变形镁合金中的织构及其优化设计

来源期刊:中国有色金属学报2011年第10期

论文作者:丁文江 靳丽 吴文祥 董杰

文章页码:2371 - 2381

关键词:变形镁合金;织构;基面滑移;孪生;织构

Key words:wrought Mg alloy; texture; basal slip; twin; texture

摘 要:针对变形镁合金存在的典型织构以及织构优化设计方面的研究工作和进展进行综合评述。镁合金由于基面滑移和{1012}孪生是最容易开动的变形模式,在变形镁合金中容易形成挤压丝织构及轧制板织构。通过引入剪切变形,改变成型过程中外加应力的取向,能够有效地改变变形镁合金的织构,同时通过添加微量稀土元素Nd、Ce和Y等,能够明显弱化或随机化变形镁合金织构。织构随机化后的镁稀土合金具有较好的强韧性,合金的变形各向异性得以改善。添加稀土元素后会改变稀土元素与Mg原子间的键能,改变稀土元素周围Mg-Mg原子之间的结合能等,增加非基面滑移的可能性,减弱基面滑移及{1012}孪生所占的比率,有效地弱化镁合金的织构。

Abstract:

The texture and texture evolution of wrought Mg alloy were investigated. The dislocation slip on (0001) plane and the {1012} tension twinning are the main deformation modes and resulted in the typical basal textures in Mg extrusion and sheet. The texture can be altered by changing deformation method, and the rare earth addition is another important way to weaken and randomize the texture of wrought Mg alloy, such as Nd, Ce and Y addition. The wrought alloy with random texture displays good strength and ductility, especially good tension-compression yield symmetry. The mechanism for texture randomization or weakening was also addressed. The rare earth (RE) addition may alert the bond energy between Mg atom with RE atom, improve the possibility of non-basal slip, but inhibit the basal slip and the {1012} twinning, and the texture is weakened.

文章编号:1004-0609(2011)10-2371-11

丁文江1, 2,靳 丽1,吴文祥1,董 杰1

(1. 上海交通大学 轻合金精密成型国家工程研究中心,上海 200240;

2. 上海交通大学 金属基复合材料国家重点实验室,上海 200240)

摘 要:针对变形镁合金存在的典型织构以及织构优化设计方面的研究工作和进展进行综合评述。镁合金由于基面滑移和![]() 孪生是最容易开动的变形模式,在变形镁合金中容易形成挤压丝织构及轧制板织构。通过引入剪切变形,改变成型过程中外加应力的取向,能够有效地改变变形镁合金的织构,同时通过添加微量稀土元素Nd、Ce和Y等,能够明显弱化或随机化变形镁合金织构。织构随机化后的镁稀土合金具有较好的强韧性,合金的变形各向异性得以改善。添加稀土元素后会改变稀土元素与Mg原子间的键能,改变稀土元素周围Mg-Mg原子之间的结合能等,增加非基面滑移的可能性,减弱基面滑移及

孪生是最容易开动的变形模式,在变形镁合金中容易形成挤压丝织构及轧制板织构。通过引入剪切变形,改变成型过程中外加应力的取向,能够有效地改变变形镁合金的织构,同时通过添加微量稀土元素Nd、Ce和Y等,能够明显弱化或随机化变形镁合金织构。织构随机化后的镁稀土合金具有较好的强韧性,合金的变形各向异性得以改善。添加稀土元素后会改变稀土元素与Mg原子间的键能,改变稀土元素周围Mg-Mg原子之间的结合能等,增加非基面滑移的可能性,减弱基面滑移及![]() 孪生所占的比率,有效地弱化镁合金的织构。

孪生所占的比率,有效地弱化镁合金的织构。

关键词:变形镁合金;织构;基面滑移;孪生;织构

中图分类号:TG146.2 文献标志码:A

DING Wen-jiang1, 2, JIN Li1, WU Wen-xiang1, DONG Jie1

(1. National Engineering Research Center of Light Alloy Net Forming,Shanghai Jiao Tong University,

Shanghai 200240, China;

2. Key State Laboratory of Metal Matrix Composite, Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: The texture and texture evolution of wrought Mg alloy were investigated. The dislocation slip on (0001) plane and the ![]() tension twinning are the main deformation modes and resulted in the typical basal textures in Mg extrusion and sheet. The texture can be altered by changing deformation method, and the rare earth addition is another important way to weaken and randomize the texture of wrought Mg alloy, such as Nd, Ce and Y addition. The wrought alloy with random texture displays good strength and ductility, especially good tension-compression yield symmetry. The mechanism for texture randomization or weakening was also addressed. The rare earth (RE) addition may alert the bond energy between Mg atom with RE atom, improve the possibility of non-basal slip, but inhibit the basal slip and the

tension twinning are the main deformation modes and resulted in the typical basal textures in Mg extrusion and sheet. The texture can be altered by changing deformation method, and the rare earth addition is another important way to weaken and randomize the texture of wrought Mg alloy, such as Nd, Ce and Y addition. The wrought alloy with random texture displays good strength and ductility, especially good tension-compression yield symmetry. The mechanism for texture randomization or weakening was also addressed. The rare earth (RE) addition may alert the bond energy between Mg atom with RE atom, improve the possibility of non-basal slip, but inhibit the basal slip and the ![]() twinning, and the texture is weakened.

twinning, and the texture is weakened.

