文章编号:1004-0609(2010)S1-s0006-05

热轧变形对TB-13合金组织和织构的影响

费 跃1,常 辉1,唐 斌1,寇宏超1,朱知寿2,商国强2,周 廉1

(1. 西北工业大学 凝固技术国家重点实验室,西安 710072;

2. 中国航空工业集团公司 北京航空材料研究院,北京 100095)

摘 要:采用光学显微镜和X射线衍射仪分析TB-13合金在不同热轧变形条件下组织和织构的演变规律。结果表明:TB-13合金在变形量小于50%的热轧过程中只发生动态回复,当变形量增加到59%时,该合金发生动态再结晶,且随着变形量的增加,动态再结晶程度逐渐增大,细小的再结晶亚晶粒逐渐取代原始等轴状β晶粒从而使组织细化,动态再结晶是该合金热轧过程中主要的细化机制。同时,热轧变形使得该合金形成以旋转立方取向{001}<110>织构和Goss取向{110}<001>织构为主的多种织构,且随着变形量的增大,晶粒取向由Goss取向向旋转立方取向转移。

关键词:TB-13合金;热轧变形;显微组织;织构

中图分类号:TG 146.2 文献标志码:A

Influence of hot rolling deformation on microstructure and texture of TB-13 alloy

FEI Yue1, CHANG Hui1, TANG Bin1, KOU Hong-chao1, ZHU Zhi-shou2, SHANG Guo-qiang2, ZHOU Lian1

(1. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China;

2. Beijing Institute of Aeronautical Materials, Aviation Industry Corporation of China, Beijing 100095, China)

Abstract: The evolutions of microstructure and texture for TB-13 alloy during hot rolling were investigated by optical microscopy and X-ray diffracometry. The results show that the deformation mechanism is dynamic recovery in TB-13 alloy when the deformation reduction is less than 50%. When the deformation reduction is 59%, dynamic recrystallization occurs and the volume fraction of dynamic recrystallization increases with the increase of the deformation reduction. The equiaxed β grains are substituted for the recrystal grains, which leads to microstructure refinement. This indicates that the refinement mechanism is dynamic recrystallization. The main texture components of TB-13 alloy after hot rolling deformation are {001} <110> and {110} <001> textures. The orientation of grain changes from Goss orientation to rotating cube orientation when the deformation reduction increases.

Key words: TB-13 alloy; hot rolling deformation; microstructure; texture

钛合金可以通过热轧处理来改变合金的粗大组织,在轧制过程中,发生以回复、形核、晶粒长大为主的动态再结晶和以位错运动为主的塑性变形,使合金的显微组织和织构类型、分布发生变化[1-2]。而钛合金的力学性能不仅与微观组织直接相关,而且还受到织构类型及分布的影响[3-4],其中,织构影响合金的弹性模量、疲劳性能、屈服强度和超弹性等方面[5-7]。在轧制过程中,合金的显微组织和织构类型及分布随着变形量的变化而发生改变[8-11]。如Ti-6Al-4V合金在820 ℃经75%热轧变形后,大量晶粒主要向(2110)取向聚集,且随着变形量的增加,这种取向的强度明显增加,当变形量达到96%时,(2111)[0110]主取向与(2113)[0110]取向接近,(2118)[8443]和(1014)[5232]织构明显增强[7]。

因此,通过改变热轧变形量来合理控制合金在热轧过程中的显微组织和织构非常必要。本文作者针对一种新开发的TB-13亚稳β钛合金,研究其在相变点温度以上、不同热轧变形量下合金显微组织和织构的演变规律,为优化热加工工艺提供实验和理论基础。

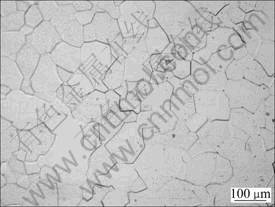

1 实验

试验选用高纯度海绵钛(99.5%)、海绵锆(99.5%)、Al-Ta(80%),Ti-Nb(50%)、Ti-Mo(30%)、铝豆、纯铬为原料,采用真空自耗电弧炉进行3次熔炼形成TB-13合金铸锭,其化学成分(质量分数)为:7.70%Mo,4.82%Nb,3.77%Ta,3.21%Cr,3.12%Zr,1.50%Al,0.125%O,0.016%C,0.009%N,0.001%H,其余为Ti。铸锭经开坯、锻造,然后在780 ℃热轧成为d26 mm的棒材,经金相法测得该合金β相转变温度为815~ 820 ℃。对d26 mm的棒材在840 ℃预热40 min,然后快速进行32%、50%、59%、75%的热轧变形并水淬。TB-13合金预热处理后的显微组织如图1所示。从图1可以看出,该合金在相变点温度以上(840 ℃)预热处理后,组织为全β组织,且晶粒呈等轴状。在变形后的棒材上沿着横截面方向切取d4 mm×4 mm的圆柱状试样,沿着轧制方向(纵截面方向)切取4 mm× 4 mm×4 mm的正方形试样;在变形量为32%和75%的棒材上沿着轧制方向切取7 mm×6 mm×2 mm的长方形试样。

