Fig. 3. The values of n and β are equal to the mean linear slope of 3.231 and 0.02375 in Figs. 3(a) and (b), respectively, and the value of α can thus be obtained to be 0.00735.

and σp are determined, as shown in Fig. 3. The values of n and β are equal to the mean linear slope of 3.231 and 0.02375 in Figs. 3(a) and (b), respectively, and the value of α can thus be obtained to be 0.00735.

Taking natural logarithms then partial derivative on both sides of Eq. (1), we have

(4)

(4)

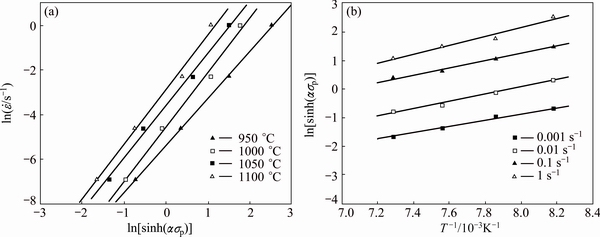

According to the relationship of ln -ln[sinh(ασp)] and ln[sinh(ασp)]-1/T shown in Fig. 4, the mean values of the linear slopes are taken as the values of

-ln[sinh(ασp)] and ln[sinh(ασp)]-1/T shown in Fig. 4, the mean values of the linear slopes are taken as the values of  and

and  which are found to be 12803 and 2.317, respectively. According to Eq. (4), the value of Q is thus found to be 246.7 kJ/mol.

which are found to be 12803 and 2.317, respectively. According to Eq. (4), the value of Q is thus found to be 246.7 kJ/mol.

The deformation activation energy is an important physical parameter applied in understanding of DRX difficulty degree during hot working. The occurrence of DRX in Ti-alloys is expected when its deformation activation energy outclasses self-diffusion activation energy [17]. Conversely, the occurrence of DRV is expected. In the present investigation, the deformation activation energy of Ti-25V-15Cr-0.2Si alloy in the β phase field is 246.7 kJ/mol, which is much higher than the self-diffusion activation energy of 153 kJ/mol [18]. This indicates that the deformation mechanism of this alloy is dominated by DRX.

Fig. 2 Typical flow stress-strain curves of Ti-25V-15Cr-0.2Si alloy deformed at 950 °C (a), 1000 °C (b), 1050 °C (c) and 1100 °C (d)

Fig. 3 Relationship between ln -lnσp (a) and ln

-lnσp (a) and ln -σp (b)

-σp (b)

3.3 Evolution of microstructure

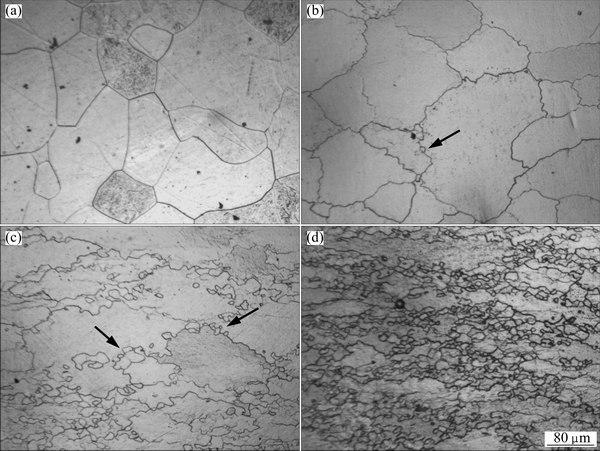

Optical microstructures of the alloy compressed at the temperature of 1100 °C and the strain rate of 0.01 s-1 with various strains are given in Fig. 5. Observation reveals the occurrence of DRX in the alloy deformed in β phase field, which results in prior β grains refinement. The initial microstructure of the alloy consists of equiaxial β grains with the grain size of about 150 μm.

As the strain is increased to 0.11, the grain boundaries extensively become serrated and bulging, along which a few small dynamically recrystallized grains can be seen (denoted by the arrow in Fig. 5(b)). This suggests that bulging could be a DRX mechanism of the alloy during hot working. As the strain is further increased to 0.51, many DRX grains along the original grain boundaries are observed, and a “necklace” structure is formed (denoted by the arrow in Fig. 5(c)). It is noted that the microstructures have no significant grain refinement due to the very small recrystallized fraction. With the increase of straining to 0.92, DRX grains become dominative, resulting in a recrystallized fraction of about 90% and a remarkable grain refinement compared with the initial microstructure.

