文章编号:1004-0609(2013)S1-s0020-04

电子束熔化逐层成形法制备Ti-6Al-4V合金的组织与力学性能

王 哲1,张 钧1,李述军2,侯文韬2,郝玉琳2,杨 锐2

(1. 沈阳大学 机械工程学院,沈阳 110044;

2. 中国科学院 金属研究所 沈阳材料国家(联合)实验室,沈阳 110016)

摘 要:研究电子束熔化逐层成形法(AM-EBM)制备Ti-6Al-4V合金的组织与力学性能,并与锻态Ti-6Al-4V合金进行比较。结果表明:EBM 法制备的Ti-6Al-4V合金的显微组织以α相片层为主,片层之间有少量β相;α相片层厚度随堆积高度的增加而变大,到一定堆积高度后其层片厚度趋于稳定;与锻态合金相比,EBM 法制备的Ti-6Al-4V合金表现出较高的屈服强度和抗拉强度,两种合金均表现出良好的拉伸塑性;EBM Ti-6Al-4V合金的断裂方式为典型的韧窝型穿片层断裂。

关键词:电子束熔化;Ti-6Al-4V合金;显微组织;拉伸性能;锻态

中图分类号:TG146.2+3 文献标志码:A

Microstructures and mechanical properties of Ti-6Al-4V alloy fabricated by electron beam melting

WANG Zhe1, ZHANG Jun1, LI Shu-jun2, HOU Wen-tao2, HAO Yu-lin2, YANG Rui2

(1. College of Mechanical Engineering, Shenyang University, Shenyang 110044, China;

2. Shenyang National Laboratory for Materials Science, Institute of Metal Research,

Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: Microstructures and mechanical properties of Ti-6Al-4V alloy fabricated by electron beam melting (EBM) were investigated and compared to those of wrought Ti-6Al-4V plates. The results indicate that the EBM Ti-6Al-4V alloy mainly consists of α lamellas with small amount of β phase. The thickness of the α lamellas increases with the distance from the building plate and tends to remain stable at the certain building distance. EBM Ti-6Al-4V samples possess higher ultimate tensile strength (UTS) and yield strength (YS) than the wrought Ti-6Al-4V plates. There are no significant differences in ductility between EBM and wrought Ti-6Al-4V alloys. Dimple translamella is observed by SEM on fractured EBM Ti-6Al-4V tensile specimen.

Key words: electron beam melting; Ti-6Al-4V alloy; microstructures; mechanical properties; wrought

电子束逐层熔化金属快速成型技术(Additive manufacturing via electron beam melting)是近年来快速发展的先进制造技术之一。此技术工艺过程类似于激光选区融化技术(Selective laser melting,SLM)[1-2],以电子束为能量源,通过对零件的三维数字模型分层切片处理,使其离散成一系列二维数据文件,然后按照每一层的文件信息,通过计算机系统控制电子束移动将金属粉末逐层熔融堆积,最终得到与设计文件完全一致的样件[3]。该技术能够快速制备精度高、结构复杂的金属部件,具有高精度、高效率和高性能等优点,在航空航天、医疗、化工等领域有着广泛的应用,受到了各国学者和研究人员的密切关注。

本文作者利用Arcam A1型电子束成型设备制备了Ti-6Al-4V合金棒材,研究了其显微组织与拉伸力学性能,并与锻态Ti-6Al-4V合金进行了对比。

1 实验

实验采用的粉末原料为Ti-6Al-4V-ELI医疗用(外科植入)合金粉末,平均粒度约为50 μm。Ti-6Al-4V粉末的元素成分为:6.04% Al,4.05% V,0.013% C,0.07% Fe,0.13% O,低于 0.005% N和H,余量为Ti (质量分数)。

利用Arcam A1型电子束逐层熔化金属成型(EBM)实验设备(瑞典曼德卡姆有限公司),制备出直径为7 mm、高60 mm的棒材。棒材紧贴并垂直于成型基板长起。相邻棒材之间至少留出20 mm距离,避免样品之间相互影响散热。锻态Ti-6Al-4V合金板材由宝钛集团有限公司提供,相变点为(975±5) ℃,经(750 ℃, 1 h, AC)+(550 ℃, 4 h)的退火和时效处理。