将圆柱状和正方形试样在砂纸和抛光机上进行研磨和抛光,使用配比为10HF-20HNO3-70H2O (体积分数,%)的Kroll试剂对试样进行腐蚀,利用OLYMPUS/ PMG3型光学显微镜观察合金在不同变形量下的显微组织。长方形试样在砂纸上磨光后,采用Siemens D5000 X射线衍射仪按Schulz反射法进行织构测定。测定时选用Mo Kα靶作为入射光源,分别测量样品(110)、(200)、(211)3个晶面的不完整极图。测量范围:α角为0?~70?,间隔5?;β角为0?~360?,测量步长为5?。然后,经校正(即扣除背底,校正散焦),再归一化后算出ODF图。

由于TB-13合金在840 ℃进行热轧变形,组织为体心立方结构的全β相,在Bunge体系下,一般分析取向空间角φ2=0?和φ2=45?的截面图即可得到其织构信息,故在此只给出φ2=0?和φ2=45?这两个截面的ODF图。

图1 TB-13合金在840 ℃预热处理40 min并水淬后的显微组织

Fig.1 Microstructure of TB-13 alloy after heat treatment at 840 ℃ for 40 min and water quenching

2 结果与讨论

2.1 热轧变形量对TB-13合金组织的影响

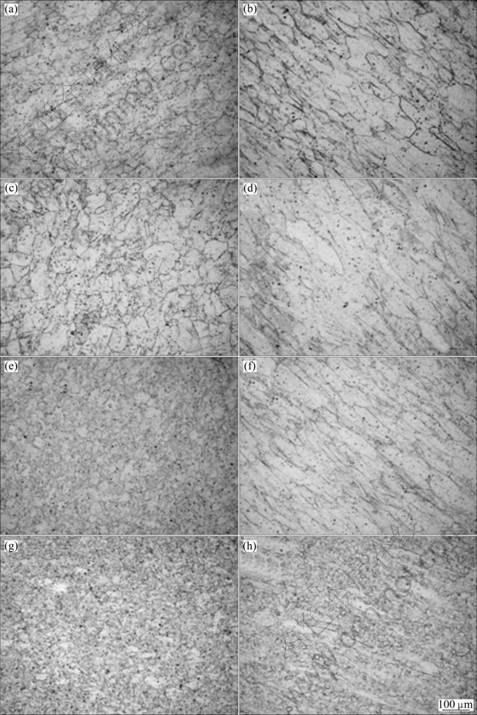

图2所示为TB-13合金在840 ℃预热处理后经不同变形量热轧变形后横截面和纵截面的金相显微组织。从图2可以清楚地看出,TB-13合金的热轧变形组织对变形量较敏感,动态再结晶程度随着变形量的增大而增加。当变形量为32%时(见图2(a)和(b)),部分原始等轴β晶粒发生畸变,晶粒沿轧制方向被拉长,晶界较为平直,组织特征为扁平状的β晶粒。随着变形量的增加(见图2(c)和(d)),晶粒被压扁和拉长的程度逐渐增大,晶粒未发生动态再结晶。说明当TB-13合金在变形量小于50%的情况下进行热轧变形时,组织只发生动态回复。在这个过程中,β基体发生刃型位错的攀移和螺型位错的交滑移[12-13]。当变形量增加到59%时(见图2(e)和(f)),被压扁、拉长的晶粒在轧挤压力作用下继续发生畸变,部分晶界出现锯齿状。锯齿状晶界是由于聚集在晶界处的位错产生应力集中所致[14],且细小的再结晶晶粒在晶界处形成,可见轧制变形组织在此变形量下已发生动态再结晶。这是因为随着变形量的增加,合金中的畸变能逐渐增多,动态再结晶的驱动力逐渐增大,使变形组织发生动态再结晶[12]。继续增大变形量,当变形量达到75%时(见图2(g)和(h)),拉长的晶粒被分布于晶界处大量细小的动态再结晶晶粒包裹,形成所谓的“项链组织”,并且部分项链组织向晶粒内部发展、长大,原始晶粒被新的细小的动态再结晶晶粒消耗。对比图2(g)、2(h)和图1可以看出,对TB-13合金进行大变形量的热轧变形处理,可以获得细小的等轴β晶组织,从而提高合金的力学性能。通过以上分析可以得出动态再结晶是TB-13合金热轧过程中主要的细化机制。

