DOI:10.11817/j.ysxb.1004.0609.2021-37990

大洋多金属结核低温氢还原-酸浸新工艺研究

周小舟,彭俊,沈裕军,黄宗朋,蔡云卓,钟山

(长沙矿冶研究院有限责任公司 矿产资源开发利用技术研究所,长沙 410012)

摘 要:大洋多金属结核是一种复杂难选的多金属氧化矿,本文以其为原料,开展了低温氢还原-酸浸新工艺研究。首先考察了氢还原温度、时间及氢气流量等因素对有价金属氧化物还原的影响,得出了优化的还原工艺条件:还原温度 600 ℃、时间90min、氢气流量 50mL/min。在此基础上,针对优化条件下的还原物料进行浸出研究,考察了浸出温度、时间、液固比、终点pH、双氧水和氧气用量对有价金属浸出的影响,结果表明:在浸出液固比6:1、温度80℃、氧气流量250mL/min、浸出时间6h、控制终点pH1.5~2.0的条件下,Ni、Co、Cu、Mn浸出率分别达99.09%,98.35%,94.97%,98.58%,实现了多金属结核中有价金属的高效浸出。

关键词:大洋多金属结核;低温氢还原;浸出;硫酸

中国分类号:TF19 文献标志码:A

大洋多金属结核广泛分布于世界各大洋底,含有 70 多种元素,主要含 Mn、Fe、Ni、Cu、Co,还含有 Mo、V、Zn、W、Ti等,以Mn、Cu、Ni和Co最具有回收价值,被认为可能是海底分布最广、储量最大的金属资源[1]。美、德、法、日、印、韩等国家均投入大量人力和财力开展大洋多金属锰结核资源的勘探及冶炼加工研究。大洋多金属结核是一种复杂难选的多金属氧化矿,其中的镍、铜、钴主要以类质同相嵌布于铁锰氧化物晶格中,为提取这些有价金属,必须将多金属结核中的水锰矿MnO2还原为二价锰[2-7]来破坏其矿相。自20世纪50 年代开始世界各国就进行了大量研究,开发出了一系列具有代表性的冶炼工艺,主要包括:还原焙烧-氨浸法、熔炼硫化浸出法、亚铜离子氨浸法、SO2还原-硫酸浸出法和熔炼-锈蚀浸出等[8-14]。这些方法无一例外均通过采用焦炭或一氧化碳或二氧化硫/亚硫酸盐/硫铁矿等作还原剂,要么存在冶炼温度高、成本高并产生大量温室气体,要么还原剂有毒且不易获得及环境污染等问题。

氢能被视为 21 世纪最具发展潜力的清洁能源,由于具有来源多样、清洁低碳等优点,被多国列入能源战略部署中[15],在当今国家大力宣传“碳达峰”和“碳中和”的大背景下,随着对氢冶金认识的越来越深入[16-17],氢冶金必将受到重视。

基于以上考虑,本研究探索了以氢代焦还原大洋多金属结核新工艺,并取得了预期的试验结果。

1 实验

1.1 试验原料及试剂

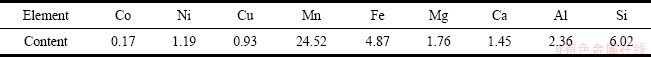

试验用大洋多金属结核为中国大洋协会提供的 DY125-14 航次矿样。其直径在5到10厘米之间,大小如土豆。表面多为光滑,也有粗糙、呈椭球状或其他不规则形状,多金属结核经干燥、破碎、细磨至-0.074mm的占70.82%,其化学组成见表1。

表1 大洋多金属结核化学组成,%

Table 1 Chemical composition of ocean polymetallic nodules (mass fraction, %)

本试验研究所采用的试剂及其品级为:氢气(H2)(纯度≥99.5%),氮气(N2) (纯度≥99.9%),氧气(O2),硫酸(H2SO4) (分析纯),双氧水(H2O2) (分析纯)。

1.2试验设备与分析仪器

管式电阻炉(SGQ-4-12),数显恒速搅拌器(OS20/40-S),电子天平,加热板(HP550-S),实验室pH计(ST3100)。分析仪器为热场发射扫描电子显微镜及智能能谱与电子背散射衍射一体化系统(日本电子JSM-7900F),X-射线衍射仪(德国布鲁克D8 Advance),X-荧光光谱仪(德国布鲁克S4 Pioneer),原子吸收分光光度计(北京普析通用仪器有限责任公司TAS-990super)。

