文章编号:1004-0609(2010)04-0667-07

离心铸造TC4合金冷速对其组织和力学性能的影响

贾丽敏1,徐达鸣1,郭景杰1,白世鸿2,王红红2

(1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 北京航空材料研究院, 北京 100095)

摘 要:实验与模拟计算相结合研究Ti-6Al-4V(TC4)合金在陶瓷壳型离心精铸条件下,铸件模数对凝固过程冷速的影响,以及铸件组织、性能随模数和冷速之间的统计关系。结果表明:当铸件模数较小时,模数大小对凝固过程冷速影响比较显著,而随着模数的进一步增加,当M>7.00 mm时,铸件冷却速度随模数变化并不明显;晶粒尺寸、α/β片层厚度及二次枝晶间距均随铸件模数的增加及冷速的减小而增大,抗拉强度则呈现相反趋势。得出了TC4离心精铸件组织、性能与铸件模数和冷速之间定量关系的表达式。

关键词:Ti-6Al-4V合金;离心精密铸造;组织;抗拉强度;冷却速度;铸件模数

中图分类号:TG249.4;TG146.2+3 文献标志码:A

Effect of cooling rate on structure and tensile strength of centrifugally cast TC4 alloy in ceramic-shell mold

JIA Li-min1, XU Da-ming1, GUO Jing-jie1, BAI Shi-hong2, WANG Hong-hong2

(1. School of Materials Science and Technology, Harbin Institute of Technology, Harbin 150001, China;

2. Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: Both the experimental analyses and computer simulation were conducted to determine the statistical relationship between the structures and mechanical properties of centrifugally cast TC4 alloy in ceramic-shell mould. The results show that, when the cast modulus (M) is smaller, the modulus has significant influence on the cooling rate. But with increasing modulus, the influence of modulus on the cooling rate is weakened while M is larger than 7.00 mm. The grain size, α/β lamellar thickness and secondary dendrite arm spacing all increase with increasing the casting module or decreasing the cooling rate, while the tensile strength varies in an opposite changing manner. The regression functions for the corresponding relationships are given according to the present investigations.

Key words: Ti-6Al-4V alloy; centrifugal casting; structure; tensile strength; cooling rate; cast modulus

钛合金精密铸件及精密铸造技术的研发在现代航空航天领域里具有十分重要的应用背景和战略意义。离心铸造工艺使合金充型能力更强、铸件组织更致密,在材料液态成形工程中具有重要的应用背景,因此钛合金精铸件大多应用离心浇铸工艺来完成[1-2]。凝固 与相变组织是影响钛合金力学性能的主要因素,国内外许多研究学者对钛合金的组织与性能相关性进行了研究[3-8]。钛合金铸件在凝固及冷却过程中冷却速度的大小直接影响其宏观及微观组织,而对于用量较大的TC4合金在离心浇铸时组织及性能随冷速变化规律的研究只是起始阶段[9]。因此,研究TC4合金离心精密铸件组织、性能与冷速之间的定量关系,建立相应模型,通过改变局部冷却条件来控制铸件的组织和性能,为钛合金组织与性能计算机模拟提供预测模型。

本文作者应用AnyCasting软件计算TC4合金在离心精铸时普遍使用的陶瓷型壳条件下,铸件在凝固及相变过程中的冷却速度,研究铸件模数变化对凝固过程中冷却速度的影响;分析并确定离心精密铸造TC4合金组织、性能与冷速和模数之间的定量关系。

