文章编号:1004-0609(2016)02-0439-08

全尾砂絮凝沉降的影响因素

吴爱祥1, 2,周 靓1, 2,尹升华1, 2,王雷鸣1, 2

(1. 北京科技大学 金属矿山高效开采与安全教育部重点实验室, 北京 100083;

2. 北京科技大学 土木与环境工程学院, 北京 100083)

摘 要:全尾砂絮凝沉降过程是膏体充填工艺的重要环节。为考察多因素耦合条件下尾砂絮凝沉降规律,开展全尾砂静态絮凝沉降实验,应用Design-Expert软件分析并筛选影响全尾砂絮凝沉降的重要因素,探究单位面积处理量最大时各重要影响因素的最优值。结果表明:不同影响因素耦合条件下,各絮凝沉降曲线形态基本一致,呈现先迅速下降后趋于水平的趋势。影响絮凝沉降的重要因素为尾砂入料浓度、絮凝剂用量、絮凝剂溶液浓度,其最优值分别为16.02%、28.35 g/t、0.1541%,此时单位面积固体处理量最大,为3.04 t/(m2·h)。

关键词:充填采矿法;全尾砂;絮凝沉降;影响因素;最优值

中图分类号:TD853 文献标志码:A

资源开采的深部化和地表尾矿废石的灾害化是当今矿业发展面临的两大难题,对此,于润沧[1]、WANG等[2]认为将尾矿制备成膏体充填至井下采空区是理想的解决方案。膏体具有不沉淀、不离析、不分层、充填质量好、脱水量少等优点[3-5],从而达到有效保护矿区地表及周边生态环境、提高矿石回收率、减少尾矿排放、合理控制采场地压的目的[6]。尾砂的浓密脱水过程是整个膏体充填工艺的前提,在尾砂浆中添加絮凝剂以提高尾砂沉降速度具有便捷性和可操作性,因而絮凝沉降技术在矿山尾矿浓密脱水中得到了广泛的应用[7-8]。

絮凝沉降过程是一个复杂的物理化学过程[9]。近年来,国内外学者对尾砂絮凝沉降开展了多方面研究工作。SELOMUYA等[10]采用光学激光显微镜和X射线衍射,对絮团颗粒和沉积层微观结构进行三维可视化研究。王星等[11]对絮凝剂的种类、矿浆的浓度以及不同药剂添加量对沉降速度的影响进行了絮凝沉降试验,肯定了高分子絮凝剂加速颗粒沉降的作用。王洪江等[12]采用均匀设计方法,以单位面积固体处理量和底流体积分数作为尾砂浓密效果的评价指标,考察各因素对尾砂浓密效果的影响。ESWARAIA等[13]研究超细铁尾矿的沉降特性,分别向不同pH范围的料浆中添加阳离子型、阴离子型和非离子型3种类型絮凝剂,发现添加微量的阴离子型絮凝剂,即可获得很好的絮凝效果,而阳离子型和非离子型即使添加量很大,絮凝效果仍然很差。焦华喆等[14]探究给料浓度和絮凝剂单耗对尾矿最大沉降速度和静止沉降极限浓度的影响,并通过对实验数据回归分析得出简易的沉降速度模型。王新民等[15]建立全尾砂沉降速度GA-SVM优化预测模型,利用遗传学算法对全尾砂沉降速度进行优化预测。TAO等[16]研究了量筒内砂浆絮凝沉降规律,认为在沉降过程中存在扰动区、沉降区和压密区。 等[17]对不同截面形状沉降装置进行絮凝沉降性能研究,提出了一种连续沉降和浓缩数学模型。王勇等[18]考察了絮凝剂用量对尾矿浓密的影响机理,提出不同絮凝剂用量区间对尾矿浓密的影响机理。焦华喆等[19]采用均匀法设计室内实验,研究絮凝剂单耗、絮凝剂溶液浓度和给料浓度三因素对固液分离技术中沉降速度和沉降浓度的影响。上述研究主要从絮凝剂种类与用量、料浆浓度、絮凝沉降微观现象等多方面对絮凝沉降影响机理进行探究,但对沉降过程中各可能影响因素的影响程度及耦合作用下的絮凝沉降研究较少。