1.3试验方法

多金属结核氢还原:取干燥后的多金属结核矿粉35g加入瓷坩埚中,置于管式电阻炉中加热升温,同时通入N2排空炉内空气,至设定温度时通入H2和N2混合气 (流量比为1:1),到设定时间后关闭氢气并降温至100℃以下,取出并取样分析。还原效果主要通过还原物料中有价金属的浸出率来评价:取20g还原料粉,加入硫酸及矿重量40%的双氧水,浸出液固比L:S=8:1,硫酸浓度为1.3mol/L,浸出时间3h,浸出温度90℃,反应过程中通过pH计检测体系pH变化,通过往体系中加入硫酸或氢氧化钠调整浸出pH,控制浸出终点pH=1.5~2.0,浸出过程结束后过滤洗涤,滤饼于100℃干燥12h后称重、取样分析并计算各有价金属的浸出率。

浸出实验:称取一定量的还原料与一定浓度的硫酸按照一定的液固比加入烧杯中,加温,在设定温度下加入适量的氧化剂反应一段时间,反应过程中通过pH计检测体系pH变化,通过往体系中加入硫酸或氢氧化钠调整浸出pH,控制浸出终点pH至 目标值,反应完成后,过滤洗涤滤饼,并于100℃干燥12h后称重并分析相关元素的含量,经计算得出各金属的浸出率。

2. 多金属结核氢还原热力学分析

大洋多金属结核是一种多晶或者微晶态复合氧化物,其中有价金属Mn、Fe、Cu、Co、Ni均以氧化物形态存在。利用HSC6.0软件对多金属结核氢还原反应热力学进行计算。

大洋多金属结核氢还原过程可能发生的化学反应及其反应吉布斯自由能和温度的关系如下:

NiO(s)+H2(g)=H2O(g)+Ni(s) (1)

=[-4.18-0.00867T] KJ·mol-1 T始=-482℃

=[-4.18-0.00867T] KJ·mol-1 T始=-482℃

CoO(s)+H2(g)=H2O(g)+Co(s) (2)

=[-3.67-0.00448T] KJ·mol-1 T始=-819℃

=[-3.67-0.00448T] KJ·mol-1 T始=-819℃

CuO(s)+H2(g)=H2O(g)+Cu(s) (3)

=[-24.29-0.00818T] KJ·mol-1 T始=-2969℃

=[-24.29-0.00818T] KJ·mol-1 T始=-2969℃

3Fe2O3(s)+H2(g)=H2O(g)+2Fe3O4(s) (4)

=[-6.47-0.022T] KJ·mol-1 T始=-294℃

=[-6.47-0.022T] KJ·mol-1 T始=-294℃

Fe3O4(s)+H2(g)=H2O(g)+3FeO(s) (5)

=[10.62-0.0144T] KJ·mol-1 T始=738℃

=[10.62-0.0144T] KJ·mol-1 T始=738℃

FeO(s)+H2(g)=H2O(g)+Fe(s) (6)

=[3.89-0.00325T] KJ·mol-1 T始=1197℃

=[3.89-0.00325T] KJ·mol-1 T始=1197℃

MnO2(s)+H2(g)=H2O(g)+MnO(s) (7)

=[-29.66-0.0131T] KJ·mol-1 T始=-2264℃

=[-29.66-0.0131T] KJ·mol-1 T始=-2264℃

MnO(s)+H2(g)=H2O(g)+Mn(s) (8)

