DOI: 10.11817/j.issn.1672-7207.2016.10.032

絮凝沉降对全尾砂料浆流变特性的影响

杨柳华1, 2,王洪江1, 2,吴爱祥1,李红1, 2,陈辉1,霍成月3

(1. 北京科技大学 土木与环境工程学院,北京,100083;

2. 金属矿山高效开采与安全教育部重点实验室,北京,100083;

3. 北京科技大学 化学与生物工程学院,北京,100083)

摘要:通过研究沉降后料浆流变参数变化规律,探索基于料浆流变特性作为全尾砂絮凝沉降参数优化的可行性。以某铜锌矿全尾砂为实验材料,通过考察絮凝剂种类、入料体积分数、絮凝剂单耗这3个因素,进行静态絮凝沉降及料浆流变测试实验。实验结果表明:在絮凝剂种类筛选实验中,所选4种絮凝剂沉降效果区别较小,不同絮凝沉降后料浆屈服应力相差不大,添加N123作为絮凝剂时料浆黏度最小,絮团内部水分容易被挤出,絮凝沉降效果最佳;在入料体积分数及单耗实验中,当入料体积分数为10%~15%、絮凝剂单耗为25 g/t时,单位面积固体处理量和底流体积分数均较高,并且屈服应力及黏度达到极小值,有利于料浆进一步压密脱水及耙架运行。

关键词:絮凝沉降;流变特性;压密脱水;絮凝剂

中图分类号:TD853 文献标志码:A 文章编号:1672-7207(2016)10-3523-07

Effect of flocculation settling on rheological characteristics of full tailing slurry

YANG Liuhua1, 2, WANG Hongjiang1, 2, WU Aixiang1, LI Hong1, 2, CHEN Hui1, HUO Chengyue3

(1. School of Civil and Environment Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Key Laboratory of High-Efficient Mining and Safety of Metal Mines, Ministry of Education, Beijing 100083, China;

3. School of Chemistry and Biological Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The feasibility of optimizing flocculation settling parameters by analyzing how slurry rheological parameters change was tested. The flocculation settling experiments and the slurry rheological tests were carried out with full tailings from a copper zinc deposit in which three factors (flocculant type, feed slurry concentration and flocculant dosage) were studied. The results show that in the flocculant type screening experiments, there is little difference between the four flocculants and the yield stress of their respective slurries. The slurry has the minimum viscosity when using N123, and the inside water of aggregates can be easily extruded, thus the best flocculation settling results are obtained. The solid flux and the underflow volume fraction are high when the feed slurry concentration is 10%-15% and the flocculant dosage is 25 g/t. Meanwhile, the minimum yield stress and viscosity can be reached, which benefits the consolidation dewatering and rake running.

Key words: flocculation settling; rheological characteristics; dewatering; flocculant

近年来,随着矿山环保要求的提高,深锥浓密机在我国开始得到广泛关注。其工作原理为:低体积分数尾矿浆在机体上部中心进料筒中与絮凝剂溶液混合后,尾砂颗粒形成较大尺寸絮团,絮团沉降至深锥底部,并在重力及搅拌作用下浓密脱水,形成高体积分数的底流[1]。深锥浓密效率及效果主要取决于3个方面:絮凝沉降、床层压缩、耙架运行。而这3个方面与絮团的大小、结构和表面化学特性直接相关,絮团的物理化学特征决定了料浆的流变特征。王洪江等[2-3]对入料体积分数、停留时间、絮凝剂单耗等多个因素进行了探讨,但这些研究都是以单位面积固体处理量和底流体积分数等作为评价指标。料浆在深锥中的停留时间及最终底流体积分数受限于压密脱水过程,单位面积固体处理量和底流体积分数不能全面反映絮凝沉降过程的效果,可能造成后期底流体积分数偏低或者压耙等事故[4]。料浆的屈服应力涉及深锥耙架的稳定运行及絮团网状结构的剪切破坏,而黏度越小,则压密脱水性能越好[5-6],通过料浆的流变特性能很好地反映出全尾砂絮凝沉降过程的效果。全尾砂絮凝沉降属于一个快速沉降过程,尾矿颗粒通过高分子的架桥作用形成大絮团,改变了颗粒表面积及全尾砂内部水的分布[7],减少对水分的吸附,改善全尾砂压密脱水性能[8]。絮团结构的变化过程与沉降参数息息相关,在不同的絮凝剂、入料体积分数[9]及絮凝剂单耗[10-11]作用下引起改变,对料浆的流变特性影响明显[12]。本文作者从絮凝沉降和流变实验入手,探索不同絮凝沉降环境下浓密效果及料浆流变特性,对实验结果进行分析,指出两者之间相互关系,得到基于料浆流变特性的全尾砂絮凝沉降参数优化方法,以保证一定的深锥底流体积分数,且设备高效稳定运行。

