DOI: 10.11817/j.issn.1672-7207.2017.12.019

全尾砂动态絮凝沉降试验研究

卞继伟1,王新民1,肖崇春2

(1. 中南大学 资源与安全工程学院,湖南 长沙,410083;

2. 飞翼股份有限公司,湖南 长沙,410600)

摘要:运用浓密机动态试验装置,通过连续进料和连续放砂,以沉降速度、底流质量分数、溢流水悬浮物质量浓度作为动态絮凝沉降效果的评价指标,研究不同条件下全尾砂动态絮凝沉降的变化规律。研究结果表明:沉降速度与絮凝剂单耗、供料速度、料浆质量分数均呈正相关;底流质量分数随絮凝剂单耗的增加先增加后基本保持不变,与供料速度呈负相关,与料浆质量分数呈正相关;溢流水悬浮物质量浓度与絮凝剂单耗呈正相关,与供料速度、料浆质量分数均呈负相关。确定该尾砂最佳动态絮凝沉降条件如下:絮凝剂单耗为10 g/t,供料速度为1.5 L/min,全尾砂料浆质量分数为13%左右。

关键词:全尾砂;动态沉降;絮凝沉降

中图分类号:TD853 文献标志码:A 文章编号:1672-7207(2017)12-3278-06

Experimental study on dynamic flocculating sedimentation of unclassified tailings

BIAN Jiwei1, WANG Xinmin1, XIAO Chongchun2

(1. School of Resources and Safety Engineering, Central South University, Changsha 410083, China;

2. Feny Ltd., Changsha 410600, China)

Abstract: Taking sedimentation velocity, underflow density and suspended solid concentration of overflow water as the evaluation indexes of dynamic flocculating sedimentation effect, the changing laws of dynamic flocculating sedimentation of unclassified tailings were experimented at different conditions using the dynamic test apparatus of thickener for continuous feeding and continuous sands-discharge. The results show that there is a clear positive correlation between the sedimentation velocity and the changes of flocculant consumption, feed velocity and solution concentration. The underflow density increases firstly with the increase of the flocculant consumption, then remains unchanged, and it has negative correlation with the feed velocity and positive correlation with solution concentration. The suspended solid concentration of overflow water is positively correlated with flocculant consumption, but is negatively correlated with feed velocity and solution concentration. The best conditions for dynamic flocculating sedimentation are as follows: flocculant consumption is 10 g/t; the feed velocity is 1.5 L/min, and the solution concentration is about 13%.

Key words: unclassified tailings;dynamic sedimentation;flocculating sedimentation

随着资源的日益匮乏和人们对环境保护意识的提高,充填采矿法在矿山得到广泛应用[1-2]。尾砂是选厂排放的废弃物,将矿山产出的尾砂充填至井下采场,不仅解决了矿山充填料来源问题,而且有利于矿山环境保护,但其质量分数一般仅为5%~25%,无法直接制备高质量分数的充填料浆[3-4]。而全尾砂充填特别是胶结充填,一般要求充填料浆的质量分数达到65%以上,全尾砂浓缩成为充填采矿的主要研究方向之一[5-7]。传统的全尾砂浓缩一般依靠全尾砂在立式砂仓中自然沉降,但全尾砂沉降速度较慢,沉降物质量分数较低,无法满足连续供砂和制备高质量分数浆体的要求[8],同时,溢流水悬浮物质量浓度较高,达不到工业用水排放标准。针对以上问题,国内外学者在添加絮凝剂[9-11]和改善浓缩设备等方面进行了研究。焦华喆等[12]通过全尾砂絮凝沉降试验,研究了给料质量分数和絮凝剂单耗对沉降速度和沉降物质量分数的影响,并构建了简易的速度沉降模型;张钦礼等[13-14]建立了全尾砂絮凝沉降参数优化预测模型,对絮凝沉降参数进行了预测和优化。 等[15-18]利用沉降装置研究了絮凝沉降性能,提出了一种连续沉降和浓缩数学模型;王勇等[19]通过添加转子导流系统模拟尾砂动态沉降,提出了不同区间的絮凝剂对尾砂浓密的影响机理;李辉等[20]利用室内深锥相似模型,研究了尾砂质量分数和絮凝剂添加量对絮凝沉降效果的影响。以上研究均以静态沉降为基础,无法实现连续进料和连续放砂,不能真实体现全尾砂动态沉降的规律,无法应用于深锥浓密机沉降浓密。为此,本文作者采用浓密机动态试验装置进行试验,通过连续进料和连续放砂,探讨不同条件下全尾砂料浆沉降速度、底流质量分数和溢流水悬浮物质量浓度的变化规律,以期为深锥浓密机的连续沉降浓密和连续放砂提供依据。