Key words: wrought Mg alloy; texture; basal slip; twin; texture

镁合金具有比强度和比刚度高、导热导电性好、阻尼减震、电磁屏蔽、易于加工成形和容易回收等优点,在汽车、电子通信、航空航天和国防军事等领域具有极其重要的应用价值和广阔的应用前景,被誉为“21世纪绿色工程材料”[1]。与铸造镁合金相比,变形镁合金具有更大的发展潜力,通过材料结构的控制、热处理工艺的应用,变形镁合金可获得更高的强度、更好的延展性和更多样化的力学性能,从而满足多样化工程结构件的应用需求。镁合金由于具有密排六方晶体结构,室温下独立的滑移系少,导致变形加工困难。因此,变形镁合金往往需要加热到一定温度并通过挤压、轧制及锻造等热成形技术加工而成。镁合金有限的滑移系导致了其在塑性变形后容易形成较强的基面织构。近年来,随着变形镁合金用量的增加以及研究的不断深入,织构对镁合金力学性能的影响越来越受到材料学者和工程设计人员的重视[2-3]。关于镁合金织构的研究已成为变形镁合金的研究热点之一。一方面,通过对织构形成机制的研究可丰富镁合金塑性变形的基础理论;另一方面,通过引入新的变形方式和添加微量稀土元素可弱化镁合金织构,从而实现织构的优化设计,这对于发展新型的塑性成型技术和开发具有成形性高的镁合金材料具有重要意义。本文作者针对现有镁合金的主要织构类型及织构优化设计方面的研究进展进行了综合评述。

1 变形镁合金织构优化设计及控制

1.1 变形镁合金织构形成机理

镁单晶的滑移系有![]() (0001)、

(0001)、![]() 、

、![]() 的a滑移, 以及

的a滑移, 以及![]() 方向沿

方向沿![]() 、

、![]() 、

、![]() 和

和![]() 等晶面的c+a滑移。但是滑移系开动的临界剪切应力(CRSS)在各自滑移系上的差别非常明显。基面滑移系的CRSS值最低约为0.5~0.7 MPa,而柱面及锥面滑移系的CRSS约为基面滑移系的100倍[4-5]。除了位错滑移,镁合金中有

等晶面的c+a滑移。但是滑移系开动的临界剪切应力(CRSS)在各自滑移系上的差别非常明显。基面滑移系的CRSS值最低约为0.5~0.7 MPa,而柱面及锥面滑移系的CRSS约为基面滑移系的100倍[4-5]。除了位错滑移,镁合金中有![]() 拉伸孪生、

拉伸孪生、![]() 压缩孪生,以及

压缩孪生,以及![]() 、

、![]() 等晶面的孪生[6-7]。但是,

等晶面的孪生[6-7]。但是,![]() 拉伸孪生变形的临界驱动力最低[8]。通常镁合金中最容易发生变形的方式为基面a滑移及

拉伸孪生变形的临界驱动力最低[8]。通常镁合金中最容易发生变形的方式为基面a滑移及![]() 孪生变形,这也是镁合金中形成强织构的主要原因。

孪生变形,这也是镁合金中形成强织构的主要原因。

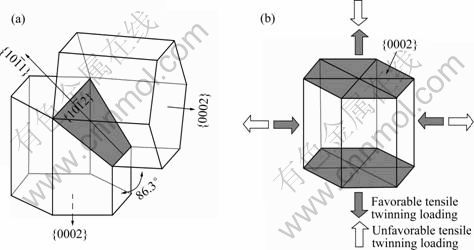

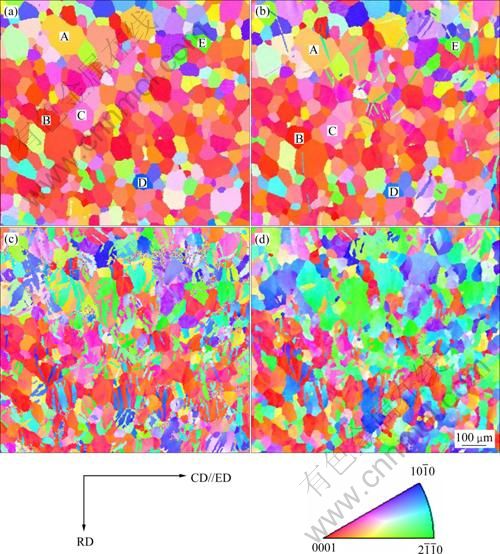

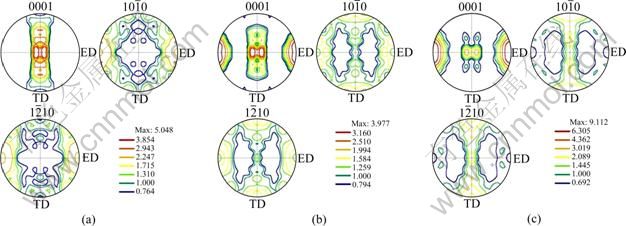

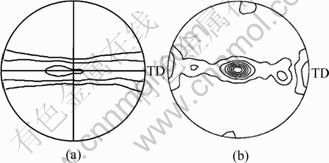

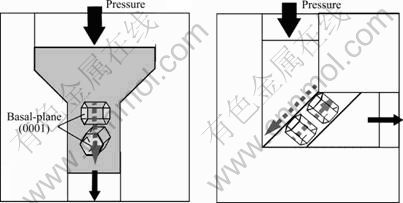

如图1所示,当镁晶体中c轴处于受拉状态时,容易发生![]() 孪生变形,孪生后的取向与母体晶粒成86.3°的位向关系[9-10]。孪生后晶体的c轴平行于外加应力轴。所以发生孪生变形后的镁合金,容易形成c轴平行于外加应力轴的织构,如挤压丝织构及轧制板织构。对纯镁压缩变形后的原位背散射电子衍射(EBSD)观察发现,随着变形量增加,孪晶的体积分数增加、合金的取向逐步发生变化,如图2所示[11]。孪生变形后,晶粒的取向发生明显变化。如图3所示,压缩过程中,c轴逐渐转向于压缩轴平行(压缩轴平行于ED)。20%变形后,主要的织构取向显示其c轴几乎都平行于压缩轴。这就是镁合金在变形过程中容易形成织构的原因。因为变形模式的单一化增强了晶粒取向与外加应力场的依赖性。镁合金变形过程中,如果其他非基面滑移系增加,以及其他孪生方式增加,而不是较单一的基面位错滑移和