图2 TB-13合金以不同变形量热轧变形后的横截面与纵截面的显微组织

Fig.2 Microstructures of cross-section and longitudinal section of TB-13 alloy after hot rolling at different deformation reductions: (a), (b) 32%; (c), (d) 50%; (e), (f) 59%; (g), (h) 75%

2.2 热轧变形量对TB-13合金织构的影响

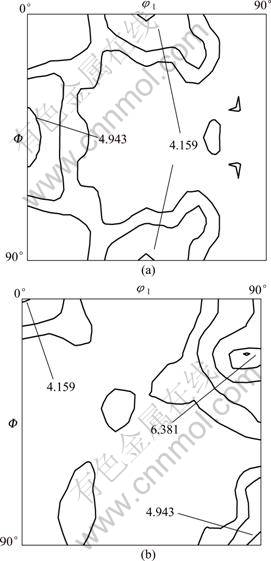

图3所示为TB-13合金在840 ℃预热处理后经32%热轧后的ODF图。从图3可以看出,当变形量为32%时,晶粒在旋转立方取向{001}<110>(45?,0?,0?)、(45?,90?,0?)、(0?,0?,45?)处和在Goss取向{110}<001> (0?,45?,0?)、(90?,90?,45?)处存在一定程度的聚集,且Goss取向{110}<001>织构的密度为4.943,高于旋转立方取向{001}<110>织构的密度4.159;同时,晶粒在(90?,20?,45?)处也有较大程度的聚集,取向密度为6.381。根据相关文献[15]介绍,在Bunge方法中,(φ1,Ф,φ2)取向与(HKL)[uvw]织构类型之间的解析关系(立方晶系)为

H: K: L= sinФsinφ2: sinФcosφ2: cosФ (1)

u:v:w=(cosφ1cosφ2-sinφ1sinφ2cosФ):(-cosφ1sinφ2-

sinφ1cosφ2cosФ): sinφ1sinФ (2)

利用公式(1)和(2),算得该合金在(90?,20?,45?)处织构为{114}< >。

>。

图3 TB-13合金经32%热轧变形后的ODF图

Fig.3 ODF maps observed in TB-13 alloy after hot rolling at 32% deformation reduction: (a) φ2=0?; (b) φ2=45?

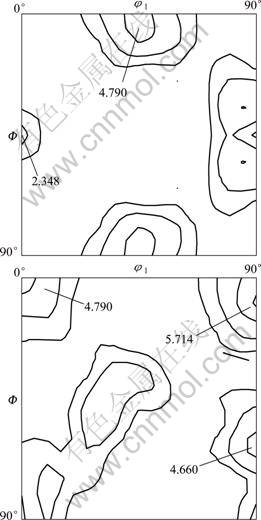

图4所示为TB-13合金经840 ℃预热处理后和75%热轧后的ODF图。从图4中可以看出,当变形量增加到75%时,晶粒取向发生变化,晶粒在旋转立方取向处的聚集程度加强,Goss取向处的聚集程度减

弱,使得Goss取向{110}<001>织构的密度低于旋转立方取向{001}<110>织构的密度;在(90?,90?,45?)和(90?,20?,45?)处晶粒聚集程度减弱;在(90?,60?,45?)和(90?,10?,45?)处晶粒聚集程度加强。利用公式(1)和(2),算得该合金在(90?,60?,45?)处形成{665}< >织构,在(90?,10?,45?)处形成{118} <

>织构,在(90?,10?,45?)处形成{118} < >织构。

>织构。

图4 TB-13合金经75%热轧变形后的ODF图

Fig.4 ODF maps observed in TB-13 alloy after hot rolling at 75% deformation reduction: (a) φ2=0?; (b) φ2=45?

3 结论

1) 当TB-13合金在小变形量(小于50%)下进行热轧处理时,只发生动态回复。在这个过程中,基体发生刃型位错的攀移和螺型位错的交滑移;随着变形量的继续增加,组织发生动态再结晶,晶界呈现锯齿状;当变形量增加到75%时,获得细小的等轴状再结晶组织。较大变形量的热轧处理有利于细化TB-13合金组织,且细化机制是动态再结晶。

2) TB-13合金在热轧过程中织构随着变形量的增加发生改变。当变形量为32%时,合金中形成

{001}<110>织构、{110}<001>织构和{114} < >织构;当变形量为75%时,合金中形成{001}<110>织构、{110}<001>织构、{118}<

>织构;当变形量为75%时,合金中形成{001}<110>织构、{110}<001>织构、{118}< >织构和{665}<

>织构和{665}< >织构。热轧变形量的增加使得TB-13合金晶粒取向由Goss取向向旋转立方取向转移。

>织构。热轧变形量的增加使得TB-13合金晶粒取向由Goss取向向旋转立方取向转移。

REFERENCES

[1] BANUMATHY S, MANDAL R K, SINGH A K. Texture and anisotropy of a hot rolled Ti-16Nb alloy[J]. Journal of Alloys and Compounds, 2010, 500: L26-L30.