等[15-18]利用沉降装置研究了絮凝沉降性能,提出了一种连续沉降和浓缩数学模型;王勇等[19]通过添加转子导流系统模拟尾砂动态沉降,提出了不同区间的絮凝剂对尾砂浓密的影响机理;李辉等[20]利用室内深锥相似模型,研究了尾砂质量分数和絮凝剂添加量对絮凝沉降效果的影响。以上研究均以静态沉降为基础,无法实现连续进料和连续放砂,不能真实体现全尾砂动态沉降的规律,无法应用于深锥浓密机沉降浓密。为此,本文作者采用浓密机动态试验装置进行试验,通过连续进料和连续放砂,探讨不同条件下全尾砂料浆沉降速度、底流质量分数和溢流水悬浮物质量浓度的变化规律,以期为深锥浓密机的连续沉降浓密和连续放砂提供依据。

1 试验研究

1.1 试验装备

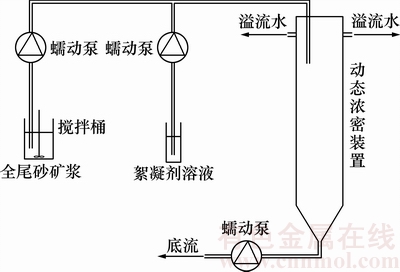

本文试验装置采用浓密机动态试验装置如图1所示,试验原理示意图如图2所示。

1.2 试验材料

1) 絮凝剂:阴离子聚丙烯酰胺(APAM,相对分子质量分别为800万和1 200万);阳离子聚丙烯酰胺(CPAM,相对分子质量为1 200万);聚合氯化铝(PAC)。

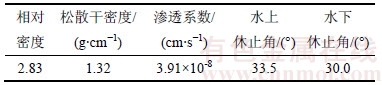

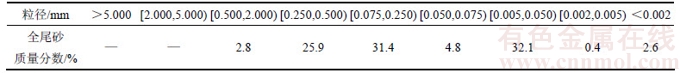

2) 全尾砂:其主要物理性质及粒径分布如表1和表2所示。

1.3 试验设计

动态试验选用3个蠕动泵,分别用于将全尾砂料浆、絮凝剂溶液泵入浓密试验装置的给料系统中,以及从试验装置底部泵出底流矿样,实现连续供料、连续放砂。参考静态沉降絮凝剂单耗、全尾砂料浆质量分数,本试验初步设定试验条件如下:絮凝剂单耗为7.5 g/t,全尾砂料浆质量分数为10%,供料速度为1.5 L/min,并依据试验过程实际结果进行调整。