孪生变形,孪生后的取向与母体晶粒成86.3°的位向关系[9-10]。孪生后晶体的c轴平行于外加应力轴。所以发生孪生变形后的镁合金,容易形成c轴平行于外加应力轴的织构,如挤压丝织构及轧制板织构。对纯镁压缩变形后的原位背散射电子衍射(EBSD)观察发现,随着变形量增加,孪晶的体积分数增加、合金的取向逐步发生变化,如图2所示[11]。孪生变形后,晶粒的取向发生明显变化。如图3所示,压缩过程中,c轴逐渐转向于压缩轴平行(压缩轴平行于ED)。20%变形后,主要的织构取向显示其c轴几乎都平行于压缩轴。这就是镁合金在变形过程中容易形成织构的原因。因为变形模式的单一化增强了晶粒取向与外加应力场的依赖性。镁合金变形过程中,如果其他非基面滑移系增加,以及其他孪生方式增加,而不是较单一的基面位错滑移和![]() 孪生,镁合金的织构则会随之弱化。

孪生,镁合金的织构则会随之弱化。

1.2 变形镁合金中的典型织构

变形镁合金中主要有两类变形织构:挤压(拔丝)时形成纤维织构,板材轧制时形成的板织构,而通过等通道角挤压等变形方式形成了其他类型的变形 织构。

图1 ![]() 拉伸孪生变形示意图

拉伸孪生变形示意图

Fig.1 Schematic diagram of ![]() tensile twin system in magnesium: (a) 86.3° reorientation of twin grain relative to parent grain[9]; (b) Applied loading direction respecting c-axis[10]

tensile twin system in magnesium: (a) 86.3° reorientation of twin grain relative to parent grain[9]; (b) Applied loading direction respecting c-axis[10]

图2 纯镁压缩变形过程中原位背散射电子衍射观察的取向分布图(IPF map)[11]

Fig.2 IPF maps of pure Mg by compression to different deformation rates by electron back scan diffraction[11]: (a) Before deformation; (b) 3.3%; (c)10%; (f) 20% (Available online)

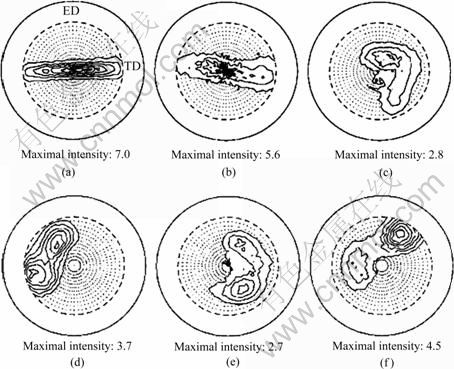

图3 纯镁压缩变形过程中的极图

Fig.3 Pole figures of pure Mg by compression to different deformation rates: (a) Before deformation; (b) 10%; (c) 20% (Available online)

1) 镁合金纤维织构

镁合金在挤压(拔丝)等塑性变形过程中易形成(0001)平面平行于挤压(拔丝)方向(ED)的纤维织构,同时在单向压缩过程中能形成(0001)平面垂直于压缩方向的纤维织构[12]。图4所示为挤压过程中形成纤维织构的晶粒的取向示意图。绝大多数晶粒的基面是平行于挤压方向的。镁合金挤压后的织构还随着挤压制品断面的不同而有所区别:在进行棒材挤压时,应力状态为轴对称状态,(0001)面平行于挤压方向,晶粒取向自由度大,晶粒可以保证基面平行于挤压方向的同时围绕着挤压方向发生360°转动;而在进行板材等复杂断面型材挤压的时候,由于仅在局部是面对称,晶粒取向自由度较小,基面法向TD方向偏移较少。在挤压管材的时候,容易形成两个取向的丝织构,一种是c轴平行于径向(RD组分),另一种是c轴平行于管材切向(TD)[13]。图5所示为AZ31棒材挤压[14]和AZ61板材挤压态镁合金(0001)面极图[15]。可以发现,在板材挤压时有少量的晶粒(0001)面垂直于挤压方向,而在棒材挤压过程中,在检测区域内所有晶粒基面平行于挤压方向。

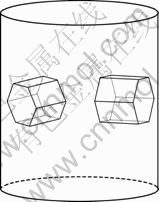

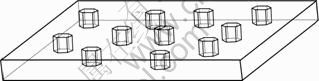

图4 镁合金挤压棒材丝织构晶粒取向示意图

Fig.4 Schematic diagram of orientation of grains after extrusion of Mg alloy

图5 镁合金挤压后(0001)面极图[14-15]

Fig.5 (0001) pole figure of AZ31 extrusion rod(a)[14] and AZ61 extrusion sheet(b)[15]

挤压工艺对镁合金挤压后的织构具有明显的影响,PARK等[16]研究AZ31合金在不同温度及变形速度下挤压后的织构,变形温度及速度的差异导致基面织构的强弱差异。AZ31经300 ℃挤压后比经250 ℃挤压后的丝织构更强。而挤压速度高,丝织构更明显。但是温度及速度对挤压后织构的影响规律也因合金体系不同有明显差别。SHAHZAD和WAGNER[17]研究发现,AZ80合金挤压过程中,挤压比对于合金的织构有明显的影响,挤压比小的条件下对应的合金丝织构更强。

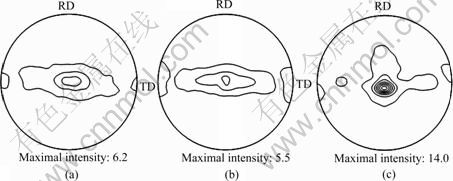

2) 镁合金板织构

镁合金在轧制过程中将形成(0001)面平行于轧面的织构[12, 18]。图6所示为在轧制过程中形成板织构后的晶粒取向示意图。同样,在轧制过程中形成的板织构随着轧制道次的增加而变化[15]。图7所示为不同道次轧制后AZ61合金板材的(0001)极图。在轧制次数 少的厚轧板中,基面织构强度较弱,有较多晶粒由基面法向向TD方向偏移,当轧制道次增加,轧板厚度降低时,基面织构的强度增强,大多数晶粒基面平行于轧板平面。

