文章编号:1004-0609(2010)06-1032-07

往复挤压Mg-4Al-2Si合金的高温拉伸性能

郭学锋1,杨文朋2,宋佩维2

(1. 河南理工大学 材料科学与工程学院,焦作 454000;

2. 西安理工大学 材料科学与工程学院,西安 710048)

摘 要:利用往复挤压制备细晶Mg-4Al-2Si合金,采用OM、XRD和SEM分析合金组织,在150 ℃和1.33×10-3 s-1初始应变速率下测试合金的拉伸性能。结果表明:铸态组织由α-Mg、β-Mg17Al12、共晶型汉字状Mg2Si和少量初生块状Mg2Si组成。经过8道次往复挤压后,α-Mg和Mg2Si颗粒的尺寸分别为2.1和1.3 μm,高温抗拉强度、屈服强度、伸长率和拉伸强度保持率分别为250 MPa、197 MPa、62%和88%。优良的高温性能归因于细小的基体组织和稳定的Mg2Si颗粒对晶界的有效钉扎作用。

关键词:镁合金;Mg-4Al-2Si合金;Mg2Si;往复挤压;高温拉伸性能

中图法分类号:TG379 文献标志码:A

Elevated temperature tensile properties of Mg-4Al-2Si alloy prepared by reciprocating extrusion

GUO Xue-feng1, YANG Wen-peng2, SONG Pei-wei2

(1. School of Materials Science and Engineering, Henan Polytechnic University, Jiaozuo 454000, China;

2. School of Materials Science and Engineering, Xi’an University of Technology, Xi’an 710048, China)

Abstract: The fine grained Mg-4Al-2Si alloy was prepared by reciprocating extrusion (RE). The microstructures were analyzed by X-ray diffractometry (XRD), optical microscopy (OM) and scanning electron microscopy (SEM). The elevated temperature tensile properties were measured at 150 ℃ with an initial strain rate of 1.33×10-3 s-1. The results show that the as-cast alloy consists of α-Mg, β-Mg17Al12 and Chinese script Mg2Si formed during the eutectic reaction and some primary block Mg2Si. After 8 passes reciprocating extrusion (RE), the average sizes of α-Mg grain and Mg2Si particle are 2.1 and 1.3 mm, respectively. The elevated temperature ultimate tensile strength, yield strength, elongation and retaining rate of ultimate tensile strength are 250 MPa, 197 MPa, 62% and 88%, respectively. The excellent elevated temperature properties are ascribed to the fine matrix and thermally stable Mg2Si particles, which can firmly pin the grain boundaries.

Key words: Mg alloy; Mg-4Al-2Si alloy; Mg2Si; reciprocating extrusion; elevated temperature tensile properties

镁合金具有密度低、比强度和比刚度高、阻尼性和切削加工性以及铸造性能好等优点,正得到日益广泛的应用[1-2]。Mg-Al合金是目前应用最广泛的镁合金之一,它具有优良的铸造性,可完全通过铸造工艺生产仪表盘和散热器支架等大结构件[3]。然而,当温度高于120 ℃时,Mg-Al合金中的β-Mg17Al12相便开始软化,对晶界的钉扎和抑制高温晶界滑移的作用减弱[4],导致合金的强度和抗蠕变性能急剧下降[5]。因此,Mg-Al合金不能应用于高温工作的部件。通过合金化或微合金化形成高熔点的Mg2X(X=Si,Ge和Sn)等金属间化合物是提高Mg-Al合金高温性能的重要途径之一[6]。其中Mg2Si熔点高(1 085 ℃)、硬度高(4.5×109N/m2)、弹性模量高(120 GPa)、热膨胀系数低(7.5×10-6 K-1)、密度(1.99×103 kg/m3)与镁合金基体密度接近、耐磨性好、热稳定性优良,是高温镁基合金中理想强化相[7-9]。然而,在普通铸造情况下,当w(Si)>1.38%时,合金中会出现多边形块状和粗大树枝状的初生Mg2Si相[7]。初生Mg2Si相容易产生应力集中,并割裂基体,从而降低材料整体的力学性能。因此,细化Mg2Si颗粒,并使其均匀分布是提高合金性能的关键。众多研究者通过微合金化[7-8]、固溶处理[9]、快速凝 固[10]工艺改变Mg2Si相的形貌,但获得的合金组织中Mg2Si颗粒尺寸仍较大,且分布均匀度不高。往复挤压作为一种大塑性变形工艺,可以使合金中金属间化合物破碎并均匀分布,目前已成功应用于Mg-Zn-Y[11]、Mg-Al-Zn[4]等合金。本文作者利用往复挤压工艺细化Mg-4Al-2Si(AS42)合金组织,研究往复挤压道次对合金组织和高温性能的影响,探讨其高温强化机制。