1.3.1 试验步骤

1) 絮凝剂溶液配制。在1 000 mL量筒中配制质量分数为1‰的絮凝剂溶液,并搅拌均匀。

2) 全尾砂料浆配制。称取一定的全尾砂放入体积为100 L的桶内,加入一定量的水,配制为相应质量分数的全尾砂料浆,用电动搅拌机充分搅拌均匀。

3) 开启蠕动泵,调节转速,使得全尾砂料浆和絮凝剂以设定速度和相应单耗连续泵入浓密试验装置。

图1 浓密机动态试验装置

Fig. 1 Dynamic test apparatus of thickener

图2 试验装置示意图

Fig. 2 Schematic diagram of test apparatus

表1 全尾砂的物理特性

Table 1 Physical properties of unclassified tailings

表2 全尾砂粒径分布

Table 2 Particle size distribution of unclassified tailings

4) 测定底流质量分数、沉降速度和溢流水悬浮物质量浓度。

1.3.2 絮凝剂选型试验

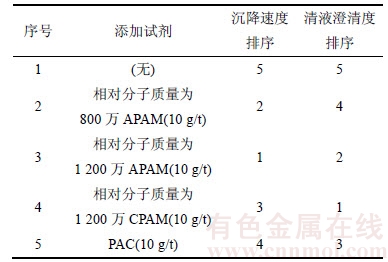

本组安排5个试验,即:不加任何试剂,按7.5 g/t分别添加相对分子质量分别为800万和1 200万的APAM、相对分子质量为1 200万的CPAM和PAC,对比全尾砂的沉降速度和溢流水澄清度。

1.3.3 全尾砂动态沉降条件优化试验

1) 控制料浆质量分数、供料速度不变,测定不同絮凝剂单耗下全尾砂絮凝沉降速度、底流质量分数、溢流水悬浮物质量浓度的变化规律。

2) 控制料浆质量分数、絮凝剂单耗不变,测定不同供料速度下全尾砂絮凝沉降速度、底流质量分数、溢流水悬浮物质量浓度的变化规律。

3) 控制絮凝剂单耗、供料速度不变,测定不同料浆质量分数下全尾砂絮凝沉降速度、底流质量分数、溢流水悬浮物质量浓度的变化规律。

1.4 浓密效果评价指标

1) 溢流水悬浮物质量浓度。当泥层高度为120 mm时开始取样测溢流水。首先称取滤膜质量,将1 000 mL溢流水用抽滤机进行抽滤,对滤膜在(105±2) ℃下进行烘干,称质量,放入烘箱,在同样条件下处理30 min。取出称质量,如此重复2次。比较3次质量,看质量是否达到恒定,精确至0.1 mg。

2) 底流质量分数。当泥层高度为240 mm时开始取样测底流质量分数。取1 kg左右底流称质量,烘干,称质量,放入烘箱,在同样条件下处理30 min,复取出称质量,如此重复2次。比较3次质量,看质量是否达到恒定。

3) 沉降速度。记录泥层高度由120 mm上升至240 mm的时间。

2 试验结果

2.1 絮凝剂选型试验

絮凝剂种类对全尾砂絮凝沉降的效果影响很大,定性对比添加不同类型絮凝剂全尾砂料浆的沉降速度和溢流水澄清度,试验结果如表3所示。无论从沉降速度还是从清液澄清度,添加絮凝剂的效果都好于不添加絮凝剂的效果,即所有类型的絮凝剂都可以改善全尾砂沉降效果。聚丙烯酰胺分子上的极性基团吸附尾砂颗粒,连接而形成较大的絮凝物,可以在短时间内实现全尾砂料浆沉降。与阳离子聚丙烯酰胺和聚合氯化铝相比,阴离子聚丙烯酰胺更适合此料浆的絮凝沉降。

