DOI: 10.11817/j.ysxb.1004.0609.2020-37587

6082铝合金热变形过程中的动态再结晶行为

徐振宇1, 3,胡道春2, 4

(1. 金华职业技术学院 机电工程学院,金华 321007;

2. 南京工业职业技术学院 工程技术实训中心,南京 210023;

3. 金华职业技术学院 汪卫华院士专家工作站,金华 321007;

4. 江苏省精密制造工程技术研究开发中心,南京 210023)

摘 要:借助电子背散射衍射(EBSD)和透射电子显微镜(TEM)研究6082铝合金在623~773 K和0.01~5 s-1条件等温热压缩时的动态再结晶行为。结果表明:6082铝合金真应力-应变曲线虽无明显单峰值特征,但仍发生动态再结晶,并且动态再结晶程度与Z参数紧密相关。在ln Z=24.9014(723 K, 0.1 s-1)热压缩时,动态再结晶体积分数最高,为38.6%。应用加工硬化率确定了动态再结晶初始临界应变,建立临界应变与Z参数之间的定量关系,得到动态再结晶临界应变方程。结合EBSD分析测试结果建立6082铝合金动态再结晶动力学模型。微观组织分析发现,原始晶粒内形成的亚晶结构随着变形的进行持续吸收位错,其取向差不断增大至大角度晶界,从而形成新的再结晶晶粒。在原始晶界附近通过亚晶界迁移引起亚晶粗化,使其小角度晶界形成大角度晶界的连续动态再结晶是其动态再结晶的主要机制。

关键词:6082铝合金;动态再结晶模型;Zener-Hollomon参数;连续动态再结晶

文章编号:1004-0609(2020)-06-1230-08 中图分类号:TG146.2 文献标志码:A

Al-Mg-Si系变形铝合金具有优异的比强度、可加工性和耐腐蚀性等综合性能,广泛应用于航空航天、汽车工业等领域,对实现结构轻量化具有重要意义。但是,由于Mg2Si相和过剩Si相的宏观偏析,导致Al-Mg-Si系变形铝合金铸态下晶粒偏大且相分布极不均匀,力学性能难以满足实际服役要求[1-2]。因此,Al-Mg-Si系变形铝合金需要借助热变形工艺优化来改善材料的第二相分布和宏观偏析,以获得均匀且细小晶粒尺寸的微观组织,从而显著提升材料的综合力学性能。

6082铝合金是一种新型的Al-Mg-Si系变形铝合金,热处理后可获得较高的强度。许多学者对6082铝合金热处理工艺及热变形条件对力学性能、微观组织的影响规律进行了研究。刘胜胆等[3]研究结果表明,6082铝合金强度随着固溶温度的升高表现出先升高后下降的趋势,且在520~540 ℃时达到最高值,而伸长率呈现不断升高的趋势。刘维坊[4]通过对固溶处理后的6082铝合金等温压缩试验,发现材料的平均晶粒尺寸随着应变速率的增大而逐渐增大;而随着变形温度的升高,平均晶粒尺寸逐渐减小且混晶现象逐渐消升;同时,变形温度较低时,晶粒尺寸随着变形量的增加呈现出先增大后减小的趋势,但在较高温度时,晶粒尺寸基本不受变形量的影响。KUMAR等[5]研究了变形温度对6082铝合金沉淀相析出、组织演变、力学性能和腐蚀性能的影响规律,分析得出在较高温度下6082铝合金更容易发生回复、动态再结晶等组织演变。MA等[6]通过实验分析了工艺参数对AA6082铝合金力学性能的影响,并通过对析出相分布的观测分析,揭示了其强化机理。CHANG等[7]通过快速红外热处理工艺,使得6082铝合金在快速固溶处理过程中产生了较大的临界起始应变,并具有更显著的沉淀强化效应,从而提高了材料的力学性能。CECILIA等[8]基于位错密度模型描述了6082铝合金在热变形过程中的应变硬化、动态回复和静态再结晶过程,也解释了再结晶后晶粒尺寸的演化规律。LI等[9]对A6082铝合金静态软化行为进行了间断热模拟试验,研究了A6082铝合金静态再结晶体积分数与静态软化分数的定量关系,建立了该材料的静态再结晶动力学模型。

