DOI: 10.11817/j.issn.1672-7207.2018.07.002

大洋多金属结核与低品位硫化镍矿耦合浸出特性

冯雅丽1,康金星1,李浩然2,杜竹玮2,邓祥意1,王洪君1

(1. 北京科技大学 土木与资源工程学院, 北京,100083;

2. 中国科学院过程工程研究所 生化工程重点实验室, 北京,100190)

摘要:基于低品位硫化镍矿的还原活性和大洋多金属结核的氧化活性,提出复杂低品位多金属矿的耦合酸浸处理工艺。主要考察Mn与S矿石质量比、硫酸浓度、温度对主金属元素浸出的影响,并采用XRD和SEM-EDS及电化学极化、循环伏安等分析耦合酸浸处理过程中主金属元素的浸出特性。研究结果表明:在最佳条件即Mn与S矿石质量比为0.55、初始硫酸浓度为1.3 mol/L、温度为355 K时,Ni,Mn,Cu,Co和Fe的浸出率分别为96.8%,97.3%,92.2%,97.9%和28.9%;金属硫化物还原MnO2而溶出结核中Ni,Cu和Co,同时自身被氧化腐蚀成S0,SO42-和金属离子而溶解;将Fe以铁矾或氧化矿物形式沉淀在渣相中,选择性浸出Ni,Mn,Cu和Co可行;耦合酸浸工艺利用矿石的氧化还原活性,实现了不同类型的复杂低品位矿石中有价金属的高效提取。

关键词:多金属结核;低品位硫化镍矿;耦合浸出;极化;循环伏安

中图分类号:TF111.31 文献标志码:A 文章编号:1672-7207(2018)07-1582-08

Characteristics of polymetallic nodules and low-grade nickel sulfide ore coupled leaching

FENG Yali1, KANG Jinxing1, LI Haoran2, DU Zhuwei2, DENG Xiangyi1, WANG Hongjun1

(1. School of Civil and Resource Engineering, University of Science and Technology, Beijing 100083, China;

2. Key State Laboratory of Biochemical Engineering, Institute of Process Engineering, Chinese Academy of Sciences, Beijing 100190, China)

Abstract: A coupled leaching process of low-grade sulfide ore and polymetallic nodules in sulfuric acid solution was proposed according to the reduction performance of the former and the oxidation activity of the latter. The effects of mass ratio of Mn and S ore, sulfuric acid concentration and temperature on leaching efficiencies of the main metal elements were investigated. The leaching characteristics of the main metallic minerals were measured by X-ray, scanning electron microscope, energy dispersion spectrum,electrochemical polarization and cyclic voltammetry. The results show that in the optimal conditions of coupled leaching, i.e. temperature is 355 K, the mass ratio of Mn and S ore is 0.55,H2SO4 concentration is 1.3 mol/L, the extraction ratios of Ni, Mn, Cu, Co and Fe are 96.8%, 97.3%, 92.2%, 97.9% and 28.9%, respectively. Ni, Cu and Co are released owing to the reduction of MnO2 by sulfide. The metal-containing sulfide minerals are simultaneously oxidized to S0, SO42- and metallic ions,and are finally dissolved. Fe element can be precipitated in the slag phase in the form of oxide or jarosite, which can provide a feasible way for the selective leaching of Ni, Cu, Co and Mn. The coupled leaching using oxido-reduction activity is an efficient process to extract valuable metal from low-grade and intractable ores.

Key words: polymetallic nodules; low-grade nickel sulfide ore; coupled leaching; polarization; cyclic voltammetry