1 实验

1.1 铸态AS42合金的配制

用纯镁、Al-50%Si中间合金和纯铝制备AS42合金。在RJ-2覆盖剂保护下熔化纯镁,在760 ℃加入Al-50%Si中间合金和纯铝,熔炼过程中持续搅拌,使熔体中合金元素分布均匀。浇铸前用溶剂精炼处理,保温15 min后浇铸成d 52 mm金属型试棒。为了描述方便,该试样记为CT-AS42,经420 ℃,12 h固溶处理后记为CT-AS42-T4。

1.2 往复挤压

往复挤压的详细工艺见文献[11]。本文挤压参数:挤压筒直径d0=50 mm,挤压颈直径dm=14 mm;由于挤压过程中有温升,因此,1、2道次挤压温度为375 ℃,3、4道次为380 ℃,5、6道次为385 ℃,7、8道次为390 ℃,各挤压道次温控波动±5 ℃;压力约为 1.44×106 N,挤压轴线线速度约为1.2 mm/min。每个挤压道次(包括往复挤压过程中连续的挤压与镦粗)合金获得真应变Δε=5.09(Δε=4ln(d0/dm)) [4]。往复挤压后的材料记为RE-n-AS42(n为往复挤压道次)。

1.3 组织观察和力学性能测试

RE-n-AS42合金金相试样沿挤压径向截取。试样经过打磨、抛光后,使用60%C2H5OH+20%CH3COOH+ 19%H2O+1%HNO3(体积分数)溶液腐蚀。用Nikon Epiphot光学显微镜观察金相。用截线法测定晶粒大小(d=1.74L,L为截线尺寸[12])。用XRD-7000S型X射线衍射仪标定相组成,辐射源为CuKα,步进扫描步长为0.02?,扫描范围为20?~90?。

高温实验常用“约比温度(T/Tm)”表述温度的高低。其中,T为实验温度,Tm为材料的熔点。当T/Tm大于0.4~0.5时为高温,反之则为低温[13]。本研究的测试温度为150 ℃,约比温度为0.46。拉伸试样沿挤压轴向截取,尺寸按国标GB4338—84执行,采用d 5 mm×25 mm标准短试样。用CMT型电子万能拉伸机测试高温性能,试样升温至150 ℃,保温15 min后拉伸,拉伸速率初始应变速率 =1.33×10-3 s-1。采用JSM-6700F型扫描电镜观察拉伸断口。

=1.33×10-3 s-1。采用JSM-6700F型扫描电镜观察拉伸断口。

2 结果与分析

2.1 显微组织

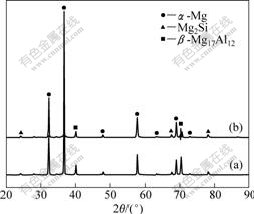

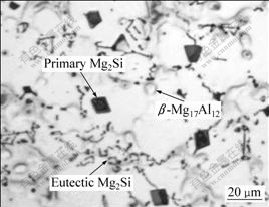

图1所示为CT-AS42和CT-AS42-T4合金的XRD谱。由图1可知,CT-AS42合金由α-Mg、β-Mg17Al12和Mg2Si三相组成。固溶处理后,部分β相固溶于基体,峰值略有降低。图2所示为CT-AS42-T4的金相组织。结合XRD分析结果可知,基体为α-Mg固溶体,分布于晶界上的白色颗粒相是未溶解的β相,少量菱形块状颗粒为初生Mg2Si相,灰黑色汉字状为共晶Mg2Si相。

