不同轧制方式对铌箔微观组织和织构的影响

黄元春1,谢成2,唐建国2,邓运来2

(1. 中南大学 轻合金研究院,湖南 长沙,410083;

2. 中南大学 材料科学与工程学院,有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083)

摘要:采用取向分布函数(ODF),并通过光学金相(OM)显微组织观察,研究分析经4种不同轧制方式变形及其在1 050 ℃退火1 h过程中微观组织和织构的演变。研究结果表明:对于顺轧变形方式的铌箔,经1 050 ℃退火1 h后较其他3种轧制方式晶粒细小均匀,晶粒的平均尺寸约为40 μm;交叉轧制变形方式能形成较强的{001}<110>形变织构,并且经退火后能强化{111}再结晶织构,有利于提高铌材的深冲性能,同时减少{001}<100>立方织构,而其他3种轧制方式对{001}<100>织构具有强化作用;4种不同轧制方式变形不能强化{111}<110>形变织构。

关键词:铌箔;轧制方式;微观组织;织构

中图分类号:TG111.7,TG146.4+16 文献标志码:A 文章编号:1672-7207(2013)02-0501-07

Microstructure and texture of niobium foils fabricated by different rolling methods

HUANG Yuanchun1, XIE Cheng2, TANG Jianguo2, DENG Yunlai2

(1. Institute of Light Alloy, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University,

Key Laboratory of Nonferrous Materials Science and Engineering of Ministry of Education, Changsha 410083, China)

Abstract: Evolutions of microstructures and textures of niobium foils were studied by OM and ODF techniques, and the niobium foils processed by four different cold-rolling methods prior to 1 050 ℃/1 h final annealing. The results show that the rolling direction parallel to the ingot centerline obtains fine grain (the mean size of grain is 40 μm). Strong {001}<110> texture is developed in cross-rolled niobium foils. After annealing, a stronger {111} texture together with weaker {001}<100> texture is developed in the cross-rolled foils, which can enhances the deep drawability, while a stronger {001}<100> texture is developed in other methods. The deformation textures {111}<110> can not be strengthened after being processed by the four different cold-rolled methods.

Key words: niobium foil; rolling method; microstructure; texture

铌是稀有高熔点难熔金属,由于其具有优异的性能,金属铌成为在电子工业、化学工业、原子能工业、航空航天、薄膜技术和超导技术等现代工业生产和技术中得到广泛应用的高科技材料[1-4]。近年来,金属铌作为一种电极材料和表面工程材料(BM),被广泛应用于船舶、化工、液晶显示器以及耐热耐腐蚀高导电等镀膜工业中。特别是因为铌和铌的化合物具有高导电性、高热稳定性和对外来原子的阻挡作用,在工件和集成电路表面上使用溅射法镀上铌层,可以防止腐蚀和铜向基体硅中扩散。王国栋等[5-6]研究了轧制和热处理工艺对铌材组织及晶粒度和铌带深冲性能的影响。{王国栋, 2008 #36}现代工业的飞速发展对溅射用铌材提出了更高的技术要求,主要体现在铌靶材的化学纯度、晶粒度、织构和均一性等方面[7]。本文作者将纯铌板经4种不同轧制方式后在1 050 ℃最终退火1 h,研究铌箔的显微组织和织构的演变规律,对铌箔的变形及再结晶行为进行探讨,以便为铌材的工业化生产和在电子工业等领域的大规模应用提供必要的技术支持。

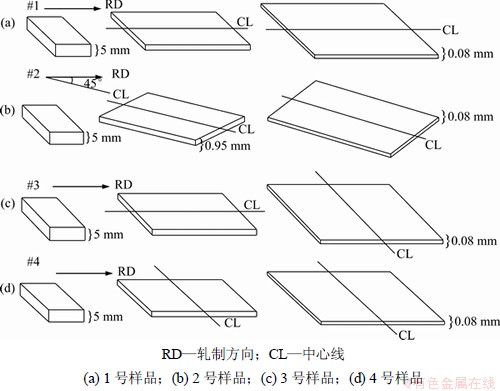

1 实验

本研究实验材料来源于国内某大型铌材生产厂商。经多次电子束熔炼(EBM)的纯铌锭经开坯后轧制成厚度为5 mm的铌板。将实验材料分别编号为1号,2号,3号和4号。对1号,2号,3号和4号样品分别进行顺轧、斜轧、交叉轧制和横向轧制。即所有样品先轧制到0.95 mm,其中1号和3号铌板轧制方向与5 mm厚铌板的轧制方向相同,2号的轧制方向与原5 mm铌板成45°夹角,4号的轧制方向与原方向垂直,随后进行中间热处理,最后将3号铌板轧制方向旋转90°,其他样品不改变轧制方向轧制到厚度0.08 mm(如图1所示)。4个样品轧制的总变形量均为98.4%。