开发利用海洋矿产资源是必然趋势,选冶技术直接影响海洋矿产资源的开发[1-3]。多金属结核是一类重要的海洋矿产资源,富含Ni,Mn,Cu和Co等有价金属[4],提取其有价金属的关键是破坏铁锰氧化矿物的晶格[5]。高价锰矿物的还原一直是研究热点[6-7],常用方法有还原氨浸、酸性还原浸出[8]、微生物提取[9]、还原焙烧[10]等。我国是典型的贫镍国家,随着优质镍矿资源的急剧消耗,低品位镍矿的开发成为镍冶金的焦点[11]。在金川地区,低品位硫化镍矿中镍以微细粒矿物赋存,与Mg,Fe,Cu和Co等矿物关系密切[12],常采用选矿富集[13]、微生物浸出[14]、化学提炼[15]等方法处理,但选矿药剂适应性弱,回收微细粒矿物困难,而微生物受限于高镁的浸出环境[16-17]。大洋多金属结核与低品位硫化镍矿都含大量Ni,Cu和Co,前者需破坏锰包裹结构,后者硫化物酸溶性差直接浸取困难。为此,本文作者利用多金属结核与低品位硫化镍矿的氧化还原活性,提出低品位多金属硫化镍矿与氧化锰矿耦合酸浸工艺,协同提取矿石中的Mn,Ni,Cu和Co,研究耦合浸出的工艺条件和机理,以便为实现复杂低品位多金属矿石资源利用提供新的途径及理论 参考。

1 试验

1.1 试验材料

多金属锰结核取自中国在太平洋的开辟区,其主要化学成分见表1,XRD图谱见图1。多金属结核中Mn以高价锰矿物形式存在,Ni,Cu和Co呈离子态赋存在锰铁矿物中,脉石矿物有石英、钙长石等。金川高镁型低品位硫化镍矿主要化学成分见表2,XRD图谱见图2,其主要金属矿物为紫硫镍矿、镍黄铁矿、黄铜矿、磁黄铁矿等,脉石矿物为镁绿泥石和辉石等。Ni,Mn和Fe的化学物相分析见表3,有价金属在多金属结核中被高价氧化锰矿物包裹,而以还原性的硫化物赋存于低品位硫化镍矿中。

表1 多金属结核的主要化学成分(质量分数)

Table 1 Chemical compositions of polymetallic nodule %

表2 低品位硫化镍矿的主要化学成分(质量分数)

Table 2 Chemical compositions of low-grade nickel sulfide ore %

图1 多金属结核的XRD图谱

Fig. 1 XRD pattern of polymetallic nodule

图2 低品位硫化镍矿的XRD图谱

Fig. 2 XRD pattern of low-grade nickel sulfide ore

1.2 试验仪器

主要试验仪器有:集热式磁力加热搅拌器(DF-101S);三辊四筒棒磨机(XRM-70);紫外分光光度计(UV-1750);电子天平(AR1140);电热恒温鼓风干燥箱(DHG-9140A);电化学工作站(CHI160D);X线衍射仪(D/max 2550VB+);扫描电镜与能谱分析仪(JSM-7001F+INCA X-MAX)。

表3 多金属结核与低品位硫化镍矿中镍、锰、铁的物相分析

Table 3 Phase analysis of Ni, Mn and Fe in polymetallic nodule or low-grade nickel sulfide ore

1.3 试验方法

先将大洋多金属结核与低品位硫化镍矿磨至一定粒度,按质量比称取试验用样置于磨口锥形瓶中,再配制矿浆,并配入一定浓度的硫酸;然后将锥形瓶置于恒温油浴中,在一定温度下搅拌浸出一定时间,冷却后抽滤,得浸出液和浸出渣;浸出渣烘干后,分别采用重铬酸钾-硫酸亚铁铵滴定法、丁二酮肟光度法、铜试剂光度法、1-亚硝基-2-萘酚光度法、锡(II)还原-重铬酸钾法测定其Mn,Ni,Cu,Co和Fe质量分数,以浸出渣中金属质量分数推算浸出率。采用XRD,SEM和EDS等分析原料及浸渣的矿物组成;用三电极体系进行电化学极化、循环伏安分析,以试样为工作电极,铂电极为辅助电极,饱和甘汞电极为参比电极。

2 结果与讨论

2.1 Mn与S矿石质量比对主金属元素浸出的影响

多金属结核与低品位硫化镍矿耦合硫酸浸出时,矿石粒度、搅拌速度、液固比、浸出时间、Mn与S矿石质量比、温度和酸度等对有价金属的浸出和浸出动力学均产生影响。单因素试验结果表明:当磨矿粒度低于0.038 mm的质量分数为80%、液固比为5 mL/g、搅拌速度为300 r/min、浸出时间为12 h时,主金属元素的浸出主要受Mn与S矿石质量比、温度和酸度影响。