1 实验设计

1.1 实验材料及仪器

1.1.1 全尾砂

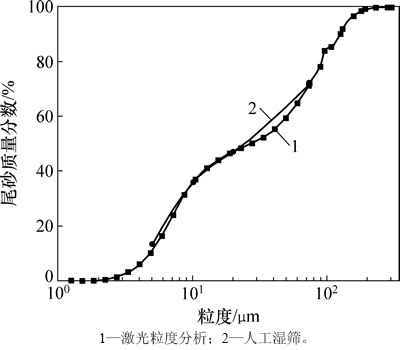

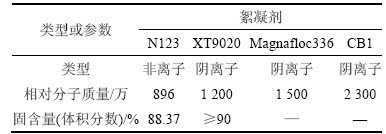

实验以某铜锌矿全尾砂为材料,采用激光粒度仪和人工湿筛对全尾砂粒级组成进行分析,分析结果见图1。备选絮凝剂共有4种,分别为N123,XT9020,Magnafloc336和CB1,各种絮凝剂技术指标见表1。

1.1.2 实验仪器及流变特性测试原理

实验仪器为R/S型四叶桨式旋转流变仪。其测试原理是四叶桨式转子浸入料浆中,以变化剪切速率旋转,通过控制软件进行实时监测,并输出剪切应力-剪切速率曲线并进一步对其进行处理。

图1 全尾砂粒度分析结果

Fig. 1 Results of particle size analysis of unclassified tailings

表1 絮凝剂技术指标

Table 1 Qualification parameters of flocculants

一般认为,全尾砂膏体近似于Bingham体,可以应用以下公式对实验数据进行拟合:

(1)

(1)

式中:τ为剪切应力,Pa;τ0为动态屈服应力,Pa;η为黏度系数,Pa.s;γ为剪切速率,s-1。

1.2 絮凝剂筛选实验

先将每种絮凝剂制备成质量分数为0.3%溶液,实验具体步骤如下。

1) 按表2取尾矿8份,并编号为A1~A4和B1~B4共2个组,体积分数均配制成15%。其中对A1~A4进行絮凝沉降实验,固定总质量为1 kg;对B1~B4进行流变实验,为保证底流料浆足够进行流变测试,固定尾砂量为600 g。

2) 从每种絮凝剂溶液中各取2份,每份3.33 g,絮凝剂单耗固定为20 g/t。

3) 在A1和B1中加入絮凝剂N123,在A2和B2中加入絮凝剂XT9020,在A3和B3中加入絮凝剂Magnafloc336,在A4和B4中加入絮凝剂CB1。这4种絮凝剂均能在15 s内完成沉降。

4) 记录A组中30 min内各时间点沉降高度,并作固液分离界面高度与沉降时间关系曲线。

5) B组静止沉降30 min后去掉上层清液,取底部料浆并进行流变测试,设定剪切速率为0~120 s-1。

1.3 不同入料体积分数实验

固定絮凝剂单耗为20 g/t,采用N123对不同入料体积分数进行对比实验,寻求最佳入料体积分数。实验分为C1~ C6和D1~D6共2个组,每组设定入料体积分数5%~30%递增的6个水平,实验配料见表3。其中,C1~ C6固定总质量为1 kg。对D1~D6进行流变实验,固定尾砂质量为600 g。