图6 镁合金轧制板材织构晶粒取向示意图

Fig.6 Schematic diagram of orientation of grains after rolling of Mg alloy

镁合金轧制变形过程中的工艺参数影响轧制过程中的位错滑移及孪生方式,从而影响板材的最终织构与力学性能[19-20],AZ31合金轧制过程中,当轧制温度从300 ℃升高到400 ℃时,增加了![]() 压缩孪晶的比率。由于

压缩孪晶的比率。由于![]() 拉伸孪晶与母晶粒成86.3°的位向关系,

拉伸孪晶与母晶粒成86.3°的位向关系,![]() 压缩孪晶与母晶粒成56°位向关系,如图8所示[19],从而基面织构弱化,合金伸长率提高。

压缩孪晶与母晶粒成56°位向关系,如图8所示[19],从而基面织构弱化,合金伸长率提高。

3) 其他类型变形织构

镁合金等通道角挤压(ECAP)是一种能够有效细化晶粒的塑性变形方式,由于变形过程中,镁合金发生了明显的剪切变形,其剪切的角度跟ECAP的模具结构以及挤压道次间的路线设计直接相关[21]。镁合金在进行ECAP变形时易产生基面与挤压方向成一定夹角的织构。晶粒取向示意图如图9所示[22]。图10所示为AZ61圆棒在经过不同道次ECAP挤压后织构演变情况[23]。随着挤压道次的增加,由典型的丝织构转化为其他类型织构取向。

图7 AZ61镁合金不同道次轧制后(0002)面极图[15]

Fig.7 (0002) pole figure of AZ61 Mg alloy after different rollings[15]: (a) 10 mm thick; (b) 4 mm thick; (c) 1 mm thick

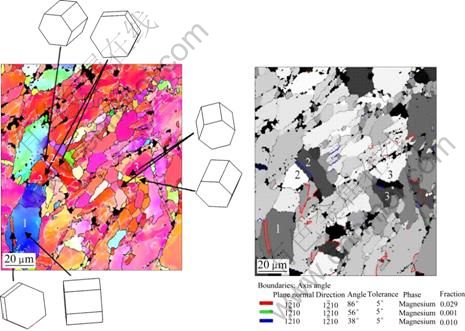

图8 400 ℃轧制AZ31镁板的微观组织[19]

Fig.8 Microstructures of AZ31 Mg alloy sheet after rolled 1 pass with reduction of 50% at 400 ℃: (a) IPF map and lattice orientation of parent and twins; (b) Grain shape map with defined twin boundaries, extension twin boundaries (86°![]() ±5°) are outlined in red, contraction twin boundaries (56°

±5°) are outlined in red, contraction twin boundaries (56°![]() ±5°) outlined in green and double twin boundaries (38°

±5°) outlined in green and double twin boundaries (38°![]() ±5°) outlined in blue[19] (Available online)

±5°) outlined in blue[19] (Available online)

图9 镁合金ECAE织构晶粒取向示意图[22]

Fig.9 Schematic diagram of orientation of grains after ECAE of Mg alloys[22]

图10 经过不同道次ECAP挤压的AZ61镁合金(0002)面极图[23]

Fig.10 {0002} pole figures of unECAPed and ECAPed Mg alloys after different passes[23]: (a) 0-pass; (b) 1-pass; (c) 2-pass; (d) 3-pass; (e) 4-pass; (f) 8-pass

2 织构对镁合金力学性能的影响

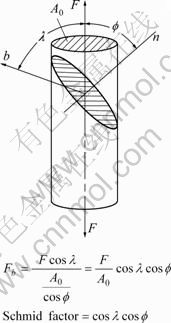

位错滑移及孪生是镁合金的主要变形方式。织构影响镁合金的力学性能主要体现在影响其位错滑移及孪生。材料外加应力与滑移系的对照关系可以用Schmid因子来说明,如图11所示。外力施加在滑移系上的剪切力与Schmid因子有关,Schmid及外力施加在滑移面上的分切应力计算公式如图11中所示。对于可动独立滑移系较多的FCC及BCC金属而言,晶体取向对Schmid因子的影响非常小。但是镁合金的滑移系非常少。所以外加应力在基面滑移系上的Schmid因子高时,位错滑移更容易开动,合金塑性好,反之,当镁合金存在强织构并且基面滑移系的分切应力低时,合金的塑性成形能力差。图12所示为室温条件下镁单晶体的平面应变压缩应力—应变曲线[24],说明了晶体取向对镁单晶的变形抗力有明显的影响。

对应于具有纤维织构的镁合金棒材,大部分晶粒{0001}基面平行于挤压方向。在沿着挤压方向拉伸的时候,晶粒沿c轴受到压缩,同时基面滑移系Schmid因子接近于0,分切应力也接近于0,所以滑移系的开动比较困难。同时由于合金中c轴处于受压状态,![]() 孪晶的开动困难,必须在较高的应力下才能够开动压缩孪晶及其他孪生模式。当具有该织构的合金沿挤压方向压缩时,c轴处于受拉状态,

孪晶的开动困难,必须在较高的应力下才能够开动压缩孪晶及其他孪生模式。当具有该织构的合金沿挤压方向压缩时,c轴处于受拉状态,![]() 孪生容易启动,合金变形抗力低。从而在含丝织构的合金中容易出现明显的拉压不对称性[25-27]。而具有板织构的镁合金板材,织构对合金力学性能的影响的原理与此类似,在与轧制方向为0°、45°、90°的样品表现了明显的各向异性。