冷轧后对4种不同轧制的铌箔试样进行真空退火处理。真空退火制度为:在0~500 ℃以10 ℃/min升温,在500~1 050 ℃以5 ℃/min升温;退火温度为1 050 ℃,保温时间为1 h,自然冷却,于60 ℃以下出炉。

对冷轧和真空再结晶退火后的试样分别进行微观组织和织构分析。利用XJP-6A型金相显微镜观察试样的光学显微组织(OM),金相试样采用电解抛光法和电解腐蚀法进行制样,电解抛光时间为8 min,电解腐蚀时间为50 s,所用电解抛光液和电解腐蚀液均是乳酸、浓硫酸、氢氟酸体积比为3:2:1的混合试剂。铌箔样品的织构测试分析采用Brucker D8 Discover测量{110},{200},{211}和{113} 4个不完全极图,运用球谐函数级数展开求出l=34 时的取向分布函数(ODF)的C-系数(包括奇数项和偶数项)[8]。

2 实验结果与分析

2.1 轧制方式对显微组织的影响

采用不同方式的大变形量轧制变形,可以充分改变坯料组织,细化晶粒,使其沿材料厚度方向分布趋于均匀,并且塑性变形也会深入到材料芯部,从而明显地改变材料的组织和性能。对于金属铌板,大变形量冷轧将直接影响变形后板坯的微观组织和性能。

图1 轧制流程示意图

Fig.1 Schematic view of rolling processes

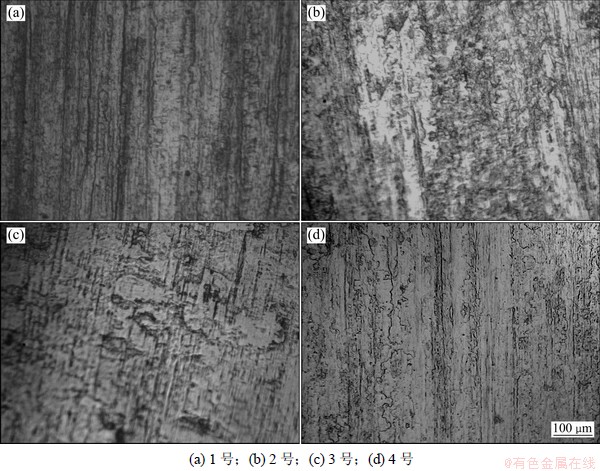

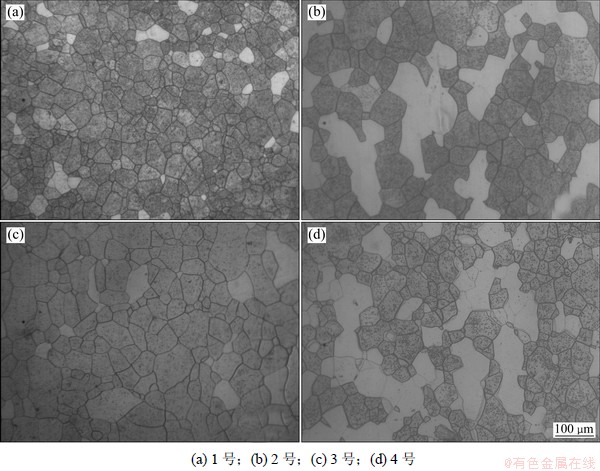

图2所示为5 mm原始铌板表面的光学金相照片,从图2可以看出:铌板的晶粒粗大。图3所示为5 mm厚的铌板经总变量为98.4%的大变形,多道次冷轧至厚度为0.08 mm的板坯微观组织。从图3可以看出:经过98.4%的变形量后,铌板坯沿轧制方向都形成了纤维组织。图3(a)所示为晶粒沿顺轧轧制变形方向被拉长压扁细化,纤维组织明显。对于斜轧(图3(b))和交叉轧制(图3(c)),晶粒之间发生相互挤压。

图2 5 mm铌板光学金相照片

Fig.2 Optical micrograph of 5 mm Nb sheet

2.2 轧制对织构的影响

金属材料发生塑性变形的过程中,采用不同的加工方式可以获得不同类型的加工态组织结构,同时将直接影响变形及热处理后材料的织构类型和组分。立方金属各晶粒的取向总是倾向于聚集在取向空间内不同的稳定的取向线附近。对于铌、钽和钢铁等体心立方金属,常见的取向线有α线、γ线和η线等[9],它们对金属的各种性能的各向异性有很大的影响。Vandermeer等[10]的研究表明:当铌材轧制且道次压下量超过40%时,表面织构参数将接近1,此时在φ=0°处将出现峰值,即出现高取向密度的{001}<110>织构。