铝合金热塑成形过程中伴随着微观组织的变化,为使产品具有良好的综合力学性能,人们总是希望材料内部具有细小且均匀的晶粒组织。动态再结晶作为材料组织细化的重要手段之一,一直受到材料成形工艺参数优化及组织预测及控制等研究领域的关注。长期以来人们认为,铝及其合金等高层错能金属在热塑变形过程中主要发生动态回复,极少发生动态再结晶[10-11],也难以通过金相观察到细小的亚晶结构。但是,随着电子显微技术的发展,亚晶的小角度晶界可以通过电子背散射衍射(EBSD)技术所观察到。SAKAI等[12]借助EBSD技术观察到7475铝合金的小角度晶界,即变形后形成的亚晶结构。同时发现,随着变形的继续,亚晶界取向差达到临界值后最终演变为大角度晶界(HAB),从而形成了新的再结晶晶粒。PARVIZIAN等[13]建立了6082铝合金热变形过程中微观组织的动态演化模型,借助EBSD技术测量了6082铝合金热变形后的晶粒和亚晶结构,并基于几何动态再结晶现象揭示了其热变形机制。

本文拟结合等温热模拟试验、透射电子显微镜(TEM)与电子背散射衍射(EBSD)技术研究6082铝合金不同热变形条件下的力学性能及组织演化规律,建立该合金的动态再结晶模型,探讨其动态再结晶机制,为科学制定6082铝合金热成形工艺提供实验数据及理论依据。

1 实验

实验所用材料为台州市百达电器有限公司提供的6082铝合金棒材,其化学成分(质量分数,%)如下:Si 0.95%、Fe 0.18%、Cu 0.06%、Mn 0.45%、Mg 0.65%、Cr 0.12%、Zn 0.005%、Ti 0.03%,其余为Al。将棒材线切割成d 8 mm×12 mm的圆柱体试样,两端加工有深0.2 mm的凹槽,槽内填充润滑剂(75%石墨+20%机油+5%硝酸三甲苯脂(质量分数))以减小摩擦对应力状态的影响。在河南科技大学的Gleeble-1500热模拟实验机上对6082铝合金进行单向热压缩试验,加热速度1 ℃/s,保温时间5 min,总压缩应变量为70%。热压缩变形温度为623、673、723和773 K,应变速率为0.01、0.1、1和5 s-1。每次试验结束后立即将试样进行水淬以固定高温变形组织,便于观察热变形后的显微组织特征。

分别利用EBSD和TEM对变形后的组织进行观测分析,观测位置均为压缩后试样的心部纵剖面。EBSD试样先用水砂纸由粗到细预磨至2000#,再用抛光机进行机械抛光至表面无划痕为止(金刚石抛光剂,粒度为3 μm和0.5 μm),抛光完成后试样经超声波清洗5 min,吹干试样后进行电解抛光,抛光液为90% HClO4+10% C2H6O(体积分数),抛光电压为20 V,电流为0.3 A,温度为-273 ℃。TEM试样经金刚砂纸机械减薄及抛光研磨至100 μm以下,再用冲孔机分离出d 3 mm的透射电镜试样,然后经丙酮清洗后在MTP-Ⅱ型双喷液电解减薄仪上进行双喷电解减薄至300 nm以下,双喷液为10% HClO4+90% CH3OH溶液,工作电压为20 V,电流为0.1 A,温度为-273 ℃。