当浸出温度为363 K、硫酸浓度为1.2 mol/L时,考察多金属结核与低品位硫化镍矿试样质量比对主元素酸浸的影响,试验结果如图3所示。从图3可见:Mn浸出率随硫化镍矿用量占比的增大,从43.5%增大到99.0%以上;Ni,Cu和Co的浸出率在Mn与S矿石质量比为1:2时达到最大,分别为94.8%,88.1%和96.5%;继续增大硫化镍矿用量,Ni和Cu浸出率呈下降趋势,而Co浸出达到准平衡;由于结核和硫化矿中均含有Ni及Cu,当硫化矿过量时,结核被还原较彻底,渣中残余Ni和Cu为过剩硫化镍矿中的Ni和Cu,从而使得Ni和Cu的浸出率略有下降;当Mn与S矿石质量比为0.5~1.0时,Fe浸出率变化小于2.0%,均低于32.0%,Mn与S质量比过大或过小都会增大铁的浸出量。高价锰矿物与硫化镍矿发生耦合氧化还原反应,硫化矿氧化产生的电子数与高价锰为电子受体所接受的电子数相等,任意矿石过量均会引起有价金属残余量增大。

图3 Mn与S矿石质量比对Me (Ni, Mn, Cu, Co, Fe) 浸出的影响

Fig. 3 Effect of mass ratio of Mn to S on Me (Ni, Mn, Cu, Co, Fe) leaching

2.2 酸度对主金属元素浸出的影响

当Mn与S矿石质量比为1:2、浸出温度为363 K时,考察酸度对主金属元素浸出的影响,结果如图4所示。从图4可见:随着初始硫酸浓度增加,Ni,Mn,Cu和Co的浸出率分别能提高12.1%,9.0%,9.3%和14.6%,铁的浸出率都低于32%;当硫酸浓度为1.3 mol/L时,Ni和Mn浸出率最高,分别为95.9%和99.3%,铁浸出率低于28%;增加初始硫酸浓度,硫化矿与高价氧化锰矿反应向右移动;当初始硫酸浓度较低时,反应进行不完全或产生S0吸附在矿石表面影响浸出;酸过量时,浸出选择性变差[18],Fe易溶出且会随酸的消耗而水解覆盖矿石表面,不利于Ni和Mn浸出。

图4 硫酸浓度对Me(Ni, Mn, Cu, Co, Fe)浸出的影响

Fig. 4 Effect of concentration of H2SO4 on Me (Ni, Mn, Cu, Co, Fe) leaching

2.3 温度对主金属元素浸出的影响

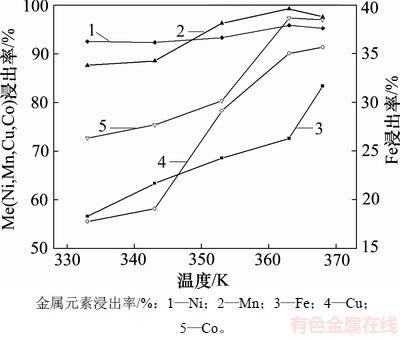

当Mn与S矿石质量比为1:2、硫酸浓度为1.3 mol/L时,不同温度下主金属元素浸出率的变化如图5所示。从图5可见:温度对金属Me(Ni, Mn, Cu, Co, Fe) 的浸出有明显影响;随着温度升高,主元素浸出率增大;在363 K时,Ni,Mn和Co浸出率最大,都大于95.0%;Cu和Fe浸出率则在368 K最大,分别为91.4%和31.7%;当温度由343 K升高到363 K时,Ni和Mn浸出率分别提高3.4%和9.9%,Cu和Co浸出率分别由55.6%和72.7%提高到90.1%和97.4%。这是由于温度升高加速了分子内振动,加快了反应速率[19]。