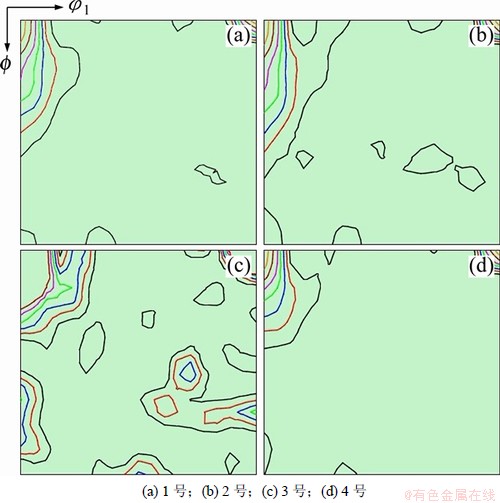

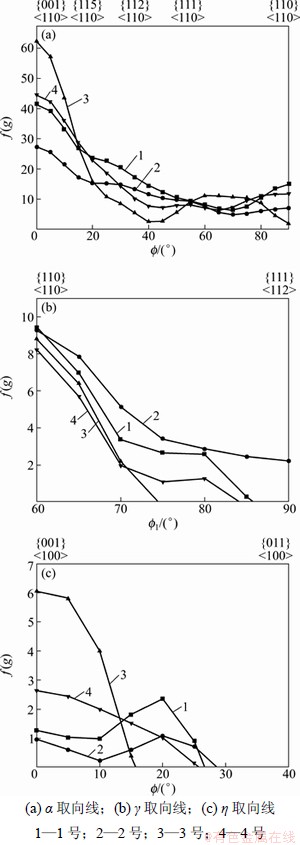

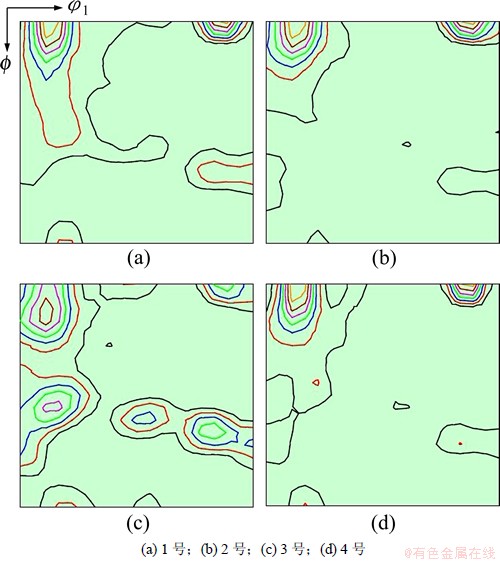

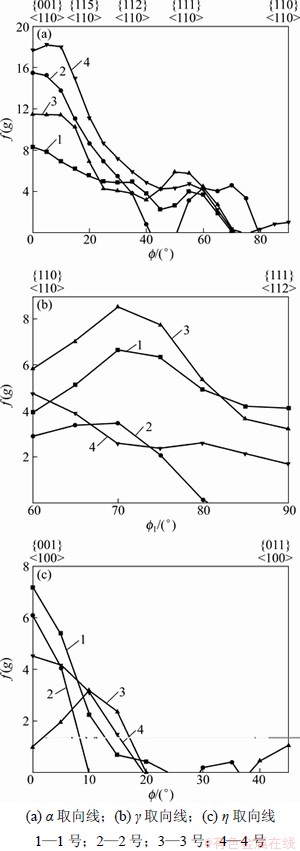

图4所示为变形态铌箔取向分布函数(ODF)图的φ2=45°截面。从图4可以看出:取向密度最大的都是{011}<110>织构,其中交叉轧制变形方式(3号)的织构组态明显不同于其他轧制方式。图5所示为0.08 mm的4种变形态铌箔的取向线图。从图5可以看出:经4种不同的轧制变形后,都可以得到高取向密度的{001}<110>织构,其中又以交叉轧制(3号)所形成的取向密度最高。沿α取向线在φ=55°附近{111}<110>织构强度趋于一致,即4种不同轧制方式变形不能强化形变织构{111}<110>。沿γ取向线上4种变形态铌箔在φ1=60°附近形成1个明显的尖峰,这与其他一些变形态的体心立方金属(如钽[11]、铁[12]等)有明显区别。其中铌板经斜轧(2号)后,其在图5中各条曲线走势比较平缓,即斜轧后各种织构沿取向线的分布较其他3种变形方式要均匀些,经过交叉轧制后(3号)相对于其他3种轧制方式易得到较强的{001}<110>旋转立方取向和{001}<100>立方取向织构,顺轧(1号)和横轧(4号)次之,斜轧(2号)最弱。

