文章编号:1004-0609(2007)03-0390-06

添加0.10%Ce对Sn-0.7Cu-0.5Ni焊料与Cu基板间界面IMC的影响

卢 斌,王娟辉,栗 慧,朱华伟,焦宪贺

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:研究Sn-0.7Cu-0.5Ni-xCe(x=0,0.1)焊料与铜基板间543 K钎焊以及453 K恒温时效对界面金属间化合物(IMC)的形成与生长行为的影响。结果表明:往Sn-0.7Cu-0.5Ni焊料合金中添加0.10%Ce,能抑制等温时效过程中界面IMC的形成与生长;焊点最初形成的界面IMC为Cu6Sn5,时效10 d后,Sn-0.7Cu-0.5Ni和Sn-0.7Cu-0.5Ni-0.10Ce这2种焊料中均有Cu3Sn形成,与Sn-0.7Cu-0.5Ni/Cu焊点相比,Sn-0.7Cu-0.5Ni-0.10Ce/Cu界面IMC层较为平整;该界面IMC的形成与生长均受扩散控制,主要取决于Cu原子的扩散,添加稀土元素Ce能抑制Cu原子的扩散,Sn-0.7Cu-0.5Ni和Sn-0.7Cu-0.5Ni-0.10Ce焊点界面IMC层的生长速率分别为6.15×10-18和5.38×10-18 m2/s。

关键词:无铅焊料;界面反应;等温时效;IMC;生长率

中图分类号:TG 425.1 文献标识码:A

Effect of 0.10% Ce on intermetallic compounds at Sn-0.7Cu-0.5Ni/Cu interface

LU Bin, WANG Juan-hui, LI Hui, ZHU Hua-wei, JIAO Xian-he

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract:Intermetallic compound(IMC) formation and growth of Sn-0.7Cu-0.5Ni solder with addition 0.1% Ce were studied for Cu-substrate during soldering at 543 K and isothermal aging at 453 K. The results show that addition of 0.1% Ce into Sn-0.7Cu-0.5Ni solder inhibits the excessive formation and growth of intermetallic compounds during the soldering reaction and thereafter under aging condition. The intermetallic compound layer formed firstly at the interface is Cu6Sn5, after 10 d of aging a thin Cu3Sn layer is also observed for both solders. After several days of aging, Sn-0.7Cu-0.5Ni-0.1Ce solder gives comparatively planar intermetallic layer at the solder-substrate interface than Sn-0.7Cu-0.5Ni solder. The formation of intermetallic compounds during aging for both solders follows the diffusion control mechanism. Intermetallic growth rate constants for Sn-0.7Cu-0.5Ni and Sn-0.7Cu-0.5Ni-0.1Ce solder are 6.15×10-18 and 5.38×10-18 m2/s, respectively, which has significant effect on the growth behavior of intermetallic compounds during aging.

Key words: lead-free solder; interfacial reaction; isothermal aging;IMC; growth rate

目前,Sn-Pb合金焊料广泛应用于现代电子装置中。然而,Pb有毒,对环境和人们的身体健康产生不利影响,因而,必需用环保型无铅焊料来代替含铅焊料[1]。在波峰焊接中,Sn-Cu共晶焊料(Sn-0.7Cu,质量分数,%,下同)被认为是最有希望替代共晶Sn-Pb焊料的无铅焊料[2-3]。与Sn-3.5Ag和Sn-3.8Ag-0.7Cu焊料相比,Sn-0.7Cu共晶焊料被认为是一种更适用于倒装焊接的焊料[4]。然而,该焊料的润湿性相对较差,以至不能很好地焊接,制约其在单相印刷电路板(PCB)等波峰焊接中的应用。其解决方法主要是通过添加Ag,Ni和P等来提高其可靠性[5-7]。研究结果表明[7],在Sn-0.7Cu焊料合金中,添加Ni元素的效果最好,Ni不仅能改变熔融焊料中金属间化合物(IMC)的形状,避免焊接时出现焊点桥连等缺陷,而且当Ni质量分数高达0.5%时,焊料还具有好的流动性能和蠕变抗力。