Fig. 4 Relationship between ln -ln(sinh(ασp)) (a) and ln(sinh(ασp))-1/T (b)

-ln(sinh(ασp)) (a) and ln(sinh(ασp))-1/T (b)

Fig. 5 Optical microstructures of specimens hot compressed at 1100 °C, 0.01 s-1 and strain of 0 (a), 0.11 (b), 0.51 (c), 0.92 (d)

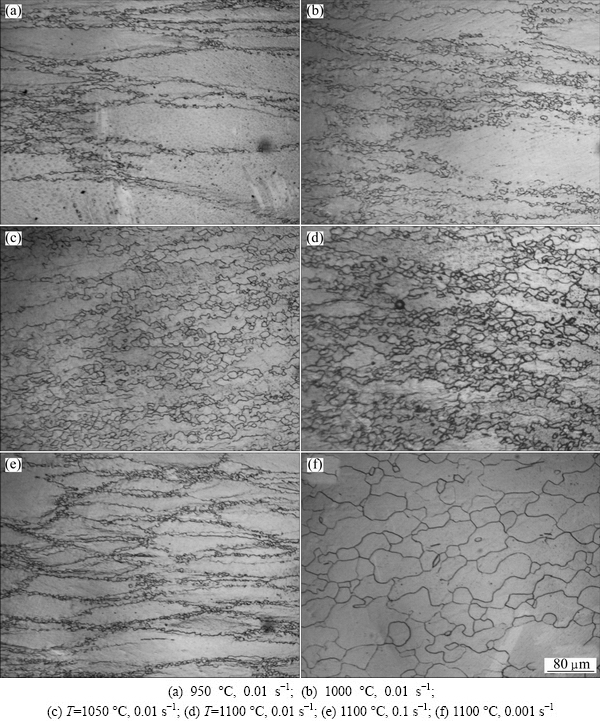

The influence of the deformation temperature and the strain rate at a strain of 0.92 on the microstructure associated with DRX is illustrated in Fig. 6. The obvious microstructure changes of the alloy deformed in different deformation conditions are observed. At the deformation temperature of 950 °C, the initial grain becomes elongated and the fine equiaxed DRX grains appear near the initial grain bourdaries (as shown in Fig. 6(a)). It has no significant grain refinement of the alloy due to the small fraction of recrystallized grains. At the deformation temperature of 1000 °C and 1050 °C, more DRX grains occur (as shown in Figs. 6(b) and (c)). When the deformation temperature is 1100 °C, the microstructure shows apparent DRX with the recrystallized fraction of about 90%, leading to grain refinement compared with the initial microstructure (as shown in Fig. 6(d)). With the increase of strain rate, the percentage of DRX and the size of the DRX grains decrease. It is worth noting that no significantly grain refinement of the alloy deformed at strain rate of higher than 0.1 s-1 or lower than 0.001 s-1 happens (as shown in Figs. 6(e) and (f)), the reason of which lies in small fraction of recrystallized grains at strain rate of higher than 0.1 s-1 and coarsened DRX grains predominantly at lower than 0.001 s-1.

Fig. 6 Optical micrographs of specimens hot compressed with strain of 0.92

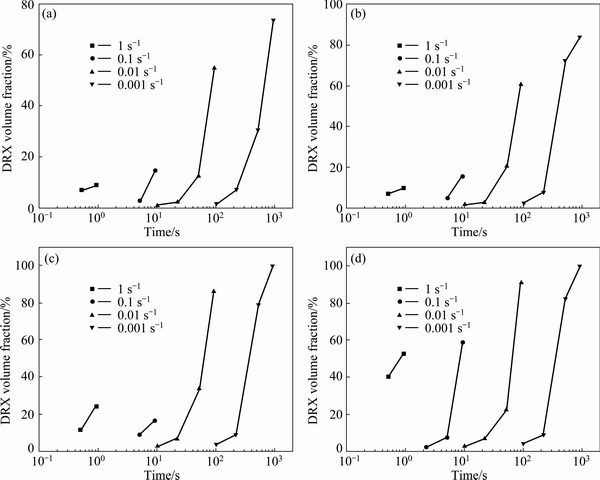

Fig. 7 Dependence of dynamic recrystallization fraction on deformation time at temperature of 950 °C (a), 1000 °C (b), 1050 °C (c) and 1100 °C (d)