将两种材料加工成拉伸试样,试样工作段尺寸为d 3 mm×20 mm。拉伸试验在Instron 8872型拉伸疲劳试验机上进行,拉伸速率为2.5×10-4 s-1。利用ZEISS- AXIO金相显微镜(OM)、Shimadzu SSX550扫描电镜(SEM)和Philips EM420透射电镜(TEM)进行显微组织观察。用于金相和扫描电镜观察的试样采用HF+HNO3+H2O(体积比2:5:43)混合溶液进行腐蚀;透射样品通过机械减薄和电解双喷获得。

2 结果与分析

2.1 EBM Ti-6Al-4V合金的显微组织

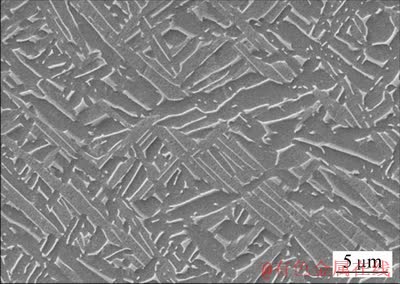

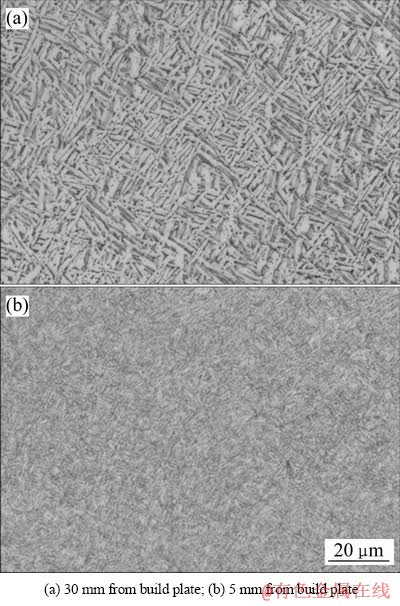

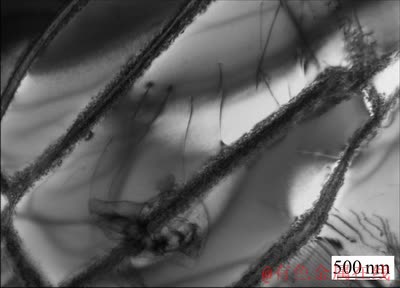

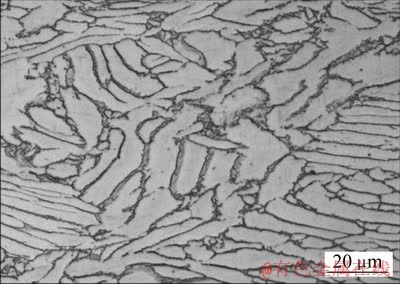

由图1可见,EBM Ti-6Al-4V合金的显微组织以α相片层为主体,相邻α相片层之间存在尺寸很小的间隙β相[4]。在EBM Ti-6Al-4V棒材生长过程中,随着温度从β相变点以上迅速降低,融化层快速凝固,与此同时,β相转变为α相,α相片层厚度受冷却速率影响。在贴近不锈钢成型基板凝固成型时,冷却速率最大,α相呈细小针状;随着堆积高度的增加,冷却速率变小,α相片层厚度增大(图2)。当堆积高度达到20 mm后,α相片层厚度趋于稳定。对EBM 法制备的Ti-6Al-4V合金进行透射电镜观察(图3),发现α相片层厚度约为1.3 μm,片层内含有大量位错,主要是由合金凝固时产生的内应力造成的。与EBM Ti-6Al-4V合金的显微组织相比,锻态Ti-6Al-4V合金退火+时效后的α相为层片状组织,层片厚度较大(图4)。

图1 EBM Ti-6Al-4V合金的SEM像

Fig. 1 SEM image of EBM Ti-6Al-4V sample

图2 不同堆积高度的EBM Ti-6Al-4V合金的金相组织

Fig. 2 Optical microstructures of EBM Ti-6Al-4V samples

值得注意的是,对EBM 法制备的Ti-6Al-4V合金,在紧贴成型基板平面500 μm厚度的合金基体中,发现其成分与整个合金的组织成分有很大差别[5]。其主要原因是在底层合金粉末融化凝固时受到了不锈钢成型基板的影响。金相中可观察到少量孔洞缺陷,这些孔洞缺陷普遍存在于EBM Ti-6Al-4V合金中,主要是由于气雾化法制备Ti-6Al-4V合金粉末时有残余氩气附着于粉末表面,这些气孔缺陷可以通过热等静压来消除[6]。