等[17]对不同截面形状沉降装置进行絮凝沉降性能研究,提出了一种连续沉降和浓缩数学模型。王勇等[18]考察了絮凝剂用量对尾矿浓密的影响机理,提出不同絮凝剂用量区间对尾矿浓密的影响机理。焦华喆等[19]采用均匀法设计室内实验,研究絮凝剂单耗、絮凝剂溶液浓度和给料浓度三因素对固液分离技术中沉降速度和沉降浓度的影响。上述研究主要从絮凝剂种类与用量、料浆浓度、絮凝沉降微观现象等多方面对絮凝沉降影响机理进行探究,但对沉降过程中各可能影响因素的影响程度及耦合作用下的絮凝沉降研究较少。

本文作者采用Design-Expert软件,采取Plackett-Burman(PB)与中心组合设计(Central composite design, CCD)实验设计及处理方法,分析影响全尾砂絮凝沉降效果的重要因素,探究多因素耦合条件下全尾砂絮凝沉降规律,并以单位面积固体处理量为评价标准,考察絮凝沉降重要影响因素最优值。

1 实验

1.1 实验材料

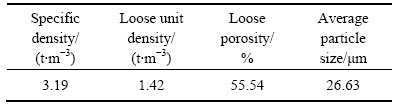

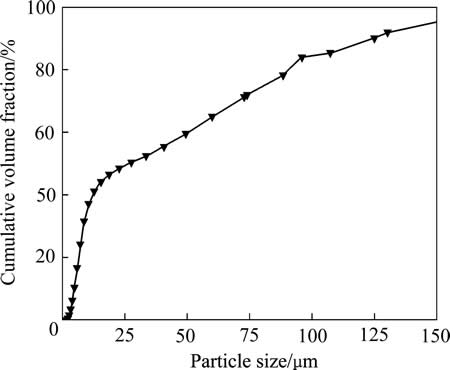

实验尾砂取自黑龙江某铜锌矿。尾砂松散容重小且孔隙率较大,松散孔隙率超过50%,平均粒径为26.63 μm。尾砂基本物理参数如表1所列。

尾砂中20 μm以下及40 μm以上的颗粒含量较多,其中粒径小于20 μm的细颗粒含量占颗粒总量的47.12%,属细粒尾砂[20],全尾砂粒级组成如图1所示。

表1 全尾砂基本物理性能

Table 1 Basic physical properties of unclassified tailings

图1 全尾砂粒级组成

Fig. 1 Grain size distribution of unclassified tailings

1.2 实验原理

克托克斯定律[21]指出,固体颗粒在悬浮液中的自由沉降速度与颗粒直径的平方成正比,与液体黏度成反比,如式(1)所示:

(1)

(1)

式中:v为颗粒自由沉降速度,m/s;g为重力加速度,9.81 m/s2; 为液体黏度,Pa·s;

为液体黏度,Pa·s; 为颗粒密度,kg/m3;ρ1为液体密度,kg/m3;d为颗粒直径,m。

为颗粒密度,kg/m3;ρ1为液体密度,kg/m3;d为颗粒直径,m。

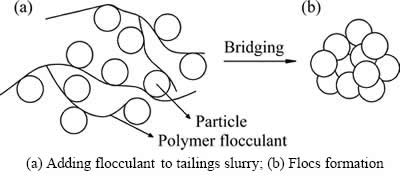

实验所用絮凝剂为R1050。絮凝剂通过形成高分子链对微细颗粒进行网捕,即架桥作用[22]。伴随着网捕颗粒数量的增加,絮团逐渐形成,并且絮团直径迅速变大,体积增加,沉降速度加快,进而加速了致密过程。高分子絮凝剂的架桥作用如图2所示。

