文章编号: 1004-0609(2005)04-0519 -05

6061铝合金ECAP变形后退火组织稳定性和织构变化

覃继宁1, 张 荻1, 张国定1, J. C. Lee2

(1. 上海交通大学 金属基复合材料国家重点实验室, 上海 200030;

2. Division of Materials Science and Engineering,Korea University, Anam, Seoul 136-701, Korea)

摘 要:采用一种基于等通道角挤压(ECAP)变形模式的全新的方法——DCAP方法, 对6061板料进行了DCAP变形, 并利用透射电镜和X射线衍射对6061 铝合金DCAP变形后的退火组织和织构进行了研究。 结果表明: 材料经DCAP变形退火后的晶粒在330℃左右仍能保持较细的晶粒度, 晶粒大小约为0.6μm; 与轧制过程中通常出现的立方织构不同, DCAP退火后的主要再结晶织构为旋转立方织构{001}〈110〉, 并伴有{111}〈110〉次要织构分量; 退火时旋转立方织构表现出的强烈的择优生长趋势, 是其成为DCAP变形后主要再结晶织构的原因。

关键词:铝合金; 等通道角挤压; 再结晶; 织构 中图分类号:TG376; TG379

文献标识码: A

Microstructure and texture change in equal channel angular

pressed 6061 aluminum sheet by static annealing

QIN Ji-ning1, ZHANG Di1, ZHANG Guo-ding1, J. C. Lee2

(1. State Key Laboratory of Metal Matrix Composites,Shanghai Jiaotong University, Shanghai 200030, China;

2. Division of Materials Science and Engineering,

Korea University, Anam, Seoul 136-701, Korea) Abstract: A novel equal channel angular pressing(ECAP) based process called dissimilar channel angular pressing(DCAP) was conducted to 6061 aluminum. The samples after DCAP were annealed isochronally up to 330℃, and the microstructural change and the texture evolution were investigated by means of TEM and three-dimensional orientation distribution functions (ODFs), which were determined by X-ray diffraction. The results show that the ultrafine grains induced by DCAP are quite stable, remaining in size of 0.6μm up to the annealing temperature of 330℃. The macrotexture after annealing is characterized by two components: {111}〈110〉 component and a very sharp rotated cube texture component in place of the cube component, which generally appears to be the dominant component in rolling deformation. The occurrence of preferential growth of rotated cube grains may give rise to the strong intensity of rotated cube orientation in recrystallized texture.

Key words: aluminum alloy; equal channel angular pressing; recrystallization; texture

近十几年来, 等通道角挤压(ECAP—Equal Channel Angular Pressing)由于可制备出细晶和超细晶金属材料正受到越来越广泛的重视[1-3]。 材料进行等通道角挤压时每道次的变形量大, 变形后试样横截面基本保持不变, 这样可以通过多道次变形而在试样内得到大量累积塑性应变, 由于工艺相对简单, 使其具有应用于大规模工业生产的前景。

但ECAP变形时, 无论其试样截面是方形还是圆形, 通常试样都为棒状。 对于板状试样, 采用传统的ECAP方法不能对其变形。 为解决板料的ECAP变形问题, 一种新的ECAP方法—DCAP方法(Dissimilar Channel Angular Pressing)被提出来[4, 5]。 与等通道角挤压对应, DCAP可以表达为非等通道角挤压。 它以一种类似于轧制的变形方式, 连续不断地将剪切应变引入板料中。 与ECAP方法一样, 它也可以对试样进行多道次变形以增加试样中的累积应变量。 对于DCAP变形方式, Lee等[6]对1050铝合金经DCAP变形后的微观组织演变进行了研究, Han等[7, 8]研究了DCAP变形后的材料内织构的变化。 但目前对DCAP变形后材料退火时织构的变化, 还未见研究报道。 本文作者针对DCAP变形后6061铝合金在退火时的组织变化, 以及其宏观织构的变化进行了初步探讨。 DCAP变形方法虽然是针对板料的变形, 但其变形模式与一般的ECAP变形一样, 都是在材料内引入大量纯剪切应变。 因此其研究结果对ECAP变形同样有意义。

1 实验

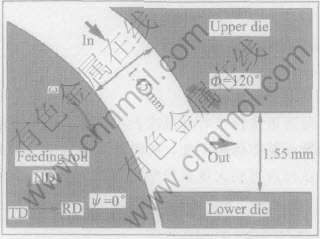

图1所示为DCAP变形方式示意图。 其基本原理为以类似于轧制的方法来作为进料方式, 而不是传统的靠冲头推进作为进料方式。 这一改变保证了可以连续地进行送料, 从而使板料的ECAP成为可能, 并且坯料的长度理论上可以达到无限长。 DCAP的出口通道为1.55mm, 比入口通道1.45mm稍大, 这也是其名称DCAP的来历。 两通道接合处发生ECAP剪切变形, 本文所采用的转角为20°, 根据下式可以计算出DCAP变形量[6]:

本实验中K=0.935, Φ为通道之间的夹角, 本实验为120°。 ε为DCAP变形的等效应变, 可以看出, 此时的DACP变形量为0.58。

图1 DCAP变形模具示意图

Fig.1 Schematic representation of DCAP

实验用材料为5mm厚工业用6061铝合金板材, 其成分(质量分数, %)为Al-1.0Mg-0.6Si-0.3Cu-0.2Cr。

材料首先经过350℃, 1h不完全退火处理后, 再在250℃以每道次10%~15%的轧下量进行轧制。 经过75%的轧制变形后, 将5mm厚的板料轧制到1.55mm。 将板料裁成20mm×200mm的板条状试样, 并使板条的长边方向与轧制方向平行。 随后试样在Φ角为120°的DCAP模具中进行DCAP变形, 得到变形量为0.58的DCAP试样。 DCAP试样在炉中进行不同温度下的1h退火。 退火后在Vickes硬度试验机上测量试样硬度的变化, 以确定退火终了时的温度。

电镜试样用机械方法在试样的侧面截取, 即试样的横向(TD)与电镜样品的法向平行, 用砂纸减薄至30μm后采用离子减薄至穿孔。 试样在Hitachi H-800透射电镜上以加速电压175kV进行观测。 利用选区电子衍射(SADE)斑点来半定量判断亚晶之间的位相差, 衍射选自〈110〉或〈111〉晶带轴, 选区范围约4μm。

宏观织构试样的表面法线与DCAP试样表面法线ND方向一致, 在Phillops Xpert自动测量仪上用CuKα射线测量。 为了避免在制备样品的过程中试样表面的任何机械划伤导致织构测量的误差, 样品在60℃的NaOH溶液中减薄至0.5mm。 用Schultz[9]反射法测量{111}, {200}及{220}3个不完整极图, 并利用这3个极图以WIMV方法计算样品的取向分布函数(ODF)。

2 结果及分析

2.1 DCAP后退火时6061铝合金的微观组织变化

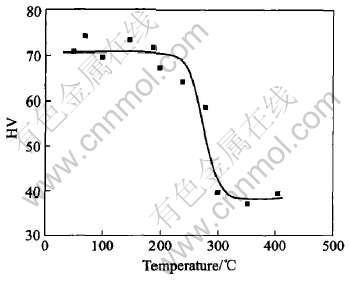

图2所示为6061铝合金经变形量为0.58的DCAP后退火1h时不同退火温度下维氏硬度随温度的变化曲线。 从图2中可以看出, 退火温度在330℃左右时, 材料基本退火完毕。 因此我们选取经240, 285和330℃退火这3个试样来观察材料微观组织的变化和宏观织构的演变。

图2 6061铝合金DCAP后退火1h时退火温度与维氏硬度的关系

Fig.2 Vickers hardness vs annealing temperature of 6061 Al annealed for 1h after DCAP