图3 冷轧后铌箔的光学金相照片

Fig.3 Optical micrographs of Nb foils after cold rolling

图4 变形态铌箔的取向分布函数图φ2=45°截面

Fig.4 φ2=45° section of ODFs of deformed Nb foils

2.3 热处理对铌箔微观组织的影响

板带材的轧制过程中消除应力退火和最终退火的制度对轧制产品的最终组织和性能都有较大的影响。铌材的再结晶退火规范一般为在真空状态下随炉升温到1 050~1 150 ℃,保温1~2 h[13]。本文选择在1 050 ℃下对不同轧制方式的铌箔退火1 h作为最终退火制度,并制定了其他相应的中间退火制度。

图6所示为退火后铌箔的微观组织。由图6(a)可以看出:经顺轧变形后的铌箔经1 050 ℃退火后,铌箔发生再结晶,形成均匀的细小等轴晶粒,变形组织已基本消失,晶粒较其他几种轧制方式细小均匀,平均晶粒粒径约为40 μm,此时已发生连续再结晶。从图6(b)可以看出:经1 050 ℃退火后,连续多道次45°斜向轧制后的晶粒发生了异常长大,可清晰观察到小晶粒被其他晶粒吞噬,说明此时发生了二次再结晶。由图6(c)可以看出:经交叉轧制的铌箔在退火后变形组织已消失,并且发生了明显的晶粒长大,说明经1 050 ℃/1 h退火处理后交叉轧制变形方式的铌箔已发生非连续再结晶,晶粒的平均粒径约为57 μm,较顺轧方式粗大。从图6(d)可以看出:横轧后的铌箔经退火后出现了细小的等轴晶粒(核),不连续再结晶已经开始。

图5 变形态铌箔的取向线分析

Fig.5 Orientation fibers of deformed Nb foils

图6 退火后铌箔的光学金相照片

Fig.6 Optical micrographs of Nb foils after annealing

2.4 热处理对织构的影响

对于体心立方金属,{111}织构是增强材料深冲性能的极为有利的织构[14]。Clark等[15]研究横轧对纯钽的微观组织和织构演变时发现,交叉轧制可以强化再结晶织构{111},有利于提高材料的深冲性能,同时降低{100}<0vw>取向的强度。

图7所示为退火后铌箔取向分布函数(ODF)图的φ2=45°截面。从图7可以看出:从{111}<110>到{111}<112>的γ取向线上有明显的取向聚集现象。图8所示为0.08 mm的铌箔经最终退火后的取向线图。从取向线图可更清晰地分析不同轧制方式后经1 050 ℃/1 h真空退火后铌箔再结晶织构组分的差异。不同轧制方式的铌箔经真空退火后,α取向线上的密度明显减弱。γ取向线上,取向{111}<110>的密度有所下降,取向{111}<112>的密度除斜轧(2号)下降外,其他3种变形方式有所上升,其中尤其以交叉轧制变形方式(3号)最明显,同时,交叉轧制方式的再结晶过渡型织构{111}<146>附近的取向密度有明显上升,而其他3种变形方式基本不变。η取向线上,交叉轧制方式变形(3号)退火处理后{001}<100>立方织构得到弱化,其他3种变形方式则有强化效果。由此可知:交叉轧制方式(3号)能有效增强{111}织构,提高铌材的深冲性能,同时弱化{001}<100>立方织构。

图7 退火后铌箔的取向分布函数图φ2=45°截面

Fig.7 φ2=45° section of ODFs of Nb foils after annealing

图8 退火后铌箔的取向线分析

Fig.8 Orientation fibers of Nb foils after annealing

3 结论

(1) 经1 050 ℃/1 h退火后,对于顺轧变形方式的铌箔晶粒较其他3种轧制方式的晶粒细小均匀,晶粒的平均尺寸约为40 μm;交叉轧制方式变形的铌箔已发生非连续再结晶。

(2) 交叉轧制变形方式能形成较强的{001}<110>变形织构,经退火处理后能强化再结晶织构{111},有利于提高铌板带材的深冲性能,同时减少{001}<100>立方织构,其他3种轧制方式对{001}<100>织构具有强化作用。4种不同轧制方式变形不能强化{111}<110>形变织构。

参考文献:

[1] 郭青蔚, 王肇信. 现代铌钽冶金[M]. 北京: 冶金工业出版社, 2009: 615-645.