采用响应曲面法中心复合设计原理对主元素的耦合浸出条件进行优化[20],选取Mn与S矿石质量比、温度和酸度为影响因素,Ni,Mn和Fe的浸出率为响应值,用Design-Expert 8.0进行三因素两水平(表4) Optimal设计及分析。图6(a),(b)和(c)所示分别为Ni,Mn和Fe浸出率试验真实值与预期值。在低酸用量基础上,设定Ni和Mn浸出率均大于96.5%,Fe浸出率小于30%,得到最优浸出条件如下:Mn与S矿石质量比为55:100,温度为355 K,硫酸浓度为1.30 mol/L。在此最优条件下所得结果如表5所示,可见Ni,Mn,Cu,Co和Fe的浸出率平均值分别为96.8%,97.3%,92.2%,97.9%和28.9%。

图5 温度对Me(Ni, Mn, Cu, Co, Fe)浸出的影响

Fig. 5 Effect of temperature on Me(Ni, Mn, Cu, Co, Fe) leaching

表4 优化设计中不同因素和水平

Table 4 Optimal design of independent variables and their levels

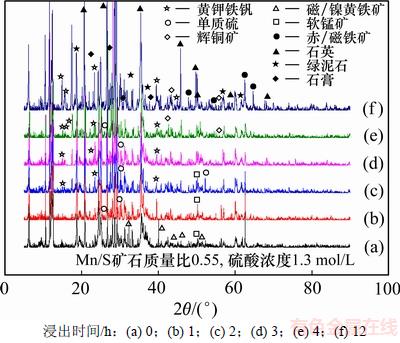

2.4 耦合浸出过程分析

在355 K下,不同时间浸渣的XRD分析结果如图7所示。从图7可见:在耦合浸出反应中,高价锰矿与镍硫化矿酸性耦合腐蚀溶解,并未出现新的渣物相,铁以氧化铁或黄钾铁矾的形式残留于渣相中;反应初始时,高价锰矿迅速与硫化物反应;浸出2 h后,高价锰矿物与含镍硫化物衍射峰消失,由于镍硫化矿物氧化腐蚀电位较低,优先与高价锰矿反应;当浸出反应1 h时,有单质S0生成,继续反应时,S0被氧化,说明在酸性环境下,MnO2氧化硫化矿的 先转变为S0,继而被氧化成

先转变为S0,继而被氧化成 ;反应2 h时,渣相中铁的硫化物基本溶解,开始出现新的黄钾铁矾矿相,且其衍射峰峰强随时间延长越明显,可知铁的硫化物溶解产生Fe2+,Fe2+还原高价锰矿或硫化物后转变为Fe3+,再与体系中碱金属离子结合生成铁矾沉淀;在此过程中,铁的氧化物溶解量较少,多以高价铁氧化物残留在渣相中;浸出时间4 h后,渣中铜矿物呈现辉铜矿矿相,这可能是Cu2+/Cu2S电极反应所致。

;反应2 h时,渣相中铁的硫化物基本溶解,开始出现新的黄钾铁矾矿相,且其衍射峰峰强随时间延长越明显,可知铁的硫化物溶解产生Fe2+,Fe2+还原高价锰矿或硫化物后转变为Fe3+,再与体系中碱金属离子结合生成铁矾沉淀;在此过程中,铁的氧化物溶解量较少,多以高价铁氧化物残留在渣相中;浸出时间4 h后,渣中铜矿物呈现辉铜矿矿相,这可能是Cu2+/Cu2S电极反应所致。

