DOI: 10.11817/j.ysxb.1004.0609.2020-37563

全尾砂深锥浓密过程中絮团的动态沉降规律

薛振林1,闫泽鹏1,焦华喆2,甘德清1,张友志1,刘志义1

(1. 华北理工大学 矿业工程学院,唐山 063200;

2. 河南理工大学 土木工程学院,焦作 454000)

摘 要:为了探明全尾砂浆深锥浓密过程中絮团的动态沉降规律,自制连续浓密实验平台开展动态絮凝沉降实验,基于互相关原理和颗粒追踪软件进行数据处理,分析入料速度、耙架搅拌速度及料浆质量分数对絮团沉降行为的影响。结果表明:絮团在竖直方向上受到沉降柱内水体紊动和底部水流回流公共作用导致沉降速度呈逐渐降低的趋势;入料速度、耙架搅拌与水体紊动剪切作用呈正相关,紊动剪切作用较弱时,促进絮团颗粒的凝结,提高絮团沉降速率。反之,则会破坏絮团结构,抑制絮团沉降过程;底部絮团沉降速度与料浆质量分数呈负相关;保持剪切强度在峰值区有利于絮团的快速沉降,本实验条件下建议耙架搅拌速度为0.2~0.6 r/min、入料速度为0.2~0.3 m/s。

关键词:全尾砂;动态絮凝沉降;颗粒追踪;紊动剪切

文章编号:1004-0609(2020)-09-2206-10 中图分类号:TD853 文献标志码:A

近年来社会发展速度加快,矿产资源消耗巨大,地表浅部资源开发越来越困难,国内外矿山开始进行深部开采,高地应力、高地温、高渗透压和开采扰动等问题日益明显[1]。充填采矿法的出现较好的解决了采场地压问题[2],同时降低了地表尾矿的堆存量,具有环境友好、保护远景资源等特点,得到了日益广泛的重视和应用[3]。全尾砂浓密过程是充填工艺中的关键环节[4]。浓密机的底流浓度是衡量浓密效率的标准,而影响底流浓度的重要因素是单位时间内到达底部的絮团数量,也就是絮团的沉降速度。传统的尾砂浓密工艺主要是依靠絮团自身重力在立式砂仓中进行自然沉降,尾砂沉降速度慢浓密效率低,达不到矿山充填的要求[5]。

针对前述问题,国内外学者对影响絮团沉降速度的多种因素进行了研究。KRANENBURG[6]认为水流速度的变化对于黏性颗粒的絮凝沉降具有双重的作用。BIGGS等[7]研究发现水流速度变化引起水体紊动,水体紊动会对絮团结构产生影响,低紊动状态时会促进尾砂颗粒凝结,导致絮团粒径增大。LICK等[8]认为较高浓度下,絮团间会发生剧烈碰撞导致絮团破碎,且絮团沉降速度随着砂浆浓度的增大而减小。柴朝晖等[9]认为絮凝作用是影响絮团沉降的重要因素,并通过实验得到紊动剪切对絮凝影响的临界值。张钦礼等[10-11]采用多种预测模型对絮凝沉降的参数进行优化选择,得出各个参数的最优值。USHER等[12]开发了一种计算絮凝沉降的算法,为固体吞吐量、床层高度和底流固体浓度之间的相互关系提供了理论的支撑。李宗楠等[13]建立了关于絮团沉降的数学模型,研究得出细粒尾矿在垂直砂仓的沉降规律。同时,部分学者对于絮凝沉降的室内实验装置做出一些改进,并开展了相关的研究工作[14]。刘凯等[15]采用量筒进行静置实验来模拟大红山铜矿的絮凝过程,对絮凝剂进行优选。卞继伟等[16]考虑到外部因素对于沉降性能的影响,运用浓密机动态试验装置进行实验,得出了尾砂在不同絮凝剂条件下的沉降规律。王洪江等[17]在普通的浓密机模型上添加了转子导流装置,使得实验模型更加接近于实际情况,通过该装置得出浓密效率与絮凝剂单耗呈正相关。

前述实验大多研究絮团在沉降过程中的静态规律,缺乏深入絮团尺度的细观沉降规律的研究(如絮团在沉降过程中的瞬时速度等),并且大部分以絮凝剂性质为主要变量,缺乏对于料浆外部影响因素的研究,入料速度、耙架搅拌速度等因素对于尾砂沉降的影响不容忽视。本文选用高透光有机玻璃制作沉降柱,添加耙架搅拌装置改进重力浓密实验设备。控制入料速度、给料质量分数、耙架搅拌速度等参数,利用高速相机记录絮团的沉降过程,基于互相关理论对实验图像进行计算,得到絮团在沉降过程中的瞬时速度与矢量分布,并通过颗粒追踪软件对单个絮团的沉降轨迹进行追踪记录,进而探究在絮团浓密过程中的动态沉降规律,为矿山的充填环节提供理论依据。