3.4 Dynamic recrystallization kinetics

The relationship between DRX fraction and straining time of the alloy deformed in the temperature range of 950-1100 °C and the strain rate range of 0.001-1 s-1, plotted as a DRX kinetics, is presented in Fig. 7. It can be seen that the DRX kinetic curves are characterized by S-shape, in which the fraction of DRX slowly increases firstly, then rapidly increases and slowly increases finally again with the increase of strain. In addition, with the increase of deformation temperature and the decrease of strain rate, DRX fraction increases. In general, the recrystallized fraction is used to fit an Avrami-type sigmoidal curve as follows [19,20]:

(5)

(5)

where XDRX is the recrystallized fraction, ε is the strain, εc is the critical strain in which DRX occurs, K and nd are constants, ε0.5 is the strain for 50% of recrystallization, which can be expressed by

(6)

(6)

where B1, B2 and Q1 are constants. According to the value of ε0.5 determined from DRX kinetic curves shown in Fig.7, the values of B1, B2 and Q1 in Eq. (6) can be determined by regression analysis to be 7.14, 0.4991 and 4229.7, respectively, and Eq. (6) can therefore be written as

(7)

(7)

Taking natural logarithms on both sides of Eq. (5), we have

(8)

(8)

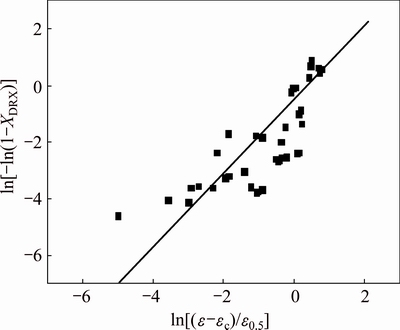

According to the relationship of ln[-ln(1-XDRX)] and  shown in Fig. 8, the values of nd and ln k are equal to linear slope of 1.193 and linear intercept of -0.4108, respectively.

shown in Fig. 8, the values of nd and ln k are equal to linear slope of 1.193 and linear intercept of -0.4108, respectively.

Fig. 8 Relationship between ln[-ln(1-XDRX)] and ln[(ε-εc)/ε0.5] for Ti-25V-15Cr-0.2Si alloy

As a result, the following equation for the

recrystallized fraction is obtained as

(9)

(9)

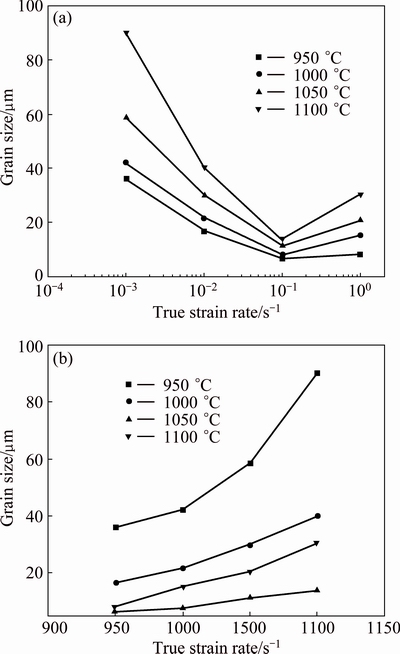

3.5 Dynamic recrystallization grain size

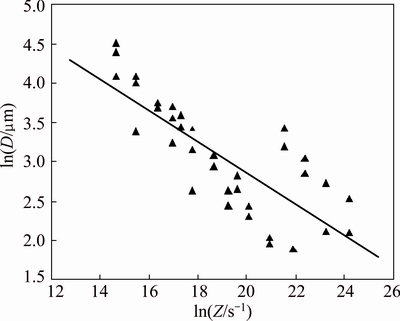

The variation of dynamically recrystallized grain size as a function of the strain rate and the deformation temperature is shown in Fig. 9. It can be seen that dynamically recrystallized grain size clearly decreases with increasing strain rate and decreasing deformation temperature. As the strain rate increases and temperature decreases, more small DRX grains are formed, resulting in a reduced grain size. It is worth noting that an incompletely DRX arises at high strain rate or low temperature, in which the fraction of recrystallized grains is very small and no significant grain refinement happens.