图6 镍、锰、铁浸出率预期值与实际值对比曲线

Fig. 6 Comparison of predictive and experimental leaching of Ni, Mn and Fe

表5 浸出最优条件下验证试验结果

Table 5 Test results under optimal leaching conditions

图7 不同时间浸渣XRD图谱

Fig. 7 XRD pattern of residue at different leaching time

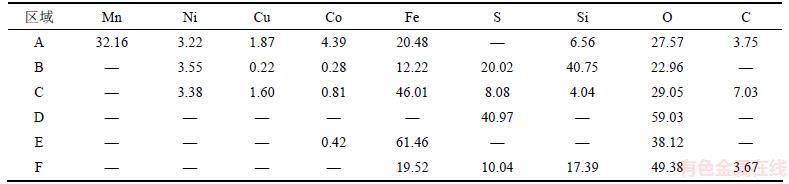

对不同浸渣的扫描电镜形貌及不同区域能谱进行分析,结果如图8所示。从图8可见:浸出初始时,矿石颗粒表面清晰轮廓明显,Ni,Cu和Co以氧化物与锰铁共生关系紧密(见图8(a)中的区域A处),或Ni,Cu和Co以微细粒的硫化物形式赋存(见图8(a)中的区域B处);浸出4 h后颗粒被溶解腐蚀,细小颗粒黏附到大颗粒周边。图8(b)中区域D处为吸附于矿石表面的S0,区域C处少量的镍、铜、钴矿物与铁矾关系紧密,说明过程中产生的铁矾对主金属矿物覆盖;浸出12 h后矿石颗粒腐蚀成更细小颗粒团聚,渣中残留的铁主要为磁性铁氧化物与铁矾存在。这表明耦合酸浸能破坏锰铁包裹结构及将镍铜硫化物转变为单质S0及 和金属离子,实现了Ni,Mn,Cu和Co的选择性提取。

和金属离子,实现了Ni,Mn,Cu和Co的选择性提取。

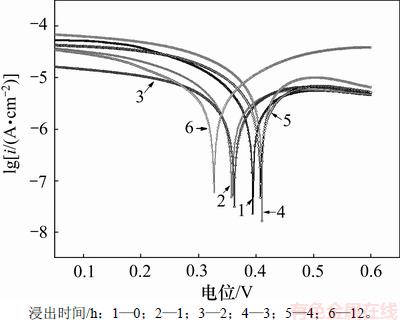

不同时间浸渣的极化曲线如图9所示(其中,i为电流密度)。从图9可见:随着浸出时间增加,试样自腐蚀电位由0.393 V发生0.031 V的负移,之后又正移至0.410 V,最后又负移到0.327 V。由于Me(Ni, Cu, Fe)S与MnO2耦合反应起始时,高还原活性的MeS与MnO2反应速度较快引起电位负移;而后随着硫化物的溶解及生成S0覆盖矿物表面又引起电位正移;当主金属溶解趋于平衡时,留在渣中的铁矿物引起电位再次负移。拟合极化曲线所得的自腐蚀电流密度i随浸出时间延长由7.433×10-6 A·cm-2逐渐增大到5.681× 10-5 A·cm-2,浸渣腐蚀溶解速度变快,其原因是Fe2+溶解到溶液中催化了MnO2的溶解,此外,渣中含铁矿物增多引起试样电导率增大。不同时间浸渣的能谱化学组分见表6。

图8 不同时间浸渣的SEM-EDS图

Fig. 8 SEM and EDS pictures of residue at different leaching time

表6 不同时间浸渣的能谱化学组分(质量分数)

Table 6 Chemical composition of leaching residue tested by EDS %

2.5 耦合浸出机理分析

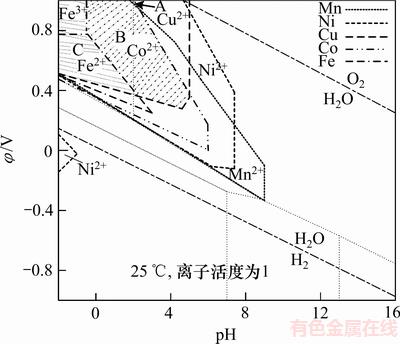

Me(Mn, Ni, Cu, Co, Fe)-S-H2O系中电势与pH的关系见图10。从图10可见:在A区域能提取Ni,Cu和Co元素,但不能还原Mn(Ⅳ);在B区域,Mn,Ni,Cu和Co能被选择性化学酸性同时提取,而Fe留在固相中;C区域为Fe2+/Fe3+,Mn2+,Ni2+,Cu2+和Co2+的热力学稳定区,浸出无选择性且酸耗加大,Fe的大量溶解对后续工艺不利。控制耦合浸出条件处于B区域,既能还原破坏结核的高价锰矿物包裹结构,又可将铁留在渣相,选择性溶出Mn,Ni,Cu和Co。