图3 EBM Ti-6Al-4V合金的TEM像

Fig. 3 TEM image of EBM Ti-6Al-4V sample

图4 锻态Ti-6Al-4V合金退火+时效态金相组织

Fig. 4 Optical microstructure of wrought Ti-6Al-4V plates after heat treatment of (750 ℃, 1 h, AC)+(550 ℃, 4 h)

2.2 EBM Ti-6Al-4V合金的拉伸性能

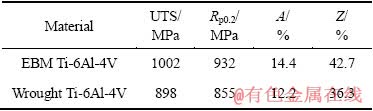

EBM 法制备的Ti-6Al-4V合金的拉伸性能如表1所示。与锻态合金相比,EBM Ti-6Al-4V合金表现出较高的屈服强度和抗拉强度,其中屈服强度高出77 MPa,抗拉强度高出104 MPa。塑性指标差别较小,两种样品均表现出了良好的拉伸塑性。

EBM Ti-6Al-4V棒材生长过程在真空环境中进行,电子束在逐层融化粉末的同时产生大量热量,散热比较困难,导致成型仓的整体温度保持在较高的水平,棒材起到了消除应力退火的作用,有助于强度和塑性等性能的均一化。有研究表明, 两相钛合金的力学性能与α相片层厚度密切相关,层片厚度增加,强度下降。其中屈服强度 与α相尺寸的关系可用Hall-Petch方程描述[7-9]:

与α相尺寸的关系可用Hall-Petch方程描述[7-9]:

(1)

(1)

式中: 为单晶体屈服强度;Ky为晶界对强度的影响系数;d为晶粒的平均直径或片层平均厚度。根据此公式,材料的强度与其片层厚度呈反比关系,EBM Ti-6Al-4V合金α相片层厚度较小,因而其具有较高的强度。

为单晶体屈服强度;Ky为晶界对强度的影响系数;d为晶粒的平均直径或片层平均厚度。根据此公式,材料的强度与其片层厚度呈反比关系,EBM Ti-6Al-4V合金α相片层厚度较小,因而其具有较高的强度。

表1 EBM和锻态Ti-6Al-4V的拉伸性能

Table 1 Tensile properties of EBM and wrought Ti-6Al-4V samples

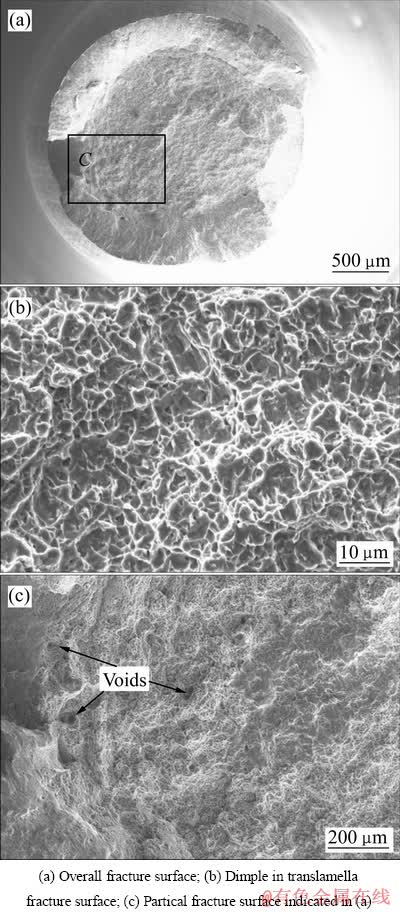

图5 EBM Ti-6Al-4V合金的拉伸断口形貌

Fig. 5 SEM images of EBM Ti-6Al-4V tensile fracture surface

图5所示为EBM Ti-6Al-4V棒材拉伸断口形貌。由图5(a)、(b)可见,断口宏观形貌为韧性杯锥状断口,断裂方式为典型的韧窝型穿片层断裂。由图5(c)可以看到很多孔洞缺陷,在拉伸过程中韧窝形核长大,形成微孔,微孔不断扩展与附近的孔洞缺陷连接形成裂纹源[10]。EBM Ti-6Al-4V合金表现出良好的塑性,说明孔洞缺陷对拉伸性能影响很小,而这些孔洞缺陷对疲劳性能的影响则有待于进一步研究。

3 结论

1) EBM法制备的Ti-6Al-4V合金的显微组织以α相片层为主,片层之间有少量β相;α相片层厚度随堆积高度的增加而变大,达到一定高度后α相片层厚度趋于稳定。

2) 与锻态合金相比,EBM Ti-6Al-4V合金表现出较高的屈服强度和抗拉强度;两种合金均表现出了良好的拉伸塑性。

3) EBM Ti-6Al-4V合金的断裂方式为典型的韧窝型穿片层断裂。

REFERENCES

[1] XUE Lei, CHEN Jing, LIN Xin,  Xiao-wei, WANG Wei, HUANG Wei-dong. Microstructure and high temperature mechanical properties of laser rapidly formed Ti-6Al-4V alloy[J]. Transactions of Nonferrous Metals Society of China, 2006, 16: 2062-2065.