1 实验

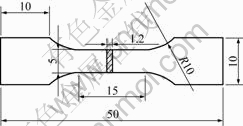

本实验中试样取自陶瓷壳型(ZrO2-Y2O3)Ti- 6Al-4V合金离心精密薄壁铸造组件本体。TC4合金铸件的实测成分如表1所列。实际离心铸造系统最大半径为60 mm,在不同半径处沿整个周向均匀分布若干组薄壁铸造件群,每群沿垂直方向分布若干层铸件,每层4个薄壁件。浇铸造系统最上端到横烧道中心距离为260 mm,在半径为400 mm处浇铸系统及铸件上切取组织观察试样及拉伸试件,金相试样规格为8 mm×8 mm×8 mm,拉伸样厚度为1.2 mm,其尺寸如图1所示。浇铸造时,离心转速约为250 r/min,浇铸时铸型预热温度为200 ℃。根据文献[10],此时可忽略离心力的改变对组织的影响。在计算模型的相应位置处设置测温热电偶以模拟计算试样切取处合金的冷却速度。本文作者应用AnyCasting软件模拟铸件充型凝固与冷却过程中各取样位置的温度变化。对切取的钛合金金相试样进行磨制、抛光(抛光液为三氧化二铬+水的悬浊液) 和组织腐蚀显现处理(腐蚀液为2%HF+4%HNO3+ H2O)。

实验分析方法如下:采用Olympus BH2-UMA光学金相显微镜观察TC4合金的晶粒组织;采用Hitachi S-4700SEM型扫描电子显微镜观察试样的显微组织;采用Instron-5569型电子万能材料试样机进行单向静态拉伸试验,测定TC4合金材料在室温下的抗拉强度;采用全谱直读等离子体发射光谱仪分析TC4铸件化学成分。

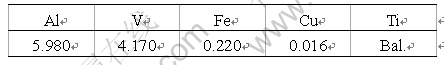

表1 离心精密铸造TC4合金的成分

Table 1 Chemical compositions of measured TC4 alloy (mass fraction, %)

图1 拉伸试样形状与尺寸

Fig.1 Shape and dimensions of tensile experiment sample (mm)

2 结果及分析

2.1 结果及处理

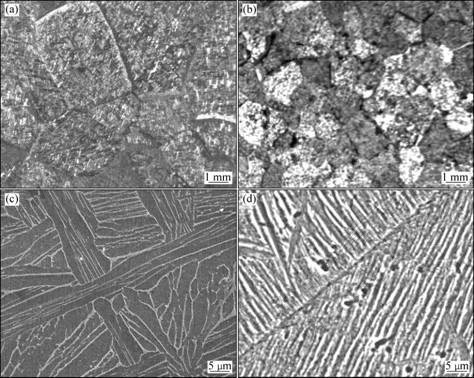

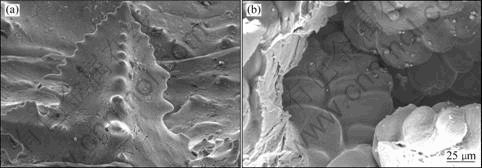

图2所示为典型凝固晶粒组织及α/β相变片层组织照片。由图2可看出,一般情况下,在Ti-6Al-4V合金凝固过程中,从β相到α相的固态相变会掩盖凝固树枝晶的组织形态。本研究中,在模数为24.50 mm(试样1)和26.00 mm(试样2)横浇道位置所取试样中含有中心集中缩孔,从孔洞中可观察到的树枝晶(见图3(a));在拉伸断口显微缩孔内壁观察到β-Ti的凝固枝晶组织(见图3(b))。

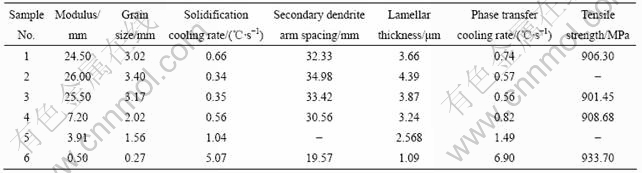

由金相组织照片及相应的标尺,用截线法对不同壁厚处钛合金的晶粒尺寸dg、二次枝晶间距d2及α/β相变片层厚度dα/β等金相组织特征尺寸指标进行测量与统计分析,测量数据汇总(包括试样的抗拉强度)如表2所列。