[2] 毛卫民, 杨 平, 陈 玲. 材料织构分析原理与检测技术[M]. 北京: 冶金工业出版社, 2008: 15-16.

MAO Wei-bin, YANG Ping, CHEN Ling. Texture analysis theory and measuring for materials[M]. Beijing: Metallurgical Industry Press, 2008: 15-16.

[3] 朱知寿, 顾家琳, 陈南平. 钛的织构与力学性能各向异性关系研究[J]. 机械工程材料, 1994, 18(2): 23-25.

ZHU Zhi-shou, GU Jia-lin, CHEN Nan-ping. Research on the relationship between texture and mechanical property in commercially pure titanium sheets[J]. Materials for Mechanical Engineering, 1994, 18(2): 23-25.

[4] ZENG Z, ZHANG Y, JONSSON S. Microstructure and texture evolution of commercial pure titanium deformed at elevated temperatures[J]. Materials Science and Engineering A, 2009, 513/514: 83-90.

[5] PETERS M, GYSLER A, LUTJERING G. Influence of texture on fatigue properties of Ti-6Al-4V[J]. Metallurgical Transactions A, 1984, 15: 1597-1605.

[6] IVASISHIN O M, TELIOVYCH R V, IVANCHENKO V G, TAMIRISAKANDALA S, MIRACLE D B. Processing, microstructure, texture, and tensile properties of the Ti-6Al-4V-1.55B eutectic alloy[J]. Metallurgical and Materials Transactions A, 2008, 39: 402-416.

[7] 尤 力, 宋西平. 轧制及退火Ti-18Nb-4Sn合金织构的影响[J]. 金属学报, 2008, 44(11): 1310-1315.

YOU Li, SONG Xi-ping. Effects of rolling and annealing on the texture of Ti-18Nb-4Sn alloy[J]. Acta Metallurgical Sinica, 2008, 44(11): 1310-1315.

[8] 尤世武. 热轧Ti-6Al-4V的织构分析[J]. 稀有金属快报, 2002(6): 24-25.

YOU Shi-wu. Texture analysis of hot rolled Ti-6Al-4V[J]. Rare Metals Letters, 2002(6): 24-25.

[9] GEY N, HUMBERT M, PHILIPPE M J, COMBRES Y. Investigation of the α- and β- texture evolution of hot rolled Ti-64 products[J]. Materials Science and Engineering A, 1996, 219: 80-88.

[10] 朱知寿, 顾家琳, 陈南平. 冷轧变形量对钛板材再结晶织构形成的[J]. 材料科学与工艺, 1995, 3(2): 49-52.

ZHU Zhi-shou, GU Jia-lin, CHEN Nan-ping. The influence of cold rolling on the formation of recrystallization texture in titanium sheet[J]. Material Science & Technology, 1995, 3(2): 49-52.

[11] 王 环, 武保林, 杜兴蒿, 徐前刚. 不同条件热处理后Ti-15-3钛合金的再结晶织构[J]. 机械工程材料, 2008, 32(11): 20-25.

WANG Huan, WU Bao-lin, DU Xing-hao, XU Qian-gang. Recrystallization texture of Ti-15-3 alloy with different heat treatments[J]. Materials for Mechanical Engineering, 2008, 32(11): 20-25.

[12] 刘智恩. 材料科学基础[M]. 西安: 西北工业大学出版社, 2003: 272.

LIU Zhi-en. Material science[M]. Xi’an: Northwestern Polytechnical University Press, 2003: 272.

[13] 薛克敏, 张 青, 李 萍, 段园培. β21S钛合金高温变形行为研究[J]. 材料工程, 2008(4): 1-4.

XUE Ke-min, ZHANG Qing, LI Ping, DUAN Yuan-pei. Hot deformation behavior of β21S alloy at elevated temperature[J]. Material Technology, 2008(4): 1-4.

[14] 张 青. TB8合金热变形组织的分形研究及演变模拟[D]. 合肥: 合肥工业大学, 2008: 35.

ZHANG Qing. Fractal analysis and simulation on microstructure of TB8 alloy under hot deformation[D]. Hefei: Hefei University of Technology, 2008: 35.

[15] 刘丹敏, 刘维鹏. 有关ODF计算方法的某些问题[J]. 北京工业大学学报, 1998, 24(3): 119-123.

LIU Dan-min, LIU Wei-peng. Some problem about the calculation of the orientation distribution function[J]. Journal of Beijing Polytechnic University, 1998, 24(3): 119-123.

(编辑 杨 华)

基金项目:航空重点基金资助项目(2007ZF21011);西北工业大学凝固技术国家重点实验室自主课题资助项目(12-QP-2008)

通信作者:费 跃; 电话: 13759964002; E-mail: aaafeiyue@163.com