2 结果与讨论

2.1 真应力-应变曲线

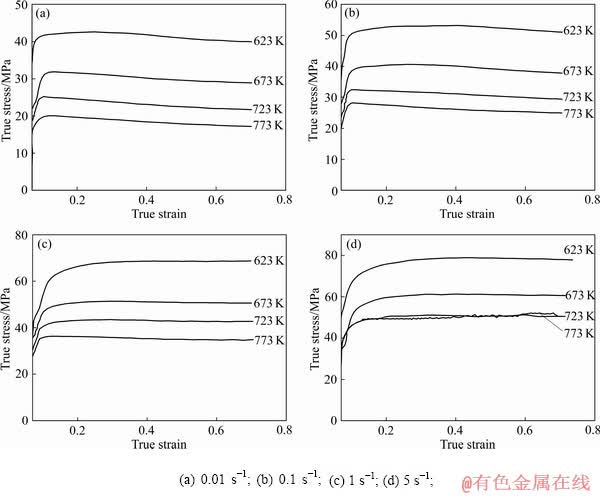

图1所示为6082铝合金在应变速率0.01~5 s-1和变形温度623~773 K条件下的应力-应变曲线。从图1中可以看出,流动应力受变形温度和应变速率的影响较为明显,随着变形温度的升高或应变速率的降低其对应的峰值应力逐渐降低。比较不同应变速率条件下的真应力-应变曲线可以发现,在较低应变速率(见图 1(a)和(b))条件下较小应变(0.1左右)即已进入稳态流动阶段,流动应力随后还略有下降。表明随着应变的不断增加,在较低应变速率下材料的动态软化作用不断增强,超过加工硬化的作用;而在较高应变速率(见图1(c)和(d))应变超过0.3以后才开始进入稳态流动阶段,而进入稳态后应力值基本保持在一个定值,表明此时动态软化与加工硬化之间达到一定的平衡。总之,随着温度的升高或应变速率的降低6082铝合金流动应力逐渐下降直至进入稳态流动阶段,应变硬化的影响逐渐减少而动态软化效应逐渐加强,并可能发生了动态再结晶现象。材料的真应力-应变曲线出现峰值应力后开始降低直至趋于定值,表明热塑性成形过程中发生了动态再结晶[14],但是,很难仅通过流变曲线来判断材料变形到何种程度动态再结晶即将开始发生。

SELLARS等[15]提出一种包含动态再结晶激活能Q和变形温度T的双曲正弦模型,用于描述高温塑性变形过程中流变应力、变形温度以及应变速率等热力学参数之间的定量关系。为了综合考虑应变速率和变形温度对动态再结晶的影响,引入了Zener-Hollomon因子Z参数:

(1)

(1)

式中:Z为Zener-Hollomon参数; 为应变速率(s-1);Q为动态再结晶激活能(试验条件下6082铝合金,Q=163.5337 kJ/mol[16]);R为摩尔气体常数(R=8.3145 J/(mol·K));A、

为应变速率(s-1);Q为动态再结晶激活能(试验条件下6082铝合金,Q=163.5337 kJ/mol[16]);R为摩尔气体常数(R=8.3145 J/(mol·K));A、 、n为材料常数(试验条件下6082铝合金,A=11.9605、

、n为材料常数(试验条件下6082铝合金,A=11.9605、 =0.0234、n=6.4741);

=0.0234、n=6.4741); 为流变应力(MPa)。

为流变应力(MPa)。

图1 6082铝合金在不同应变速率下的真应力-真应变曲线

Fig. 1 True stress-true strain curves of 6082 aluminum alloy hot compression at different strain rates

2.2 6082铝合金动态再结晶模型

如前所述,铝合金高温塑性变形过程中,难以通过金相观察到细小的亚晶结构,其真应力-应变曲线也没有留下显著的动态再结晶特征,故不能直接从流变曲线上判断动态再结晶的临界点。因此,一些关于确定动态再结晶临界条件的方法被相继提出。其中,POLIAK等[17]提出的利用材料加工硬化率(