表3 絮凝剂选型测试结果

Table 3 Test results of flocculant selection

2.2 全尾砂动态絮凝沉降条件优化试验

2.2.1 絮凝剂单耗对全尾砂絮凝沉降效果的影响

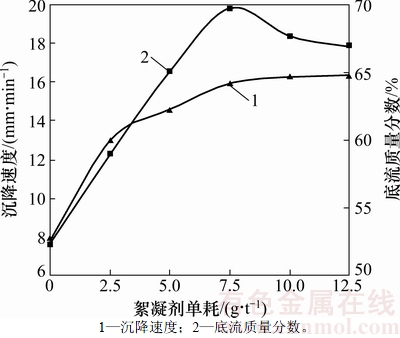

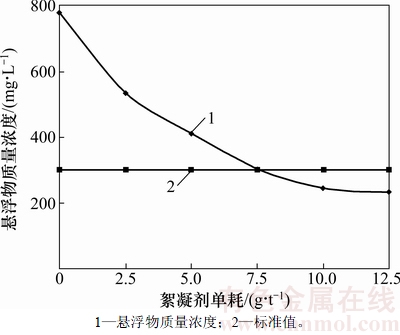

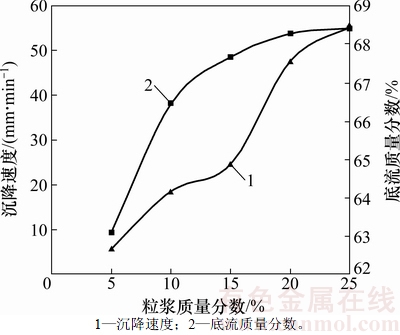

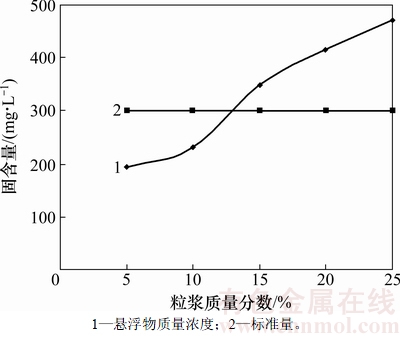

在全尾砂料浆质量分数为10%,供料速度为1.5 L/min时,全尾砂絮凝动态沉降指标(沉降速度、底流质量分数、溢流水悬浮物质量浓度)随絮凝剂单耗变化的曲线如图3和图4所示。从图3可见:随着絮凝剂单耗增加,全尾砂动态絮凝沉降速度先增加后基本保持不变,底流质量分数呈现先上升后下降的趋势;当絮凝剂单耗为7.5 g/t时,全尾砂动态絮凝沉降效果达到最佳,底流沉降速度和质量分数分别为16.384 mm/min和69.766%。从图4可见:随着絮凝剂单耗增大,溢流水悬浮物质量浓度逐渐降低;当絮凝剂单耗大于7.5 g/t时,溢流水悬浮物质量浓度小于工业废水排放标准悬浮物质量浓度(300 mg/L)。经综合考虑,当絮凝剂单耗为10 g/t时,全尾砂的动态絮凝沉降效果最佳。

当絮凝剂单耗较低时,部分全尾砂颗粒无法与絮凝剂发生作用,导致沉降速度较慢;部分细尾砂颗粒随溢流水流出,导致溢流水悬浮物质量浓度较高;沉降区以粗颗粒为主,颗粒间的孔隙较大,故底流质量分数较低。随着絮凝剂单耗增加,尾砂颗粒与絮凝剂充分作用,有效扰动打破了部分絮团或颗粒受力平衡,同时使得处于松散状态的尾砂颗粒重新排列,周围微细颗粒落入孔隙内,底流质量分数进一步升高,沉降效果随之提升。随着絮凝剂单耗进一步增大,尾砂颗粒被絮凝剂层层包裹,同时会有大量水分积聚在絮团内部以及絮团之间,无法及时排出,导致底流质量分数降低。

图3 全尾砂沉降速度、底流质量分数与絮凝剂单耗的关系

Fig. 3 Relationship among settling velocit,underflow density and flocculant consumption

图4 全尾砂溢流水悬浮物质量浓度与絮凝剂单耗的关系

Fig. 4 Relationship between suspended solid concentration of overflow water and flocculant consumption