GUO Qinwei, WANG Zhaoxin. Modern niobium and tantalum metallurgy[M]. Beijing: Metallurgical Industry Press, 2009: 615-645.

[2] Cunningham L D. Columbium (niobium) and tantalum[R]. U.S. Geological Survey Minerals Yearbook, 1999: 22.1-22.8.

[3] Baars D, Bieler T R, Hartwing K T, et al. Processing strategies for niobium sheet used in advanced superconducting particle accelerator cavities[J]. JOM Journal of the Minerals, Metals and Materials Society, 2007, 59(6): 50-55.

[4] Bieler T R. Advances in Material Studies for SRF[J]. SRF2009 WEB Proceedings, 2009, TUOAAU03: 102-108.

[5] 王国栋, 王艳, 李高林, 等. 溅射用优质铌靶材的制备[J]. 稀有金属材料与工程, 2008(S4): 533-536.

WANG Guodong, WANG Yan, LI Gaolin, et al. Processing of niobium target for sputting[J]. Rare Metal Materials and Engineering, 2008(S4): 533-536.

[6] 王国栋, 王艳, 武宇, 等. 工艺因素对铌带深冲性能的影响[J]. 稀有金属材料与工程, 2008(8): 1446-1450.

WANG Guodong, WANG Yan, WU Yu, et al. Influence of technology factors on deep-punching performances of niobium strip[J]. Rare Metal Materials and Engineering, 2008(8): 1446-1450.

[7] 国际钽铌研究中心. 钽铌译文集: 国际钽铌研究的发展和趋势[M]. 刘贵材, 娄燕雄. 长沙: 中南大学出版社, 2009: 127-148.

International Center for the Study of Tantalum and Niobium. The set of tantalum and niobium: The research development and trend of tantalum and niobium in the international[M]. LIU Guicai, LOU Yanxiong. Changsha: Central South University Press, 2009: 127-148.

[8] Bunge H J. Mathematische methoden der texturanalyse[M]. Berlin: Akademie-Verlag, 1969: 194-211.

[9] Engler O, Randle V. Introduction to texture analysis: macrotexture, microtexture, and orientation mapping[M]. USA: Taylor and Francis Group, 2009: 153-157.

[10] Vandermeer R A, Ogle J C. Texture inhomogeneities in cold-rolled niobium[J]. Transaction of the Metallurgical Society aime, 1969, 245: 1511-1518.

[11] 袁韧, 张新明, 周卓平. 退火温度对钽丝再结晶织构的影响[J]. 稀有金属与硬质合金, 2002(3): 17-21.

YUAN Ren, ZHANG Xinming, ZHOU Zhuoping. Effect of annealing temperature on recrystallization texture of tantalum wires[J]. Rare metals and cemented carbides, 2002(3): 17-21.

[12] 毛卫民, 杨平, 陈冷. 材料织构分析原理与检测技术[M]. 北京: 冶金工业出版社, 2008: 41-48.

MAO Weimin, YANG Ping, CHEN Leng. Material texture analysis principle and detection technology[M]. Beijing: Metallurgical Industry Press, 2008: 41-48.

[13] 黄伯云, 李成功, 石力开, 等. 中国材料工程大典: 有色金属材料工程[M]. 北京: 化学工业出版社, 2006: 200-216.

HUANG Boyun, LI Chenggong, SHI Likai, et al. China materials engineering canon: nonferrous metal materials engineering[M]. Beijing: Chemical Industry Press, 2006: 200-216.

[14] 毛卫民, 张新明. 晶体材料织构定量分析[M]. 北京: 冶金工业出版社, 1993: 133-135.

MAO Weimin, ZHANG Xinming. Quantitative texture analysis of crystalline materials[M]. Beijing: Metallurgical Industry Press, 1993: 133-135.

[15] Clark J B, Garrett R K, Jungling T L, et al. Influence of transverse rolling on the microstructural and texture development in pure tantalum[J]. Metallurgical and materials transactions A, 1992, 23(8): 2183-2191.

(编辑 何运斌)

收稿日期:2012-01-10;修回日期:2012-03-22

基金项目:国家重点基础研究发展规划(“973”计划)项目(2010CB731700)

通信作者:邓运来(1969-),男,湖南常德人,博士,教授,从事有色金属材料加工工程研究;电话:13873152095;E-mail:dengylcsu@126.com