预变形对应变诱导熔化激活法制备Al-Zn-Mg-Cu合金显微组织与力学性能的影响

来源期刊:中国有色金属学报(英文版)2016年第9期

论文作者:Behzad Mohasel AFSHARI Seyed Sajad MIRJAVADI Yousef Askari DOLATABAD Mojtaba AGHAJANI Mohammad Kazem Besharati GIVI Mohammad ALIPOUR M. EMAMY

文章页码:2283 - 2295

关键词:铝合金;铸造;晶粒细化;应变诱导熔化激活法;半固态工艺;拉伸性能

Key words:aluminium alloy; casting; grain refinement; strain induced melt activation; semisolid processing; tensile properties

摘 要:研究Al-8B晶粒细化剂对应变诱导熔化激活法制备的Al-12Zn-3Mg-2.5Cu合金显微组织与力学性能的影响。并在300 °C对合金进行预变形量为60%的热加工。预变形后,将合金加热至介于固相线和液相线的某一温度(500,550和590 °C),并保温不同时间(10,20和40 min)。应变诱导熔化激活法可得到球状α(Al)晶粒。采用光学显微镜和扫描电子显微镜观察细化和未细化合金的显微组织。结果表明,应变诱导熔化激活制备过程中在550 °C下保温10 min,可以得到满意的显微组织。经T6热处理后,采用3.75% Al-8B细化和应变诱导熔化激活法制备的合金的平均拉伸强度分别从278 MPa增加至585 MPa,252MPa增加至560 MPa。SIMA合金的抗拉强度比B细化合金的抗拉强度低。

Abstract: The effects of Al-8B grain refiner on microstructure and tensile properties of an Al-12Zn-3Mg-2.5Cu alloy produced by modified strain induced melt activation process were investigated. Pre-deformation of 60% was used by hot working at 300 °C. After pre-deformation, the samples were heated to a temperature above the solidus and below the liquidus point and maintained in the isothermal conditions at three different temperatures (500, 550 and 590 °C) for varying time (10, 20 and 40 min). It was observed that strain induced melt activation has caused the globular morphology of α(Al) grains. Microstructural study was carried out on the alloy by using optical microscope and scanning electron microscope in both unrefined and B-refined conditions. The results showed that for the desired microstructures of the alloy during SIMA process, the optimum temperature and time are 550 °C and 10 min, respectively. After the T6 heat treatment, the average tensile strengths increased from 278 to 585 MPa and 252 to 560 MPa for samples refined with 3.75% Al-8B before and after SIMA process, respectively. The ultimate strength of SIMA specimens is lower than that of B-refined specimens.

Trans. Nonferrous Met. Soc. China 26(2016) 2283-2295

Behzad Mohasel AFSHARI1, Seyed Sajad MIRJAVADI1, Yousef Askari DOLATABAD2, Mojtaba AGHAJANI3, Mohammad Kazem Besharati GIVI1, Mohammad ALIPOUR4,5,6, M. EMAMY4

1. School of Mechanical Engineering, College of Engineering, University of Tehran, Tehran, Iran;

2. Department of Civil engineering, Sirjan University of Technology, Kerman, Iran;

3. Department of Industrial Engineering, Faculty of Engineering, University of Tehran, Tehran, Iran;

4. School of Metallurgy and Materials Engineering, University of Tehran, Tehran, Iran;

5. Faculty of Materials Science and Engineering, K. N. Toosi University of Technology, Tehran, Iran;

6. Department of Materials Engineering, Faculty of Mechanical Engineering, University of Tabriz, Tabriz, Iran

Received 5 September 2015; accepted 24 December 2015

Abstract: The effects of Al-8B grain refiner on microstructure and tensile properties of an Al-12Zn-3Mg-2.5Cu alloy produced by modified strain induced melt activation process were investigated. Pre-deformation of 60% was used by hot working at 300 °C. After pre-deformation, the samples were heated to a temperature above the solidus and below the liquidus point and maintained in the isothermal conditions at three different temperatures (500, 550 and 590 °C) for varying time (10, 20 and 40 min). It was observed that strain induced melt activation has caused the globular morphology of α(Al) grains. Microstructural study was carried out on the alloy by using optical microscope and scanning electron microscope in both unrefined and B-refined conditions. The results showed that for the desired microstructures of the alloy during SIMA process, the optimum temperature and time are 550 °C and 10 min, respectively. After the T6 heat treatment, the average tensile strengths increased from 278 to 585 MPa and 252 to 560 MPa for samples refined with 3.75% Al-8B before and after SIMA process, respectively. The ultimate strength of SIMA specimens is lower than that of B-refined specimens.

Key words: aluminium alloy; casting; grain refinement; strain induced melt activation; semisolid processing; tensile properties

1 Introduction

7075 aluminium alloy was developed over 70 years ago. However, many researches still have been performed on it in the past decade [1-6]. In this research, we focused on high strength 7xxx series wrought aluminium alloy which is typically used in aircraft structural parts and other highly stressed applications where very high strength and good resistance to corrosion are required [7]. There are many benefits from the use of grain refiners in aluminum alloy castings. For example, mechanical properties can be improved [8], susceptibility to hot cracking is reduced [9] and fluidity is improved [10,11].