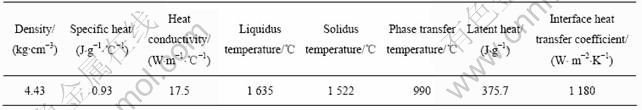

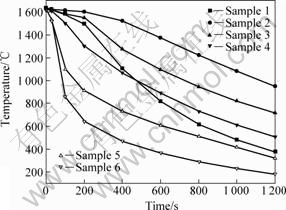

由AnyCasting模拟软件计算TC4合金离心精密铸造冷速时所用的物性参数如表3所列[11]。计算得到的不同壁厚钛合金铸件温度随时间变化曲线如图4所示。铸件凝固时冷却速度影响了其晶粒尺寸和二次枝晶臂间距,而相变时冷速则影响α/β片层厚度。由公式ε=ΔT/Δt计算不同温度区间内凝固及发生固态相变时的冷速(见表2)。由表2可以看出,铸件模数对其凝固冷速影响比较显著,铸件薄壁处(模数为0.50 mm)凝固时冷却速度约为厚壁处(模数为26.00 mm)冷却速度的15倍。不同壁厚处铸件的凝固冷速及发生α/β相变时的相变冷速见表2。由文献[12]的实验数据可知当冷速ε=2.62 ℃/s时,σb=918.90 MPa,d2=23.38 μm。

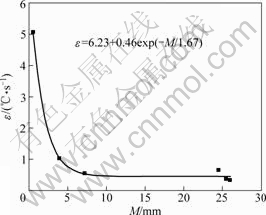

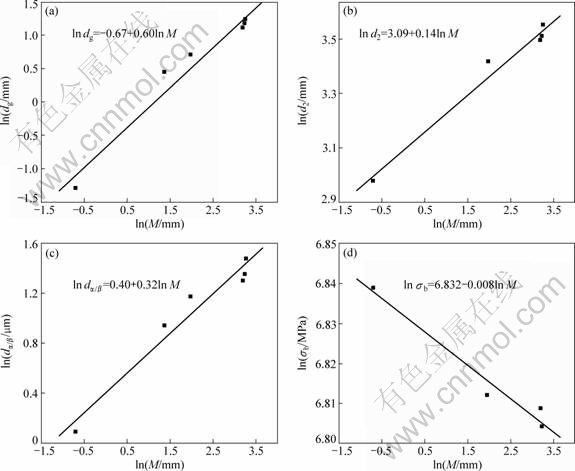

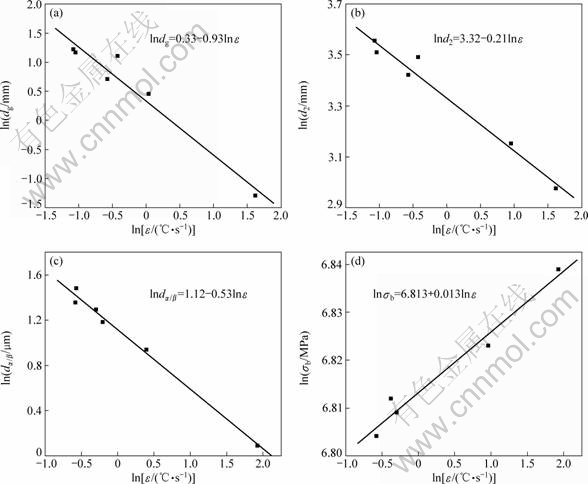

由表2及文献[12]中实验及计算分析数据,可以得到TC4陶瓷型壳中离心铸件冷速随模数的变化关系如图5所示。铸件组织和力学性能与模数及计算冷速的对应关系分别如图6和7所示。从图5~7可以看出,对于陶瓷壳型TC4合金离心精密铸件,当铸件模数较小时(M<7.00 mm),模数大小对铸件凝固过程冷速的影响比较显著;而随着模数的进一步增加,当M>