图2 高分子絮凝剂架桥作用

Fig. 2 Polymer bridging in flocculation

1.3 实验方案

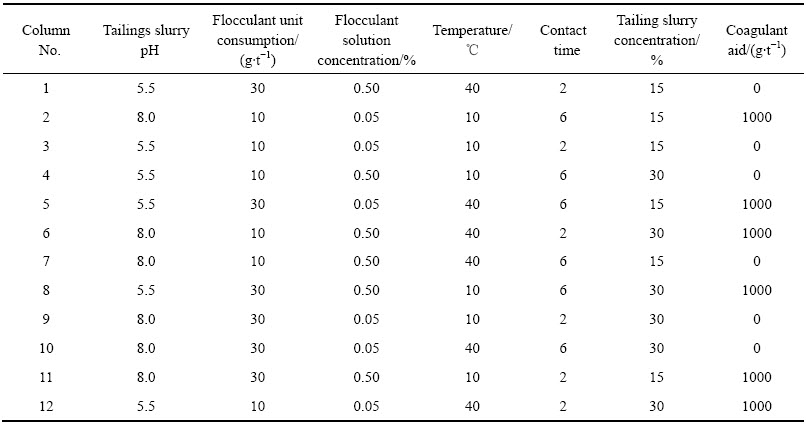

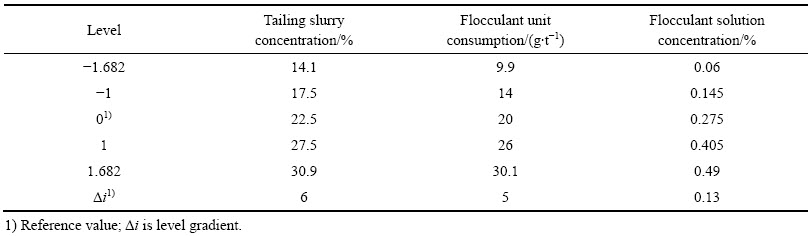

实验包括两部分:影响因素筛选实验与重要影响因素的最佳水平确定实验。影响因素筛选实验采用Plackett-Burman(PB)实验设计及处理方法。实验组数N=12,选取的影响因素共7个,分别为尾砂入料浓度、尾砂浆pH值、絮凝剂单耗、絮凝剂溶液浓度、温度、接触次数、助凝剂,依据实际生产经验,确定不同影响因素取值域,如表2所列。

根据表2配制尾砂浆,将配置成的尾砂浆置于恒温箱内,使其达到实验所需温度。按要求称取适量的絮凝剂溶液,加入与助凝剂溶液混合的砂浆中,按接触次数要求翻转摇晃量筒,静置,记录不同时间点固液分离界面的高度。以单位面积固体处理量为评价指标,根据PB分析得到各因素的影响程度(P值),从而确定重要的影响因素。

重要影响因素的最佳水平确定实验则采用CCD实验设计及处理方法,每个因素确定5个梯度水平,进行旋转组合实验。以单位面积固体处理量为考量标准,通过CCD处理获得最大单位面积固体处理量及对应的各重要影响因素最优值,其实验操作与数据处理方式同上。

2 结果与讨论

2.1 多因素耦合条件下絮凝沉降规律

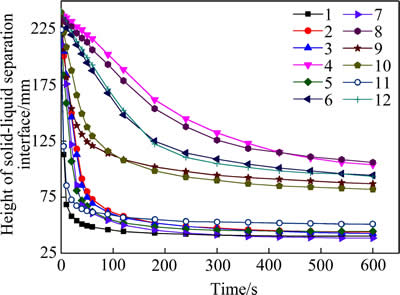

沉降开始前,尾砂浆均质、无分层现象,各实验组初始的固液分离界面高度基本一致。絮凝沉降曲线如图3所示,各实验组的固液分离界面高度先迅速下降,后降速减缓,最后趋于不变。添加絮凝剂后,在内聚力与絮凝剂长链结构的共同作用下,尾矿颗粒吸附聚集形成较大絮凝团,使得尾矿颗粒沉降速度迅速加快,从而在沉降过程中尾砂浆出现明显分区现象:上部为澄清区,中部为沉降区,底部为压缩区。随着时间推移,澄清区不断扩大,澄清区与沉降区界面分明且以较快的速度不断下移;沉降区内上部能观察到尾砂颗粒不断下降,下部则有浆体翻涌上升;压缩区尾砂不断沉积,尾砂沉积高度上升;上清液中的细尾砂颗粒少。