Light weight structural materials, especially Al alloys, play an important role in achieving vehicle weight reduction and improving fuel economy in the automotive industry. Liquid metal high pressure die-casting (HPDC) currently satisfies the bulk of the automotive industry’s needs in this regard. Last two decades have seen a rise in the consumption of Al alloys in car and in light weight truck market. Growing demands for improved quality and weight reduction, however, have been driving the development of new processing technologies. Problems inherently associated with liquid metal HPDC have resulted in enhanced interest in semisolid metal (SSM) casting processes [12].

Semisolid processing can be done in two ways namely: rheocasting and thixocasting. Shaping of materials in the semi-liquid state includes both casting and deformation processes. The critical volume fraction of liquid phase, which allows the material to maintain its shape, is the criterion for the distinction between casting and forming processes. The volume fraction of liquid phase is a function of temperature in the range between solidus and liquidus. The research, which has been carried out in recent years, has proved that deformation of materials with the presence of a liquid phase exhibits some abilities, which are not attainable in conventional metal forming. These processes are referred in the literature as forming in mushy state or forming in semi-liquid state or thixoforming. The basic principle of these processes is deformation at temperatures between solidus and liquidus points. However, the alloy has to be prepared before deformation in a special way, so that it has a very fine spherical microstructure. The low melting temperature phase should be located at the grain boundaries. Such a microstructure is called thixoforming microstructure. As one of the SSM processes, the strain induced melt activation (SIMA) process is adapt to produce the semisolid Al and Mg-based alloys [12,13].

SIMA process has been used to enhance the mechanical properties of Al alloy in recent years. For this method, residual strain is stored in a billet and a global structure is evolved by the strain energy stored in the billet after reheating [14]. Parameters such as heating time, temperature and the degree of cold working are critical factors in controlling the semisolid microstructures in SIMA process [14-18]. In this research, the new modified strain induced melt activation (SIMA) process was used. A modified SIMA process includes homogenization and warm deformation instead of cold working in the convectional SIMA process [18]. It has been shown that the microstructure of an alloy prepared in the semisolid state depends on its microstructure prior to partial remelting, so it is important to study the initial microstructure and subsequent evolution process during partial melting.

The main objective of this investigation is to study the effect of Al-8B and modified SIMA process on the microstructure and tensile properties of the Al-12Zn-3Mg-2.5Cu alloy.

2 Experimental

The alloys were cast in the form of rectangular strips with dimensions of 100 mm × 50 mm × 40 mm. The experiment consisted of mainly three stages.

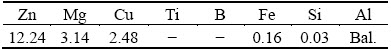

In stage 1, Al-12Zn-3Mg-2.5Cu alloy was prepared according to conventional melting and casting procedure. The chemical composition of Al-12Zn-3Mg-2.5Cu aluminum alloy is shown in Table 1. Melting procedure of the alloy was carried out in an electrical resistance furnace using a SiC crucible. In order to prepare alloys with different B contents, the parent alloy was remelted in a small electrical resistance furnace (with accurate temperature measuring system, 5 °C). Then, Al-8B master alloys were added to the molten alloy at 750 °C.

Table 1 Chemical composition of primary ingots (mass fraction, %)

In stage 2, the modified SIMA process was applied to the refined sample by optimum amount of the master alloy, i.e., 0.3% B (3.75% Al-8B). For the modified SIMA process (Fig. 1), all the cast specimens were homogenized at 460 °C for 24 h and then quenched in water (25 °C). The samples were mechanically worked with the help of a forging press. Warm working was used instead of cold working. Later, the samples were heated to 300 °C and forged with a reduction of 60%. The amount of the stored energy by working and its distribution are the most critical factors in SIMA process since they control the recovery and crystallization kinetics and the uniformity of the resultant microstructure. In the last stage, the worked samples were given heat treatment in an electric resistance furnace.

Fig. 1 Schematic illustration of new modified SIMA process

In the last stage, the temperature was in the freezing range which was varied from 500 °C to 590 °C, the soaking time was 5, 10, 20 and 40 min [18,19]. After this, the samples were quenched in water. The quenched samples were taken for microstructural study. The specimens were polished by standard metallographic practice and etched with the Keller’s reagent to reveal the microstructure. For structural studies, both optical microscope equipped with an image analysis system (Clemex Vision Pro. Ver.3.5.025) and scanning electron microscope performed in a Cam Scan MV2300 SEM, equipped with an energy dispersive X-ray analysis (EDX) accessory have been used. The average grain size of the specimens was measured according to the ASTM: E112 standard.

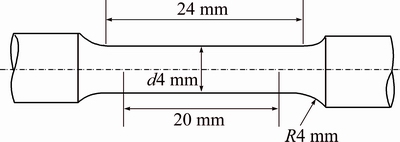

Before testing, T6 heat treatment was applied to the castings containing optimum amount of the master alloy, i.e., 0.3%B (3.75% Al-8B) and all SIMA specimens. For this purpose, the specimens were subjected to T6 heat treatment including heating up to 460 °C for 8 h, quenching in water (25 C) and aging at 120 °C for 24 h [3]. For tensile tests, specimens were machined according to ASTM, B557 M-94 standard (Fig. 2). For each condition, 4 specimens were tested. Tensile tests were carried out at a constant cross-head speed of 1 mm/min at room temperature.