在钎焊过程中,熔化的焊料与基体反应,在钎焊界面处形成界面金属基化合物(IMC)。IMC的形成一方面表明钎焊质量可靠,即焊料通过与基体反应形成较薄的IMC层有利于获得良好的冶金结合;另一方面,若IMC层太厚,则会产生负面效果[8-9]。微量稀土元素Ce能细化Sn-Ag-Cu焊料合金组织,还能抑制焊料合金与Cu基板间的IMC的生长[10],有利于提高钎焊质量的可靠性。目前,尚未见稀土元素Ce对Sn-0.7Cu-Ni焊料合金与Cu基板间的IMC的形成和生长的影响的报道。在此,本文作者以Sn-0.7Cu-0.5Ni焊料合金为研究对象,探讨稀土元素Ce对Sn-0.7Cu-0.5Ni/Cu钎焊接头IMC的形成以及恒温时效过程中IMC生长的影响,以期为研究稀土元素在无铅焊料中的作用提供实验依据。

1 实验

实验用原材料为纯度高于99.9%的单质金属Sn和Sn-10%Cu,Sn-4.7%Ni以及Sn-3.7%Ce等中间合金。按Sn-0.7Cu-0.5Ni-xCe(x=0, 0.1)名义成分配好后在真空感应熔炼炉中熔炼,熔炼温度为873~923 K。

钎焊基板尺寸为15 mm×3 mm×15mm(W×D×L),纯度为99.9%的Cu片,将其抛光后,用5% NaOH溶液、蒸馏水清洗后,再用体积分数为5% HCl水溶液清洗,然后用蒸馏水清洗。在铜片上涂覆一层活性松香助焊剂(RMA),滴入助焊剂后,将焊料Sn-0.7Cu- 0.5Ni-xCe(x=0,0.1)焊料样品放置于Cu基板上,放入干燥箱中加热,在543 K保温5 min,将焊料样品熔化获得钎焊态样品。对上述2种成分的钎焊态样品沿中心剖开切割成尺寸为3 mm×3 mm×8 mm(W×D×L)的样品,分别放入干燥箱中进行时效处理,干燥箱的控温精度为±1 K。钎焊态样品经过453 K分别恒温时效5,10和20 d后取出空冷。为了便于界面IMC的研究,样品被镶嵌在环氧树脂里,打磨,抛光,腐蚀。腐蚀液为95% C2H5OH+5% HCl混合液。在KYKY2800扫描电子显微镜(SEM)上分析IMC的微观组织,并测量其厚度。对每个样品测量30次,取其平均值。

2 结果与讨论

2.1 焊点界面组织的变化

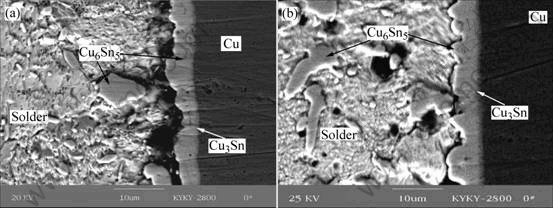

图1所示为Sn-0.7Cu-0.5Ni-xCe(x=0,0.1)焊料/Cu基板间543K钎焊态焊点接头微观组织的SEM照片。可以看出,焊料与Cu基板界面上形成IMC层。EDX分析结果表明,焊料/Cu基板间界面IMC为Cu6Sn5相。此外,还观察到靠近IMC层的基体中形成一些粗大的Cu6Sn5相,且相对于Sn-0.7Cu-0.5Ni/Cu体系而言,Sn-0.7Cu-0.5Ni-0.1Ce/Cu焊料体系的基体中所形成的Cu6Sn5相的数量较少(见图1和2)。测量结果表明,Sn-0.7Cu-0.5Ni-xCe(x=0,0.1)/Cu的钎焊界面Cu6Sn5层厚度分别为1.95 μm(x=0)和1.73 μm(x=0.1)。在钎焊过程中,基板中的Cu原子以扩散方式通过界面Cu6Sn5层进入熔化的焊料基体中。当Cu原子在熔化焊料中的富集量超过某一最小临界值时,富集的Cu原子就会与焊料基体中的Sn原子反应生成Cu6Sn5,导致在钎焊界面附近的焊料基体中形成一些粗大的Cu6Sn5相。实验结果表明,稀土元素Ce能抑制Cu原子在Sn-0.7Cu-0.5Ni焊料/Cu基底间的界面IMC层中扩散。