孪生容易启动,合金变形抗力低。从而在含丝织构的合金中容易出现明显的拉压不对称性[25-27]。而具有板织构的镁合金板材,织构对合金力学性能的影响的原理与此类似,在与轧制方向为0°、45°、90°的样品表现了明显的各向异性。

图11 施密特因子计算示意图

Fig.11 Schematic diagram of Schmid factor

图12 室温条件Mg单晶体的平面应变压缩应力—应变 曲线[24]

Fig.12 Strain—stress curves of single crystalline magnesium at room temperature[24]

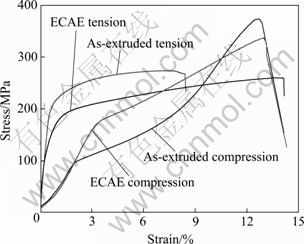

对应于经ECAP等变形方式成型的镁合金,由于织构取向中显示其基面与挤压发现成接近45°的方向,所以在基面滑移系上的分切应力因子高,从而大幅度提高了合金的室温塑性[28-30],图13所示为挤压态和ECAE态AZ31镁合金的室温拉伸和压缩曲线。由图13可以看出,织构的改变明显改善了镁合金的力学性能[25]。

图13 挤压态和ECAE态AZ31合金室温拉伸和压缩曲线[25]

Fig.13 Uniaxial tension and compression curves of as- extrusion and ECAE AZ31 Mg alloys at room temperature[25]

3 变形镁合金织构优化设计

织构的存在对变形镁合金的力学行为影响明显,因此,镁合金的织构优化设计对改善和提高变形镁合金的塑性成型性具有非常重要的意义。而近年来关于织构优化的设计方向也受到广大研究者的关注,其中比较明显的两个研究方向是:1) 通过改变镁合金塑性成型的路径,引入剪切变形等,改变基面的取向分布;2) 通过引入稀土元素,获得织构随机化的效果,开发具有高塑性的镁稀土合金体系。

3.1 镁合金塑性成型路径对织构的影响

通过变形路径改变镁合金织构的思路最早由MUKAI等[22]提出。如图9所示,由于变形路径中合金经历了一定角度的剪切变形,使得最终样品中基面法向与挤压方向成30°~45°角度。因为基面位向的改变而合金的伸长率大幅提高,由此而引出了更多的研究方向,在镁合金的塑性成形过程中引入适当的剪切变形,可优化合金的织构取向,包括ECAP的大塑性变形[22, 25, 29]、异步轧制[31-34]、反复叠轧[32]等变形工艺。AZ31合金轧制过程中,由于增加了反复剪切变形,板材基面织构弱化及晶粒细化,合金强度可提高到400 MPa[35]。镁合金在实施搅拌摩擦焊加工过程中,表面层金属受到剪切应力作用,合金表层基面织构弱化,由表层往中心织构梯度明显。合金的伸长率提高但强度降低[36]。镁合金板材经过异步轧制后,基面板织构的最大极密度降低,这也是由于轧制过程中引入剪切变形促使的织构弱化效应[32-34]。虽然改变变形路径一定程度上可以改变或弱化镁合金的纤维织构或板织构,但是当生产较大尺寸的挤压板型材时,设计特别的路径给工业生产带来了新的困难和挑战。

3.2 稀土合金化与镁合金织构随机化

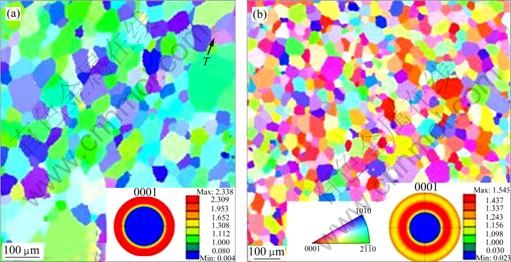

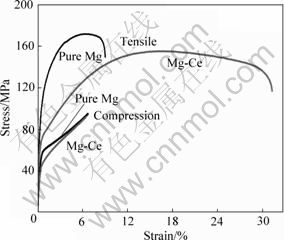

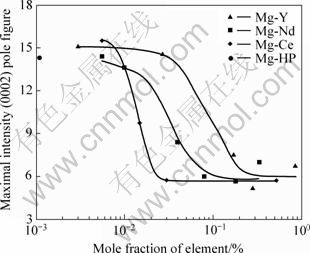

MISHRA等[26]指出纯镁添加0.2%Ce后挤压态合金表现出明显的织构弱化,如图14所示,织构强度最大值从2.7下降到1.5。而添加0.2%Ce以后的Mg-Ce二元合金的伸长率大幅提升,如图15所示。微量稀土添加后镁合金板材也有明显的织构弱化效果,HANTZSCHE等[37]研究了Nd、Y和Ce元素添加后对合金板材织构的影响规律(如图16所示),随着稀土含量增加,基面板织构明显弱化。

虽然少量稀土元素添加后能够弱化镁合金变形织构,伸长率大幅提升,但是合金强度依然很低。需要增加强化因素提高合金的综合强韧性。引入合适的强化因子,包括析出相、固溶强化等。在Mg-Ce二元合金基础上添加Zn元素,明显提高合金的强度[38-39]。Al元素常被用于提高镁合金强度和硬度,但是Al元素易与Ce在镁合金中形成Al11Ce3,削弱Ce对于合 金晶粒细化和织构弱化的效果。比如在AZ31合金中添加Ce及Y等元素,合金的织构取向变化不大。Zn元素常被用于提高变形镁合金强度。LUO等[38]研究了不同含量的Zn(2.4%、4.9%和7.6%)元素对Mg-Zn-Ce合金组织和性能的影响,随着Zn元素含量增加,合金强度提高,但是塑性降低,当Zn含量为2.4%时,合金表现出良好的塑性及较好的强度,综合力学性能较好。

图14 纯镁和Mg-0.2Ce合金挤压后(0001)反极图和极图[26]

Fig.14 (0001) PF and IPF maps of extruded pure Mg(a) and Mg-0.2Ce alloy(b)[26]

图15 挤压态Mg及Mg-0.2Ce合金棒材的拉伸和压缩曲线

Fig.15 Tensile and compression curves of for extruded Mg and Mg-0.2Ce rods (extrusion ratio is 25:1).