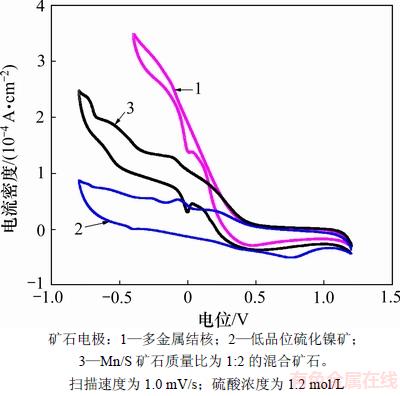

多金属结核、低品位硫化镍矿、混合试样的循环伏安曲线 (CV) 见图11。从图11可见:多金属结核分别在0.04 V和0.48 V处有氧化峰电流密度,可能的电极反应(vs SHE)为:

MnO2+H2O+2e=Mn(OH)2+2OH-, V (1)

V (1)

Fe3++e=Fe2+, V (2)

V (2)

其中: 为电极反应的标准电极电位。低品位硫化镍矿分别在-0.25,-0.10和0.25 V出现还原峰,相应的电极反应(vs SHE)为:

为电极反应的标准电极电位。低品位硫化镍矿分别在-0.25,-0.10和0.25 V出现还原峰,相应的电极反应(vs SHE)为:

图9 不同时间浸渣的极化曲线

Fig. 9 Polarization curves of residues at different leaching of time

图10 Me(Mn, Ni, Cu, Co, Fe)-S-H2O的φ-pH图

Fig. 10 φ-pH diagrams of Me(Mn, Ni, Cu, Co, Fe)-S-H2O system

图11 不同矿石的循环伏安曲线

Fig. 11 Cyclic voltammetry curves of different ores

Cu2++S0+2e=CuS, V (3)

V (3)

Ni2++S0+2e=NiS, V (4)

V (4)

3Ni2++2S0+6e=Ni3S2, V (5)

V (5)

S0+2e=S2-, V (6)

V (6)

H2SO3+4H++4e=S0+3H2O, V (7)

V (7)

在-0.40 V和0.78 V处出现氧化峰;其中,在 -0.40 V处的氧化峰应为电对Ni2+/Ni和Fe2+/Fe电极反应引起,在0.78 V处出现的氧化峰对应Fe3+/Fe2+的氧化还原。

Mn与S矿石质量比为1:2的混合试样在-0.6~ -0.5 V和-0.1~-0.04 V间有明显的氧化还原峰,主金属矿物构成耦合自腐蚀电池而被溶解;-0.04 V处有尖锐氧化峰,表明MnO2为电子主要受体。主要电极反应如下。

阴极反应:

MnO2+2H++2e=Mn2++2OH- (8)

阳极反应:

Me(Ni, Cu, Fe)S-2e=Me2+(Ni, Cu, Fe)+S0 (9)

S0+8OH--6e= +4H2O (10)

+4H2O (10)

在酸性体系下,大洋多金属结核与低品位硫化镍矿耦合浸出,硫化矿为高价锰矿的还原剂,MnO2被还原为Mn2+,被包裹的离子态Ni,Cu和Co随之溶出;低品位硫化矿经MnO2氧化为单质S0及 ,Ni,Cu和Co金属离子溶解,结核中Mn(Ⅳ)与硫化矿中

,Ni,Cu和Co金属离子溶解,结核中Mn(Ⅳ)与硫化矿中 发生氧化还原反应,Ni,Cu和Co浸出,反应可归纳为:

发生氧化还原反应,Ni,Cu和Co浸出,反应可归纳为:

→

→ (11)

(11)

→

→ (12)

(12)

3 结论

1) 采用多金属结核与低品位硫化镍矿耦合酸浸工艺,利用矿石自身的氧化还原活性,低品位硫化镍矿将多金属结核中MnO2还原为Mn2+,破坏高价锰包裹结构而溶出Mn,N,Cu和Co,同时所含有的Ni,Cu和Co硫化物被氧化为S0, 和金属离子溶出,实现有价金属的高效耦合溶出。