表2 影响因素筛选实验方案

Table 2 Scheme of screening influence factors test

图3 液分离界面高度随时间变化曲线

Fig. 3 Changes of height of solid-liquid separation interface with time

由图3可见,曲线集中分布于图中4个区域:最上一个区域,包含2条曲线,分别为曲线4和8;在0~400 s内,固液分离界面以相对较慢的速度下降; 400 s后,该区域曲线逐渐趋于水平,最终固液界面高度降至105 mm;中上区域,包含2条曲线,分别为曲线6和12,在0~300 s内,固液分离界面高度处于下降过程,300 s后逐渐稳定至93~95 mm。由此可以看出,其与最上区域曲线形态相似,但其曲率更大,即固液分离界面高度下降更快,絮凝沉降效果更佳;中间区域2条曲线,分别为曲线9和10,降落速度明显变大,该段图中反映为0~100 s,并于100 s后,曲线逐渐趋于水平,界面高度最终约为85 mm;最下部分区域,包含6条曲线,分别为曲线1、2、3、5、7和11,该区域内固液分离界面迅速下降;在0~50 s内,固液分离界面由240 mm降至55~65 mm,尾矿颗粒迅速沉积;100 s后,各界面高度变化小,最终稳定在38~52 mm。综合而言,第一组达到絮凝终点所需时间最少,且上清液澄清效果最佳。以300 s时各组曲线的固液分离界面高度为评价指标,由优至劣依次为1、7、5、3、2、11、10、9、12、6、8和4组。

由图3与表2发现,图中12组实验中,沉降效果较差的6组曲线其砂浆浓度均为30%,较好的6组曲线砂浆浓度均为15%,一般悬浮粒子含量越高,絮凝剂溶液均匀分散到浆体中就越困难,部分絮凝剂被包裹。同时,固体颗粒之间机械碰撞的机会增多,导致颗粒下沉阻力增大。故推测砂浆浓度对尾砂沉降影响较大,但仍需通过P值来验证。

2.2 不同因素对絮凝沉降的影响程度

以单位面积固体处理量、底流质量分数为考察指标,评价不同影响因素耦合条件下絮凝沉降效果,筛选确定重要影响因素。

单位面积固体处理量是指单位时间内通过浓密机单位横截面积的尾砂处理量,与入料体积分数和沉降速度有关,其计算如式(2)所示:

(2)

(2)

式中:G为单位面积固体处理量,t/(m2·h); 为尾砂密度,g/cm3;

为尾砂密度,g/cm3; 为入料体积分数,g/cm3。

为入料体积分数,g/cm3。

底流质量分数计算如式(3)所示,实验过程中无尾砂损耗。

(3)

(3)

式中:wm为底流质量分数,%;m1为底流中尾砂的质量,g;m2为底流的质量,g。

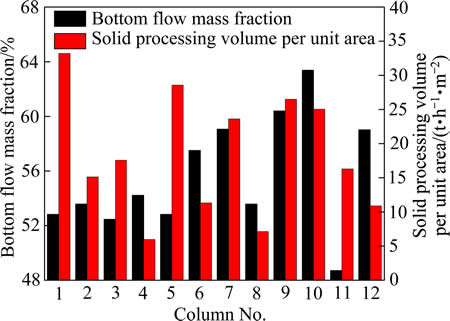

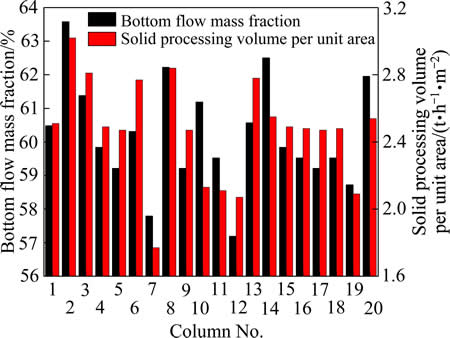

单位面积固体处理量与底流质量分数如图4所示。

图4 实验底流质量分数与单位面积固体处理量

Fig. 4 Bottom flow mass fraction and solid processing volume per unit area of experiments

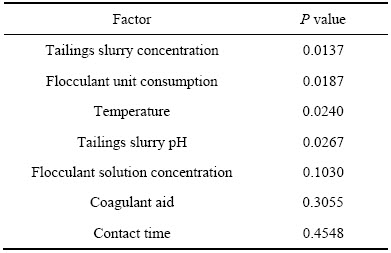

由图4可见,底流质量分数与单位面积固体处理量均呈现在一定范围内往复波动的趋势。其中,各组底流质量分数介于48%~64%之间,其波动基准值约为53%;单位面积固体处理量介于5.98~33.21 t/(m2·h)之间,波动基准值约为20 t/(m2·h)。对比底流质量分数与单位面积固体处理量二者跨度,可见后者跨度更大,更能体现各组实验之间的差别。以单位面积固体处理量为考量标准,获得各因素的影响程度值(P值),评价其影响程度。P值越小,表明该因素对实验结果的影响越大,且当P值小于0.1时,表明该因素对实验结果影响显著。各影响因素对应P值如表3所示。