采用自制搅拌装置对料浆和絮凝剂进行混合。由于粗颗粒相对较多,在混合过程中粗颗粒依靠重力下沉,而絮凝剂的主要作用是使得料浆中的极细颗粒尽快沉降。料浆絮凝沉降过程很快,一般在10余s内就能完成。由于尾砂絮凝沉降是一个匀速下降的过程,因此,可通过记录C组10 s内澄清界面下降的高度来计算沉降速度,结合入料体积分数求得单位面积处理能力。单位面积处理量计算式为

(2)

(2)

式中:Gs为固体单位面积处理量,t/(h·m2);ρs为尾砂密度,t/m3;φv为入料体积分数,%;ν为分离界面沉降速度,mm/min。

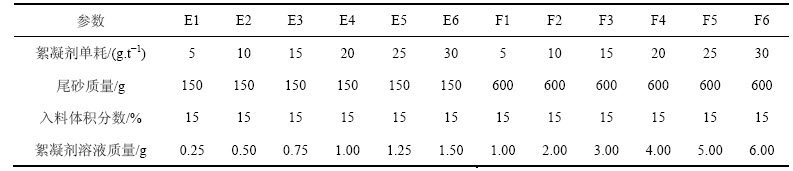

1.4 絮凝剂单耗实验

根据入料体积分数试验结果,固定入料体积分数为15%。考察沉降速度、单位面积处理能力及料浆流变参数。实验分为E1~ E6和F1~F6共2组,每组设定絮凝剂单耗5~30 g/t递增的6个水平。同理,D1~ D6固定总质量为1 kg。对F1~F6进行流变实验,固定尾砂量为600 g。实验配料如表4所示。

记录E组10 s内的沉降高度,根据式(2)计算得不同絮凝剂单耗下单位面积处理能力。F组在30 min末测定其底流料浆流变特性。

表2 絮凝剂筛选实验结果

Table 2 Experiment results of flocculant screening

表3 不同入料体积分数实验结果

Table 3 Experiment results of different feed concentrations

表4 絮凝剂单耗实验结果

Table 4 Experiment results of flocculant dosage

2 实验结果分析及讨论

2.1 絮凝剂种类对料浆流变特性影响

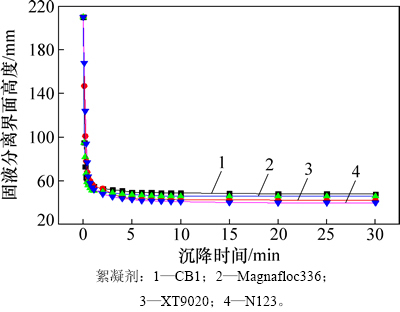

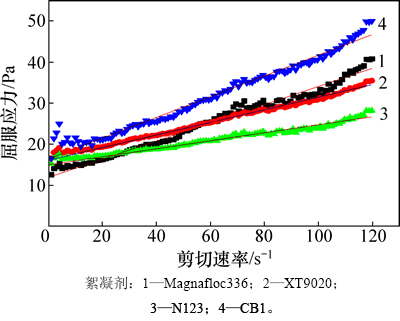

实验结果絮凝沉降曲线如图2所示,添加不同种类絮凝剂料浆流变曲线如图3所示。

图2 絮凝沉降曲线

Fig. 2 Curves of flocculation settlement

图3 絮凝剂种类对料浆流变的影响

Fig. 3 Effect of flocculants on rheological curves of slurry

从图1可见:在沉降区及压缩区,4种絮凝剂差异不大。从图2可见:在不同絮凝剂作用下料浆屈服应力相差很小,而在N123作用下黏度仅为0.102 Pa/s;全尾砂在N123絮凝作用下,不但能取得良好的絮凝沉降效果,而且料浆后期浓密脱水容易,耙架运行平稳,有利于进一步压密脱水。在适宜的沉降速度与底流体积分数下,料浆屈服应力越小,越有利于后期耙架的稳定运行及絮团的剪切破坏;黏度越小,则有利于絮团压密脱水,提高料浆底料体积分数[13],故选定N123作为进一步实验材料。