Fig. 9 Influence of strain rate (a) and deformation temperature (b) on dynamically recrystallized grain size

The dynamically recrystallized grain size as a function of the Zener-Hollomon parameter Z ( ) is plotted in Fig. 10, which is given by an inverse power law of the form as

) is plotted in Fig. 10, which is given by an inverse power law of the form as

D=AZ-n (10)

where D is the dynamically recrystallized grain size, A is a constant, and n is the power-law exponent. Equation of this form has been used to predict the dynamically recrystallized grain size developed during hot working of materials. According to a linear regression between ln D and ln Z, the values of A and n are determined in the present work to be 9.23×102 and 0.198, respectively, and thus the prediction equation of the dynamically recrystallized grain size for the alloy can be written as D=9.23×102Z-0.198.

Fig. 10 Influence of Z-parameter on dynamically recrystallized grain size

4 Conclusions

1) Deformation mechanism is dominated by DRX with the bulging mechanism as a predominant mechanism during hot working of the alloy.

2) The activation energy is calculated to be 246.7 kJ/mol which is much higher than self-diffusion energy. This may be responsible for the occurrence of dynamic recrystallization.

3) Grain refinement by DRX occurs in the strain rate range of 0.1-0.01 s-1 and the temperature range of 950-1050 °C, and coarse grain via DRX happens at the higher temperatures of 1100 °C and the lower strain rates of 0.001 s-1 during the hot deformation of the alloy.

4) The recrystallized fraction increases with increasing of deformation temperature and decreasing of strain rate. The relationship between recrystallized fraction and deformation conditions can be described by  .

.

5) The dynamically recrystallized grain size increases with decreasing of the Zener-Hollomon parameter Z. The prediction equation of the dynamically recrystallized grain size for the alloy can be written as D=9.23×102Z-0.198.

References

[1] ZONG Y Y, SHAN D B, LUO Y S. Precipitation behavior and microstructural characteristics of hydrogenated β-Ti40 alloys [J]. International Journal of Hydrogen Energy, 2009, 34(11): 4900-4905.

[2] ZONG Ying-ying, HUANG Shu-hui, WANG Yao-qi, SHAN De-Bin. Strengthening versus softening mechanisms by hydrogen addition in β-Ti40 alloy [J]. International Journal of Hydrogen Energy, 2014, 39(7): 3498-3504.

[3] ZHU Yan-chun, ZENG Wei-dong, ZHAO Yong-qing, SHU Ying, ZHANG Xue-min. Effect of processing parameters on hot deformation behavior and microstructural evolution during hot compression of Ti40 titanium alloy [J]. Materials Science and Engineering A, 2012, 552: 384-391.

[4] GUO Liang-gang, DONG Ke-ke, ZHANG Bao-jun, YANG He, ZHENG Wen-da, LIU Xiong-wei. Dynamic recrystallization rules in needle piercing extrusion for AISI304 stainless steel pipe [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S2): s519-s527.

[5] LIU J, KAWALLA R. Influence of asymmetric hot rolling on microstructure and rolling force with austenitic steel [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S2): s504-s511.

[6] HE Yun-bin, PAN Qing-lin, CHEN Qin, ZHANG Zhi-ye, LIU Xiao-yan, LI Wen-bin. Modeling of strain hardening and dynamic recrystallization of ZK60 magnesium alloy during hot deformation [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(2): 246-254.

[7] XU Yan, HU Lian-xi, SUN Yu. Dynamic recrystallization kinetics of as-cast AZ91D alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1683-1689.

[8] WU Hong-yu, YANG Jie-chen, LIAO Jing-hao, ZHU Feng-jun. Dynamic behavior of extruded AZ61 Mg alloy during hot compression [J]. Materials Science and Engineering A, 2012, 535: 68-75.

[9] WU Chuan, YANG He, LI Hong-wei. Simulated and experimental investigation on discontinuous dynamic recrystallization of a near-α TA15 titanium alloy during isothermal hot compression in β single-phase field [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1819-1829.