图2 离心铸造TC4合金不同壁厚处典型晶粒与片层组织

Fig.2 Typical grain ((a), (b)) and lamellar ((c), (d)) structures of centrifugally cast TC4 samples with different moduli (M): (a), (c) M=24.50 mm; (b), (d) M=3.00 mm

图3 浇注系统中不同位置处试样拉伸断口缩孔中树枝晶的形貌

Fig.3 Dendrite morphologies of shrinkage cavity and micropore in TC4 samples with different moduli: (a) M=26.00 mm; (b) M=7.20 mm

表2 离心铸造TC4钛合金不同壁厚处试样的拉伸性能测量与统计分析数据

Table 2 Measured and analytical data of mechanical properties of centrifugally cast TC4 alloy with different moduli

表3 AnyCasting软件计算TC4合金离心精密铸造冷速所用参数[11]

Table 3 Physical property parameters of TC4 alloy used in AnyCasting simulation[11]

图4 AnyCasting计算得到的TC4铸件不同位置处凝固冷却曲线

Fig.4 Solidification cooling curves of different locations of TC4 casting by AnyCasting software package

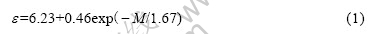

7.00 mm时,铸件冷却速度随模数变化并不明显;其晶粒尺寸、二次枝晶间距及α/β片层厚度都随着铸件模数的增加和冷速的减小而增加,而其抗拉强度随着铸件模数的增加和冷速的减小而减小。对图5~7中各关系曲线采用Origin软件进行拟合回归处理,得到TC4合金离心精密铸件的组织、性能与模数和冷速之间实验数据的拟合函数关系如下。

铸件凝固过程冷速(ε)与铸件模数(M)之间满足关系式:

晶粒尺寸(dg)与铸件模数(M)和冷速(ε)之间的拟合关系式分别为

二次枝晶间距(d2)与铸件模数(M)和冷速(ε)之间的拟合关系式分别为

α/β片间距(dα/β)与铸件模数(M)和相变冷速(ε)之间的拟合关系式分别为

铸件抗拉强度(σb)与铸件模数(M)和冷速(ε)之间的拟合关系式分别为

图5 TC4陶瓷型壳中离心铸件冷速随模数的变化

Fig.5 Change of cooling rate with cast modulus for TC4 alloy centrifugal casting in ceramics mold

2.2 分析和讨论

由以上实验结果可以看出,在陶瓷壳型(ZrO2- Y2O3)中离心浇铸TC4合金时,当铸件模数较小时,模数大小对铸件凝固过程冷速影响比较显著,而随着模数的进一步增加,铸件冷却速度随模数变化并不明显;铸件晶粒尺寸、二次枝晶间距和α/β相变片层厚度均随着铸件模数的增加而增加,而抗拉强度随铸件模数的增加明显降低。

陶瓷材料由于导热系数较小而通常被设计成蓄热体,其比热容随温度的变化不大, 可以近似取为常 数[13]。当铸件模数较小时,由于铸型的激冷作用使薄壁铸件冷速较大,而在厚壁处,导热系数较小的陶瓷铸型对铸件内部冷速的影响就会明显减弱。

图6 TC4离心精密铸件的组织性能与铸件模数的关系

Fig.6 Relationships between structure, tensile strength and modulus of centrifugally cast TC4 alloy: (a) Grain size; (b) Secondary dendrite arm spacing; (c) α/β lamellar thickness; (d) Tensile strength

合金熔体在凝固过程中,当铸件模数较小时,铸件冷速会增加,这有利于晶核的形成。同时,铸件凝固所需时间t=CM2 [14],其中C为凝固常数,M为铸件模数。当模数越小时,铸件凝固时间越短,对于每个晶粒来说,允许其长大的时间越短,这遏制了晶粒的长大;β向α的转变过程也是新相形成与长大过程。如上述所分析,当铸件模数较小而冷速较大时,α/β的片层厚度就会变小,这在文献[15]中也有提到。