=[32.01-0.00502T] KJ·mol-1 T始=6377℃

=[32.01-0.00502T] KJ·mol-1 T始=6377℃

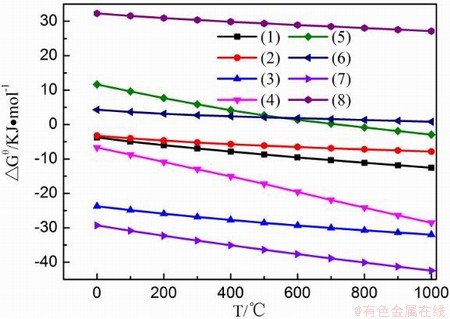

将反应式(1)~(8)相关热力学数据绘图,如图1所示。

图1 反应式(1)~(8)在不同温度下的吉布斯自由能谱图

Fig. 1 The Gibbs free energy of equations (1) ~ (8) at different temperatures

根据及计算的各反应的起始温度T始可知,多金属结核中各氧化物被氢还原的趋势顺序为:CuO→Cu>MnO2→MnO>CoO→Co>NiO→Ni>Fe2O3→Fe3O4,其中,多金属结核中的水锰矿MnO2被氢还原为MnO 的趋势较钴、镍、铁氧化物还原为相应的钴、镍、铁金属要大。因此,理论上用氢还原大洋多金属结核来破坏其水锰矿结构是可行的。

另从图1可知,在500~1200℃温度下,多金属结核中的镍、钴、铜、铁氧化物均可被氢还原为金属,而MnO2只能被还原为MnO。

3 结果与讨论

3.1 多金属结核的氢还原

3.1.1 还原温度的影响

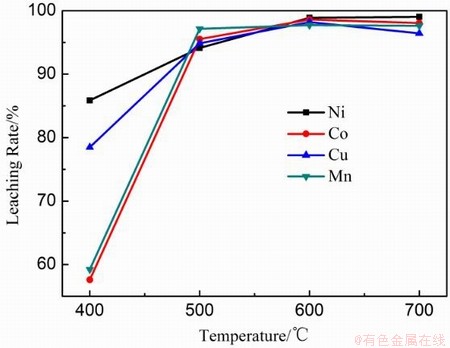

氢气和氮气流量均为200mL/min,在不同温度下还原多金属结核矿2h,考察了还原温度对各还原料中有价金属浸出的影响,结果如图2所示。

图2 还原温度对有价金属浸出率的影响

Fig. 2 Effect of reduction temperature on the leaching rate of valuable metals

结果显示,随着还原温度的升高,Ni、Co、Cu、Mn浸出率逐渐升高,当温度为600℃时,Ni、Co、Cu、Mn浸出率分别达98.88%、98.61%、98.21%和97.75%,继续升高温度,浸出率变化不大,因此,氢还原最佳温度为600℃。

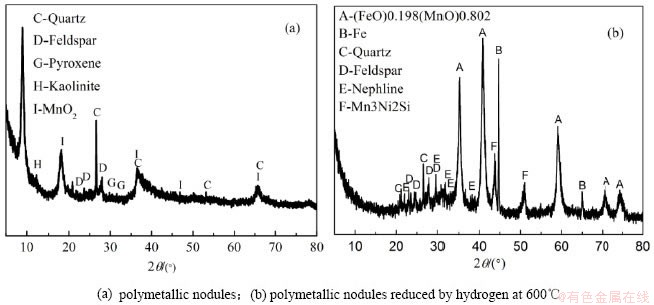

图3为多金属结核原矿及其经600℃氢还原后物料的XRD分析结果。

图3 多金属结核及其600℃氢还原物料XRD

Fig. 3 XRD of polymetallic nodules and polymetallic nodules reduced by hydrogen at 600℃

由图3可知,多金属结核经氢还原后水锰矿物相消失,还原料中出现了新的Fe、(FeO)0.198(MnO)0.802和Mn3Ni2Si物相,说明多金属结核矿物结构已被破坏。

3.1.2 还原时间的影响

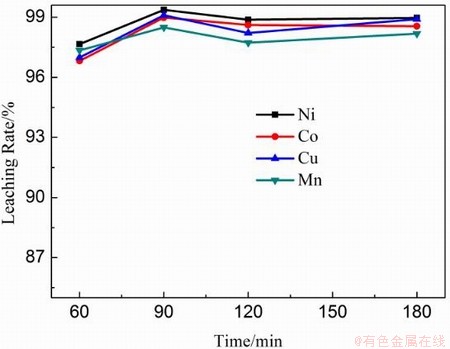

氢气和氮气流量均为200mL/min,在600℃下还原多金属结核矿不同时间,考察了还原时间对各有价金属浸出的影响,结果见图4。

图4 还原时间对有价金属浸出率的影响

Fig. 4 Effect of reduction time on the leaching rate of valuable metals

结果显示,当还原时间为60min时,Ni、Co、Cu、Mn浸出率分别达为97.65%、96.82%、96.99%、97.34%,进一步延长还原时间至180min, Ni、Co、Cu、Mn浸出率变化不明显,为保证较佳的浸出率,还原时间取90min。