Fig. 2 Tensile specimen geometry and dimensions

Fig. 3 Grain size variation with B content

3 Results and discussion

3.1 Structural characterization

The results obtained from microstructural observations of both the base alloy and refined specimens are shown in Fig. 3. To obtain an appropriate combination of refined structure, it was necessary to find optimum levels of the applied refiners. From Fig. 3, the optimum level of B was 0.3% (3.75% Al-8B). Several mechanisms have been proposed for the grain refining process [1]. In some mechanisms, the presence of some particles like TiAl3, TiB2 and AlB2 are known to be effective for grain refinement procedure. In comparison with AlB2 and TiB2, TiAl3 is known to be a potent nucleating site for aluminum [20,21]. The presence of some alloying elements, particularly Mg and Cu are known to improve the efficiency of some grain refiners such as Al-Ti-B master alloys.

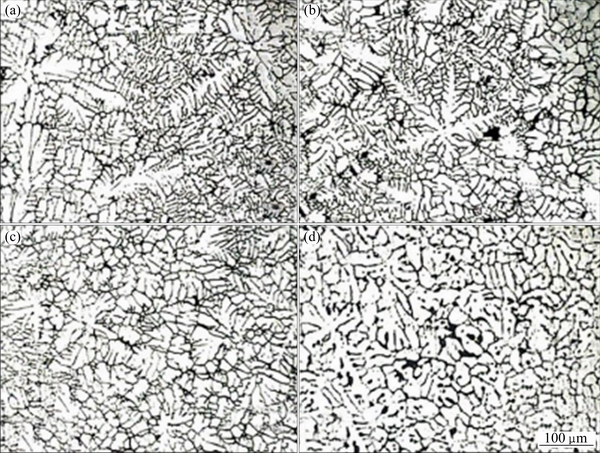

Fig. 4 Microstructures of refined specimens with 0.01% B (a), 0.05% B (b), 0. 1% B (c) and 0.3% B (d)

The microstructures of the Al-12Zn-3Mg-2.5Cu alloy cut from castings after T6 grain refinement by refiner are shown in Fig. 4. Figure 4 shows the change in dendrite morphology of the Al-12Zn-3Mg-2.5Cu alloy after grain refinement addition of refiner. The optical microstructures of B refined alloy revealed a rosette-like microstructure of primary α(Al) grains solid solution surrounded by interdendritic secondary phases. In comparison with B added specimens, unrefined specimens showed coarser morphology, as seen in Fig. 4. From Fig. 4, it is noticeable that grain refinement enhances the number of grain boundaries and therefore promotes a more homogeneous distribution of intermetallic precipitates. The most common phases observed in as-cast microstructure in the Al-Zn-Mg-Cu alloys are η-MgZn2 (as a part of eutectic structure), T-Al2Mg3Zn3 and S-Al2CuMg.

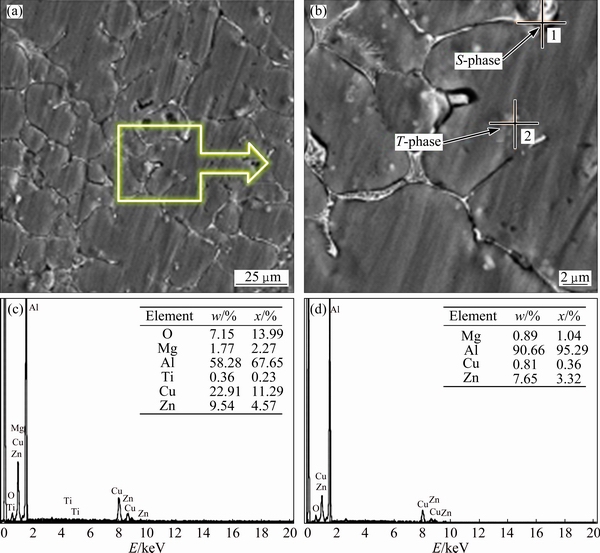

Figure 5 shows the results from line analysis and map analysis. The average composition of EDX analysis of the structure is shown in Fig. 5(a). It is important to note that the solubility of η-phase for copper is relatively high, so it can be observed in the eutectic structure.