)作为表征流变应力随应变变化速率的一个变量,可以反映材料内部组织变化的特征,并得到较为准确的动态再结晶临界条件。

)作为表征流变应力随应变变化速率的一个变量,可以反映材料内部组织变化的特征,并得到较为准确的动态再结晶临界条件。

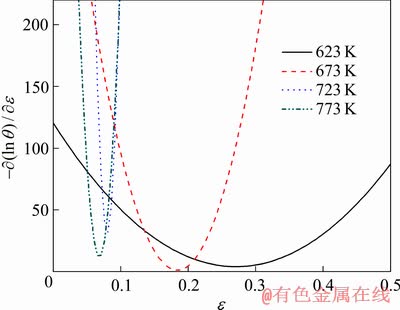

利用Origin软件对图1中各变形条件对应的真应力-应变曲线进行拟合,得到相应条件下的加工硬化

率 ,并做

,并做 关系曲线。图2所示为应变速率0.1 s-1条件下的

关系曲线。图2所示为应变速率0.1 s-1条件下的 关系曲线,可以看出,不同温度下的关系曲线均存在极小点,极小点所对应的应变即可确定为动态再结晶的临界应变。

关系曲线,可以看出,不同温度下的关系曲线均存在极小点,极小点所对应的应变即可确定为动态再结晶的临界应变。

图2 应变速率为0.1 s-1时不同变形温度下的 关系曲线

关系曲线

Fig. 2 Relationship between and

and  with strain rate of 0.1 s-1 at different temperatures

with strain rate of 0.1 s-1 at different temperatures

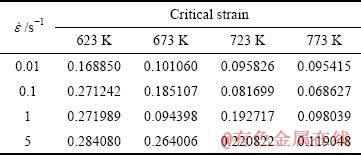

按照上述方法,可以获得不同变形条件下的临界应变,结果如表1所示。

表1 不同变形条件下的临界应变

Table 1 Critical strain under different deformation conditions

从表1数据可以看出,临界应变随着应变速率的增加或温度的降低而增加,表现出正的应变速率敏感性和负的温度敏感性。这是由于在相同变形温度下,应变速率越大,变形时间越短,塑性变形时异号位错来不及相互抵消,导致变形时位错密度越来越高,加工硬化倾向明显,发生动态再结晶的临界应变随之增大;相同应变速率下,随着温度的升高,空位原子扩散及螺型位错滑移、刃型位错攀移的驱动力增大,发生动态再结晶将更加容易,从而使动态再结晶的临界应变量减小[18-19]。

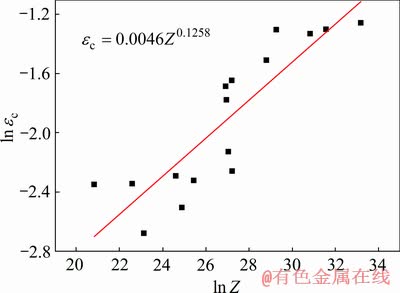

图3 临界应变 与Z参数的关系

与Z参数的关系

Fig. 3 Relationship between Z parameter and critical strain

绘制 曲线如图3所示。可以看出,临界应变随着Z参数的增大而增加。这是因为在材料变形至临界应变时,加工硬化和回复导致位错亚结构的形成,并由缠结位错构成了亚结构边界,而不是清晰的二维网格结构。这些高能态缠结亚晶界能够使局部区域获得足够的储存能,从而导致亚晶界取向差继续增加,直至形成大角度晶界,形成新的动态再结晶。因此,随着应变速率的增加和变形温度的降低,临界应变的增长扩大了移动亚晶界两侧的储能差,能够确保在移动边界处的位错密度破坏初始驱动力之前,使得晶界以足够快的速度移动,促使亚晶粗化,从而实现动态再结晶晶核的长大[20]。利用Origin软件线性拟合得到动态再结晶临界应变

曲线如图3所示。可以看出,临界应变随着Z参数的增大而增加。这是因为在材料变形至临界应变时,加工硬化和回复导致位错亚结构的形成,并由缠结位错构成了亚结构边界,而不是清晰的二维网格结构。这些高能态缠结亚晶界能够使局部区域获得足够的储存能,从而导致亚晶界取向差继续增加,直至形成大角度晶界,形成新的动态再结晶。因此,随着应变速率的增加和变形温度的降低,临界应变的增长扩大了移动亚晶界两侧的储能差,能够确保在移动边界处的位错密度破坏初始驱动力之前,使得晶界以足够快的速度移动,促使亚晶粗化,从而实现动态再结晶晶核的长大[20]。利用Origin软件线性拟合得到动态再结晶临界应变 与Z参数的关系表达式为:

与Z参数的关系表达式为:

(2)

(2)

动态再结晶体积分数与塑性应变之间的关系及晶粒尺寸可分别描述为:

(3)

(3)

(4)

(4)

式中:XDRX是动态再结晶体积分数; 、

、 和

和 分别为高温变形过程中的应变、临界应变和峰值应变;k、m为材料常数;dDRX、d0分别为动态再结晶和原始晶粒尺寸;

分别为高温变形过程中的应变、临界应变和峰值应变;k、m为材料常数;dDRX、d0分别为动态再结晶和原始晶粒尺寸; 、T分别为应变速率和变形温度;Q为动态再结晶激活能;R为摩尔气体常数;a、n1、n2、n3、k、m1为材料常数。