3.1.3 氢气流量的影响

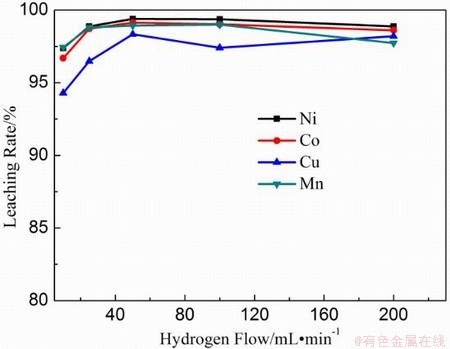

氢气和氮气流量为1:1,在600℃下还原多金属结核矿2h,考察了氢气流量对各有价金属浸出的影响,结果见图5。

图5 氢气流量对有价金属浸出率的影响

Fig. 5 Effect of hydrogen flow on the leaching rate of valuable metals

结果显示,随着氢气流量由10mL/min上升至50mL/min时,Ni、Co、Cu、Mn浸出率分别达到99.40%、99.14%、98.34%、98.94%,继续增加氢气流量,浸出率变化不大,因此,氢气流量选择50mL/min。

综上所述,较优的多金属结核氢还原条件为:多金属结核矿样35g,氢气和氮气流量均为50mL/min,还原温度600℃,还原时间90min。

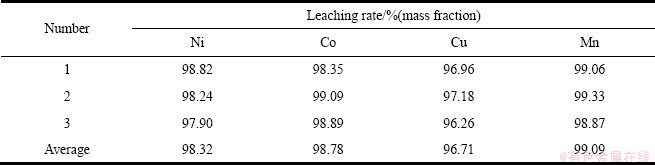

进行了优化条件下的验证试验,结果列于表2。

表2 多金属结核氢还原验证试验

Table 2 Verification experiment of hydrogen reduction of polymetallic nodules

结果显示,在优化的还原工艺条件下,多金属结核还原料中Ni、Co、Cu、Mn平均浸出率分别达到了98.32%、98.78%、96.71%、99.09%,说明多金属结核氢还原工艺可靠。

3.2 多金属结核氢还原料的浸出

3.2.1 浸出终点pH的影响

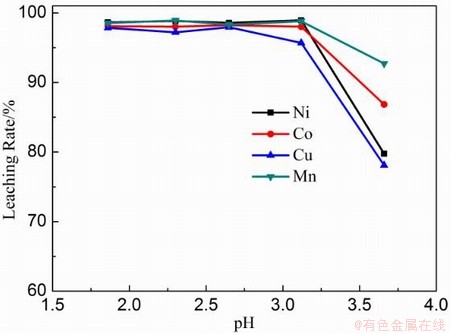

取一定量还原料,在浸出液固比L:S=8:1,温度80℃,时间3h,双氧水加入量为矿重量的40%条件下,考察浸出终点pH对有价金属浸出率的影响,结果如图6所示。

图6 浸出pH对有价金属浸出率的影响

Fig. 6 Effect of leaching pH on the leaching rate of valuable metals

结果显示,随着浸出终点pH升高,Ni、Co、Cu、Mn的浸出率逐渐降低,当浸出pH=1.86~2.65时,Ni、Co、Mn、Cu浸出率分别达98%、98%、97%和98%以上,继续提高浸出终点pH至3.25左右,Ni、Co、Mn 浸出率变化不大,但Cu的浸出率下降至94%左右,因此,浸出终点pH控制在1.5~2.5。

3.2.2 浸出液固比的影响

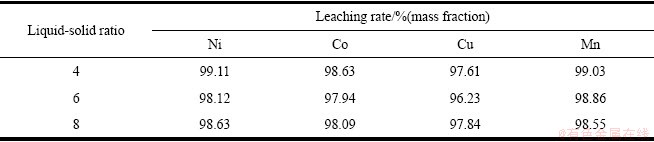

取一定量还原料,在80℃、双氧水加入量为矿重量的40%,浸出时间3h,浸出液终点pH2.0~2.5的条件下,考察浸出液固比对各金属浸出率的影响,结果列于表3。

表3 液固比对有价金属浸出率的影响

Table 3 Effect of liquid-solid ratio on the leaching rate of valuable metals

结果显示,在试验条件下液固比L:S对各金属浸出率影响不大,Ni、Co、Mn均保持在98%以上,Cu在97%左右,但是,在实验过程中发现,当L:S=4/1时,浸出矿浆较粘稠,过滤速度较慢,因此,后续实验过程中,L:S应该大于4/1,取6~8/1为宜。