在不同药剂的作用下,生成的絮团结构及表面化学特性不同,导致料浆的流变特性存在差异[14]。全尾砂颗粒加入絮凝剂后,在带电基团的静电作用下形成直径较小的絮团。在搅拌过程中,絮凝剂高分子链上碳基、—NH2—等基团,通过氢键力、范德华力、配位键力等物理化学作用与污泥颗粒发生作用,增强对全尾砂颗粒的吸附能力。在絮凝剂的桥架作用下形成的絮团结构强度较大,不易破碎而有利于结构中自由水脱去。絮凝剂的长链状结构与小絮团相互结合,小絮团之间形成大絮团。而絮凝剂分子结构上具有的—CH2—和—NH—等疏水基团,有利于絮团表面附着水转化为游离水,同时降低底流料浆黏度,从而改善料浆的脱水性能。絮凝剂表面化学特性,既影响高分子絮凝剂与尾砂颗粒之间的相互作用,也决定了絮团的表面特征。实验所选4种絮凝剂均能到达快速絮凝沉降该全尾砂的效果,而在N123作用下料浆黏度最小,根据以上分析选定N123为最佳絮凝剂。

2.2 入料体积分数对料浆流变特性影响

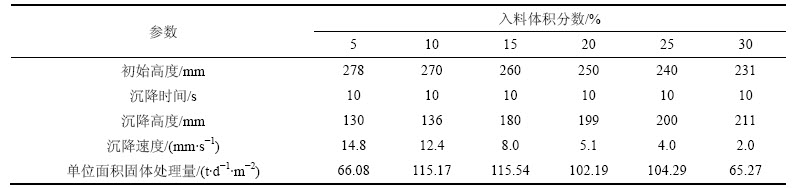

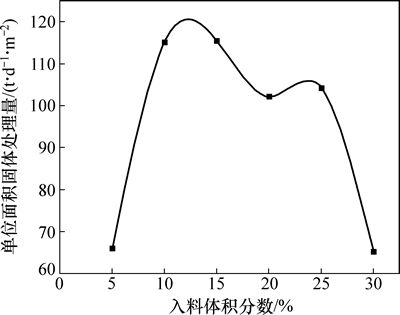

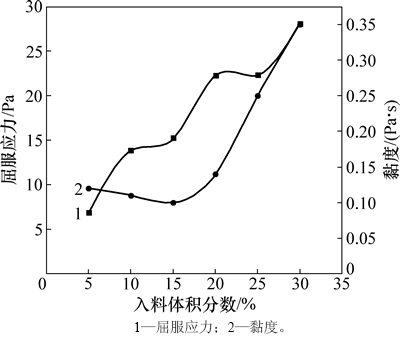

进行不同入料体积分数实验可以看出,当入料体积分数小于15%时,料浆上清液澄清;当入料体积分数大于20%时,上清液渐显浑浊。据实验结果及式(2)计算不同入料体积分数下单位面积固体处理量,如表5所示。

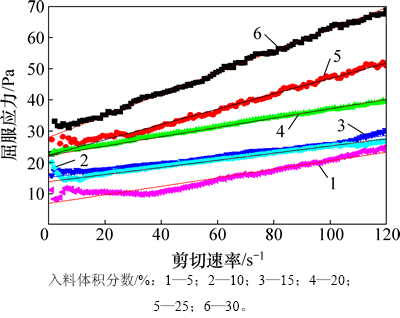

D组在沉降30 min后去掉上层清液,取底部料浆并进行流变测试,结果如图4所示。

表5 实验结果及相应单位面积固体处理量

Table 5 Experimental results and the corresponding solid fluxes

图4 不同入料体积分数下的流变曲线

Fig. 4 Rheological curves of slurry at different feed volume fractions

根据表5所示实验结果及单位面积固体处理量计算结果,绘制单位面积处理能力与入料体积分数之间关系曲线,如图5所示。根据图4所示实验曲线,作出不同入料体积分数作用下料浆流变参数变化曲线,如图6所示。

从图5可知:单位面积处理量随入料体积分数变化曲线整体呈现先增大后减小规律,且在10%~15%之间存在最大值。从图6可见:屈服应力总体趋势增大,在10%~15%之间增长曲线变缓,黏度达到最小。