、T分别为应变速率和变形温度;Q为动态再结晶激活能;R为摩尔气体常数;a、n1、n2、n3、k、m1为材料常数。

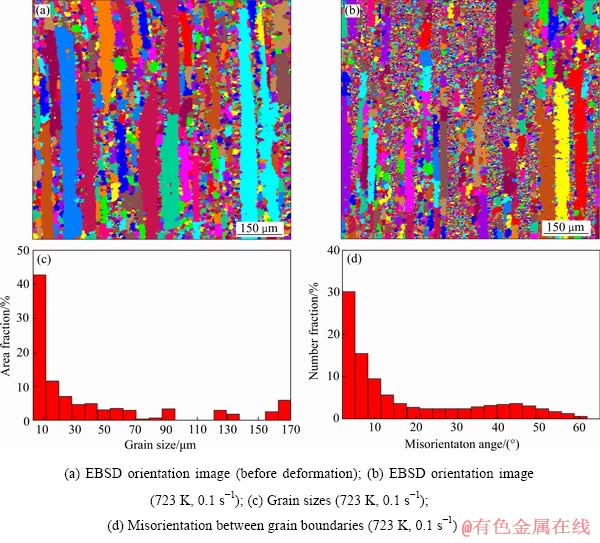

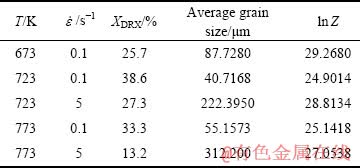

一般情况下,动态再结晶体积分数和晶粒尺寸可通过对热变形的高温组织“冻结”后进行金相组织观察而确定。但是,由于动态再结晶体积分数主要取决于再结晶晶粒的形核速率以及晶粒的长大速率,在高温塑性变形过程中,动态再结晶晶粒有可能被吞并,也有可能进一步长大,以致于组织中难以观察到细小的动态再结晶晶粒,甚至出现大变形后的晶粒尺寸反而比原始未变形晶粒还要大的现象,采用金相法区别动态再结晶晶粒和原始晶粒将变得困难。借助EBSD大面积定量分析的优点,可以获得再结晶晶粒尺寸、取向差大小及其分布等显微组织和晶体学信息。6082铝合金在变形前和变形温度723 K、应变速率0.1 s-1条件下的EBSD取向成像图如图4所示。根据EBSD定量测量的各个晶粒的尺寸大小再求其平均值,以用于定量表征该变形条件下的晶粒尺寸;不同的颜色代表不同的晶粒取向,亚晶界和晶界临界取向差一般可设为3°和15°。利用Channel 5软件中的Recrystallized Fraction Component功能可以获得各晶粒取向差(见图4(b))及各自的含量(见图4(c)),此时,对应的ln Z= 24.9014,XDRX=38.60%。按照同样的方法,可以获得不同条件下的动态再结晶体积分数、平均晶粒大小和ln Z等数据,如表2所列。

将表中数据代入式(3)和式(4),可得到6082铝合金动态再结晶动力学模型如下:

(5)

(5)

(6)

(6)

同时还可以看出,在较低的ln Z值(ln Z=24.9014)时,动态再结晶体积分数较多(XDRX=38.6%),表明较低应变速率、较高变形温度的变形条件(对应较低的Z值)更有利于6082铝合金动态再结晶的发生。