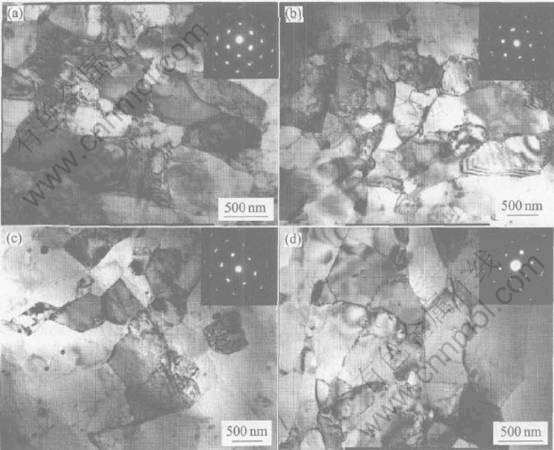

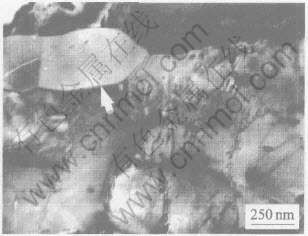

图3所示为6061铝合金DCAP变形后经1h不同温度退火后的电镜照片以及相应的选区电子衍射图。 可见材料经DCAP变形后的微观组织(图3(a))表现为晶粒内存在大量的位错缠结, 和一些被拉长的晶粒, 其宽度只有0.5μm, 长度为2~4 μm, 并且存在一些曲折的、 较厚的晶界, 表明此时有大量的非平衡晶界。 选区衍射斑点表明亚晶之间的位相差为5°~7°。 当材料经过240℃, 1h退火后(图3(b)), 可以看到一些亚晶中虽然仍存在位错堆积, 但有一些亚晶中的位错逐渐减少, 并且晶界开始清晰, 可测得此时的晶粒平均尺寸约为0.48μm, 晶粒平均尺寸为与晶粒或亚晶有相同面积的等效晶粒的平均值。 而当材料经285℃退火后(图3(c)), 可明显看到晶粒较240℃退火时大, 晶界已变得较为平直, 但晶粒中仍可以看到位错结构, 此时晶粒大小约为0.52μm。 材料在330℃退火1h后, 硬度测试表明此时退火过程已经结束(图2), 电镜照片中(图3(d))也可看到晶粒内已基本无位错, 晶界多为平直晶界。 表明此时晶界已是平衡晶界结构, 晶粒大小约为0.58μm。 退火过程中选区衍射斑点一直处于5°~7°左右, 说明在退火过程中亚晶或晶粒之间的位相差基本未变。

图3 DCAP后(a)及在240℃ (b), 285℃ (c)和330℃ (d)退火1h后的试样电镜照片

Fig.3 Microstructures of specimens as-DCAPed (a) and after annealing for 1h at temperatures of 240℃ (b), 285℃ (c) and 330℃ (d)

2.2 退火后6061铝合金织构的变化

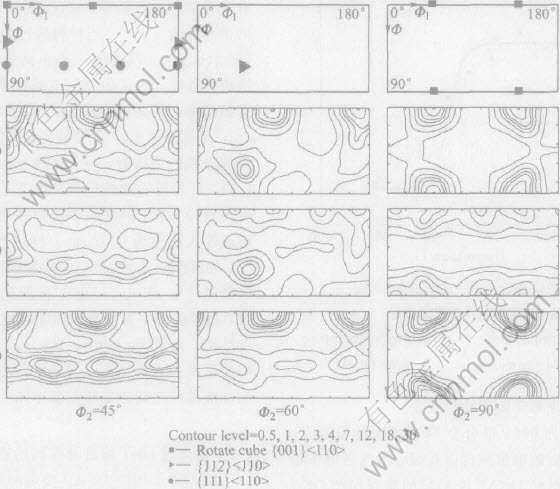

图4所示为经DCAP变形的6061铝合金变形织构和1h等温退火后的取向分布函数(ODF)在Φ2为45°, 60°和90°上的截面图。 由于DCAP变形模式为剪切变形方式, 不同于一般的轧制变形, 此时DCAP变形并没有3个对称轴而只有2个对称轴。 因此, 在Eular子空间中Φ1取值范围是0°~180°, Φ及Φ2的取值范围是0°~90°[10]。 从图中可以看到, 6061铝合金DCAP变形后的织构表现为2个织构分量, 其中旋转立方织构{001}〈110〉为主要织构分量, 同时有{112}〈110〉织构的存在。 当在285℃退火1h后, 可以看到材料内所有织构强度相对减弱, 特别是旋转立方织构。 而当材料在330℃退火1h后, 可以看到材料中又出现很强的旋转立方织构和{111}〈110〉织构, 其中旋转立方织构为主要织构分量, 其强度达到了14倍于随机强度。

图4 DCAP后变形织构(a)及285℃(b)和330℃(c)温度下退火1h后的再结晶织构

Fig.4 Textures of specimens as-DCAPed (a) and annealed for 1h at temperatures of 285℃ (b) and 330℃ (c)

根据近年的研究, 铝合金的再结晶过程由于其层错能较高, 可以是连续再结晶过程, 也可以是非连续再结晶过程[11, 12]。 在本实验中, 由于稳定化处理工序及前道热轧工序的影响, 6061中的沉淀相并没有呈针片状弥散分布, 因此铝的再结晶过程阻力并不是很大。 其次, 在285℃退火时的宏观织构中也可以看出(图4(b)), 此时的宏观织构取向分布强度总体变弱, 如果是连续再结晶, 其所有的变形织构分量应不断增强, 说明此时铝合金并不是进行连续再结晶过程。 而对于铝合金的非连续再结晶过程, 可能会有2种机制, 第二相形核(PSN)和晶界形核, 第二相形核一般在低温大塑性变形中产生, 引起PSN的晶粒一般应该为粗大的第二相粒子, 以可行的观点来看, 至少应大于1μm[13, 14]。 本实验中的电镜观察显示这个条件并不具备。 此外由于第二相周围变形的不均匀性造成晶格不同角度的转动, PSN形核会引起随即织构, 这也是通过退火获得铝合金随即织构的少数方法之一[13]。 而这也与本实验结果不符, 因为从图4(c)中可以看到强烈的再结晶织构。