图1 AS42合金的XRD谱

Fig.1 XRD patterns of AS42 alloys: (a) As-cast, CT-AS42; (b) Solution heat treated at 420 ℃ for 12 h, CT-AS42-T4

图2 经420 ℃,12 h固溶处理后CT-AS42合金的金相组织

Fig.2 Optical microstructure of CT-AS42 alloy after solution heat treated at 420 ℃ for 12 h

图3和4分别为RE-n-AS42(n=2,4,6,8)合金的基体组织和Mg2Si颗粒分布[14]。由图3和4可知,基体为动态再结晶后形成的均匀等轴晶。随着道次的增加,晶粒尺寸减小,Mg2Si颗粒逐渐破碎细化和均匀化。往复挤压2道次后,晶粒平均尺寸为9.5 μm(见图3(a));汉字状Mg2Si已完全破碎为细小颗粒,部分初生块状Mg2Si得到初步细化,部分仍保持原貌,尺寸为10 μm(见图4(a));4道次后,晶粒尺寸为4.8 μm,局部有晶粒大小不均匀现象(见图3(b));Mg2Si颗粒细化且分布均匀,平均尺寸约1.6 μm(见图4(b));6道次后,晶粒平均尺寸为2.8 μm(见图3(c));Mg2Si颗粒分布更加均匀,平均尺寸为1.4 μm(见图4(c));8道次后,晶粒平均尺寸为2.1 μm(见图3(d));Mg2Si平均尺寸为1.3 μm(见图4(d))。

图3 RE-n-AS42合金的金相组织[14]

Fig.3 Optical microstructures of RE-n-AS42 alloys[14]: (a) n=2; (b) n=4; (c) n=6; (d) n=8

图4 RE-n-AS42合金中Mg2Si颗粒分布[14]

Fig.4 Distribution of Mg2Si particles in RE-n-AS42 alloys[14]: (a) n=2; (b) n=4; (c) n=6; (d) n=8

2.2 高温拉伸性能

图5所示为合金的高温抗拉强度、屈服强度和伸长率随挤压道次变化的曲线,其中挤压道次0是铸态试样。由图5可知,铸态合金力学性能较低,抗拉强度、屈服强度和伸长率分别为97 MPa、58 MPa和18%;2道次后,抗拉强度、屈服强度和伸长率分别提高至150 MPa、96 MPa和27%。随着挤压道次增多,合金获得的真应变增大,抗拉强度、屈服强度和伸长率都逐渐升高;8道次挤压后,分别为250 MPa、197 MPa和62%,比铸态合金分别提高了157.7%、239.7%和244.4%。

图5 合金的高温抗拉强度、屈服强度和伸长率与挤压道次的关系

Fig.5 Relationships among elevated temperature ultimate tensile strength, yield strength and elongation and RE pass number for alloy

表1所列为几种耐热镁合金150 ℃时的强度保持率η=σT/σRT,σT为高温强度,σRT为室温强度[15]),可在一定程度上反映合金的高温性能。对比可知,150 ℃时,RE-8-AS42仍具有较高的强度保持率,其抗拉强度和屈服强度保持率分别为88%和73%。

表1 几种镁合金在150 ℃下拉伸时的强度保持率

Table 1 Strength retaining rate of several Mg alloys at tensile temperature of 150 ℃