Fig. 5 Results from line analysis in sample (a) and map analysis (b) of Al-12Zn-3Mg-2.5Cu alloy

Figure 5 shows the distribution of the major elements by scanning electron microscopy and line analysis. Analysis of the EDX result of MgZn indicated that copper and aluminum contents are higher than the average level of chemical composition in the alloy. In spite of more contribution of aluminum, matrix may be involved in the EDX signal of the MgZn because of its small size. It is obvious that the MgZn dissolved the Cu and Al elements, and formed the Mg(Zn,Cu,Al)2 phase, which is consistent with the present literatures. The segregation of solute that occurred during casting led to the high concentration of Cu, Mg and Zn in the interdendritic eutectic regions. The diffusion velocity of copper is lower than that of zinc and magnesium, which resulted in the higher concentration of copper in the regions of eutectic structures during solidification. The driving force for the phase transformation from Mg(Zn, Cu, Al)2 to AlCuMg must be supersaturation of copper in the regions of eutectic structures, which makes AlCuMg a stable phase. The microstructure of Al-12Zn-3Mg-2.5Cu alloy contains highly primary α-phase (solid solution of aluminum), S-Al2CuMg and T-Al2Mg3Zn3 phases (Fig. 6). T-phase is present mostly as divorced phase (also in some cases as part of the eutectic structure). S-phase exists in rather small volumes, entirely as a divorced phase with spherical morphology.

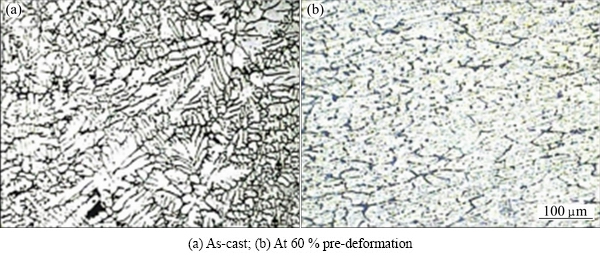

Figure 7(a) shows optical micrograph of conventionally cast Al-12Zn-3Mg-2.5Cu alloy where α(Al) dendrites can be seen along with the eutectic mixture. Figure 7(b) shows 60% pre-deformation which clearly exhibits heavily oriented α(Al) dendrites in the direction that was vertical to the hot working direction. During plastic deformation of samples, internal strain energy is stored in the form of dislocation multiplication, elasticity stress and vacancies, which provide the driving force for recovery and recrystallization. The energy increases with the degree of pre-deformation which promotes the morphological transition from dendritic to globular structure.

Fig. 6 BSE image of eutectic structure, S and T phase presenting in sample unrefined (a, b) and X-ray energy spectra of S phase (c), and X-ray energy spectra of T phase (d)

Fig. 7 Optical micrographs of cast Al-12Zn-3Mg-2.5Cu alloy

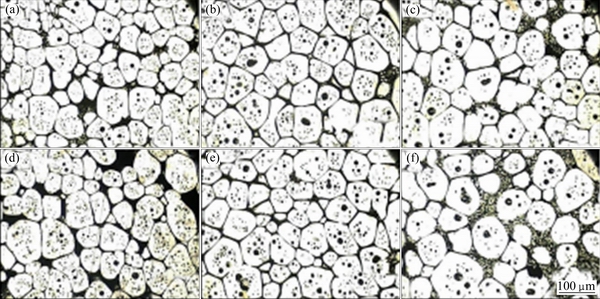

Fig. 8 Microstructures of 60% pre-deformed after holding at 500 °C for 10 min (a), 20 min (b), 40 min (c) for unrefined alloy and 10 min (d), 20 min (e), 40 min (f) for refined alloy

Fig. 9 Microstructures of 60% pre-deformed after holding at 550 °C for 10 min (a), 20 min (b), 40 min (c) for unrefined alloy and 10 min (d), 20 min (e), 40 min (f) for refined alloy

Fig. 10 Microstructures of 60% pre-deformed after holding at 590 °C for 10 min (a), 20 min (b), 40 min (c) for unrefined alloy and 10 min (d), 20 min (e), 40 min (f) for refined alloy

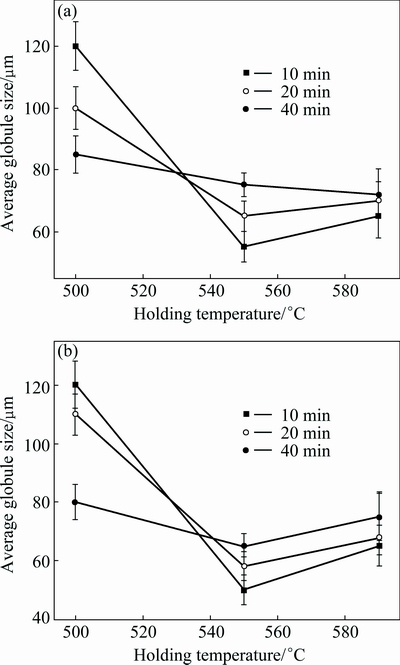

Figures 8, 9 and 10 show the microstructures of unrefined and B-refined specimens after applying different globalizing time and holding temperature during SIMA process. From Figs. 8, 9 and 10, it is clear that the fine and uniform structures are related to Figs. 9(a) and (d) with 10 min holding time at 550 °C. As shown in these images, the recrystallized grains combine with each other and grow as temperature increases. The coarsening of the grains by increasing of the holding temperature is observable in these figures except for Figs. 9(a) and (d). As it is shown in Fig. 9, the average globule size increases with increasing the temperature. From Figs. 11 and 12, it can be seen that the minimum average globule sizes for unrefined and B-refined Al-12Zn-3Mg-2.5Cu alloy are 55 μm and 50 μm, respectively. It is expected that at short holding time, only a small quantity of the eutectic phase melts and as the time proceeds to longer time, most of the eutectic Zn located at the boundaries of primary phase melts. Grain coarsening also occurs at longer time (40 min) (Figs. 10(c) and (f)).