和金属离子溶出,实现有价金属的高效耦合溶出。

2) 当Mn与S矿石质量比为0.55、多金属结核与低品位硫化镍矿矿石粒度低于0.038 mm的矿石质量分数为 80%、液固比为5 mL/g、搅拌速度为300 r/min、初始硫酸浓度为1.3 mol/L、温度为355 K、浸出12 h时,Ni,Mn,Cu和Co的浸出率分别达96.8%,97.3%,92.2%和97.9%,Fe浸出率低于30%。

3) 在酸性体系中,多金属结核与金属硫化矿通过氧化-还原耦合, 先转变为S0继而被氧化成

先转变为S0继而被氧化成 ;选择性浸出Ni,Mn,Cu和Co时,Fe以铁矾或氧化物的形式残留在渣中,且Fe2+/Fe3+电对对耦合浸出反应有催化作用。

;选择性浸出Ni,Mn,Cu和Co时,Fe以铁矾或氧化物的形式残留在渣中,且Fe2+/Fe3+电对对耦合浸出反应有催化作用。

参考文献:

[1] 董冰洁. 我国海洋多金属矿产资源研究现状及战略性开发前景[J]. 世界有色金属, 2016, 31(12): 168-169.

DONG Bingjie. Research status and strategic development prospect of marine polymetallic mineral resources in China[J]. World Nonferrous Metals, 2016, 31(12): 168-169.

[2] VANREUSE A, HILARIO A, RIBEIRO P A, et al. Threatened by mining, polymetallic nodules are required to preserve abyssal epifauna[J]. Scientific Report, 2016, 6: 26808.

[3] 肖业祥, 杨凌波, 曹蕾, 等. 海洋矿产资源分布及深海扬矿研究进展[J]. 排灌机械工程学报, 2014, 32(4): 319-326.

XIAO Yexiang, YANG Lingbo, CAO Lei, et al. Distribution of marine mineral resource and advances of deep-sea lifting pump technology[J]. Journal of Drainage and Irrigation Machinery Engineering, 2014, 32(4): 319-326.

[4] 王振荣, 兰江华, 王菲菲. 中国海洋国土的确定及矿产资源[J]. 矿物岩石, 2010, 30(3): 1-14.

WANG Zhenrong, LAN Jianghua, WANG Feifei. Regional tectonics and mineral resources of marine territory in China[J]. Journal of Mineral Petrol, 2010, 30 (3): 1-14.

[5] SENANAYAKE G. Acid leaching of metals from deep-sea manganese nodules: a critical review of fundamentals and applications[J]. Minerals Engineering, 2011, 24(13): 1379-1396.

[6] TANG Qing, ZHONG Hong, WANG Shuai, et al. Reductive leaching of manganese oxide ores using waste tea as reductant in sulfuric acid solution[J]. Transaction of Nonferrous Metals Society of China, 2014, 24(3): 861-867.

[7] VU H, JANDOVAJ, LISA K, et al. Leaching of manganese deep ocean nodules in FeSO4-H2SO4-H2O solutions[J]. Hydrometallurgy, 2005, 77(1): 147-153.

[8] BABA A A, GHOSH M K, PRADHAN S R, et al. Characterization and kinetic study on ammonia leaching of complex copper ore[J]. Transaction of Nonferrous Metals Society of China, 2014, 24(5): 1587-1595.

[9] KUMARI A, NATARAJAN K A. Electrobioleaching of polymetallic ocean nodules[J]. Hydrometallurgy, 2001, 62(2): 125-134.

[10] 黄柱成, 柴斌, 赵鹏, 等. 高铁锰矿直接还原及其还原行为[J]. 中南大学学报(自然科学版), 2014, 45(1): 9-15.

HUANG Zhucheng, CHAI Bin, ZHAO Peng, et al. Reduction of high iron content manganese ore and its mechanism[J]. Journal of Central South University(Science and Technology), 2014, 45(1): 9-15.

[11] 路长远, 鲁雄刚, 邹星礼, 等. 中国镍矿资源现状及技术进展[J]. 自然杂志, 2015, 37(4): 269-277.

LU Changyuan, LU Xionggang, ZOU Xingli, et al. Current situation and utilization technology of nickel ore in China[J]. Chinese Journal of Nature, 2015, 37(4): 269-277.