表3 各因素对应P值

Table 3 P values corresponding to various factors

由表3可见,各因素按影响程度由大到小依次为尾砂入料浓度、絮凝剂单耗、温度、尾砂浆pH值、絮凝剂溶液浓度、助凝剂、接触次数。其中,尾砂入料浓度、絮凝剂单耗、温度、尾砂浆pH值、絮凝剂溶液浓度的P值均较小,影响较为显著;而接触次数、助凝剂等对单位面积固体处理量的影响较小。

此外,实验尾砂浆pH值为7.32,偏碱性,与理论最优值8.00相差不大,故不将pH值作为考察因素;尾砂浆量较大,所受影响因素较多,导致浆体温度难以有效控制。故最终取尾砂入料浓度、絮凝剂单耗、絮凝剂溶液浓度为重要影响因素。

2.3 重要影响因素的最优值分析

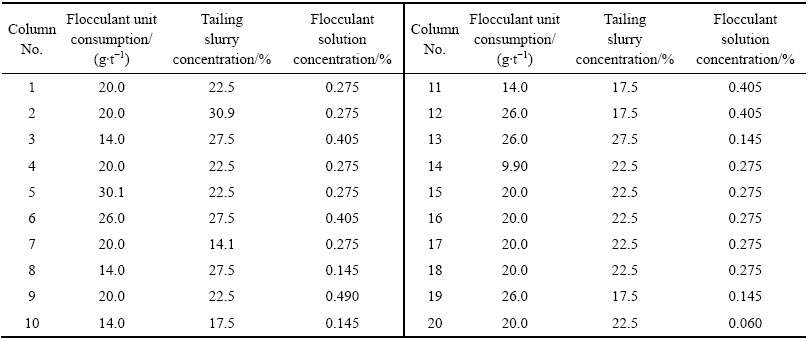

由影响因素筛选试验得知,重要影响因素为尾砂入料浓度、絮凝剂单耗、絮凝剂溶液浓度,每个因素确定5个梯度水平,具体如表4所列,利用CCD进行重要影响因素最优值确定实验设计方案,实验组数N=20,各组实验条件如表5所示。

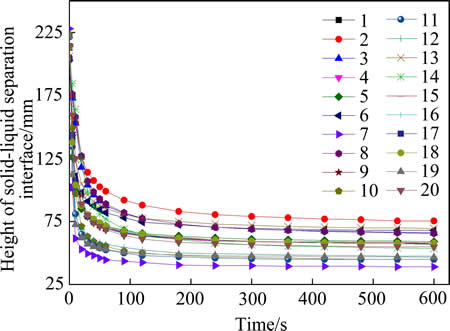

记录不同时刻固液分离界面高度,得到各组絮凝沉降曲线,如图5所示。由图5可见,不同影响因素耦合作用下,各曲线初始高度基本相同,随絮凝沉降的进行,呈现先迅速下降后趋于稳定的趋势,各曲线的固液分离界面高度降落趋势基本一致。絮凝沉降初期,固液分离界面高度迅速下降,图中反映为0~50 s段;在此之后,固液分离界面高度下降速度明显减缓,称之为絮凝沉降中期,图中反映为50~180 s段。180 s后,各组固液分离界面高度趋于稳定,曲线趋于水平。利用式(2)与(3)计算底流质量分数和单位面积固体的处理量,其结果如图6所示。

表4 尾砂入料浓度、絮凝剂单耗、絮凝剂溶液浓度变化范围

Table 4 Range of tailings slurry concentration, flocculant unit consumption, flocculant solution concentration

表5 最佳组合水平实验方案

Table 5 Scheme of best combination level test

图5 固液分离界面高度随时间变化曲线

Fig. 5 Changes of height of solid-liquid separation interface with time

图6 各实验底流质量分数与单位面积固体处理量

Fig. 6 Bottom flow mass fraction and solid processing volume per unit area of experiments