图1 543 K钎焊后焊料/Cu焊点微观结构的SEM照片

Fig.1 SEM images of solder/Cu interfaces after soldering at 543 K: (a) Sn-0.7Cu-0.5Ni solder; (b) Sn-0.7Cu-0.5Ni-0.10Ce solder

图2 543 K钎焊后焊料基体中IMC的形成

Fig.2 Formation of intermetallic compound in bulk of solder after soldering at 543 K: (a) Sn-0.7Cu-0.5Ni solder; (b) Sn-0.7Cu- 0.5Ni-0.10Ce

图3所示为Sn-0.7Cu-0.5Ni-xCe(x=0,0.1)/Cu钎焊界面经过180 ℃/时效5 d后的背散射SEM照片。可以看出,经过453 K/5 d时效后,界面IMC的厚度分别增至3.26 μm(x=0)和2.98 μm(x=0.1)。在相邻的扇贝形IMC谷底,IMC的生长速度高于峰顶的生长速度,这与Lee等[11]报道的结果相一致。时效5 d后,界面IMC的形态从最初的扇贝状(见图1)向较为平整的平层状转变(见图3)。此外,时效5 d后并未在界面IMC中发现Cu3Sn相,但是在所报道的Sn-Pb共晶焊料/Cu界面研究中却明显发现有Cu3Sn形成[12]。这可能与钎焊接头反应层或者产物中Cu3Sn非常薄而且小有关,以至实验中未发现界面IMC层中的Cu3Sn相。

图3 453 K/5 d时效后焊料/Cu接头微观组织的SEM照片

Fig.3 SEM images showing solder/Cu interfaces after 5 d of aging: (a) Sn-0.7Cu-0.5Ni solder; (b) Sn-0.7Cu-0.5Ni- 0.10Ce

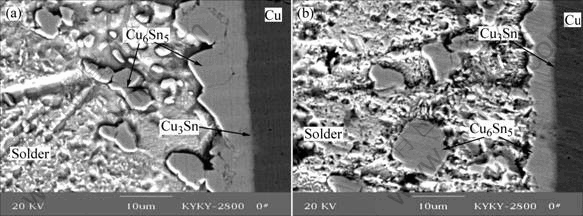

进一步增加等温时效时间,发现在Cu6Sn5相与基体Cu界面出现层状的Cu3Sn相。图4和5所示分别为453 K时效10 d和20 d后的背散射SEM照片。可以看到,焊料/Cu界面IMC均呈现出Cu6Sn5和Cu3Sn的复层结构,且Sn-0.7Cu- 0.5Ni/Cu的IMC层形貌比Sn-0.7Cu-0.5Ni-0.10Ce/Cu的层形貌粗糙和不平直。EDX分析结果证实,IMC层中的Cu6Sn5相靠近焊料侧,Cu3Sn相靠近Cu基底侧。由于Sn在Cu6Sn5相中的扩散系数低于Cu在Cu6Sn5相中的扩散系数,导致通过界面Cu6Sn5层的Sn减少,基底中的Cu向IMC层中扩散,并与Cu6Sn5发生发应,在界面Cu6Sn5层下面形成Cu3Sn层(见图4(b)和5(b))。这与Tu等[13]的报道结果相吻合。此外,EDX分析结果还显示出界面Cu6Sn5相中含有一定的Ni(其原子分数为4.3%),符合(Cu,Ni)6Sn5化学配比,说明该界面Cu6Sn5相应为(Cu,Ni)6Sn5合金相,(Cu,Ni)6Sn5的Ni元素应来自焊料中。由于焊料中含有较高的Ni(质量分数为0.5%),在反应初始阶段,Sn-Cu-Ni焊料中的Ni原子像Sn在Cu6Sn5相中的扩散一样而向界面Cu6Sn5中扩散,且可参与界面反应形成合金IMC。在回流循环过程中,Zhang等[14]也发现Ni能够扩散至整个焊料接头中形成(Cu,Ni)6Sn5三元相。