2.2.2 供料速度对全尾砂絮凝沉降效果的影响

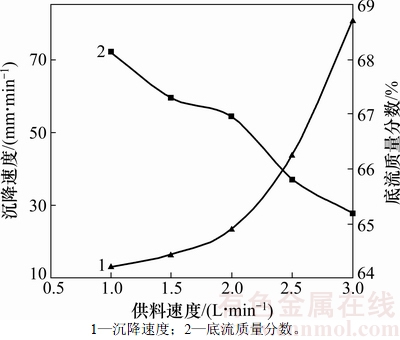

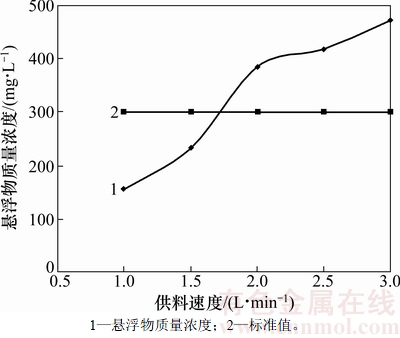

在全尾砂料浆质量分数为10%,絮凝剂单耗为10 g/t时,全尾砂动态絮凝沉降指标(沉降速度、底流质量分数、溢流水悬浮物质量浓度)随供料速度变化的曲线如图5和图6所示。从图5可见:随着供料速度增加,全尾砂动态絮凝沉降速度逐渐变大,底流质量分数逐渐变小。从图6可见:随着供料速度增大,溢流水悬浮物质量浓度逐渐上升;当供料速度大于1.7 L/min时,溢流水悬浮物质量浓度大于工业废水排放标准悬浮物质量浓度(300 mg/L)。经综合考虑,当供料速度为1.5 L/min时,全尾砂的动态絮凝沉降效果最佳。

图5 全尾砂沉降速度、底流质量分数与供料速度的关系

Fig. 5 Relationship among settling velocity,underflow density and feed velocity

图6 全尾砂溢流水悬浮物质量浓度与供料速度的关系

Fig. 6 Relationship between suspended solid concentration of overflow water and feed velocity

当供料速度较低时,料浆与絮凝剂溶液在试验装置停留时间较长,使得尾矿颗粒发生絮凝反应的时间延长,絮凝反应更彻底,絮凝沉降效果较好;随着供料速度增加,尾砂质量分数逐渐增加,沉降速度逐渐增加,料浆在试验装置中停留时间减少,絮凝剂无法与尾砂颗粒充分作用,部分细尾砂颗粒随溢流水流出,溢流水悬浮物质量浓度增加,底流质量分数减小。

2.2.3 料浆质量分数对全尾砂絮凝沉降效果的影响

在全尾砂料浆供料速度为1.5 L/min,絮凝剂单耗为10 g/t时,全尾砂动态絮凝沉降指标(沉降速度、底流质量分数、溢流水悬浮物质量浓度)随料浆质量分数变化如图7和图8所示。从图7可见:随着料浆质量分数增大,全尾砂动态絮凝沉降速度呈现上升趋势,底流质量分数先上升后基本维持平衡。从图8可见:随着料浆质量分数增加,溢流水悬浮物质量浓度逐渐上升;当料浆质量分数超过13%时,溢流水悬浮物质量浓度大于工业废水排放标准悬浮物质量浓度(300 mg/L)。经综合考虑,当料浆质量分数为13%时,全尾砂的动态絮凝沉降效果最佳。

图7 全尾砂沉降速度、底流质量分数与料浆质量分数的关系

Fig. 7 Relationship among settling velocity,underflow density and solution concentration

图8 全尾砂溢流水悬浮物质量浓度与料浆质量分数的关系

Fig. 8 Relationship between suspended solid concentration of overflow water and solution concentration

当料浆质量分数较低时,尾砂质量分数较低,故沉降速度较慢;随着料浆质量分数增加,絮凝剂与尾砂颗粒接触的概率增加,絮凝沉降效果提高;料浆质量分数进一步增加导致尾砂颗粒与絮凝剂的接触困难,故溢流水悬浮物质量浓度增加。

3 结论

1) 本试验采用浓密机动态试验装置,实现连续进料和连续放砂,更能体现全尾砂动态絮凝沉降的规律。

2) 随着絮凝剂单耗增加,全尾砂动态絮凝沉降速度先增加后基本保持不变,底流质量分数呈现先上升后下降的趋势,溢流水悬浮物质量浓度逐渐降低;随着供料速度增加,全尾砂动态絮凝沉降速度逐渐增大,底流质量分数逐渐变小,溢流水悬浮物质量浓度逐渐上升;随着料浆质量分数增加,全尾砂动态絮凝沉降速度呈上升趋势,底流质量分数先上升后基本维持平衡,溢流水悬浮物质量浓度逐渐上升。