3.2.3 浸出温度的影响

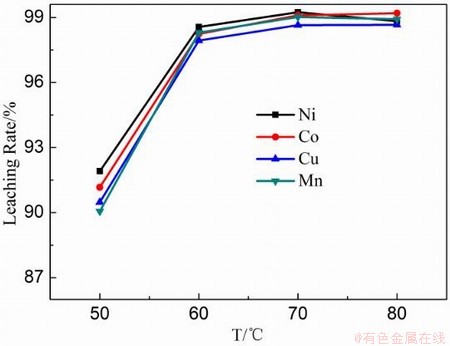

取一定量还原料,在液固比L:S=8:1,反应时间3h,双氧水加入量为矿重量的40%,终点pH2.0~2.5的条件下,考察浸出温度对各金属浸出率的影响,结果如图7所示。

图7 浸出温度对有价金属浸出率的影响

Fig. 7 Effect of leaching temperature on the leaching rate of valuable metals

结果显示,随着浸出温度由50℃升高至60℃时,Ni、Co、Cu、Mn浸出率分别达到98.56%、98.24%、97.94%、98.30%,继续升高温度,Ni、Co、Cu、Mn浸出率变化不大,但是,在浸出温度低于70℃时,浸出矿浆过滤很慢,为保证较好的矿浆过滤性能,浸出温度取80℃为宜。

3.2.4 双氧水加入量的影响

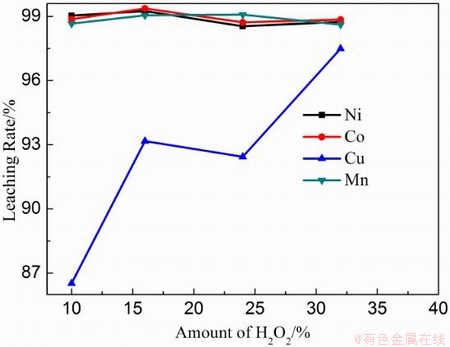

取一定量还原料,在液固比L:S=6:1,温度80℃,浸出时间3h,终点pH2.0~2.5的条件下,考察双氧水加入量对各金属浸出率的影响,结果如图8所示。

图8 双氧水加入量对有价金属浸出率的影响

Fig. 8 Effect of amount of H2O2 on the leaching rate of valuable metals

结果显示,在试验条件下,双氧水加入量对Ni、Co、Mn浸出率影响不大,而对Cu的浸出影响较大,双氧水用量由10%上升至32%时,铜浸出率由86.52%上升至97.69%。

3.2.5 氧气代替双氧水试验

考虑到双氧水用量过大,在此探索了用氧气代替双氧水的试验效果。

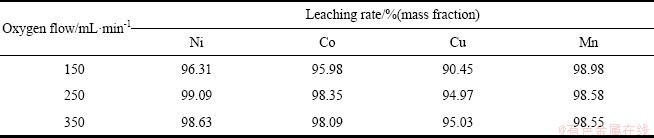

取一定量还原料,在液固比L:S=6:1,温度80℃,浸出时间6h,终点pH1.5~2.0的条件下,考察了氧气流量对各金属浸出率的影响,结果列于表4。

表4 氧气流量对有价金属浸出率的影响

Table 4 Effect of oxygen flow on the leaching rate of valuable metals

结果显示,随着氧气流量由150mL/min增加至250mL/min时,Ni、Co、Cu、Mn浸出率分别达到99.09%, 98.35%, 94.97%, 98.58%,继续增加氧气流量,各金属浸出率变化不大,因此,氧气流量取250mL/min。