由图6可见,底流质量分数与单位面积固体处理量变化具有协同性和一致性。曲线波动较大,不同实验之间单位面积固体处理量差异较大,最优实验组的单位面积处理能力是最差实验组的1.7倍。其中,第2组的单位面积固体处理量最优,其值为3.02 t/(m2·h),且第2组底流质量分数最大,为63.58%;第7组单位面积固体处理能力最小,处理量仅为1.77 t/(m2·h),而第12组底流质量分数最小,其值为57.19%。此外,对比图4和6可得,在重要影响因素最优值实验中,各组底流质量分数波动不大,基本维持于50%~60%。并由于实验静态沉降过程中没有设置导水杆,因此,不考虑导流作用,尾砂颗粒之间的水不能导出,因而相比实际生产,底流质量分数偏小。

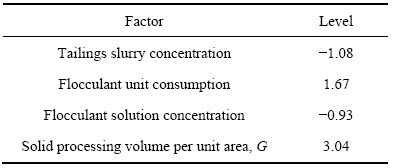

利用CCD进行数据分析,以单位面积固体处理量G为考量指标(G可取得取大值3.04 t/(m2·h)),此时,各重要影响因素水平值见表6。

表6 最大单位面积固体处理量及其对应的各因素水平

Table 6 Maximum solid processing capacity per unit area and factors level corresponding to maximum level

由表6可见,当G取最大值时,尾砂入料浓度、絮凝剂单耗、絮凝剂溶液浓度对应的水平分别为-1.08、1.67、-0.93。以单位面积固体处理量G为评价指标,利用表4、表6与式(4),计算当G取得最大值时的各因素最优水平B:

B=L0+LB×Δi (4)

式中:L0为表4中水平为0时该因素对应的水平代值;LB为表6中该因素对应的水平代值。

利用式(4),当单位面积固体处理量取最大时,各重要因素取得最优值,分别为尾砂入料浓度16.02%,絮凝剂用量28.35 g/t,絮凝剂溶液浓度0.1541%,此时单位面积固体处理量为3.04 t/(m2·h)。

3 结论

1) 全尾砂絮凝沉降过程受是多因素耦合作用、共同影响的结果。絮凝沉降高度随时间均呈现先迅速降低后趋于稳定的变化趋势,依据影响因素耦合作用效果不同而有所区别,此外,底流质量分数和单位面积固体处理量变化具有协同性。

2) 影响絮凝沉降过程的各因素按其影响程度由大到小依次为尾砂入料浓度、絮凝剂单耗、温度、尾砂浆pH值、絮凝剂溶液浓度、助凝剂、接触次数。

3) 以单位面积固体处理量为考察指标,得到影响絮凝沉降的重要因素及其最优值分别为尾砂入料浓度16.02%、絮凝剂用量28.25 g/t、絮凝剂溶液浓度0.1541%,此时,最大单位面积固体处理量最优,为3.04 t/(m2·h)。

REFERENCES

[1] 于润沧. 我国胶结充填工艺发展的技术创新[J]. 中国矿山工程, 2010, 39(5): 1-3.

YU Run-cang. Development and innovation of cemented filling technology in China[J]. China Mine Engineering, 2010, 39(5): 1-3.

[2] WANG Xin-min, ZHAO Bin, ZHANG Qin-li, XU Dong-sheng. Cemented backfilling technology with unclassified tailings based on vertical sand silo[J]. Journal of Central South University of Technology, 2008, 15(6): 801-807.

[3] 乔登攀, 程伟华, 张 磊, 姚维信, 王贤来, 王虎. 现代采矿理念与充填采矿[J]. 有色金属科学与工程, 2011, 2(2): 7-14.

QIAO Deng-pan, CHENG Wei-hua, ZHANG Lei, YAO Wei-xin, WANG Xian-lai, WANG Hu. Modern mining concepts and filling technique[J]. Nonferrous Metal Science and Engineering, 2011, 2(2): 7-14.

[4] 许毓海, 许新启, 李建雄. 高浓度(膏体)充填流变特性及自流输送参数的合理确定[C]// 中国有色金属学会第八届国际充填采矿会议论文集. 北京: 矿业研究与开发, 2004: 234-236.

XU Yu-hai, XU Xin-qi, LI Jian-xiong. Rheological behavior of high-density backfill and reasonable determination of the parameters for its gravity-flow transport[C]// Eighth International Filling Mining Conference Proceedings of China Nonferrous Metals Society. Beijing: Mining Research and Development, 2004: 234-236.