The variations of the shape factor of α-globules with holding temperature for the 60% pre-deformed and heated specimens at various temperatures for 10, 20 and 40 min are plotted in Fig. 12. Also, Fig. 13 shows BSE images of 60% predeformed specimens after holding at 500 °C for 40 min.

Fig. 11 Variations of average globule size after SIMA process with holding temperature in 10, 20, 40 min after 60% pre-deformation for unrefined (a) and refined (b) alloy

Fig. 12 Variations of shape factor after SIMA process with holding temperature in 10, 20, 40 min after 60% pre-deformation for unrefined (a) and refined alloy (b)

Generally, SIMA is considered a process in which the basic forged, extruded or rolled bars are subjected to additional deformation to accumulate a large quantity of deformation energy for inducing sufficient strain, and then heated to the semisolid condition to transform the dendritic structure to a fine, uniform and spheroidal microstructure. The deformation energy accumulated by increasing dislocation density is closely related to the deformation process. It was well shown that in SIMA process, increasing the globalizing temperature increases the amount of liquid at the grain boundaries. Due to the effects of surface tension and interface curvature, the convex edges of the dendrites melt and decrease the interface area of the dendrites leading to a lower free energy. Moreover, the concentration of the solute in the concave parts of the grains is higher, which increases the amount of liquid in these areas. When the liquid of the two concaves contacted with each other, the grains would separate into autonomous small grains. It should be noted that increasing the heat treatment temperature causes a further dissolution of eutectics and spheroidi-zation of the α(Al) grains. At temperatures more than the eutectic temperature, the eutectic phase dissolves completely and the atoms diffuse to the α(Al) grains due to increasing of the diffusion capacity and the solubility of the elements in α(Al) at higher temperatures [22]. It was resulted that the structure of grains should gently become irregular with decreasing holding time. At the deformation stage, the samples accumulated enough deformation energy at the boundaries of grains and subgrains to provide the kinetic of partial remelting. When the samples were heated to the semisolid temperature, melting would occur at these boundaries and novel grains appeared. With increasing holding time, the structure of these grains became bigger and more spheroidal. Under the condition of long holding time, the grains coarsened due to the mechanisms of coalescence and Ostwald ripening [23,24]. The microstructure evolution to spheroidal structure was promoted by the reduction of the area of interface between the solid and the liquid phase. Clearly, enough holding time ensured the complete evolution of the microstructure. The fine and spheroidal grains could only be acquired if the intellectual holding time was selected. The experiment provides witness that supports the deformation-recrystallization mechanism proposed by DOHERTY et al [25] as the main mechanism responsible for the formation of the spheroidal microstructure via the SIMA process. According to the results of Figs. 11 and 12, the optimum time and optimum temperature for SIMA process are 10 min and 550 °C, respectively.

Fig. 13 BSE images of 60% pre-deformed specimens after holding at 500 °C for 40 min

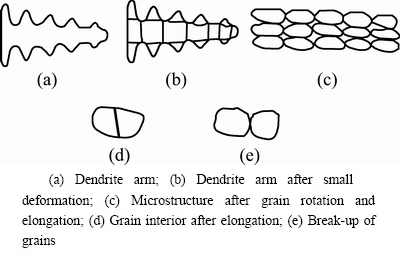

There are two steps for the SIMA process. The first step is plastic deformation below solidus temperature for the material with a dendrite structure. This is accomplished usually by hot rolling or cold rolling or/and then by upsetting to increase the amount of plastic deformation. The second step is to rapidly heat the material to a temperature between the solidus and liquidus. In the first step, the microstructure will change in the follow steps: 1) when the plastic deformation is small, in addition to slip and cross-slip in which dislocations move and cause material to deform, twinning will be aroused by the load [26]; 2) there will appear new grain boundaries where the atoms are not properly spaced as shown in Fig. 14(b); 3) for higher levels of deformation, the grains rotate and elongate, as shown in Fig. 14(c); 4) when grains (single crystal) elongate, they will be broken up as step 1), which is shown in Fig. 14(d). The microstructure evolution for the first step can be verified [27]. In the second step, the material is heated to the temperature between the solidus and liquidus where the grain boundary has more energy will melt first, and the grains gradually change to a rounded (global) shape. In order to explain this phenomenon, we may cite the relationship between surface curvature of the grain and the decrease in equilibrium melting point [28]. When heating, the effect of solid surface curvature on the equilibrium melting point can be expressed as [28]

ΔTr=-2σTMVsk/ΔH

where ΔTr=TM-T is the decrease in equilibrium melting point, TM is the equilibrium transformation temperature, k is the mean surface curvature of the solid, VS is the solid volume, σ is the surface tension and ΔH=HS-Hl (which is negative) is the molar change in enthalpy of the solid and liquid. When the surface curvature is positive, the equilibrium melting point is reduced at the dendrite tip, and ΔTr in the above equations is positive. The more the surface curvature, the more the equilibrium melting point is reduced. Thus, the sharp tip of the grain will melt and the grain will change gradually to a global shape without sharp corners.