3.2.6 浸出时间的影响

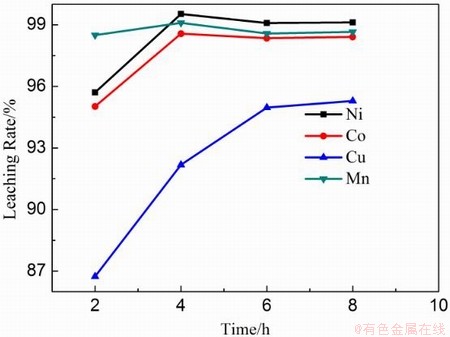

取一定量还原料,在液固比L:S=6:1,温度80℃,氧气流量250 mL/min,终点pH 1.5~2.0的条件下,考察了浸出时间对各金属浸出率的影响,结果如图9所示。

图9 浸出时间对有价金属浸出率的影响

Fig. 9 Effect of leaching time on the leaching rate of valuable metals

结果显示,随着浸出时间延长由2h增加至6h,还原料中Ni、Co、Cu、Mn的浸出率逐渐升高至99.09%、98.35%、94.97%、98.58%,继续延长浸出时间各金属浸出率变化不大,因此,浸出时间取6h为宜。

综上所述,多金属结核还原料的优化浸出条件为:液固比L:S=6:1,浸出温度80℃,浸出时间6,浸出终点pH1.5~2.0,氧气流量250mL/min。

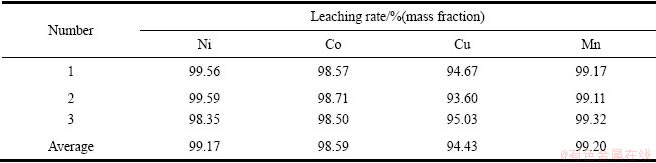

进行了该优化条件下的浸出验证试验,结果列于表5。

表5 浸出验证试验结果

Table 5 Result of leaching verification experiment

结果显示,在优化的浸出条件下,Ni、Co、Cu、Mn浸出率平均分别为99.17%、98.59%、94.43%、99.20%,说明多金属结核氢还原料的浸出工艺可靠。

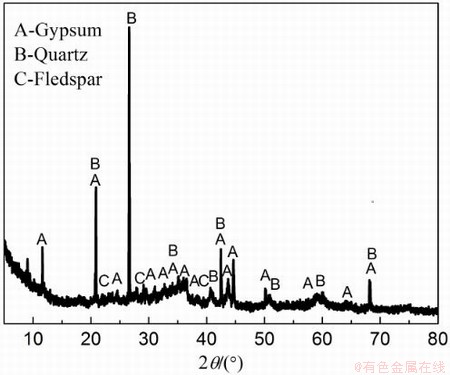

进一步对浸出渣进行XRD物相分析,结果如图10所示。

图10 浸出渣XRD

Fig. 10 XRD of leaching slag

结果显示,浸出渣中主要物相为石膏、石英和长石,所有有价金属相物相全部消失,说明还原料中有价金属均被高效浸出。

4 结论

(1)通过采用低温氢还原-酸浸工艺可以实现大洋多金属结核中各有价金属的高效浸出。

(2)多金属结核氢还原的优化工艺条件为:还原温度 600 ℃,还原时间90min,氢气流量 50mL/min。

(3)多金属结核氢还原料的优化浸出工艺为:浸出液固比6:1,浸出温度 80 ℃,浸出时间6h, 浸出终点pH1.5~2.0,氧气流量250mL/min,该优化条件下,Ni、Co、Cu、Mn的浸出率分别达99.09%,98.35%,94.97%,98.58%。

REFERENCES

[1] 于淼, 邓希光, 姚会强,刘永刚. 世界海底多金属结核调查与研究进展[J]. 中国地质, 2018(1):29-38.

YU Miao, DENG Xi-guang, YAO Hui-qiang, Liu Yong-gang. The progress in the investigation and study of global deep-sea polumetallic nodules[J]. GEOLOGY CHINA, 2018(1):29-38.

[2] 钟志杰,徐徽,杨喜云,王小弟,伍玲龙,陈志鑫.以海底多金属结核制备三元正极材料前驱体Ni0.5Co0.2Mn0.3(OH)2[J].中国有色金属学报,2020,30(11):2605-2614.

ZHONG Zhi-jie, XU Hui, YANG Xi-yun, WANG Xiao-di, WU Ling-long. Preparation of ternary cathode material precursor Ni0.5Co0.2Mn0.3(OH)2 from seafloor polymetallic nodules[J]. The Chinese Journal of Nonferrous Metals,2020,30(11):2605-2614.