2.3 断口形貌

图6所示为RE-4-AS42和RE-8-AS42合金拉伸断口SEM像。由图6可看出,RE-4-AS42合金断口由大小不等的韧窝组成,韧窝周围有尖锐的撕裂棱;断口也存在少量Mg2Si解理断裂面,解理面上存在较多二次裂纹,部分裂纹宽而深(见图中箭头所示),解理断裂均存在于破碎后比较粗大的块状初生Mg2Si相上。从断口形貌可以推测,在拉伸过程中,粗大的Mg2Si颗粒容易产生应力集中,当应力达到一定程度时,Mg2Si解理断裂,之后,裂纹进一步向基体扩展,导致材料最终断裂。RE-8-AS42合金断口由均一的等轴韧窝组成,韧窝底部为细小球形的Mg2Si颗粒,韧窝边缘有尖锐的撕裂棱,为典型的韧性断口。

图6 RE-n-AS42合金拉伸断口的SEM像

Fig.6 SEM images of fractures of RE-n-AS42 alloy: (a) n=4; (b) n=8

3 讨论

随着挤压道次增加,Mg2Si逐渐细化、分布逐渐均匀化。基体在往复挤压过程发生动态再结晶,由粗大枝晶演化成为细小等轴晶。从理论上讲,往复挤压过程中的动态再结晶包括变形细化、再结晶细化、晶粒长大3个过程。如果控制不当,甚至会出现晶粒的异常长大。对于AS42合金,由于细小的Mg2Si颗粒能有效钉扎晶界,抑制动态再结晶晶粒长大,通过多次的动态再结晶,最终会形成细小等轴晶,不会出现晶粒的长大。当然,这必须同时具备两个条件:一是变形再结晶过程;二是有细小稳定的强化相颗粒分布在晶界上。

WANG和HUANG[17]在200 ℃和 =10-3 s-1下测试了晶粒度为1.1 μm的细晶AZ61合金的拉伸性能,合金强度仅为35 MPa。由此可见,高温下β-Mg17Al12相因软化而对强度的贡献有限。因此,AS42合金的高温强度主要是Mg2Si相的强化作用。CT-AS42合金基体组织粗大,Mg2Si相除汉字状共晶外还有少量块状初生相,特别是菱形的初生Mg2Si相,很容易割裂基体。所以,高温下强度和伸长率低。基体组织和Mg2Si相的细化是合金力学性能提高的根源。8道次往复挤压后,Mg2Si颗粒被完全破碎至1.3 μm,并均匀、弥散分布,基体晶粒细化至2.1 μm。由断口形貌可知,Mg2Si颗粒已趋于球形,对基体的割裂作用降低,合金极限抗拉强度、屈服强度和伸长率也分别增至250 MPa、197 MPa和62%。

=10-3 s-1下测试了晶粒度为1.1 μm的细晶AZ61合金的拉伸性能,合金强度仅为35 MPa。由此可见,高温下β-Mg17Al12相因软化而对强度的贡献有限。因此,AS42合金的高温强度主要是Mg2Si相的强化作用。CT-AS42合金基体组织粗大,Mg2Si相除汉字状共晶外还有少量块状初生相,特别是菱形的初生Mg2Si相,很容易割裂基体。所以,高温下强度和伸长率低。基体组织和Mg2Si相的细化是合金力学性能提高的根源。8道次往复挤压后,Mg2Si颗粒被完全破碎至1.3 μm,并均匀、弥散分布,基体晶粒细化至2.1 μm。由断口形貌可知,Mg2Si颗粒已趋于球形,对基体的割裂作用降低,合金极限抗拉强度、屈服强度和伸长率也分别增至250 MPa、197 MPa和62%。