图4 6082铝合金不同条件下的EBSD取向成像图

Fig. 4 OIM of EBSD for 6082 aluminum alloy

表2 不同变形条件下的试验数据

Table 2 Experimental data under different deformation conditions

2.3 6082铝合金动态再结晶软化的微观组织

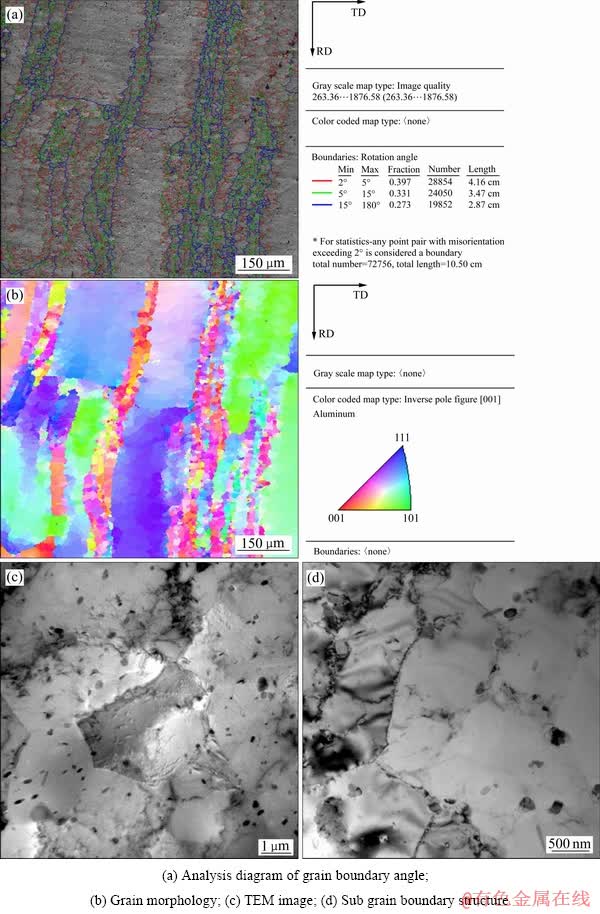

6082铝合金在变形温度723 K、应变速率5 s-1条件下的微观组织如图5所示。图5(a)所示的晶粒角度分析图显示,蓝色线条所代表的晶界具有较大的取向差。同时,晶粒形貌图中可观测到一些细小的新晶粒(见图5(b))。并从对应的TEM像(见图5(c))中发现晶粒内部位错发生了湮灭,位错密度显著降低,表明此时已出现了动态再结晶。

铝合金高温塑性变形过程中,由于其层错能较高,变形时扩展位错宽度窄且极易集束,刃型位错攀移、螺位错交滑移易于在滑移面间转移,使得异号位错相互抵消、湮灭,位错分布形式也将改变并形成封闭的胞壁,将原本完整的晶粒分割成许多低位错密度区域[21]。随着变形的进行,位错胞壁发生多边形化,形成规则的边界以及小角度亚晶(LAB)。从图中明显可见红色线条所代表的小角度晶界(见图5(b)),即变形后形成的亚晶结构(见图5(d))。同时,后续变形中生成的位错会继续移动并在小角度晶界上汇集,从而导致亚晶界的取向差继续增大,当变形量足够大时,亚晶界的取向差达到临界值最终演变为大角度晶界(HAB),从而形成新的再结晶晶粒[22]。这一再结晶过程没有形核-长大的机制参与,是随着变形逐步积累完成,属于连续性动态再结晶的组织演化规律[23]。

图5 6082铝合金动态再结晶软化微观组织

Fig. 5 Microstructure of dynamic recrystallization softening of 6082 aluminum alloy

3 结论

1) 6082铝合金真应力-应变曲线虽无明显单峰值特征,但仍发生了动态再结晶,并且动态再结晶体积分数随着Z参数值降低而增加;在ln Z=24.9014(723 K, 0.1 s-1)热压缩时,动态再结晶体积分数最高,为38.6%。

2) 应用加工硬化率确定了动态再结晶初始临界应变,建立了临界应变与Z参数之间的定量关系,得到动态再结晶临界应变方程: 。结合EBSD分析测试结果获得了6082铝合金动态再结晶体积分数模型和晶粒度模型。

。结合EBSD分析测试结果获得了6082铝合金动态再结晶体积分数模型和晶粒度模型。

3) 在6082铝合金热塑性变形过程中,原始晶界附近产生亚晶,并通过亚晶界迁移引起亚晶粗化,使其小角度晶界形成大角度晶界,出现新的再结晶晶粒,其主要机制为连续性动态再结晶。

REFERENCES

[1] PANAGOPOULOS C N, GEORGIOU E P, GAVRAS A G. Corrosion and wear of 6082 aluminum alloy[J]. Tribology International, 2009, 42(6): 886-889.

[2] 韦 韡, 蒋 鹏, 曹 飞. 6082铝合金的高温本构关系[J]. 塑性工程学报, 2013, 20(2): 100-106.

WEI Wei, JIANG Peng, CAO Fei. Constitutive equations for hot deformation of 6082 aluminum alloy[J]. Journal of Plasticity Engineering, 2013, 20(2): 100-106.

[3] 刘胜胆, 陈小连, 张端正, 邓运来, 张新明. 固溶温度对6082铝合金显微组织与性能的影响[J]. 中国有色金属学报, 2015, 25(3): 582-588.

LIU Sheng-dan, CHEN Xiao-lian, ZHANG Duan-zheng, DENG Yun-lai, ZHANG Xin-ming. Effect of solution heat treatment temperature on microstructure and properties of 6082 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(3): 582-588.

[4] 刘维坊. 锻造工艺参数对6082铝合金组织演变影响规律的研究[D]. 北京: 机械科学研究总院, 2016: 32-42.