Xiao-wei, WANG Wei, HUANG Wei-dong. Microstructure and high temperature mechanical properties of laser rapidly formed Ti-6Al-4V alloy[J]. Transactions of Nonferrous Metals Society of China, 2006, 16: 2062-2065.

[2] 李 闯, 顾冬冬, 沈以赴, 孟广斌. 选区激光熔化制备TiCx/Ti纳米复合材料的致密化及显微组织[J]. 中国有色金属学报, 2011, 21: 1554-1561.

LI Chuang, GU Dong-dong, SHEN Yi-fu, MENG Guang-bin. Densification and microstructure of TiCx/Ti nanocomposites prepared by selective laser melting[J]. The Chinese Journal of Nonferrous Metals, 2011, 21: 1554-1561.

[3] 杨 鑫, 奚正平, 刘 咏, 汤慧萍, 齐海波. 电子束选区熔化技术对钛合金组织和力学性能的影响[J]. 稀有金属材料与工程, 2009, 38: 1272-1275.

YANG Xin, XI Zheng-ping, LIU Yong, TANG Hui-ping, QI Hai-bo. Effect of electron beam selective melting on the microstructure and mechanical properties of Ti alloy[J]. Rare Metal Materials and Engineering, 2009, 38: 1272-1275.

[4] MURR L E, GAYTAN S M, RAMIREZ D A, MARTINEZ E, HERNANDEZ J, AMATO K N, SHINDO P W, MEDINA F R, WICKER R B. Metal fabrication by additive manufacturing using laser and electron beam melting technologies[J]. J Mater Sci Technol, 2012, 28: 1-14.

[5] AL-BERMANI S S, BLACKMORE M L, ZHANG W, TODD I. The origin of microstructural diversity, texture, and mechanical properties in electron beam melted Ti-6Al-4V[J]. Metall Mater Trans A, 2010, 41: 3422-3434.

[6] SAFDAR A, WEI L Y, SNIS A, LAI Z. Evaluation of microstructural development in electron beam melted Ti-6Al-4V[J]. Materials Characterization, 2012, 65: 8-15.

[7] MURR L E, ESQUIVEL E V, QUINONES S A, GAYTAN S M, LOPEZ M I, MARTINEZ E Y, MEDINA F, HERNANDEZ D H, MARTINEZ E, MARTINEZ J L, STAFFORD S W, BROWN D K, HOPPE T, MEYERS W, LINDHE U, WICKER R B. Microstructures and mechanical properties of electron beam-rapid manufactured Ti-6Al-4V biomedical prototypes compared to wrought Ti-6Al-4V[J]. Materials Characterization, 2009, 60: 96-105.

[8] LEYENS C, PETERS M. 钛与钛合金[M]. 陈振华, 译. 北京: 化学工业出版社, 2005: 100-101.

LEYENS C, PETERS M. Titanium and titanium alloys[M]. CHEN Zhen-hua, transl. Beijing: Chemical Industry Press, 2005: 100-101.

[9] 时海芳, 任 鑫. 材料力学性能[M]. 北京: 北京大学出版社, 2010: 22-28.

SHI Hai-fang, REN Xin. Mechanical properties of materials[M]. Beijing: Beijing University Press, 2010: 22-28.

[10] HULL D. 断口形貌学[M]. 李晓刚, 董超芳, 杜翠薇, 高 瑾, 卢 琳, 译. 北京: 科学出版社, 2009: 221-247.

HULL D. Fractography[M]. LI Xiao-gang, DONG Chao-fang, DU Cui-wei, GAO Jing, LU Lin, transl. Beijing: Science Press, 2009: 221-247.

(编辑 袁赛前)

基金项目:国家自然科学基金资助项目(51071152,51271182);国家重点基础研究发展计划项目(2012CB619103,2012CB933901,2012CB933902)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:郝玉琳,研究员,博士;电话:024-83978841;E-mail: ylhao@imr.ac.cn