铸件的二次枝晶间距直接依赖于合金冷速和局部凝固时间,冷却速度与局部凝固时间的关系为[16] tf=ΔTs/ε,其中ΔTs为非平衡凝固温度区间,ε为合金熔体的冷却速度,由此可以看出,当铸件模数较小时,铸件冷却速度越快,二次枝晶臂粗化的时间越短,二次枝晶间距也就越小。

合金的抗拉强度由晶界和片层界面共同控制[17],材料的塑性变形是由位错通过晶体滑移面密堆方向上的剪切变化引起的。当外加载荷使合金滑移时,Schmid因子较大的滑移系首先开始滑移,当载荷进一步增加时,位错滑移至晶界时受到晶界的阻挡而在晶界处塞积,位错塞积能引起很高的内应力,阻止变形的进一步进行,提高变形抗力。在多晶材料中,晶粒在承受外在载荷的同时,晶粒之间还相互作用,使得每个晶粒所受的应力重新分布,当滑移由一个晶粒向另一个晶粒扩展时,受到高应力状态晶界的阻碍,使位错塞积,阻碍滑移,晶粒越小这种应力值增加得越多。当片层厚度较小时,位错沿片层方向滑动的距离缩短或者片间位错的滑动距离减小,这会增加滑移的阻力。通过上述的分析可知,当铸件模数较小时,其晶粒尺寸和片层厚度也相对较小,所以,铸件的抗拉强度就会增加。

图7 TC4离心精密铸件组织性能与计算冷速之间的关系

Fig.7 Relationships between structure, tensile strength and calculated cooling rate of centrifugally cast TC4 alloy: (a) Grain size; (b) Secondary dendrite arm spacing; (c) α/β lamellar thickness; (d) Tensile strength

3 结论

1) 对于陶瓷壳型TC4合金离心精密铸件,当铸件模数较小时,M<7.00 mm,模数大小对铸件凝固过程冷速影响比较显著;而随着模数的进一步增加,当M>7.00 mm时,铸件冷却速度随模数变化并不明显;当铸件模数由7.20 mm减小到0.50 mm时,凝固冷却速度从0.56 ℃/s增加到5.07 ℃/s,增加了近10倍。铸件凝固过程冷速(ε)与模数(M)之间定量关系可由ε=6.23+0.46exp(-M/1.67)表述。

2) 对于陶瓷壳型TC4合金离心精密铸件,其晶粒尺寸dg、二次枝晶间距d2及α/β片层厚度(dα/β)都随着铸件模数(M)的增加和冷却速度(ε)的减小而增加,而其抗拉强度(σb)随着铸件模数的增加和冷速的减小而减小。

REFERENCES

[1] 张鹏省, 毛小南, 赵永庆, 曾卫东, 洪 权, 李 辉. 世界钛及钛合金产业现状及发展趋势[J]. 稀有金属快报, 2007, 26(10): 1-6.

ZHANG Peng-sheng, MAO Xiao-nan, ZHAO Yong-qing, ZENG Wei-dong, HONG Quan, LI Hui. Development tendency of titanium and titanium alloys production[J]. Journal of Nonferrous Metals, 2007, 26(10): 1-6.

[2] NASTAC L, GUNGOR M N, UCOK I, KLUG K L, TACK W T. Advances in investment casting of Ti-6Al-4V alloy[J]. International Journal of Cast Metals Research, 2006, 19(2): 73-93.

[3] NAKAJIMA K, TERAO K, MIYATA T. The effect of microstructure on fatigue crack propagation of α+β titanium alloys in-situ observation of short fatigue crack growth[J]. Mater Sci Eng A, 1998, 243: 176-181.

[4] EYLON.D, HALL J A, PIERCE C M, RUCKLE D L. Microstructure and mechanical properties relationships in the Ti-11 alloy at room and elevated temperature[J]. Metal Trans A, 1990, 21(6): 1733-1744.