Fig. 14 Illustration of microstructure evolution model for SIMA

Coalescence and Ostwald ripening mechanisms [29] play an important role to increase the average size of the α(Al) particles. The coarsening mechanism is the coalescence of α(Al) grains, which occurs between adjoining grains at low liquid fraction. Liquid content plays an important role in kinetics of coalescence since it defines the number of solid necks between grains. It has been shown that the coalescence frequency is proportional to the number of adjacent grains. Therefore, coalescence is expected to occur at early stages of heating or in high fraction solid in the semi-solid regime where the number of necks per grain is relatively high and grains are discrete. Ostwald ripening involves the growth of larger α(Al) particles at the expense of smaller α(Al) particles, and it is governed by the Gibbs-Thompson effect. This effect changes the chemical potential of solutes at the particle/liquid interface, depending on the curvature of the interface [29]. The lowering of interfacial energy between the solid phase and liquid phase supplies the driving force for grain coarsening. The larger grain gradually becomes spheroidal to lower the solid/liquid interfacial energy. Ostwald ripening is active at higher liquid fraction, in which α(Al) grains continuously coarsen and the small grain gradually melts. The isothermal holding time, temperature and degree of predeformation have effects on the average size and degree of spheroidization of α(Al) particles of semisolid slurry.

Table 2 Mechanical properties of wrought 7075 Al alloy under T6 treatment conditions

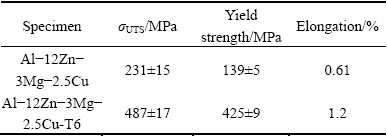

Table 3 Results of tensile and elongation of specimens

3.2 Tensile properties

Table 2 shows the mechanical properties of Al-12Zn-3Mg-2.5Cu alloy as standard conditions for comparing the different steps of processes in this study. In Table 3, UTS, yield strength and elongation values of the specimens in the different conditions are shown. As it is shown in Table 3, the average ultimate tensile strength (UTS) of the warm pressed specimens decreases from (278±16) MPa to about (252±14) MPa after holding at 550 °C for 10 min without T6 heat treatment. But, due to the several mechanisms engaging in strengthening of Al 7xxx alloys, especially precipitation hardening, the dependence of the strength to grain size was unclear. Intermetallic compounds are brittle and considered as important crack initiating sites during loading. Several reports indicate that metastable coherent or semicoherent η precipitates are formed during aging treatment [30,31]. Figure 15 shows the fracture surfaces of the unrefined and refined specimens in the different conditions. Ultimate strength of globular microstructure specimens has a low value which is due to the presence of shrinkage porosities inside the grains and boundaries which is illustrated in Table 4 and Fig. 16. Table 3 shows that specimen with globular microstructure shows the lowest ultimate strength than B-refined-T6 specimen in all conditions. According to Table 3, specimen with globular microstructure shows the lowest elongation before fracture. As it can be seen, the elongated grains of Al matrix (bright regions) with intermediate compounds such as intermetallics are observed in Fig. 15. The precipitation hardening phase is MgZn2 that has more than 1% Cu [32]. High elongation value in globular microstructure specimens is related to shrinkage porosities inside the globular grains.

Fig. 15 Fracture surfaces of refined specimens

Table 4 Porosity of samples in various stages of preparation for mechanical test

Reduction of elongation in SIMA specimens in comparison with other specimens is due to one reason:

Presence of liquid phase in grain boundaries and inside the globular grains with smaller ratio, results in formation of shrinkage porosities after solidification which reduces elongation of specimens (Fig. 16). This problem is resolved to some extent with T6 post-treatment but it is one of the main problems in semisolid processing.

Fig. 16 Secondary electron images of fracture surface related to globular microstructure specimen

3.3 Fractography of tensile specimens

Figure 15 shows fracture surface of specimen related to initial Al-12Zn-3Mg-2.5Cu-0.3B alloy.

Figures 15(d)-(f) show a typical fracture surface of a B-refined specimen after T6 heat treatment, indicating an intergranular brittle fracture. As it was mentioned before, casting defects seem to play a significant role in the data scatter of tensile properties. The casting process makes it difficult to fully eliminate the presence of defects, such as shrinkage porosity. Figures 15 and 16 show microshrinkage porosity on the fracture surface of a B-refined specimen under T6 tempering treatment. Also, Table 4 shows the porosity in different conditions.

Figure 16 shows the secondary electron image for the fracture surface of one specimen related to globular microstructure before and after T6 heat treatment. With attention to the presence of shrinkage porosities in grain boundaries, the fracture occurred completely intergranular, and the grain deformation rarely happened which resulted brittle fracture for this group of specimens.

Last tensile specimens related to globular microstructure under T6 tempering treatment product, show more complex behavior in comparison with the two previous ones. According to Fig. 16, the mixture fracture (cup and cone) is predictable for this group of specimens. As shown in Fig. 16, some regions probably show the cleaved facets of the grain inclusions representing brittle fracture. Ultimate strength of globular microstructure specimens under T6 tempering treatment has a lower value than B-refined specimens after T6 heat treatment without SIMA process. The main reason for this result is the presence of shrinkage porosities inside the grains and grain boundaries which is illustrated in Fig. 16.