图4 453 K时效10 d后焊料/Cu钎焊接头微观组织的SEM照片

Fig.4 SEM images showing the solder/Cu interfaces after aged at 453 K for 10 d: (a) Sn-0.7Cu-0.5Ni sloder; (b) Sn-0.7Cu- 0.5Ni-0.10Ce

图5 53 K/20 d时效后焊料/Cu接头微观组织的SEM照片

Fig.5 SEM images showing solder/Cu interfaces after aged at 453 K for 20 d: (a) Sn-0.7Cu-0.5Ni solder; (b) Sn-0.7Cu- 0.5Ni-0.10Ce

据图4和5计算界面IMC厚度。结果表明,随着时效时间的增加,焊点界面的IMC层明显增厚,经过10 d等温时效后,界面IMC的总厚度分别增至4.34 μm(x=0)和3.97 μm(x=0.1);经20 d等温时效后,界面IMC的总厚度分别增至5.21 μm(x=0)和4.78 μm(x=0.1)。

2.2 等温时效过程中焊料/Cu界面的IMC的生长

在时效过程中,所形成的界面IMC的厚度与时效时间的关系可用下面的抛物线型公式来描述:

Kim等[15]认为,在固态时效时,界面IMC的生长一般遵循线性或者抛物线规律变化。当生长率受到生长地方的反应速率控制时,IMC的生长遵循直线规律。反之,IMC的生长受到扩散控制时,遵循抛物线规律。对于受扩散控制的过程,界面IMC的生长厚度应当遵循时间的平方根的动力学理论,并且可以表述为Y=kt0.5,此时时间指数n为0.5[16]。

图6所示为Sn-0.7Cu-0.5Ni-xCe(x=0,0.1)/Cu钎焊界面IMC层的总厚度与时效时间的平方根的函数关系。可以看出,IMC层厚度的增加与时效时间的平方根近似呈直线关系,且Sn-0.7Cu-0.5Ni/Cu焊料体系中IMC层的生长速率高于Sn-0.7Cu-0.5Ni-0.10Ce/Cu焊料体系的生长速率。图中显示出该2种焊料体系中IMC层的生长都遵循抛物线生长规律,即IMC的生长行为受扩散过程控制[17-19]。

图6 IMC总厚度与时效时间的平方根的关系

Fig.6 Thickness of intermetallic compound layer as function of square root of aging time

为了进一步了解Sn-0.7Cu-0.5Ni-xCe(x=0,0.1)/Cu焊料体系中IMC的生长行为,据Y对应t0.5的关系,由多元线性回归分析方法计算生长率k。图6所示为Sn-0.7Cu-0.5Ni-xCe(x=0,0.1)/Cu钎焊界面IMC总厚度与时效时间平方根的关系。图中所示的曲线斜率即为Sn-0.7Cu-0.5Ni/Cu和Sn-0.7Cu-0.5Ni-0.10Ce/Cu焊料体系中的k,分别为6.15×10-18 m2/s和5.38×10-18 m2/s。可见,在恒温时效过程中,Sn-0.7Cu-0.5Ni/Cu焊料合金体系中IMC的生长率略高于Sn-0.7Cu-0.5Ni-0.10Ce/Cu焊料体系的生长率。由此也可以看出,微量稀土Ce具有抑制界面IMC生长的作用。线性回归系数R2是所有平方根总和与线性回归的平方根总和的比率,该值在Sn-0.7Cu-0.5Ni/Cu和Sn-0.7Cu-0.5Ni- 0.10Ce/Cu体系中分别为0.990 0和0.990 3,此表明这2种焊料体系中IMC的形成近似遵循扩散定律。

在恒温时效过程中,与IMC生长有关的时间指数n可由下式计算[20]:

式(2)的对数表达式为

图7所示为ln(Yt-Y0)对lnt的关系。由曲线的斜率可得到Sn-0.7Cu-0.5Ni-xCe(x=0,0.1)/Cu焊料合金体系中n分别为0.55和0.54。n对于扩散过程的影响很大,从而也影响Sn-0.7Cu-0.5Ni-xCe(x=0,0.1)/Cu焊料体系中IMC的形成。计算所得的IMC生长速率的平方值k2、线性相关系数R2和时间指数n见表1。

图7 ln(Y–B)与 lnt的关系

Fig.7 Relationship between ln(Y–B) and lnt

表1 计算所得的IMC生长速率的平方值k2、线性相关系数R2和时间指数n

Table 1 Calculated square of growth rate constants (k2), linear correlation coefficients (R2) and time exponent n

由表1可知, IMC层厚度取决于Cu原子的扩散过程,且Cu在Sn-0.7Cu-0.5Ni/Cu体系中的扩散速度要高于Sn-0.7Cu-0.5Ni-0.10Ce/Cu体系的扩散速度。在钎焊反应中来自于基底中的Cu原子与焊料基体中的Sn原子反应,并在焊料与基底的界面以及焊料基体中形成IMC,Cu原子通过IMC持续扩散。尽管如此,界面反应并没有快到消耗所有扩散来的Cu原子,导致没有反应完的Cu原子深入扩散到焊料基体的内部与Sn反应生成Cu6Sn5相。因此,随着基体中Cu原子的减少,基底中更多的Cu原子向焊料基体中扩散。此外,当基体中Cu原子的溶解度降低时,Cu6Sn5化合物便在已经形成的IMC层上面沉淀,导致IMC层厚度增加。

3 结论

1) 在钎焊接头界面反应中,随着时效时间的延长,界面反应产物由Cu6Sn5单层向Cu6Sn5+Cu3Sn双层IMC转变,且该2种焊料界面IMC层厚度也均有所增加,其中Sn-0.7Cu-0.5Ni焊料合金/Cu体系中形成的IMC厚度略大于Sn-0.7Cu-0.5Ni-0.10Ce焊料合 金/Cu体系的厚度。

2) Sn-Cu界面IMC的形成和生长取决于Cu原子从基底中向基体中的扩散,加入稀土元素Ce能降低Sn-0.7Cu-0.5Ni/Cu中界面IMC的生长率,抑制IMC的生长。Sn-0.7Cu-0.5Ni的生长速率为k2=6.15×10-18 m2/s;Sn-0.7Cu-0.5Ni-0.10Ce的生长速率为k2=5.38×10-18 m2/s。

REFERENCES

[1] 陈国海,黎小燕,耿志挺. 新型无铅焊料合金Sn-Zn-Ga的研究[J]. 稀有金属材料与工程,2004,33(11):1222.

CHEN Guo-hai, LI Xiao-yan, GENG Zhi-ting. The study on the new type lead-free solder alloys Sn-Zn-Ga[J]. Materials and Engineering of Rare Metal, 2004, 33(11): 1222.

[2] Chen W T, Lee S W, Yip M C. Mechanical properties and intermetallic compound formation at the Sn/Ni and Sn-0.7wt.%/Ni joints[J]. Journal of Electronic Materials, 2003, 32(11): 1284-1289.

[3] Zeng K, Tu K N. Six cases of reliability study of Pb-free solder joints in electronic packaging technology[J]. Mater Sci Eng R, 2002, 38(2): 55-105.

[4] Yoon J W, Kim S W, Jung S B. Interfacial reaction and mechanical properties of eutectic Sn-0.7Cu/Ni BGA solder joints during isothermal long-term aging[J]. Journal of Alloys and Compounds, 2005, 391: 82-89.

[5] 田民波,马鹏飞. 电子封装无铅化技术进展[M]. 印刷电路资讯,2004(3):52-59.

TIAN Min-bo, MA Peng-fei. The Summarization of Lead-Free Technology in Electronic Packing[M]. Printed Circuit Board Information, 2004(3): 52-59.

[6] 晏 勇,蒋晓虎,张继忠, 等. 一种高性能实用型Sn-Cu无铅电子钎料[J]. 电子元件与材料, 2004,24(4):54-56.