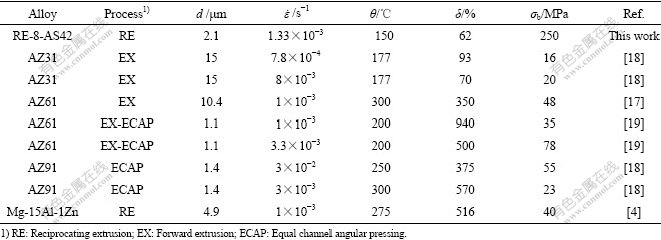

表2所列为几种镁合金的高温力学性能。由表2可知,合金发生超塑性变形时(δ>200%),合金的极限抗拉强度均小于80 MPa。因为超塑性行为通常是由晶界滑移为主要控制机制的变形[18-20],晶界滑移时,晶界强度必然大大降低,从而导致高温强度很低。AZ61合金通过EX-ECAP工艺得到约为1 μm的等轴晶组织,在200 ℃和3.3×10-3初始应变速率下拉伸,拉伸强度仅有78 MPa。由此可见,基体晶粒细化不能大幅度提高合金的高温强度。当Al含量从3%增加至15%(实质上增加了β-Mg17Al12相)时,并没有提高Mg合金的高温强度。LEE等[4]通过研究往复挤压Mg-15Al-1Zn合金的高温性能指出,高温下β-Mg17Al12相对晶界没有钉扎作用,反而成为晶界滑移的润滑剂。添加2%Si的RE-AS42合金具有出色的高温强度,这归功于Mg2Si相的高温稳定性。在RE-AS42合金中,Mg2Si颗粒几乎全部分布在α-Mg的晶界处,在高温受力时,能够牢固地钉扎晶界,阻碍晶界滑移。拉伸断口可以证明,RE-AS42合金未出现任何晶界滑移现象。稳定的晶界使合金在高温时具有高强度,同时表现出适中的伸长率。可见,通过高温稳定的二次相钉扎晶界、提高合金晶界强度是改善镁合金高温强度的关键。

表2 几种镁合金的高温拉伸性能

Table 2 Tensile properties of several Mg alloys at elevated temperatures

因Mg2Si颗粒阻碍晶界滑移,使得晶界滑移对伸长率几乎没有贡献,RE-AS42高温表现出的伸长率源自晶内滑移。对于粗晶镁合金,非基面滑移系的临界剪切应力比基面滑移系要大两个数量级。室温下,滑移模式主要为{0001}á11 0?基面滑移。高温下,原子活动能力增强,一方面,有利于相邻晶粒之间滑移的传播和连续性,使晶界附近大的应力集中得到及时释放;另一方面,使非基面滑移系与基面滑移系之间的临界剪切应力差值减小,棱柱面和锥面等潜在的非基面滑移系可通过热激活启动,从而使合金的塑性变形能力得到一定的提高。随着挤压道次的增加,伸长率逐渐提高,主要是晶粒细化的作用:1) 晶粒细化使位错滑移程缩短,变形更分散、均匀;2) 晶粒细化使晶粒转动变得容易,晶粒转动属于无效应变,但能使晶粒取向发生变化,使硬取向晶粒转动到有利于变形的取向,使晶粒变形得到协调并区域均匀;3) 晶粒细化能激活棱柱面和锥面潜在的非基面滑移系。非基面滑移的范围大约在距晶界10 μm左右,因此,当晶粒细化至小于10 μm时,非基面滑移可以贯穿整个晶粒内部,尤其是当基面与晶界相交时,螺型位错易由基面交滑移至非基面。KOIKE等[21]通过研究AZ31B合金(晶粒尺寸为6.5 μm)的变形显微组织发现,a位错能发生从基面至棱柱面的交滑移,并且非基面滑移对总应变的贡献可达40%,并能有效地抑制孪晶的形成。此外,随挤压道次的增加,Mg2Si颗粒细化并球化,对基体的割裂作用大大降低,这也是获得高伸长率的必要条件。