[5] 张修香, 乔登攀. 粗骨料高浓度充填料浆的管道输送模拟机试验[J]. 中国有色金属学报, 2015, 25(1): 258-266.

ZHANG Xiu-xiang, QIAO Deng-pan. Simulation and experiment of pipeline transportation of high density filling slurry with coarse aggregates[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 258-266.

[6] 吴 迪, 蔡嗣经, 杨 威, 王文潇, 王 章. 基于 CFD 的充填管道固液两相流输送模拟及试验[J]. 中国有色金属学报, 2012, 22(7): 2133-2140.

WU Di, CAI Si-jing, YANG Wei, WANG Wen-xiao, WANG Zhang. Simulation and experiment of backfilling pipeline transportation of solid-liquid two-phase flow based on CFD[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 2133-2140.

[7] 王新民, 古德生, 张钦礼. 深井矿山充填理论与管道输送技术[M]. 长沙: 中南大学出版社, 2012.

WANG Xin-min, GU De-sheng, ZHANG Qin-li. Conveying technology in deep mine filling theory and pipeline[M]. Changsha: Central South University Press, 2012.

[8] RULYOV N N, LASKOWSKI J S, CONCHA F. The use of ultra-flocculation in optimization of the experimental flocculation procedures[J]. Physicochemical Problems of Mineral Processing, 2011, 47: 5-16.

[9] ADDAI-MENSAH J. Enhanced flocculation and dewatering of clay mineral dispersions[J]. Powder Technology, 2007, 179(1): 73-78.

[10] SELOMUYA C, JIA X, WILLIAMS R A. Direct prediction of structure and permeability of flocculated structures and sediments using 3D tomographic imaging[J]. Chem Eng Res Des, 2005, 83(7): 844.

[11] 王 星, 瞿圆媛, 胡伟伟, 韩文亮, 吴 淼. 尾矿浆絮凝沉降影响因素的试验研究[J]. 金属矿山, 2008, 383(5): 149-151.

WANG Xing, QU Yuan-yuan, HU Wei-wei, HAN Wen-liang, WU Miao. Experiment research on factors influencing tailing pulp flocculation settling[J]. Met Mine, 2008, 383(5): 149-151.

[12] 王洪江, 陈琴瑞, 吴爱祥, 翟永刚, 张新普. 全尾砂浓密特性研究及其在浓密机设计中的应用[J]. 北京科技大学学报, 2011, 33(6): 676-681.

WANG Hong-jiang, CHENG Qin-rui, WU Ai-xiang, ZHAI Yong-gang, ZHANG Xin-pu. Study on the thickening properties of unclassified tailings and its application to thickener design[J]. Journal of University of Science and Technology Beijing, 2011, 33(6): 676-681.

[13] ESWARAIAH C, BISWAL S K, MISHRA B K. Settling characteristics of ultrafine iron ore slimes[J]. Int J Miner Metall Mater, 2012, 19(2): 95-99.

[14] 焦华喆, 王洪江, 吴爱祥, 吉学文, 严庆文, 李 祥. 全尾砂絮凝沉降规律及其机理[J]. 北京科技大学学报, 2010, 32(6): 702-707.

JIAO Hua-zhe, WANG Hong-jiang, WU Ai-xiang, JI Xue-wen, YAN Qing-wen, LI Xiang. Rule and mechanism of flocculation sedimentation of unclassified tailings[J]. Journal of University of Science and Technology Beijing, 2010, 32(6): 702-707.

[15] 王新民, 赵建文, 张德明. 全尾砂絮凝沉降速度优化预测模型[J]. 中国有色金属学报, 2015, 25(3): 793-798.

WANG Xin-min, ZHAO Jian-wen, ZHANG De-ming. Optimal prediction model of flocculating sedimentation velocity of unclassified tailings[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(3): 793-798.

[16] TAO D, PAREKH B K, ZHAO Y M, ZHANG P. Pilot-scale demonstration of deep cone TM paste thickening process for phosphatic clay/sand disposal[J]. Separation Science and Technology, 2008, 45(10): 1418-1425.

[17]  R, DAMASCENOB J J R, KARLSENC K H. A mathematical model for batch and continuous thickening of flocculated suspensions in vessels with varying cross section[J]. International J Miner Process, 2004, 73(2/4): 183.