图16 镁合金板材(0002)极图上最大的极密度随稀土元素含量的分布[37]

Fig.16 Maximum (0002)-pole figure intensity in as-rolled condition for mg alloy sheet with RE addition[37]

4 织构随机化机理研究的最新进展

通过改变镁合金变形路径从而改变镁合金织构的原因主要是因为引入了剪切变形,如ECAP等变形方式[22]。在轧制后镁合金组织常会出现变形不均匀现象,在微观组织中出现很明显的孪生、剪切带,他们可以为再结晶提供形核点,这些变形带能够使再结晶晶粒基面平行于剪切平面,造成一定程度上的织构强度的弱化[40]。

稀土合金元素的添加同样对镁合金织构弱化作用明显,但其机理还不够清晰。HUMPHREYS和HATHERLY[41]研究发现,添加10%(体积分数)的SiC颗粒后,极大地降低了镁合金变形基面织构的强度,晶粒取向分布更加随机化,也就是粒子促进形核机理(PSN)。也有研究[42]表明Ce元素织构弱化的效果主要是颗粒促进形核引起的,Ce元素的添加并不能改变镁合金的c/a值,但是Ce在镁合金中的固溶度非常低,易形成第二相颗粒,在变形中引发动态再结晶,起到弱化织构的作用。但是,PSN机制不足以解释所有织构弱化的现象。对于一些镁稀土合金,即使不含有颗粒,在挤压后也可能出现明显的织构弱化效果[43]。同样对于某些镁合金而言即使有颗粒的存在,也没出现明显的织构弱化现象[44]。

另一种观点是溶质拖曳机制(Solute drag),Jan BOHLEN[40]研究了Mg-Zn-Re镁合金轧制板材的织构,发现在试验中含有稀土元素和Y元素的合金都存在一定程度的织构弱化、取向随机化的现象,并且认为这是由于Y 的原子扩散速度比较慢,溶质拖曳效果能够强烈地影响晶界的移动、晶粒的取向和再结晶机制,进而影响变形后晶粒的取向。AGNEW等[45]对比纯镁、Mg-Y和Mg-Li合金变形织构,发现添加Y和Li元素的合金虽然在织构类型上没有变化但是其织构强度明显降低。其原因是Y和Li元素的添加改变了纯镁的晶体结构,降低了c/a值,改变了变形过程中的滑移系,从而降低基面织构的强度。

值得注意的是,CHINO等[42]研究了Ce元素对Mg-0.2%Ce合金单向压缩后织构的影响,认为在向纯镁当中添加0.035%(摩尔分数)的Ce元素并不能改变合金的c/a值,Ce元素固溶到镁基体当中不仅仅改变Mg—Ce原子之间的化学键,同样对Ce原子周围的Mg—Mg原子间化学键都有一定的影响,进而影响镁合金在变形过程中的变形方式,造成非基面织构的产生并弱化基面织构。

关于稀土元素Y、Ce、Nd等添加后织构随机化的原因,更多的研究表明,由于稀土元素的添加,改变了稀土元素与Mg原子之间的键能以及稀土元素周围Mg—Mg原子键能,并且可能改变基面及非基面的层错能,从而改变基面及非基面滑移系以及孪生开动的临界剪切应力。从改变镁合金变形机理的角度实现了织构弱化的最终效果。而关于稀土元素添加后层错能变化及非基面滑移等开动的研究正在进行及讨论中,可以期待对镁合金织构随机化机理更深入的认识,从而为我们设计高性能镁合金提供更加有力的理论 支持。

5 结论

1) 镁合金由于基面滑移和![]() 孪生是最容易开动的变形模式,在变形镁合金中容易形成挤压丝织构及轧制板织构。通过挤压工艺及轧制工艺的调整可以适当弱化织构的强度,但是织构弱化的幅度非常有限。

孪生是最容易开动的变形模式,在变形镁合金中容易形成挤压丝织构及轧制板织构。通过挤压工艺及轧制工艺的调整可以适当弱化织构的强度,但是织构弱化的幅度非常有限。

2) 通过引入剪切变形,改变成型过程中外加应力的取向,能够有效改变变形镁合金的织构,目前有效引入剪切应力、弱化织构的变形方式有等通道角挤压(ECAP)变形、异步轧制、交叉轧制、表面摩擦磨损等。通过添加微量稀土元素Nd、Ce和Y等,能够明显弱化或随机化变形镁合金织构。织构随机化后的镁稀土合金具有较好的强韧性,合金的变形各向异性得以改善。

3) 织构随机化机理值得深入探讨,理论的研究有利于设计及开发更多高性能的变形镁合金。目前研究表明,稀土元素添加后会改变稀土元素与Mg原子间的键能,改变稀土元素周围Mg—Mg原子之间的结合能等,增加了非基面滑移的可能性,减弱了基面滑移及![]() 孪生所占的比率,有效地弱化了镁合金的织构。

孪生所占的比率,有效地弱化了镁合金的织构。

REFERENCES

[1] 丁文江. 镁合金科学与技术[M]. 北京: 科学出版社, 2007.

DING Wen-jiang. Magnesium alloy science and technology[M]. Beijing: Science Press, 2007.

[2] 唐伟琴, 张少睿, 范晓慧, 李大永, 彭颖红. AZ31镁合金的织构对其力学性能的影响[J]. 中国有色金属学报, 2010, 20(3): 371-377.

TANG Wei-qin, ZHANG Shao-rui, FAN Xiao-hui, LI Da-yong, PENG Ying-hong. Texture and its effect on mechanical properties of AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 371- 377.