0?基面滑移。高温下,原子活动能力增强,一方面,有利于相邻晶粒之间滑移的传播和连续性,使晶界附近大的应力集中得到及时释放;另一方面,使非基面滑移系与基面滑移系之间的临界剪切应力差值减小,棱柱面和锥面等潜在的非基面滑移系可通过热激活启动,从而使合金的塑性变形能力得到一定的提高。随着挤压道次的增加,伸长率逐渐提高,主要是晶粒细化的作用:1) 晶粒细化使位错滑移程缩短,变形更分散、均匀;2) 晶粒细化使晶粒转动变得容易,晶粒转动属于无效应变,但能使晶粒取向发生变化,使硬取向晶粒转动到有利于变形的取向,使晶粒变形得到协调并区域均匀;3) 晶粒细化能激活棱柱面和锥面潜在的非基面滑移系。非基面滑移的范围大约在距晶界10 μm左右,因此,当晶粒细化至小于10 μm时,非基面滑移可以贯穿整个晶粒内部,尤其是当基面与晶界相交时,螺型位错易由基面交滑移至非基面。KOIKE等[21]通过研究AZ31B合金(晶粒尺寸为6.5 μm)的变形显微组织发现,a位错能发生从基面至棱柱面的交滑移,并且非基面滑移对总应变的贡献可达40%,并能有效地抑制孪晶的形成。此外,随挤压道次的增加,Mg2Si颗粒细化并球化,对基体的割裂作用大大降低,这也是获得高伸长率的必要条件。

4 结论

1) CT-AS42合金由粗大的α-Mg、β-Mg17Al12、共晶汉字状Mg2Si和少量初生块状Mg2Si组成,往复挤压后,合金组织明显细化,往复挤压道次越多,细化程度越高,8道次后,基体晶粒平均尺寸为2.1 μm,Mg2Si颗粒平均尺寸为1.3 μm。

2) RE-AS42合金高温力学性能随挤压道次的增加而提高。150 ℃时,RE-8-AS42合金抗拉强度、屈服强度和伸长率分别为250 MPa、197 MPa和62%,合金拉伸和屈服强度保持率分别为88%和73%。

3) RE-AS42合金具有好的高温性能的原因是细小的基体组织和分布在晶界上稳定、细小弥散的Mg2Si相颗粒对晶界的有效钉扎作用。

REFERENCES

[1] EASTON M, SONG W, ABBOTT T. A comparison of the deformation of magnesium alloys with aluminium and steel in tension, bending and buckling[J]. Materials and Design, 2006, 27(10): 935-946.

[2] BOEHLERT C, KNITTEL K. The microstructure, tensile properties, and creep behavior of Mg-Zn alloys containing 0-4.4% Zn[J]. Mater Sci Eng A, 2006, 417(1/2): 315-321.

[3] HAN L, HU H, NORTHWOOD D, LI N. Microstructure and nano-scale mechanical behavior of Mg-Al and Mg-Al-Ca alloys[J]. Mater Sci Eng A, 2008, 473(1/2): 16-27.

[4] LEE S, CHEN Y, WANG H, YANG C, YEH J. On mechanical properties and superplasticity of Mg-15Al-1Zn alloys processed by reciprocating extrusion[J]. Mater Sci Eng A, 2007, 464(1/2): 76-84.

[5] LUO A, PEKGULERYUZ M. Cast magnesium alloys for elevated temperature applications[J]. Journal of Materials Science, 1994, 29(20): 5259-5271.

[6] TANI J, KIDO H. First-principles and experimental studies of impurity doping into Mg2Si[J]. Intermetallics, 2008, 16(3): 418-423.

[7] GUO E, MA B, WANG L. Modification of Mg2Si morphology in Mg-Si alloys with Bi[J]. Journal of Materials Processing Technology, 2008, 206(1/3): 161-166.

[8] WANG L, GUO E, MA B. Modification effect of lanthanum on primary phase Mg2Si in Mg-Si alloys[J]. Journal of Rare Earths, 2008, 26(1): 105-109.

[9] ZHA M, WANG H, XUE P, LI L, LIU B, JIANG Q. Microstructural evolution of Mg-5Si-1Al alloy during partial remelting[J]. Journal of Alloys and Compounds, 2009, 472(1/2): 18-22.