在絮凝剂单耗不变时,随着入料体积分数增加,全尾砂絮凝沉降效果开始增强。在接近最佳入料体积分数时,此时体积分数虽然有所增大,但全尾砂絮团结构、强度、间距较适宜,絮团结构易于破坏,屈服应力增大速率小,料浆黏度小,絮团之间封闭的水分和絮团内部的水分易于挤出。当入料体积分数大于15%时,尾砂颗粒间的相互作用力增强,屈服应力又开始增大,黏度也大幅度增大。同时,底流体积分数有所增大[15],但上层清液开始变浊,絮团结构变小。

图5 不同入料体积分数下单位面积固体处理量

Fig. 5 Relationship between solid flux and feed volume fraction

图6 不同入料体积分数下料浆流变参数变化曲线

Fig. 6 Relationship between rheological parameters and feeding volume fraction

2.3 絮凝剂单耗对料浆流变特性影响

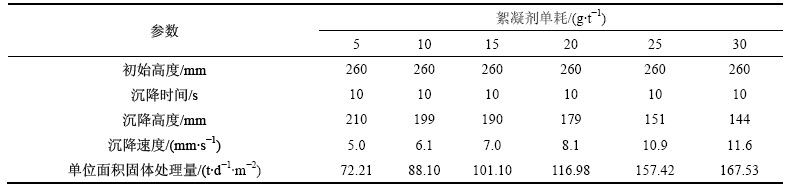

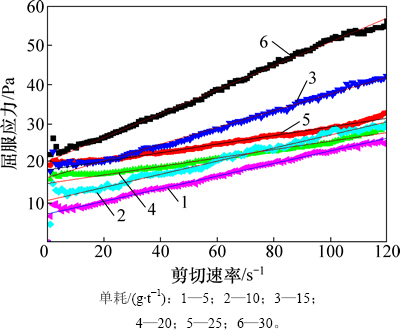

记录E组实验结果及单位面积沉降能力,结果见表6,得到F组流变曲线如图7所示。

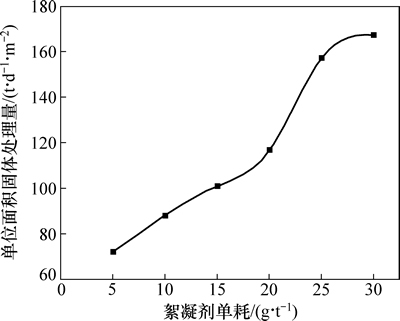

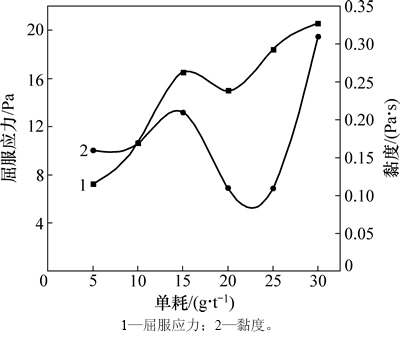

通过表6作出不同单耗下单位面积固体处理量与料浆体积分数之间关系曲线,见图8;依据图7中F组实验流变参数,作出不同絮凝剂单耗作用下料浆流变参数变化曲线,如图9所示。

由图8可知:当料浆体积分数为15%时,单位面积固体处理量随着单耗增加而增加;当单耗超过25 g/t时,变化率很小。从图9可以看出不同单耗作用下料浆流变特性的变化规律:当单耗小于15 g/t时,屈服应力增大,这是因为随着絮凝剂单耗的增加,底流体积分数增大,使得屈服应力增大,但黏度几乎不变;当单耗为15~25 g/t时,屈服应力和黏度出现先减小后增大现象,并在20 g/t附近出现极小值;当单耗大于25 g/t后,屈服应力和黏度一直增大。其主要原因是过量的絮凝剂导致絮团之间的黏连性增强,同时对絮团表面性质产生一定的影响,恶化全尾砂后期压密脱水过程[16]。这种现象解释了絮凝剂单耗对深锥底流体积分数的影响机理,在一定范围内底流体积分数与絮凝剂单耗成正相关;随絮凝剂的进一步添加,深锥底流体积分数与单耗成负相关。