3) 通过全尾砂动态沉降条件优化试验对全尾砂动态絮凝沉降条件进行优化选择,确定最佳动态絮凝沉降条件如下:絮凝剂单耗为10 g/t,供料速度为1.5 L/min,全尾砂料浆质量分数为13%左右。

参考文献:

[1] 王新民, 古德生, 张钦礼. 深井矿山充填理论与管道输送技术[M]. 长沙: 中南大学出版社, 2010: 9-10.

WANG Xinming, GU Desheng, ZHANG Qinli. Theory of backfilling activity and pipeline transportation technology of backfill in deep mines[M]. Changsha: Central South University Press, 2010: 9-10.

[2] 于润沧. 我国胶结充填工艺发展的技术创新[J]. 中国矿山工程, 2010, 39(5): 1-3, 9.

YU Runcang. Development and innovation of cemented filling technology in China[J]. China Mine Engineering, 2010, 39(5): 1-3, 9.

[3] 黄玉诚. 矿山充填理论与技术[M]. 北京: 冶金工业出版社, 2014: 12-16.

HUANG Yucheng. Mine filling theory and technology[M]. Beijing: Metallurgical Industry Press, 2014: 12-16.

[4] RANKINE R, PACHECO M, SIVAKUGAN N. Underground mining with backfills[J]. Soils and Rocks, 2007, 30(2): 93-101.

[5] 史秀志, 胡海燕, 杜向红, 等. 立式砂仓尾砂浆液絮凝沉降试验研究[J]. 矿冶工程, 2010, 30(3): 1-3.

SHI Xiuzhi, HU Haiyan, DU Xianghong, et al. Experimental study on flocculating sedimentation of tailings slurry in a vertical sand tank[J]. Mining and Metallurgical Engineering, 2010, 30(3): 1-3.

[6] 王新民, 赵建文, 张德明. 全尾砂絮凝沉降速度优化预测模型[J]. 中国有色金属学报, 2015, 25(3): 793-798.

WANG Xinmin, ZHAO Jianwen, ZHANG Deming. Optimal prediction model of flocculating sedimentation velocity of unclassified tailings[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(3): 793-798.

[7] 陈秋松, 张钦礼, 王新民, 等. 磁化水改善全尾砂絮凝沉降效果的试验研究[J]. 中南大学学报(自然科学版), 2015, 46(11): 4256-4261.

CHEN Qiusong, ZHANG Qinli, WANG Xinmin, et al. Experimental study on effect of magnetized water on flocculating sedimentation of unclassified tailings[J]. Journal of Central South University (Science and Technology), 2015, 46(11): 4256-4261.

[8] ESWARAIAH C, BISWAL S K, MISHRA B K. Settling characteristics of ultrafine iron ore slimes[J]. International Journal of Mineral Metallurgy and Materials, 2012, 19(2): 95-99.

[9] RULYOVN N, LASKOWSKI J S, MISHRA B K. The use of ultra-flocculation in optimization of the experimental flocculation procedures[J]. Physicochemical Problems of Mineral Processing, 2011, 47(1): 5-16.

[10] OWEN A T, FAWELL R D, SWIFT J D, et al. The impact of polyacrylamide flocculant solution age on flocculation performance[J]. International Journal of Mineral Processing, 2002, 67(1): 123-144.

[11] OWEN A T, NGUYEN T V, FAWELL P D. The effect of flocculant solution transport and addition conditions on feedwell performance in gravity thickeners[J]. International Journal of Mineral Processing, 2009, 93(2): 115-127.

[12] 焦华喆, 吴爱祥, 王洪江, 等. 全尾砂絮凝沉降特性实验研究[J]. 北京科技大学学报, 2011, 33(12): 1437-1441.