[10] QIN Q, ZHAO Y. Nonfaceted growth of intermetallic Mg2Si in Al melt during rapid solidification[J]. Journal of Alloys and Compounds, 2008, 462(1): L28-L31.

[11] GUO X, SHECHTMAN D. Reciprocating extrusion of rapidly solidified Mg-6Zn-1Y-0.6Ce-0.6Zr alloy[J]. Journal of Materials Processing Technology, 2007, 187/188: 640-644.

[12] SOMEKAWA H, HIRAI K, WATANABE H, TAKIGAWA Y, HIGASHI K. Dislocation creep behavior in Mg-Al-Zn alloys[J]. Mater Sci Eng A, 2005, 407(1/2): 53-61.

[13] CHEN P, LU Q, SUN Y, JIANG J, MA A. High strain rate superplasticity in SiCp reinforced AZ31 magnesium matrix composite[J]. Transactions of Nanjing University of Aeronautics and Astronautics, 2001, 18(1): 17-21.

[14] 宋佩维, 井晓天, 郭学锋. 往复挤压 Mg-4Al-2Si 镁合金的组织细化与力学性能[J]. 中国有色金属学报, 2007, 17(1): 111-117.

SONG Pei-wei, JING Xiao-tian, GUO Xue-feng. Structure refinement and mechanical properties of Mg-4Al-2Si Mg alloy by reciprocating extrusion[J]. The Chinease Journal of Nonferrous Metals, 2007, 17(1): 111-117.

[15] 袁广银. 轿车用耐热镁合金的应用基础研究[博士后研究工作报告][R]. 上海: 上海交通大学, 2001: 3-18.

YUAN Guang-yin. Applied basic research heat resistant magnesium alloys for cars[R]. Shanghai: Shanghai Jiao Tong University, 2001: 3-18.

[16] 闫蕴琪, 张廷杰, 邓 炬, 周 廉. 耐热镁合金的研究现状与发展方向[J]. 稀有金属材料与工程, 2004, 33(6): 561-565.

YAN Yuan-qi, ZHANG Ting-jie, DENG Ju, ZHOU Lian. Research and development of heat resistant Mg alloys[J]. Rare Metal Materials and Engineering, 2004, 33(6): 561-565.

[17] WANG Y N, HUANG J C. Comparison of grain boundary sliding in fine grained Mg and Al alloys during superplastic deformation[J]. Scripta Materialia, 2003, 48: 1117-1122.

[18] BUSSIBA A, BEN ARTZY A, SHTECHMAN A, IFERGAN S, KUPIEC M. Grain refinement of AZ31 and ZK60 Mg alloys—Towards superplasticity studies[J]. Mater Sci Eng A, 2001, 302(1): 56-62.

[19] MIYAHARA Y, HORITA Z, LANGDON T. Exceptional superplasticity in an AZ61 magnesium alloy processed by extrusion and ECAP[J]. Mater Sci Eng A, 2006, 420(1/2): 240-244.

[20] CHUVIL’DEEV V, NIEH T, GRYAZNOV M, KOPYLOV V, SYSOEV A. Superplasticity and internal friction in microcrystalline AZ91 and ZK60 magnesium alloys processed by equal-channel angular pressing[J]. Journal of Alloys and Compounds, 2004, 378(1/2): 253-257.

[21] KOIKE J, KOBAYASHI T, MUKAI T, WATANABE H, SUZUKI M, MARUYAMA K, HIGASHI K. The activity of non-basal slip systems and dynamic recovery at room temperature in fine-grained AZ31B magnesium alloys[J]. Acta Materialia, 2003, 51(7): 2055-2065.

________________________________

基金项目:国家自然科学基金资助项目(50271054);教育部博士点基金资助项目(20070700003);河南省科技攻关资助项目(102102210031);河南省教育厅自然科学基金资助项目(2010A430008)

收稿日期:2009-08-25;修订日期:2010-01-18

通信作者:郭学锋,教授,博士;电话:029-82312009;E-mail:guoxuef@gmail.com

(编辑 李艳红)