[3] Zhong Y, Chen Z, Javier Gonzalez F , Hein J R , Zheng X., Li G. Composition and genesis of Ferro manganese deposits from the Northern South China Sea[J]. Journal of Asian Earth Sciences, 2017, 138: 110 -128.

[4] Bloethe M, Wegorzewski, A, Mueller C, Simon F, Kuhn T, Schippers A. Manganese cycling microbial communities inside deep-sea manganese nodules[J].Environmental Science & Technology, 2015, 49(13):7692-7700.

[5] González F J, Somoza L, Lunar R, J Martínez-Frías, JAM Rubí, Torres T. Internal features, mineralogy and geochemistry of ferromanganese nodules from the Gulf of Cadiz: The role of the Mediterranean outflow water undercurrent[J]. Journal of Marine Systems, 2010, 80(3):203- 218.

[6] 沈裕军, 贺泽全, 钟祥.熔炼浸出法处理大洋多金属结核研究现状及发展.中国锰业,1998,16(2):1-4.

SHEN Yu-jun, HE Ze-quan, ZHONG Xiang. Research Status and Development of Smelting-Leaching Process for Ocean Polymetallic Nodule[J].CHINA’S MANGANESE INDUSTRY, 1998,16(2):1-4.

[7] 赵峰, 蒋训雄, 冯林永,蒋伟,汪胜东,李达. 海底多金属结核理化特性分析[J]. 有色金属(冶炼部分), 2020(3):8-11.

ZHAO Feng, JIANG Xun-Xiong, FENG Lin-yong, Jiang Wei, Wang Sheng-dong, Li Da. Physical and Chemial Characteristics of Ocean Polymetallic Nodules[J]. Nonferrous Metals(Extractive Metallurgy), 2020(3):8-11.

[8] Mishra D, Srivastava R R, Sahu K K, Singh T. Leaching of roast-reduced manganese nodules in NH3-(NH4)2CO3 medium[J]. Hydrometallurgy, 2011, 109(3):215- 220.

[9] 康金星, 冯雅丽, 李浩然,杜竹玮,邓祥意,王洪君. 多金属结核与低品位硫化镍矿共提取中Acidithiobacillus ferrooxidans增速作用[J]. 中国有色金属学报, 2018,.28(12):2580-2689.

KANG Jin-xing, FENG Ya-li, LI Hao-ran, Du Zhu-wei, Deng Xiang-yi, Wang Hong-jun. Enhancement of Acidithiobacillus ferrooxidans on polumetallic nodule and low-grade nickel sulfide ore simultaneous bioleaching[J].The Chinese Journal of Nonferrous Metals, 2018,.28(12):2580-2689.

[10] 张旭, 王雅静, 饶俊, 冯雅丽. 化学-微生物联合浸出大洋锰结核中金属元素的过程研究[J]. 矿冶工程, 2017, 37(4):73-76.

ZHANG Xu, WANG Ya-jing, RAO Jun, FENG Ya-li. A Combined Chemical-biological Leaching Process for Extracting Metallic Element from Ocean Manganese Nodules[J].MINING AND METALLURGCAL ENGINEERING,2017,37(4): 73-76.

[11] 向鹏, 李国斌, 李旭, 苏毅;黄晓梅. 锰结核中锰的浸取实验研究[J]. 材料导报, 2016, 30(1):345-347.

XIANG Peng, LI Guo-bin, LI Xu, Su Yi, Huang Xiao-mei. Experiment Research of Leaching Manganese from Manganese Nodule[J]. Materials Review,2016,30(1): 345-347.

[12] 蒋开喜,蒋训雄,汪胜东,范艳青,赵磊,利镇有.大洋多金属结核还原氨浸工艺研究[J].有色金属,2005,57(4):54-58.

JIANG Kai-xi, JIANG Xun-xiong, WANG Sheng-dong, Fan Yan-qing, Zhao Lei, Li Zhen-you. Reductive Ammonia Leaching of Ocean polymetallic Nodules[J]. Nonferrous Metals,2005,57(4):54-58.