JIAO Huazhe, WU Aixiang, WANG Hongjiang, et al. Experiment study on the flocculation settlement characteristic of unclassified tailings[J]. Journal of University of Science and Technology Beijing, 2011, 33(12): 1437-1441.

[13] 张钦礼, 陈秋松, 王新民, 等. 全尾砂絮凝沉降参数GA-SVM优化预测模型研究[J]. 中国安全生产科学技术, 2014, 10(5): 24-30.

ZHANG Qinli, CHEN Qiusong, WANG Xinmin, et al. Study on GA-SVM optimal prediction model on flocculating sedimentation parameter of unclassified tailings[J]. Journal of Safety Science and Technology, 2014, 10(5): 24-30.

[14] 张钦礼, 周登辉, 王新民, 等. 超细全尾砂絮凝沉降实验研究[J]. 广西大学学报(自然科学版), 2013, 38(2): 451-455.

ZHANG Qinli, ZHOU Denghui, WANG Xinmin, et al. Experimental study on flocculating sedimentation of ultra-fine unclassified tailings[J]. Journal of Guangxi University (Natural Science Edition), 2013, 38(2): 451-455.

[15]  R, DAMASCENOB J J R, KARLSENC K H. A mathematical model for batch and continuous thickening of flocculated suspensions in vessels with varying cross section[J]. International Journal of Mineral Processing, 2004, 73(2/3/4): 183-208.

R, DAMASCENOB J J R, KARLSENC K H. A mathematical model for batch and continuous thickening of flocculated suspensions in vessels with varying cross section[J]. International Journal of Mineral Processing, 2004, 73(2/3/4): 183-208.

[16]  R, CONCHA F. Mathematical model and numerical simulation of the settling of flocculated suspensions[J]. International Journal of Multiphase Flow, 1998, 24(6): 1005-1023.

R, CONCHA F. Mathematical model and numerical simulation of the settling of flocculated suspensions[J]. International Journal of Multiphase Flow, 1998, 24(6): 1005-1023.

[17]  R, KARLSEN K H, RISEBRO N H, et al. Numerical methods for the simulation of continuous sedimentation in ideal clarifier-thickener units[J]. International Journal of Mineral Processing, 2004, 73(2): 209-228.

R, KARLSEN K H, RISEBRO N H, et al. Numerical methods for the simulation of continuous sedimentation in ideal clarifier-thickener units[J]. International Journal of Mineral Processing, 2004, 73(2): 209-228.

[18] GARRIDO P, BURGOS R, CONCHA F, et al. Settling velocities of particulate systems: 13. A simulator for batch and continuous sedimentation of flocculated suspensions[J]. International Journal of Mineral Processing, 2004, 73(2/3/4): 131-144.

[19] 王勇, 吴爱祥, 王洪江, 等. 絮凝剂用量对尾矿浓密的影响机理[J]. 北京科技大学学报, 2013, 25(11): 1419-1423.

WANG Yong, WU Aixiang, WANG Hongjiang, et al. Influence mechanism of flocculant dosage on tailings thickening[J]. Journal of University of Science and Technology Beijing, 2013, 35(11): 1419-1423.

[20] 李辉, 王洪江, 吴爱祥, 等. 基于尾砂沉降与流变特性的深锥浓密机压耙分析[J]. 北京科技大学学报, 2013, 35(12): 1553-1558.

LI Hui, WANG Hongjiang, WU Aixiang, et al. Pressure rake analysis of deep cone thickeners based on tailings' settlement and rheological characteristics[J]. Journal of University of Science and Technology Beijing, 2013, 35(12): 1553-1558.

(编辑 陈灿华)

收稿日期:2016-12-29;修回日期:2017-03-11

基金项目(Foundation item):国家“十二五”科技支撑计划项目(2012BAC09B02) (Project(2012BAC09B02) supported by the National Science and Technology Pillar Program during the “12th Five-Year” Plan Period of China)

通信作者:王新民,博士,教授,从事采矿工艺与充填技术研究;E-mail:wxm1958@126.com