[5] BRUN M, SHAKHANOVA G. Principles of titanium alloys structure control with the purpose of increasing their mechanical properties[C]//Advances in the Science and Technology of Titanium Alloy Processing. Anaheim: The Minerals, Metals & Materials Society. 1997: 193-199.

[6] JAFEE R I, BURTE H M. Titanium science and technology[M]. New York –London: Plenum Press, 1973: 1731-1744.

[7] WANHILL R J H. Ambient temperature crack growth in titanium alloys and its significance for aircraft structures[J]. Aeronautical Journal, 1977, 81: 68-82.

[8] L?TJERING G. Influence of processing on microstructure and mechanical properties of α+β titanium alloys[J]. Mat Sci Eng A, 1998, 243: 32-45.

[9] 隋艳伟. 钛合金立式离心铸造缺陷形成与演化规律[D]. 哈尔滨: 哈尔滨工业大学, 2009: 115-127.

SUI Yan-wei. Defect formation and evolution in titanium vertical centrifugal casting[D]. Harbin: Harbin Institute of Technology, 2009: 115-127.

[10] 叶喜聪. 离心压力下凝固组织形成热力学与动力学分析[D]. 哈尔滨: 哈尔滨工业大学, 2006: 28-30.

YE Xi-cong. Analysis on thermodynamics and dynamics of the microstructure solidified under centrifugal pressure[D]. Harbin: Harbin Institute of Technology, 2006: 28-30.

[11] 王军新. 钛合金熔模精密铸造工艺计算机辅助优化设计研究[D]. 哈尔滨: 哈尔滨工业大学, 1998: 16-20.

WNG Jun-xin. Study on the CAD technology for investment casting of φ titanium alloys[D]. Harbin: Harbin Institute of Technology, 1998: 16-20.

[12] 贾丽敏. 钛合金离心铸造凝固组织与力学性能分析[D]. 哈尔滨: 哈尔滨工业大学, 2006: 29-50.

JIA Li-min Experimental analyses on solidified structures and mechanical properties of centrifugal precision titanium casting[D]. Harbin: Harbin Institute of Technology, 2006: 29-50.

[13] 李茂德, 程惠尔. 高温空气燃烧系统中陶瓷蓄热体传热特性分析研究[J]. 热科学与技术, 2004, 3(3): 254-260.

LI Mao-de, CHENG Hui-er. Theoretical analysis of heat transfer of ceramic regenerator in high temperature air combustion system[J]. Journal of Thermal Science and Technology, 2004, 3(3): 254-260.

[14] 胡汉起. 金属凝固原理[M]. 北京: 机械工业出版社, 2000: 6-9.

HU Han-qi. Principles of metal solidification[M]. Beijing: China Machine Press, 2000: 6-9.

[15] SUI Yan-wei, LI Bang-sheng, LIU Ai-hui, NAN Hai, GUO Jing-jie, FU Heng-zhi. Microstructures and hardness of Ti-6Al-4V alloy casting under centrifugal field[J]. Trans Nonferrous Met Soc China, 2008, 18: 291-296.

[16] FLEMINGS M C. Solidification processing[M]. New York: McGraw-Hill, 1974: 146-154.

[17] 曹国鑫, 林建国, 孙志鹏, 张永刚, 陈昌麒 . 晶粒尺度和片层厚度对全片层γ-TiAl合金性能的影响[J]. 稀有金属材料与工程, 2000, 29(3): 172-176.

CAO Guo-xin, LIN Jian-guo, SUN Zhi-peng, ZHANG Yong-gang, CHEN Chang-lin. Effect of grain size and lamellar thickness on property of fully lamellar TiAl alloy[J]. Journal of Nonferrous Metals. 2000, 29(3): 172-176.

(编辑 李艳红)

基金项目:国家重大基础研究计划资助项目(5131902)

收稿日期:2009-06-18;修订日期:2009-10-19

通信作者:徐达鸣,教授,博士;电话:0451-86896351;E-mail:damingxu@hit.edu.cn