[13] 刘强, 沈裕军, 彭俊, 郑铁铮,蔡云卓,何鲁华. 大洋锰结核和富钴结壳混合熔炼合金的锈蚀浸出研究[J]. 矿冶工程, 2015,35(z1):22-24.

LIU Qiang, SHEN Yu-jun, Peng Jun, ZHENG Tie-zheng, CAI Yun-zhuo, HE Lu-hua. Study on Leaching by Corrosion Process for Smelted Alloy of Ocean Manganese Nodules and Cobalt-rich Crust[J]. MINING AND METALLURGCAL ENGINEERING, 2015,35(z1):22-24.

[14] 仇云飞, 冯雅丽, 李浩然, 杜竹玮 , 康金星 , 王昌. 大洋锰结核与药渣共浸出氧化还原过程研究[J]. 中南大学学报(自然科学版), 2018, 49(10):15-22.

QIU Yun-fei, FENG Ya-li, LI Hao-ran, DU Zhu-wei, KANG Jin-xing , WANG Chang. Oxidation-reduction process of oceanic manganese nodules and pharmaceutical residue[J].Journal of Central South University(Science and Technology), 2018, 49(10):15-22.

[15] 唐 珏, 储满生, 李峰, 周渝生,王佳鑫,李胜康,柳政根.我国氢冶金发展现状及未来趋势[J].河北冶金,2020(8):1-6.

TANG Jue, CHU Man-sheng, Li Feng, Zhou Yu-sheng, Wang Jia-xin, Li Sheng-kang,LiuZheng-gen. Development Status and Future Trent of Hydrogen Metallurgy in China[J]. Hebei Metallurgy, 2020(8):1-6.

[16] 郭苗苗,席晓丽,张云河,余顺文,龙小林,蒋振康,聂祚仁,许开华.报废动力电池镍钴锰酸锂三元正极材料高温氢还原-湿法冶金联用回收有价金属[J].中国有色金属学报,2020,30(6):1416-1426.

GUO Miao-miao, XI Xiao-li, ZHANG Yun-he, YU Shun-wen, LONG Xiao-lin, JIANG Zheng-kang, NIE Zuo-ren, XU Kai-hua[J]. The Chinese Journal of Nonferrous Metals, 2020,30(6):1416-1426.

[17] 段贵生.氢冶金原理及工业化应用研究进展[J]. 河南冶金,2021,29(1):2-5.

Duan Gui-sheng. BASIC RESEARCH ON HYDROGEN METALLURGY AND DEVELOPMENT OF INDUSTRIALIZATION APPLICATION[J]. Henan Metallurgy,2021,29(1):2-5.

Novel Process of Treating Ocean Polymetallic Nodules by Low temperature Hydrogen Reduction-acid Leaching

ZHOU Xiao-zhou, PENG Jun, SHEN Yu-jun, HUANG Zong-peng, CAI Yun-zhuo, ZHONG Shan

(Institute of Mineral Resources Development and Utilization Technology, Changsha Research Institute of Mining and Metallurgy Co., LTD , Changsha 410012,China)

Abstract:Ocean polymetallic nodule is a kind of complex and difficult to concentrate polymetallic oxide. A new technology of low temperature hydrogen reduction-acid leaching was studied in this paper. Firstly, the effects of hydrogen reduction temperature, time and hydrogen flow rate on the oxidation reduction of each valuable metal were investigated. The optimal reduction process conditions were obtained: reduction temperature 600 ℃, time 90min, hydrogen flow rate 50mL/min.Under these conditions, the leaching of reduced materials under optimized conditions was studied, and the effects of leaching temperature, leaching time, liquid-solid ratio, pH and dosage of H2O2 and O2 on the leaching of valuable metals were investigated. The results showed that: Under the conditions of liquid-solid ratio 6:1, temperature 80 ℃, leaching time 6h, pH1.5~2.0 and oxygen flow rate 250mL/min, the leaching rates of Ni, Co, Cu and Mn reached 99.09%, 98.35%, 94.97% and 98.58%, respectively, which realized the efficient leaching of valuable metals from polymetallic nodules.

Key words:ocean polymetallic nodules; low temperature hydrogen reduction; leaching; H2SO4

基金项目:大洋矿产资源技术研发项目(JS —KTHT—2018—01)

通信作者:沈裕军,教授级高级工程师,硕士;电话:0731-88655998;E-mail:yjshen@vip.sina.com