LIU Wei-fang. Research on the influence of forging process parameters on microstructure evolution of 6082 aluminum alloy[D]. Beijing: China Academy of Machinery Science & Technology, 2016: 32-42.

[5] KUMAR N, JAYAGANTHAN R, BROKMEIER H G. Effect of deformation temperature on precipitation, microstructural evolution, mechanical and corrosion behavior of 6082 Al alloy[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(3): 475-492.

[6] MA Wen-yu, WANG Bao-yu, LIN Jian-guo, TANG Xue-feng. Influence of process parameters on properties of AA6082 in hot forming process[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(11): 2454-2463.

[7] CHANG Yi-ling, HUNG Fei-yi, LUI Truan-sheng. Enhancement of mechanical properties of hot-forged 6082 suspension parts via rapid IR heat treatment[J]. Metals, 2018, 8(7): 501-513.

[8] CECILIA P, ROMAIN B, PETER L, PETER S, STEFAN M, MIRJAM S. Microstructure evolution in a 6082 aluminum Alloy during thermomechanical treatment[J]. Materials, 2018, 11(8): 1319-1333.

[9] LI Xue-song, WU Lai-zhi, CHEN Jun, ZHANG Hong-bing. Static softening characteristics and static recrystallization kinetics of aluminum alloy A6082 after hot deformation[J]. Journal of Shanghai Jiaotong University (English Edition), 2010, 15(3): 307-312.

[10] 王少阳. 7075铝合金热变形的动态再结晶规律研究[D]. 合肥: 合肥工业大学, 2012: 14-17.

WANG Shao-yang. Research on dynamic recrystallization behavior of 7075 aluminum alloy during hot deformation[D]. Hefei: Hefei University of Technology, 2012: 14-17.

[11] 贾耀军. 7050铝合金热变形和动态再结晶行为的实验研究和数值模拟[D]. 重庆: 重庆大学, 2013: 27-31.

JIA Yao-jun. Experimental research and numerical simulation of hot deformation and dynamic recrystallization behavior of 7050 aluminum alloy[D]. Chongqing: Chongqing University, 2013: 27-31.

[12] SAKAI T, MIURA H, GOLOBORODKO A, SITDIKOV O. Continuous dynamic recrystallization during the transient severe deformation of aluminum alloy 7475[J]. Acta Materialia, 2009, 57(1): 153-162.

[13] PARVIZIAN F, GüZEL A, JAGER A, LAMBERS H G, SVENDSEN B, TEKKAYA A E, MAIER H J. Modeling of dynamic microstructure evolution of EN AW-6082 alloy during hot forward extrusion[J]. Computational Materials Science, 2011, 50(4): 1520-1525.

[14] 权国政, 赵 磊, 王 阳, 石 彧, 周 杰. 基于流动应力曲线的AZ80镁合金动态再结晶动力学表征[J]. 功能材料, 2011, 42(6): 1142-91146.

QUAN Guo-zheng, ZHAO Lei, WANG Yang, SHI Yu, ZHOU Jie. A characterization for the dynamic recrystallization kinetics of AZ80 magnesium alloy based on flow curves[J]. Journal of Functional Materials, 2011, 42(6): 1142-91146.

[15] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.

[16] 胡道春. 6082铝合金高温变形行为及精锻工艺数值模 拟[J]. 特种铸造及有色合金, 2015, 35(9): 927-930.

HU Dao-chun. Hot deformation behavior of 6082 aluminum and numerical simulation of precision forging process[J]. Special-cast and Non-ferrous Alloys, 2015, 35(9): 927-930.

[17] POLIAK E I, JONAS J J. Initiation of dynamic recrystallization in constant strain rate hot deformation[J]. ISIJ International, 2003, 43(5): 684-691.

[18] 韦 韡. 6082铝合金筋类锻件热变形行为及组织性能研究[D]. 北京: 机械科学研究总院, 2013: 30-41.

WEI Wei. Research on hot deformation behavior and microstructure property of 6082 aluminum alloy forging with rib[D]. Beijing: China Academy of Machinery Science & Technology, 2013: 30-41.

[19] 胡道春, 王 蕾. 基于加工图的6082铝合金热成形性 能[J]. 材料热处理学报, 2015, 36(5): 223-229.