R, DAMASCENOB J J R, KARLSENC K H. A mathematical model for batch and continuous thickening of flocculated suspensions in vessels with varying cross section[J]. International J Miner Process, 2004, 73(2/4): 183.

[18] 王 勇, 吴爱祥, 王洪江, 刘斯忠, 周 勃. 絮凝剂用量对尾矿浓密的影响机理[J]. 北京科技大学学报, 2013, 35(11): 1419-1423.

WANG Yong, WU Ai-xiang, WANG Hong-jiang, LIU Si-zhong, ZHOU Bo. Influence mechanism of flocculant dosage on tailings thickening[J]. Journal of University of Science and Technology Beijing, 2013, 35(11): 1419-1423.

[19] 焦华喆, 吴爱祥, 王洪江, 刘晓辉, 杨胜凯, 肖云涛. 全尾砂絮凝沉降特性实验研究[J]. 北京科技大学学报, 2011, 33(12): 1437-1441.

JIAO Hua-zhe, WU Ai-xiang, WANG Hong-jiang, LIU Xiao-hui, YANG Sheng-kai, XIAO Yun-tao. Experiment study on the flocculation settlement characteristic of unclassified tailings[J]. Journal of University of Science and Technology Beijing, 2011, 33(12): 1437-1441.

[20] 于 发, 张 林. 梅山细粒尾矿过滤试验研究[J]. 安徽工业大学学报, 2010, 27(S1): 94-97.

YU Fa, ZHANG Lin. Tests on the filtering of Meishan fine tailings[J]. Journal of Anhui University Technology, 2010, 27(S1): 94-97.

[21] 王桂莲. 斯托克斯法测量液体粘度设计实验的研究[J]. 医学信息, 2007, 2(3): 408-409.

WANG Gui-lian. Research of liquid viscosity by Stokes method[J]. Medical Information, 2007, 2(3): 408-409.

[22] 刘清侠, 单忠健. “架桥”絮凝模型的高分辨电镜观察[J]. 矿冶工程, 1991, 11(2): 40-42.

LIU Qing-xia, SHAN Zhong-jian. High-resolution microscopic observation of a “bridging” flocculation model[J]. Mining and Metallurgical Engineering, 1991, 11(2): 40-42.

Influence factors on flocculation sedimentation of unclassified tailings

WU Ai-xiang1, 2, ZHOU Jing1, 2, YIN Sheng-hua1, 2, WANG Lei-ming1, 2

(1. Key Laboratory of Ministry of Education for High-Efficient Mining and Safety of Metal,

University of Science and Technology Beijing, Beijing 100083, China;

2. School of Civil and Environment Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Unclassified tailings flocculation sedimentation process is an important part of paste filling process. In order to investigate the law of the flocculation sedimentation in the multi-factors coupling condition, the unclassified tailings flocculation sedimentation experiments by Design-Expert software design were carried out. Besides, the important influence factors of the unclassified tailings flocculation sedimentation and the optimal value were analyzed and selected when the solid processing volume per unit area was the best. The results show that the trends of the flocculation sedimentation curves are consistent basically in the coupling conditions of different influence factors, decreasing rapidly first and tending to level finally. The important influence factors of unclassified tailings flocculation sedimentation are tailings slurry concentration, flocculant unit consumption and flocculant solution concentration, and the optimal values successively are 16.02%, 28.35 g/t, 0.1541%. Meanwhile, the solid processing volume per unit area is the biggest (3.04 t/(m2·h)).

Key words: back-filling mining; unclassified tailings; flocculation sedimentation; influence factor; optimal volume

Foundation item: Project(51374035) supported by the National Natural Science Foundation of China; Project (NCET-13-0669) supported Program for New Century Excellent Talents in University, China; Project (201351) supported by Foundation for the Author of National Excellent Doctoral Dissertation of PR China

Received date: 2015-04-19; Accepted date: 2015-10-22

Corresponding author: YIN Sheng-hua; Tel: +86-10-62332750; E-mail: csuysh@126.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51374035);新世纪优秀人才支持计划资助项目(NCET-13-0669);全国优秀博士学位论文作者专项基金资助项目(201351)

收稿日期:2015-04-19;修订日期:2015-10-22

通信作者:尹升华,教授,博士;电话:010-62332750;E-mail: csuysh@126.com