4 Conclusions

1) As-cast microstructure of the Al-12Zn-3Mg-2.5Cu alloy shows a complex structure, including lamellar eutectics and divorced phases. The constituents are identified as α(Al) solid solution, η(MgZn), T(Al2Mg3Zn3) and S(A2CuMg).

2) Adding 3.75% Al-8B grain refiner to Al-12Zn-3Mg-2.5Cu alloy reduced its grain size from 580 μm to 120 μm.

3) Increasing of the holding temperature in SIMA process led to the coarsening of the grains for the same amounts of pre-deformation and holding time.

4) The optimum uniformity was obtained for holding time and holding temperature of 10 min and 550 °C, respectively.

5) B-refined specimens without SIMA process has a higher ultimate strength than globular microstructure specimens after SIMA process.

6) With attention to the presence of shrinkage porosities at grain boundaries, the fracture occurred completely intergranular, and the grain deformation rarely happened which resulted brittle fracture for specimens.

References

[1] WANG Shun-cheng, ZHOU Nan, QI Wen-jun, ZHENG Kai-hong. Microstructure and mechanical properties of A356 aluminum alloy wheels prepared by thixo-forging combined with a low superheat casting process [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2214-2219.

[2] WANG Zhen-yu, JI Ze-sheng, SUN Li-xin, XU Hong-yu. Microstructure of semi-solid ADC12 aluminum alloy adopting new SIMA method [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 744-748.

[3] KHOSRAVI H, ESLAMI-FARSANI R, ASKARI-PAYKANI M. Modeling and optimization of cooling slope process parameters for semi-solid casting of A356 Al alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 961-968.

[4] BOLOURI A, SHAHMIRI M, CHESHMEH E N H. Microstructural evolution during semisolid state strain induced melt activation process of aluminum 7075 alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 1663-1671.

[5] WANG Li-ping, JIANG Wen-yong, CHEN Tian, FENG Yi-cheng, ZHOU Hong-yu, ZHAO Si-cong, LIANG Zhen-qiang, ZHU Yan. Spheroidal microstructure formation and thixoforming of AM60B magnesium alloy prepared by SIMA process [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 435-444.

[6] WANG F, XIONG B, ZHANG Y, ZHU B, LIU H, WANG Z. Microstructure and mechanical properties of spray-deposited Al-10.8Zn-2.8Mg-1.9Cu alloy after two-step aging treatment at 110 and 150Dc [J]. Mater Charact, 2007, 58: 82-86.

[7] COOK R, COOPER P S, KEARNS M A. Benefits of master alloy melt treatments in the aluminum foundry in dustry [C]//Light Metals. Warrendale, PA: TMS, 1996: 647-654.

[8] APELIAN D, SIGWORTH G K, WHALER K R. Assessment of grain refinement and modification of Al/Si foundry alloys by thermal analysis [J]. American Foundry Men’s Society, Inc, 1984: 297-307.

[9] METZ S A, FLEMINGS M C. The Merton c.Flemings symposium on solidification and materials processing [M]. Warrendale: TMS, 2000-2001.

[10] DAHLE A K, ARNBERG L, TONDELAND P A, PARADIES J. Effect of grain refinement on the fluidity of two commercial Al-Si foundry alloys [J]. Metall Trans A, 1996, 8: 2305-2313.

[11] MOLLARD F R, FLEMINGS M C, NIYAMA E F. Aluminum fluidity in casting [J]. J Met, 1987, 11: 34.

[12] FLEMINGS M C. Solidification processing [J]. Metall Trans A, 1991, 22: 957.

[13] YOUNG K P, KYONKA C P, COURTOIS J A. Fine grained metal composition: US Patent, 4415374 [P]. 1982-03-30.

[14] KAPRANOS P. Semi-solid metal processing: An environmentally friendly process [J]. Mater World, 1994(9): 465-467.

[15] HIRT G, CREMER R, WINKELMANN A, WITULSKI T, ZILLGEN M. Semisolid forming of aluminum alloys by direct forging and lateral extrusion [J]. J Mater Process Technol, 1994, 45: 359-364.

[16] TURKELI A, AKBAS N. Formation of non-dendritic structure in 7075 wrought aluminum alloy by SIMA process and effect of heat treatment [C]//Proceedings of the Fourth International Conference on Semi-solid Processing of Alloys and Composites. Sheffield, UK, 1996: 71-74.

[17] LEE Sang-Yong, LEE Jung-Hwan, LEE Young-Seon. Characterization of Al 7075 alloys after cold working and heating in the semi-solid temperature range [J]. J Mater Process Technol, 2001, 111: 42-47.

[18] SONG Y B, PARK K T, HONG C P. Recrystallization behavior of 7175 Al alloy during modified strain-induced melt-activated (SIMA) process [J]. Mater Trans, 2006, 47: 1250-1256.