[10] OUYANG De-lai, WANG Ke-lu, CUI Xia. Dynamic recrystallization of Ti-6Al-2Zr-1Mo-1V in β forging process [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(4): 761-767.

[11] WANG Guo, HUI Song-xiao, YE Wen-jun, MI Xu-jun. Hot compressive behavior of Ti-3.0Al-3.7Cr-2.0Fe-0.1B titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(12): 2965-2971.

[12] SUN Y, ZENG W D, ZHAO Y Q, ZHANG X M, SHU Y, ZHOU Y G. Research on the hot deformation behavior of Ti40 alloy using processing map [J]. Materials Science and Engineering A, 2011, 528(3): 1205-1211.

[13] ZHAO Yong-qing, SHU Ying, ZENG Wei-dong, WU Wei-lu, WU Huan, ZHOU Yi-gang, YANG Hai-ying, LI Qian. Dynamic recrystallization behavior of highly stabilized β Ti40 titanium alloy [J]. Rare Metal Materials and Engineering, 2009, 38(8): 1432-1436. (in Chinese)

[14] ZHAO Y Q, ZHOU L, DENG J. High temperature deformation mechanism of Ti-40 burn resistant titanium alloy as-annealing [J]. Rare Metals, 1999, 18(3): 203-208.

[15] ZHANG Xue-min, ZHAO Yong-qing, ZENG Wei-dong, LIN Wei. Superplastic deformation behavior and mechanism of burn-resistant Ti40 alloy with large grains [J]. Rare Metal Materials and Engineering, 2010, 39(3): 433-436. ( in Chinese)

[16] McQUEEN H J, RYAN N D. Constitutive analysis in hot working [J]. Materials Science and Engineering A, 2002, 322(1-2): 43-63.

[17] XU W C, SHAN D B, LI C F. Study on the dynamic hot compression behavior and deform ation M echanism of TA15 titanium alloy [J]. Journal of Aeronautical Materials, 2005, 25(4): 10-15. (in Chinese)

[18] ROBERTSON D G, MCSHANE H B. Analysis of high temperature flow stress of titanium alloys IMI 550 and Ti-10V-2Fe-3Al during isothermal forging [J]. Materials Science and Technology, 1998, 14(4): 339-345.

[19] SERAJZADEH S. Prediction of dynamic recrystallization kinetics during hot rolling [J]. Modelling and Simulation in Materials Science and Engineering, 2004, 12(6): 1185-1200.

[20] XU Yan, HU Lian-xi, SUN Yu. Dynamic recrystallization kinetics of as-cast AZ91D alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1683-1689.

鲁世强1,欧阳德来2,崔 霞2,王克鲁1

1. 南昌航空大学 航空制造与工程学院,南昌 330063;

2. 南昌航空大学 材料科学与工程学院,南昌 330063

摘 要:对Ti-25V-15Cr-0.2Si阻燃钛合金在温度为950~1100 °C,应变速率为0.001~1 s-1条件下进行热压缩试验,研究了该合金在β相区变形时的动态再结晶行为。结果表明,该合金的热变形机制主要是由动态再结晶支配的,而动态再结晶新晶粒主要是通过弓弯形核机制来形成的。当应变速率降低和变形温度升高时动态再结晶易于发生;当应变速率为0.01~0.1 s-1,变形温度为950~1050 °C时,动态再结晶使晶粒细化;当变形温度高于1100 °C,应变速率低于0.001 s-1时,动态再结晶晶粒粗化。为了确定在不同变形条件下的动态再结晶体积分数和动态再结晶晶粒尺寸,分别建立了该合金动态再结晶动力学和动态再结晶晶粒尺寸预测模型。

关键词:阻燃钛合金;变形组织;变形机制;动态再结晶预测模型

(Edited by Yun-bin HE)

Foundation item: Projects (51261020, 51164030) supported by the National Natural Science Foundation of China; Project (GF201401007) supported by the Open Fund of National Defense Key Disciplines Laboratory of Light Alloy Processing Science and Technology, China

Corresponding author: Shi-qiang LU; Tel/Fax: +86-791-83863039; E-mail: niatlusq@126.com

DOI: 10.1016/S1003-6326(16)64197-3