[3] 余 琨, 芮守泰, 王日初, 彭超群, 薛新颖. AZ31镁合金挤压薄板织构及力学各向异性[J]. 中国有色金属学报, 2008, 18(12): 2127-2131.

YU Kun, RUI Shou-tai, WANG Ri-chu, PENG Chao-qun, XUE Xin-ying. Texture and mechanical anisotropy of AZ31 extruded sheets[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(12): 2127-2131.

[4] OBARA T, YOSHINAGA H, MOROZUMI S. ![]() slip system in magnesium[J]. Acta Metall, 1973, 21: 845-853.

slip system in magnesium[J]. Acta Metall, 1973, 21: 845-853.

[5] STOHR J F, POIRIER J P. Electron microscope study of {1122 macr} pyramidal slip in magnesium[J]. Philosophical Magazine,1972, 25(6): 1313-1329.

[6] CHRISTIAN J W, MAHAJAN S. Deformation twinning[J]. Progress in Materials Science, 1995, 39(1/2): 1-157.

[7] ANDO D, KOIKE J, SUTOU Y. Relationship between deformation twinning and surface step formation in AZ31 magnesium alloys[J]. Acta Materialia, 2010, 58(13): 4316-4324.

[8] BARNETT M R. A Taylor model based description of the proof stress of magnesium AZ31 during hot working[J]. Metallurgical and Materials Transactions A, 2003, 34(9): 1799-1806.

[9] ROBERTS C S. Magnesium and its alloys[M]. New York: Wiley, 1960.

[10] WANG Y N, HUANG J C. The role of twinning and untwinning in yielding behavior in hot-extruded Mg-Al-Zn alloy[J]. Acta Materialia, 2007, 55(3): 897-905.

[11] 靳 丽, MISHARA R K, KUBIC R. 材料变形过程中的原位电子背散射衍射(In-situ EBSD)分析[J]. 电子显微学报, 2008, 27(6): 439-442.

JIN Li, MISHARA R K, KUBIC R. In-situ EBSD analysis on the microstructures during deformation[J]. Journal of Chinese Electron Microscopy Society, 2008, 27(6): 439-442.

[12] 陈振华, 夏伟军, 程永奇, 傅定发. 镁合金织构与各向异性[J]. 中国有色金属学报, 2005, 15(1): 1-11.

CHEN Zhen-hua, XIA Wei-jun, CHEN Yong-qi, FU Ding-fa. Texture and anisotropy in magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 1-11.

[13] JIANG L, JONAS J J, MISHRA R K, LUO A A, SACHDEV A K, GODET S. Twinning and texture development in two Mg alloys subjected to loading along three different strain paths[J]. Acta Materialia, 2007, 55(11): 3899-3910.

[14] BARNETT M R. Twining and the ductility of magnesium alloys Part Ⅰ: “Tension” twins[J]. Materials Science and Engineering A, 2007, 464: 1-7.

[15] PEREZ-PRADO M T, del VALLE J A, RUANO O A. Effect of sheet thickness on the microstructural evolution of an Mg AZ61 alloy during large strain hot rolling[J]. Scripta Materialia, 2004, 50(5): 667-671.

[16] PARK S S, YOU B S, YOON D J. Effect of the extrusion conditions on the texture and mechanical properties of indirect-extruded Mg-3Al-1Zn alloy[J]. Journal of Materials Processing Technology, 2009, 209(18/19): 5940-5943.

[17] SHAHZAD M, WAGNER L. Influence of extrusion parameters on microstructure and texture development, and their effect on mechanical properties of the magnesium alloy AZ80[J]. Materials Science and Engineering A, 2009, 506: 141-147.

[18] STYCZYNSKI A, HARTIG C, BOHLEN J, LETZIG D. Cold rolling textures in AZ31 wrought magnesium alloy[J]. Scripta Materialia, 2004, 50(7): 943-947.

[19] JIN L, DONG J, WANG R, PENG L M. Effects of hot rolling processing on microstructures and mechanical properties of Mg-3%Al-1%Zn alloy sheet[J]. Materials Science and Engineering A, 2010, 527(7/8): 1970-1974.

[20] JIN Q L, SHIM S Y, LIM S G. Correlation of microstructural evolution and formation of basal texture in a coarse grained Mg-Al alloy during hot rolling[J]. Scripta Materialia, 2006, 55(9): 843-846.

[21] SHIN D H, KIM I, KIM J, KIM Y S, SEMIATIN S L. Microstructure development during equal-channel angular pressing of titanium[J]. Acta Materialia,2003, 51(4): 983-996.

[22] MUKAI T, YAMANOI M, WATANABE H, HIGASHI K. Ductility enhancement in AZ31 magnesium alloy by controlling its grain structure[J]. Scripta Materialia,2001, 45(1): 89-94.

[23] KIM W J, HONG S I, KIM Y S, MIN S H, JEONG H T, LEE J D. Texture development and its effect on mechanical properties of an AZ61 Mg alloy fabricated by equal channel angular pressing[J]. Acta Materialia, 2003, 51(11): 3293-3307.

[25] 路 君, 靳 丽, 董 杰, 曾小勤, 丁文江, 姚真裔. 等通道角挤压变形AZ31镁合金的变形行为[J]. 中国有色金属学报, 2009, 19(3): 424-432.

LU Jun, JIN Li, DONG Jie, ZENG Xiao-qin, DING Wen-jiang, YAO Zhen-yi. Deformation behaviors of AZ31 magnesium alloy by equal channel angular extrusion[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(3): 424-432.

[26] MISHRA R K, GUPTA A K, RAO P R, SACHDEV A K, KUMAR A M, LUO A A. Influence of cerium on the texture and ductility of magnesium extrusions[J]. Scripta Materialia, 2008, 59(5): 562-565.

[27] BALL E A, PRANGNELL P B. Tensile-compressive yield asymmetries in high strength wrought magnesium alloys[J]. Scripta Metallurgica et Materialia, 1994, 31(2): 111-116.