YAN Yong, JIANG Xiao-hu, ZHANG Ji-zhong, et al. High performances Sn-Cu electronic lead-free solder[J]. Electronic Components and Materials, 2004, 24(4): 54-56.

[7] Huh S H, Kim K S, Suganuma K. Effect of Ag addition on the microstructure and mechanical properties of Sn-Cu eutectic solder[J]. Materials Transactions, 2001(42): 739-744.

[8] Yoon J W, Lee Y H, Kim D G, et al. Intermetallic compounds layer growth at the interface between Sn-Cu-Ni solder and Cu substrate[J]. Journal of Alloys and Compounds, 2004, 381: 51-157.

[9] 韩宗杰,鞠金龙,薛松柏. 半导体激光软钎焊Sn-Ag-Cu焊点微观组织[J]. 中南大学学报:自然科学版,2006, 37(2): 229-234.

HAN Zong-jie, JU Jin-long, XUE Song-bai. Microstructures of Sn-Ag-Cu lead-free soldered joints with diode-laser soldering[J]. J Cent South Univ: Science and Technology, 2006, 37(2): 229-234.

[10] Wu C M L, Yu D Q, Law C M T, et al. Properties of lead-free solder alloys with rare earth element additions[J]. Mater Sci Eng, 2004, 44: 1-44.

[11] Lee T Y, Choi W J, Tu K N. Morphology kinetics and thermodynamics of solid-state aging of eutectic Sn-Pb and Pb-free solders (Sn-3.5Ag,Sn-3.8Ag-0.7Cu,Sn-0.7Cu) on Cu[J]. Journal of Materials Research, 2002, 17(2): 291-301.

[12] Hwang C W, Lee J G, Suganuma K, Mori H. Interfacial microstructure between Sn-3Ag-xBi alloy and Cu substrate with or without electrolytic Ni plating[J]. Journal of Electronic Materials, 2003, 32(2): 52-62.

[13] Tu K N, Thompson R D. Kinetics of interfacial reaction in bimetallic Cu-Sn thin films[J]. Acta Materialia, 1982, 30(5): 947-952.

[14] Zhang F, Li M, Chum C. Influence of substrate metallization on diffusion and reaction at the under-bump metallization/solder interface in flip-chip packages[J]. Journal of Materials Research, 2002, 17(11): 2757-2760.

[15] Kim D G, Jung S B. Interfacial reaction and growth kinetics for intermetallic compounds layer between In-Sn solder and bare Cu substrate[J]. Journal of Alloys and Compounds, 2005, 386: 151-156.

[16] Lee C Y, Lin K L. Preparation of solder bumps incorporating electroless nickel-boron deposit and investigation on the interfacial interaction behavior and wetting kinetics[J]. Journal of Materials Science, 1997, 8(6): 377-383.

[17] Vianco P T, Xilgo A C, Grant R. Intermetallic compound layer growth by solid state reactions between 58Bi-42Sn solder and copper[J]. Journal of Electronic Materials, 1995, 24(10): 1493-1505.

[18] Chen C C, Lin A H, Luo G L, Kao C R. Long-term aging study on the solid-state reaction between 58Bi-42Sn solder and copper[J]. Journal of Electronic Materials, 2000, 29(5): 1200-1206.

[19] Rizvi M J, Chan Y C, Bailey C, et al. Effect of adding 1wt% Bi into the Sn-Ag-Cu solder sally on the intermetallic formations with Cu-substrate during soldering and isothermal aging [J]. Journal of Alloys and Compounds, 2006, 407: 208-214.

[20] Vianco P T, Rejent J A. Properties of ternary Sn-Ag-Bi solder alloys: thermal properties and micro structural analysis [J]. Journal of Electronic Materials, 1999, 28(10): 1127-1137.

基金项目:湖南省科技重点攻关项目(01YJJ2056)

收稿日期:2006-08-25;修订日期:2006-11-19

通讯作者:卢 斌,教授;电话:0731-8836319;E-mail:luoffice@mail.csu.edu.cn

(编辑 陈灿华)