[19] ALIPOUR M, EMAMY M, AZARBARMAS M, KARAMOUZ M. Effects of Al-5Ti-1B master alloy on the microstructural evaluation of a highly alloyed aluminum alloy produced by SIMA process [C]//AIP Conf Proc. Pohang: AID, 2010: 1060-1072.

[20] MOHAMMAD A, BAHARAK G A, HAMID E R, EMAMY M. Investigation of the effect of Al-5Ti-1B grain refiner on dry sliding wear behavior of an Al-Zn-Mg-Cu alloy formed by strain-induced melt activation process [J]. Materials and Design, 2013, 46: 766-775.

[21] QUESTED T E, GREER A L. The effect of the size distribution of inoculantparticles on as-cast grain size in aluminium alloys [J]. J Acta Mater, 2004, 52: 3859-3868.

[22] MONDAL C, MUKHOPADHYAY A K. On the nature of T(Al2Mg3Zn3) and S(Al2CuMg) phases present in as-cast and annealed 7055 aluminum allo [J]. Mater Sci Eng A, 2005, 391: 367-376.

[23] BURKE K J. Semi-solid processing of aluminium 7075 [D]. UK: University of Sheffield, 1998.

[24] WITTEN T A, SANDER L M. Diffusion-limited aggregation, a kinetic critical phenomenon [J]. Phys Rev Lett, 1981, 47: 1400-1403.

[25] DOHERTY R D, LEE H I, FEEST E A. Microstructure of stir-cast metals [J]. Mater Sci Eng A, 1984, 65: 181-189.

[26] SIRONG Y, DONGCHENG L, KIM N. Microstructure evolution of SIMA processed Al 2024 [J]. Mater Sci Eng A, 2006, 420: 165-170.

[27] MORADI M, NILI-AHMADABADI M, POORGANJI B, HEIDARIAN B, PARSA M H, FURUHARA T. Recrystallization behavior of ECAPed A356 alloy at semi-solid reheating temperature [J]. Mater Sci Eng A, 2010, 527: 4113-4121.

[28] BIROL Y. Thixoforging experiments with 6082 extrusion feed stock [J]. J Alloys Compd, 2008, 455: 178-185.

[29] SEYED S M, MOHAMMAD A, HAMOUDA A M S, BESHARATIGIVI M K, EMAMY M. Investigation of the effect of Al-8B master alloy and strain-induced melt activation process on dry sliding wear behavior of an Al-Zn-Mg-Cu alloy [J]. Materials & Design, 2014, 53: 308-316.

[30] BUHA J, LUMLEY R N, CROSKY A G. Secondary ageing in an aluminium alloy 7050 [J]. Mater Sci Eng A, 2008, 492: 1-10.

[31] MONDAL C, MUKHOPADHYAY A K, RAGHU T, VARMA V K. Tensile properties of peak aged 7055 aluminum alloy extrusions [J]. Mater Sci Eng A, 2007, 454: 673-678.

[32] POLMEAR I J. Light alloys metallurgy of the light metals [M]. 3rd ed. London: Arnold, 1995.

Behzad Mohasel AFSHARI1, Seyed Sajad MIRJAVADI1, Yousef Askari DOLATABAD2, Mojtaba AGHAJANI3, Mohammad Kazem Besharati GIVI1, Mohammad ALIPOUR4,5,6, M. EMAMY4

1. School of Mechanical Engineering, College of Engineering, University of Tehran, Tehran, Iran;

2. Department of civil engineering, Sirjan University of Technology, Kerman, Iran;

3. Department of Industrial Engineering, Faculty of Engineering, University of Tehran, Tehran, Iran;

4. School of metallurgy and materials engineering, University of Tehran, Tehran, Iran;

5. Faculty of Materials Science and Engineering, K. N. Toosi University of Technology, Tehran, Iran;

6. Department of Materials Engineering, Faculty of Mechanical Engineering, University of Tabriz, Tabriz, Iran

摘 要:研究Al-8B晶粒细化剂对应变诱导熔化激活法制备的Al-12Zn-3Mg-2.5Cu合金显微组织与力学性能的影响。并在300 °C对合金进行预变形量为60%的热加工。预变形后,将合金加热至介于固相线和液相线的某一温度(500,550和590 °C),并保温不同时间(10,20和40 min)。应变诱导熔化激活法可得到球状α(Al)晶粒。采用光学显微镜和扫描电子显微镜观察细化和未细化合金的显微组织。结果表明,应变诱导熔化激活制备过程中在550 °C下保温10 min,可以得到满意的显微组织。经T6热处理后,采用3.75% Al-8B细化和应变诱导熔化激活法制备的合金的平均拉伸强度分别从278 MPa增加至585 MPa,252MPa增加至560 MPa。SIMA合金的抗拉强度比B细化合金的抗拉强度低。

关键词:铝合金;铸造;晶粒细化;应变诱导熔化激活法;半固态工艺;拉伸性能

(Edited by Yun-bin HE)

Corresponding author: Mojtaba AGHAJANI; Tel: +98-9196275596; Fax: +98-9196275596; E-mail: Alipourmo@ut.ac.ir

DOI: 10.1016/S1003-6326(16)64349-2