[12] 刘欣伟, 胡文韬, 李浩然, 等. 高镁型低品位硫化镍矿浸出工艺及机理[J]. 中国有色金属学报, 2014, 24(6): 1599-1606.

LIU Xinwei, HU Wentao, LI Haoran, et al. Leaching process and mechanism of high magnesium low-grade nickel sulfide ore[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6): 1599-1606.

[13] 冯程, 卢毅屏, 冯其明, 等. 强搅拌调浆对硫化镍矿浮选的作用[J]. 中南大学学报(自然科学版), 2016, 47(11): 3621-3626.

FENG Cheng, LU Yiping, FENG Qiming, et al. Effect of high intensity conditioning on flotation of nickel sulfide mineral[J]. Journal of Central South University(Science and Technology), 2016, 47(11): 3621-3626.

[14] LI Hongxu, LI Chao, ZHANG Zhiqian. Decomposition mechanism of pentlandite during electrochemical bio-oxidation process[J]. Transaction of Nonferrous Metals Society of China, 2012, 22(3): 731-739.

[15] 李启厚, 姜波, 刘智勇,等. 高碱性脉石低品位混合镍矿氧压浸出行为与机制研究[J]. 湿法冶金, 2013, 32(3): 154-157.

LI Qihou, JIANG Bo, LIU Zhiyong, et al. Study on leaching behaviors and mechanism of nickel from low grade ore with high alkaline gangue by high-pressure ammonia leaching[J]. Hydrometallurgy of China, 2013, 32(3): 154-157.

[16] 朱宏飞, 李辉, 刘东奇. 三种浸矿细菌协同作用的回顾及展望[J]. 微生物学通报, 2016, 43(12): 2730-2737.

ZHU Hongfei, LI Hui, LIU Dongqi. A review of synergy development and prospect of three leaching bacteria[J]. Microbiology China, 2016, 43(12): 2730-2737.

[17] PAN Haodan, YANG Hongying, TONG Linlin, et al. Control method of chalcopyrite passivation in bioleaching[J]. Transaction of Nonferrous Metals Society of China, 2012, 22(9): 2255-2260.

[18] 袁明亮, 梅贤功, 庄剑鸣, 等. 软锰矿两矿法选择性浸出[J]. 中国有色金属学报, 1996, 6(3): 22-25.

YUAN Mingliang, MEI Xiangong, ZHUANG Jianming, et al. Selective leaching of manganese dioxide ore with two ore method [J]. The Chinese Journal of Nonferrous Metals, 1996, 6(3): 22-25.

[19] 吴爱祥, 胡凯建, 王贻明, 等. 含碳酸盐脉石氧化铜矿的酸浸动力学[J]. 工程科学学报, 2016, 38(6): 760-766.

WU Aixiang, HU Kaijian, WANG Yiming, et al. Leaching kinetic of copper oxide ore containing carbonate gangue in the acid condition[J]. Chinese Journal of Engineering, 2016, 38(6): 760-766.

[20] 马致远, 杨洪英. 响应曲面法优化铜阳极泥微波浸出硒工艺[J]. 中南大学学报(自然科学版), 2015, 46(7): 2391-2397.

MA Zhiyuan, YANG Hongying. Microwave assisted leaching of selenium from copper anode slime optimized by response surface methodology[J].Journal of Central South University (Science and Technology), 2015, 46(7): 2391-2397.

(编辑 陈灿华)

收稿日期:2017-07-10;修回日期:2017-09-15

基金项目(Foundation item):水体污染与治理科技重大专项(2015ZX07205-003);中国大洋矿产资源研究计划项目(DY 125-15-T-08);国家自然科学基金资助项目(21176026,21176242) (Project(2015ZX07205-003) supported by the Major Science and Technology Program for Water Pollution Control and Treatment; Project(DY 125-15-T-08) supported by the China Ocean Mineral Resources Research & Development Program; Projects(21176026, 21176242) supported by the National Natural Science Foundation of China)

通信作者:李浩然,博士,从事非传统资源利用研究;E-mail: hrli@home.ipe.ac.cn