2.4 实验结果讨论

从对絮凝剂种类、入料体积分数及单耗3个因素实验结果分析,不同的絮凝沉降效果下料浆的流变特征变化明显,并符合后期絮团脱水变化规律。若絮团结构疏松、不规则,浆体屈服应力与黏度大,则絮团对水的吸附作用强,压密脱水困难,造成床层整体体积分数较低,耙架运行不稳定;若絮团形状规则、屈服应力及黏度较小,则絮团结构易于剪切破坏,内部水容易被挤出,压密脱水性能好,后期泥层体积分数上升容易。

表6 实验结果记录及相应单位面积沉降能力

Table 6 Experimental results and the corresponding solid flux

图7 不同单耗作用下流变曲线

Fig. 7 Rheological curves of slurry at different flocculant dosages

图8 单位面积处理量随絮凝剂单耗变化曲线

Fig. 8 Relationship between solid flux and flocculant dosage

图9 不同单耗作用下料浆流变参数变化曲线

Fig. 9 Relationship between rheological parameters and flocculant dosages

全尾砂浓密脱水包括絮凝沉降、压缩脱水两大过程,其中絮凝沉降效率影响后期压密脱水过程,关系到底流最终体积分数以及搅拌剪切阻力等。实验结果表明:基于料浆流变特性的全尾砂絮凝沉降参数的优化方法可行,也可以用作以单位面积固体处理量、底流体积分数作指标的方法补充,并且结果更能体现沉降效果。实验方法简单,避免了很多人为误差。

3 结论

1) 入料体积分数及单耗对絮团结构影响较大,进而影响料浆屈服应力;而絮凝剂种类决定了絮团表面特征,主要影响料浆黏度。实验选定絮凝剂为N123、入料体积分数为15%、絮凝剂单耗25 g/t时絮凝沉降效果最佳,此时屈服应力为15 Pa,黏度为0.1 Pa/s左右,有利于底流料浆后期压密脱水,进一步提高料浆体积分数。

2) 絮凝剂的化学特性决定絮团表面特性。全尾砂在不同种类絮凝剂作用下,料浆的黏度差异较大;在入料体积分数实验中,入料体积分数过低使得底流料浆体积分数偏低,入料体积分数过大造成颗粒间作用力增强,絮团结构较小,不利于全尾砂后期压密脱水;通过絮凝剂单耗实验,解释了絮凝剂单耗对深锥底流体积分数的影响机理,在单耗不足时全尾砂颗粒难以形成蜂窝状的三维结构,絮凝沉降速度慢,而过量的絮凝剂又容易使料浆的屈服应力及黏度增大,深锥底流体积分数低。

3) 絮凝沉降条件影响料浆流变特征,而后期压密脱水及耙架的运行与料浆流变特性密切相关。结合絮凝沉降实验,基于料浆流变特性对全尾砂絮凝沉降参数优化,以屈服应力和黏度评价絮团剪切破坏及压密脱水性能,有利于深锥耙架运行稳定及提高底流体积分数。

参考文献:

[1] 焦华喆, 王洪江, 吴爱祥, 等. 全尾砂絮凝沉降规律及其机理[J]. 北京科技大学学报, 2010, 32(6): 702-707.

JIAO Huazhe, WANG Hongjiang, WU Aixiang, et al. Rule and mechanism of flocculation sedimentation of unclassified tailings[J]. Journal of Science and Technology Beijing, 2010, 32(6): 702-707.

[2] 王洪江, 陈琴瑞, 吴爱祥, 等. 全尾砂浓密特性研究及其在浓密机设计中的应用[J]. 北京科技大学学报, 2011, 33(6): 676-681.

WANG Hongjiang, CHEN Qinrui, WU Aixiang, et al. Study on the thickening properties of unclassified tailings and its application to thickener design[J]. Journal of Science and Technology Beijing, 2011, 33(6): 676-681.

[3] 张钦礼, 周登辉, 王新民, 等. 超细全尾砂絮凝沉降实验研究[J]. 广西大学学报(自然科学版), 2013, 38(2): 451-455.

ZHANG Qinli, ZHOU Denghui, WANG Xinmin, et al. Experimental study on flocculating sedimentation of ultra-fine unclassified tailings[J]. Journal of Guangxi University (Natural Science Edition), 2013, 38(2): 451-455.