HU Dao-chun, WANG Lei. Hot formability of 6082 aluminum alloy based on processing map[J]. Transactions of Materials and Heat Treatment, 2015, 36(5): 223-229.

[20] 陈贵清, 傅高升, 颜文煅, 程超增,邹泽昌. 3003铝合金动态再结晶实验研究[J]. 材料工程, 2011(8): 77-81.

CHEN Gui-qing, FU Fao-sheng, YAN Wen-duan, CHENG Chao-zeng, ZOU Ze-chang. Experimental research on dynamic recrystallization of 3003 aluminum alloy[J]. Journal of Materials Engineering, 2011(8): 77-81.

[21] MITSCHE S, SHERSTNEV P, SOMMITSCH C, EBNER T, HACKSTEINER M. Characterisation of the subgrain structure of the aluminium alloy AA6082 after homogenization and hot forming by EBSD[C]// LUYSBERG M, TILLMANN K, WEIRICH T. EMC 2008 14th European Microscopy Congress. Berlin, Heidelberg: Springer, 2008: 579-580.

[22] 吴洁琼, 陈 科, 陈杏芳, 田 胜, 沈 治, 张澜庭, 单爱党. EBSD在Nimonic 80A动态再结晶机制研究中的应 用[J]. 电子显微学报, 2011, 30(4/5): 356-359.

WU Jie-qiong, CHEN Ke, CHEN Xing-fang, TIAN Sheng, SHEN Zhi, ZHANG Lan-ting, SHAN Ai-dang. Application of EBSD in the study of dynamic recrystallization mechanisms in Nimonic 80A[J]. Journal of Chinese Electron Microscopy Society, 2011, 30(4/5): 356-359.

[23] GIOVANNI M, PERO R, RICHETTA M, MONTANARI R. Continuous dynamic recrystallization (CDRX) model for aluminum alloys[J]. Journal of Materials Science, 2018, 53(12): 1-11.

Dynamic recrystallization behavior of 6082 aluminum alloy during hot deformation

XU Zhen-yu1, 3, HU Dao-chun2, 4

(1. Mechanical & Electrical Engineering College, Jinhua Polytechnic, Jinhua 321007, China;

2. Engineering Technology Training Center, Nanjing Institute of Industry Technology, Nanjing 210023, China;

3. Academician Wang Weihua Expert Workstation, Jinhua Polytechnic, Jinhua 321007, China;

4. Jiangsu Research and Development Center of Precision Manufacturing, Nanjing 210023, China)

Abstract: The dynamic recrystallization behaviors of 6082 aluminum alloy at the temperature range of 623-773 K and strain rate range of 0.01-5 s-1 were studied by electron back scattered diffraction (EBSD) and transmission electron microscopy (TEM). According to the experimental results, dynamic recrystallization occurs during hot deformation of 6082 aluminum alloy, although the true stress-strain curve has no obvious single peak characteristic, and the degree of dynamic recrystallization is closely related to Z parameter. Hot compression with ln Z=24.9014 (723 K, 0.1 s-1) gives rise to the highest fraction of recrystallization of 38.6%. The initial critical strain of dynamic recrystallization was determined by work hardening rate. The quantitative relationship between critical strain and Z parameters was established. Based on the results of EBSD analysis and measurement, a dynamic recrystallization kinetics model of 6082 aluminum alloy during hot deformation is deduced. Microstructure analysis shows that the subgrain structure formed in the original grain is coarsened by grain boundary migration, and the orientation difference increases continuously until the large angle grain boundary is formed, resulting in dynamic recrystallization grains, and the likely mechanism is continuous dynamic recrystallization.

Key words: 6082 aluminum alloy; dynamic recrystallization model; Zener-Hollomon parameter; continuous dynamic recrystallization

Foundation item: Project(LY18E050005) supported by the Natural Science Foundation of Zhejiang Province, China; Project(YK18-13-02) supported by the Startup Foundation for Introducing Talent of Nanjing Institute of Industry Technology, China

Received date: 2019-07-19; Accepted date: 2020-05-28

Corresponding author: HU Dao-chun; Tel: +86-18851998736; E-mail: springer_1028@163.com

(编辑 王 超)

基金项目:浙江省自然科学基金资助项目(LY18E050005);人才引进科研启动基金项目(YK18-13-02)

收稿日期:2019-07-19;修订日期:2020-05-28

通信作者:胡道春,副教授,博士;电话:18851998736;E-mail:springer_1028@163.com