因此, 从本实验中试样再结晶宏观织构的变化, 我们可以推断本实验中的晶界形核机制应主要是再结晶机制。 图5所示的电镜照片清楚地显示了晶界处形核并向变形程度大的晶粒一侧长大的情形。 由于晶粒在晶界中形核并长大, 造成了过程中整体织构的减弱。 在只有2个织构分量组织中, 由于2个织构分量的位相差大, 它们之间的大角度晶界易于移动而使其中一相易于长到另一相中, 最后形成了与变形织构相似的退火织构。 退火前后的次要织构分量相似也说明了它的形核是晶界形核。 这也与文献[15]中关于晶界形核所形成的织构结果相似。 而此时旋转立方织构的优于其他位相的择优生长造成了旋转立方织构的生长优势, 使其最终成为主要织构。

图5 晶界处形核(285℃, 1h退火)

Fig.5 Microstructure of nucleation at grain boundary (Annealed for 1h at 285℃)

3 结论

1) 经DCAP变形的6061铝合金的细晶组织具有良好的热稳定性, 退火结束后晶粒大小仍保持约为0.6μm, 晶粒仍然只有亚微米级。

2) 与轧制后铝合金常出现的退火织构为立方织构不同, 6061铝合金退火后的主要织构为旋转立方织构, 这与DCAP变形的剪切变形方式有关。

3) 与轧制变形的立方织构相似, DCAP变形后的再结晶机制应为晶界形核长大机制, 并且旋转立方织构表现出强烈的择优生长趋势是使其在退火后的取向分布中成为主要织构分量的原因。

REFERENCES

[1] Segal V M, Reznikov V I, Drobyshevskiy A E, et al. Plastic metal working by simple shear[J]. Izvestiya AN SSSR: Metally, 1981, 1: 115-123.(in Russian)

[2] Segal V M. Materials processing by simple shear[J]. Mater Sci Eng A, 1995, A197: 157-164.

[3] Nakashima K, Horita Z, Nemoto M, et al. Influence of channel angle on the development of ultrafine grains in equal-channel angular pressing [J]. Acta Mater, 1998, 46(5): 1589-1599.

[4] Lee J C, Seok H K, Han J H, et al. Controlling the textures of the metal strips via the continuous confined strip shearing(C2S2) process[J]. Materials Research Bulletin, 2001, 36: 997-1004.

[5] Lee J C, Seok H K, Suh J Y, et al. Structural evolution of a strip-cast Al alloy sheet processed by continuous equal-channel angular pressing[J]. Metallurgical and Materials Transactions A, 2002, 33: 665-673.

[6] Lee J C, Seok H K, Suh J Y. Microstructural evolutions of the Al strip prepared by cold rolling and continuous equal channel angular pressing[J]. Acta Materialia, 2002, 50: 4005-4019.

[7] Han J H, Seok H K, Chung Y H, et al. Texture evolution of the strip cast 1050 Al alloy processed by continuous confined strip shearing and its formability evaluation[J]. Materials Science and Engineering A, 2002, 323: 342-347.

[8] QIN J N, HAN J H, ZHANG G D, et al. Characteristic of textures evolution induced by equal channel angular pressing in 6061 aluminum sheets[J]. Scripta Materialia, 2004, 51: 185-189.

[9] Schultz L G. Direct method of determining preferred orientation of flat reflection sample using Geiger counter X-ray spectrometer[J]. J Appl Phys, 1949, 20: 1030-1033.

[10] Randle V, Engler O. Introduction to Texture Analysis: Macrotexture, Microtexture and Orientation Mapping[M]. Netherlands: Gordon and Breach Science Publishers, 2000.

[11] Engler O, Huh M Y. Evolution of the cube texture in high purity aluminum capacitor foils by continuous recrystallization and subsequent grain growth[J]. Materials Science and Engineering A, 1999, 271: 371-381.

[12] Humphreys F J, Hatherly M. Recrystallization and Related Annealing Phenomena[M]. Amsterdam: Elsevier Science Ltd, 1995.

[13] Perez-Prado M T, Gonzalez-doncel G, Ruano O A, et al. Texture analysis of the transition from slip to grain boundary sliding in a discontinuously recrystallized superplastic aluminum alloy[J]. Acta Mater, 2001, 49: 2259-2268.

[14] Liu W C, Zhai T, Morris J G. Comparison of recrystallization and recrystallization textures in cold-rolled DC and CC AA 5182 aluminum alloys[J]. Materials Science and Engineering A, 2003, 358: 84-93.

[15] Engler O. On the origin of the R orientation in the recrystallization textures of aluminum alloys[J]. Metallurgical and Materials Transactions A, 1999, 30: 1517-1527.

基金项目: 韩国科学技术评估院 (KISTEP)及上海市科学技术委员会重大基础研究资助项目(04DZ14002)

收稿日期: 2004-10-28; 修订日期: 2004-12-22

作者简介: 覃继宁(1964-), 男, 副教授, 博士研究生.

通讯作者: 覃继宁, 副教授; 电话: 021-62933106; E-mail: jnqin@sjtu.edu.cn

(编辑 袁赛前)