[4] 李辉, 王洪江, 吴爱祥, 等. 基于尾砂沉降与流变特性的深锥浓密机压耙分析[J]. 北京科技大学学报, 2013, 35(12): 1643-1648.

LI Hui, WANG Hongjiang, WU Aixiang, et al. Pressure rake analysis of deep cone thickeners based on tailings settlement and rheological characteristics[J]. Journal of Science and Technology Beijing, 2013, 35(12): 1643-1648.

[5] CAMPBELL H W, CRESCUOLO P J. The use of rheology for sludge characterization[J]. Water Science & Technology, 1982, 14(6/7): 475-489.

[6] 黄志斌. 污泥流变性与脱水性能关系的研究[D]. 上海: 东华大学环境科学与工程学院, 2004: 15-66.

HUANG Zhibin. Investigation on The relationship of rheology and dewatering of sludge[D]. Shanghai: Donghua University. School of Environmental Science and Engineering, 2004: 15-66.

[7] ZHAO Y Q,BACHE D H.Conditioning of alum sludge with polymer and gypsum[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2001, 194(1): 213-220.

[8] CHU C P, LEE D J. Moisture distribution in sludge:effects of polymer conditioning[J]. Journal of Environmental Engineering, 1999, 125(4): 340-345.

[9] 王新民, 刘吉祥, 陈秋松, 等. 超细全尾砂絮凝沉降参数优化模型[J]. 科技导报, 2014, 32(17): 23-28.

WANG Xinmin, LIU Jixiang, CHEN Qiusong, et al. Optimal flocculating sedimentation parameters of unclassified tailings[J]. Science & Technology Review, 2014, 32(17): 23-28.

[10] LANGER S, KLUTE R, HAHN H. Mechanisms of floc formation in sludge conditioning with polymers[J]. Water Science and Technology, 1994, 30(8): 129-138.

[11] BESRA L, SENGUPTA D K, ROY S K, et al. Influence of polymer adsorption and conformation on flocculation and dewatering of kaolin suspension[J]. Separation and Purification Technology, 2004, 37(3): 231-246.

[12] DENTEL S K. Evaluation and role of rheological properties in sludge management[J]. Water Science and Technology, 1997, 36(11): 1-8.

[13] 薛向东, 金奇庭, 朱文芳, 等. 超声对污泥流变性及絮凝脱水性的影响[J]. 环境科学学报, 2006, 26(6): 897-902.

XUE Xiangdong, JIN Qiting, ZHU Wenfang, et al. Influence of ultrasound on the rheological characterization and the flocculating dewaterability of sludge[J]. Acta Scientiae Circumstantiae, 2006, 26(6): 897-902.

[14] 刘桂华, 黄亚军, 张明, 等. 表面活性剂对铝土矿选矿尾矿流变性的影响[J]. 矿冶工程, 2009, 29(2): 25-28.

LIU Guihua, HUANG Yajun, ZHANG Min, et al. Influence of surfactants on the rheological properties of bauxite tailings[J]. Mining and Metallurgical Engineering, 2009, 29(2): 25-28.

[15] HU Huiping, ZHANG Kunyu, ZHANG Lijuan, et al. Thermal decomposition behaviour of polyacrylamidomethyltrimethyl ammonium chloride in red mud separation process[J]. Journal of Central South University of Technology, 2008, 15(6): 808-813.

[16] MURTHY S N, NOVAK J T. Influence of cations on activated-sludge effluent quality[J]. Water Environment Research, 2001, 73(1): 30-36.

(编辑 陈灿华)

收稿日期:2015-10-02;修回日期:2015-12-22

基金项目(Foundation item):国家自然科学基金资助项目(51374034);国家“十二五”科技支撑计划项目(2012BAB08B02)(Project(51374034) supported by the National Natural Science Foundation of China; Project(2012BAB08B02) supported by the National Key Technology Research and Development Program of China)

通信作者:王洪江,博士,博士生导师,从事充填采矿、溶浸采矿及岩石力学研究;E-mail: yanghuarong2014@yeah.net