[28] DEL VALLE J A, CARRENO F, RUANO O A. Influence of texture and grain size on work hardening and ductility in magnesium-based alloys processed by ECAP and rolling[J]. Acta Materialia, 2006, 54(16): 4247-4259.

[29] KIM W J, AN C W, KIM Y S, HONG S I. Mechanical properties and microstructures of an AZ61 Mg Alloy produced by equal channel angular pressing[J]. Scripta Materialia, 2002, 47(1): 39-44.

[30] KIM W J, LEE J B, KIM W Y, JEONG H T, JEONG H G. Microstructure and mechanical properties of Mg-Al-Zn alloy sheets severely deformed by asymmetrical rolling[J]. Scripta Materialia, 2007, 56(4): 309-312.

[31] 夏伟军, 蔡建国, 陈振华, 陈 刚, 蒋俊峰. 异步轧制AZ31镁合金的微观组织与室温成形性能[J]. 中国有色金属学报, 2010, 20(7): 1247-1253.

XIA Wei-jun, CAI Jian-guo, CHEN Zhen-hua, CHEN Gang, JIANG Jun-feng. Microstructure and room temperature formability of AZ31 magnesium alloy produced by differential speed rolling[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1247-1253.

[32] WATANBE H, MUKAI T, ISHIKAWA K. Differential speed rolling of an AZ31 magnesium alloy and the resulting mechanical properties[J]. Journal of Materials Science, 2004, 39: 1477-1480.

[33] KIM S H, YOU B S, YIM C D. Texture and microstructure changes in asymmetrically hot rolled AZ31 magnesium alloy sheets[J]. Materials Letters, 2005, 59(29/30): 3876-3880.

[34] KIM W J, PARK J D, KIM W Y. Effect of differential speed rolling on microstructure and mechanical properties of an AZ91 magnesium alloy[J]. Journal of Alloys and Compounds, 2008, 460(1/2): 289-293.

[35] MUKAI T, SOMEKAWA H, INOUE T, SINGH A. Strengthening Mg-Al-Zn alloy by repetitive oblique shear strain with caliber roll[J]. Scripta Materialia, 2010, 62(2): 113-116.

[36] WOO W, CHOO H, BROWN D W, LIAW P K, FENG Z. Texture variation and its influence on the tensile behavior of a friction-stir processed magnesium alloy[J]. Scripta Materialia, 2006, 54(11): 1859-1864.

[37] HANTZSCHE K, BOHLEN J, WENDT J, KAINER K U, YI S B, LETZIG D. Effect of rare earth additions on microstructure and texture development of magnesium alloy sheets[J]. Scripta Materialia, 2010, 63(7): 725-730.

[38] LUO A A, MISHRA R K, SACHDEV A K. High-ductility magnesium-zinc-cerium extrusion alloys[J]. Scripta Materialia, 2011, 64(5): 410-413.

[39] 李 广, 靳 丽, 董 杰, 吴国华, 丁文江. Zn添加对挤压态Mg-Zn-Ce-Zr合金微观组织及力学性能的影响[J]. 中国有色金属学报, 2011, 21(2): 251-258.

LI Guang, JIN Li, DONG Jie, WU Guo-hua, DING Wen-jiang. Effects of Zn addition on microstructures and mechanical properties of as-extruded Mg-Zn-Ce-Zr alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(2): 251-258.

[40] BOHLEN J, N?RNBERG M R, SENN J W, LETZIG D, AGNEW S R. The texture and anisotropy of magnesium- zinc-rare earth alloy sheets[J]. Acta Materialia, 2007, 55: 2101-2112.

[41] HUMPHREYS F J, HATHERLY M. Recrystallization and related annealing phenomena (2nd ed)[M]. Oxford: Pergamon Press, 2004.

[42] CHINO Y, KADO M, MABUCHI M. Compressive deformation behavior at room temperature-773 K in Mg-0.2 mass% (0.035at.%)Ce alloy[J]. Acta Materialia, 2008, 56(3): 387-394.

[43] SENN J, AGNEW S. Texture randomization of magnesium alloys containing rare earth elements[C]//MIHRIBAN O P, NEALE R N, RANDY S B, ERIC A N. Magnesium Technology. New Orleans: Warrendale, 2008: 153-158.

[44] LASER T, NURNBERG M R, JANZ A, HARTIG C, LETZIG D, SCHMID-FETZER R, BORMANN R. The influence of manganese on the microstructure and mechanical properties of AZ31 gravity die cast alloys[J]. Acta Materialia, 2006, 54(11): 3033-3041.

[45] AGNEW S R, YOO M H, TOME C N. Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y[J]. Acta Materialia, 2001, 49(20): 4277-4289.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(50901044)

收稿日期:2010-05-10;修订日期:2011-07-18

通信作者:丁文江,教授;电话:021-54742912;E-mail: wjding@sjtu.edu.cn

丁文江教授简介

丁文江,1953年3月出生,教授,博士,博士生导师,现任轻合金精密成型国家工程研究中心主任。曾任上海交通大学材料科学与工程学院副院长、上海交通大学高新技术办公室主任、上海交通大学副校长、上海市科委副主任等职务。多年从事轻合金材料及精密成型研究,获得多项科技成果奖励和荣誉称号,2003年获国家科技进步二等奖,2006年获国家技术发明奖二等奖,2007年及2010年两次获得上海市技术发明一等奖,并获中国优秀青年科技创业奖、GM中国科技成就一等奖,被人事部、国家教委评为中国优秀回国人员并入选国家教委跨世纪优秀人才培养计划和国家百千万人才工程第一第二层次人选。先后被评为上海市劳动模范、全国先进工作者和上海市第五届科技十大精英。发表论文321篇,SCI收录184篇,EI收录211篇,累计他引次数839次,申请发明专利105项。