1 实验

1.1 实验原理

在全尾砂重力浓密过程中,絮团沉降是一个连续的动态行为,对于絮团的沉降过程采用高速摄像机进行记录,图片间隔时间小于1 ms。互相关算法主要是通过识别相邻图像上絮团颗粒的位移对絮团的沉降速度进行计算(见图1)。

图1 互相关计算示意图

Fig. 1 Cross-correlation calculation diagram

由于每张图像中都记录了大量絮团,如何识别两张图像上的相关絮团是本次实验结果处理过程中的难点。为了解决这一问题,引入了絮团相关程度的计算公式,公式如下:

(1)

(1)

式中:f、g分别表示相邻图像中的絮团颗粒;(m, n)、(i, j)表示絮团颗粒在图像中的相对位置;X表示絮团颗粒的相关程度。

互相关算法是以被搜寻的絮团颗粒与待匹配颗粒絮团之间的差异为相似性指标,搜寻最佳的匹配颗粒。该方法通过大量的乘法与求和计算每一个移动点g(m+i, n+j)的相关系数,当f与g达到最相似时,相关系数X(m, n)为最大值,此时认为其表示的是同一个絮团颗粒[18],由此可以得出絮团的相对位移Δx、Δy,同时又已知时间间隔Δt,可以计算絮团的沉降速度v:

(2)

(2)

由于两幅相邻图像时间间隔Δt小于1 ms,所以认为v表示絮团沉降过程中的瞬时速度。

1.2 实验材料

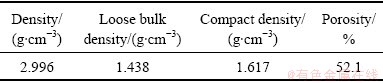

实验材料选择的是甘肃某矿全尾砂,使用的絮凝剂为XJTH,属于高分子聚丙烯酰胺絮凝剂。尾砂的堆密度采用容量瓶法进行测定,结合比重和堆密度计算其在松散状态下的孔隙率。该尾砂具体物理性质如表1所列。

表1 全尾砂的基本物理性质

Table 1 Basic physical properties of total tailings

本次实验通过筛分来确定尾砂级配。主要是测定出存留在各个筛上的集料的质量,然后根据集料试样的质量与存留在各筛孔尺寸的集料质量进行计算。得出该全尾砂粒径为74 μm的颗粒含量达到87.4%;粒径为37 μm的颗粒含量68.36%。粒径分布曲线如图2所示。

图2 全尾砂粒级分布

Fig. 2 Full tail sand level distribution

1.3 实验设备

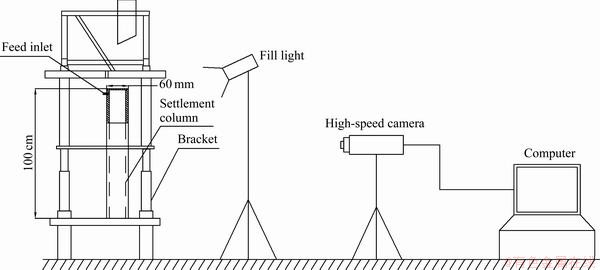

本文自制浓密过程絮团运移探测系统,其结构如图3所示。该平台可模拟浓密机运行时的实际情况,控制入料速度与耙架转动速度(耙架位置位于沉降柱正中心)。同时,配备高速摄像系统,用于获取连续浓密过程中絮团的沉降轨迹及絮团沉降速度等关键参数及其随时间的变化规律。

图3 试验平台结构示意图

Fig. 3 Schematic diagram of test platform structure

1.4 实验方案

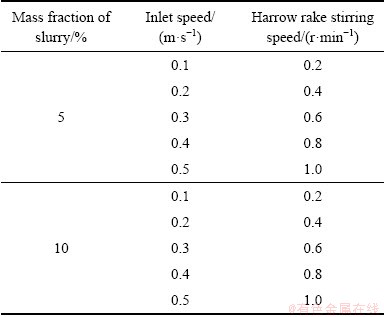

本实验选择入料速度、给料浓度、耙架搅拌速度为影响因素。通过前期实验对砂浆浓度和絮凝剂溶液进行优选,确定絮凝剂溶液浓度为0.01%、絮凝剂单耗为30 g/t。实验方案见表2。

表2 实验方案表

Table 2 Experimental plan table

1.5 实验过程

1) 按实验方案称重尾砂、絮凝剂、水,制备10%和5%的砂浆与0.01%的絮凝剂溶液(质量分数),充分搅拌后备用。

2) 连接小型实验平台上的各个设备,调试高速相机,设置合适参数,调整镜头长宽,使其能够拍摄完整的沉降柱。

3) 打开给料泵输送料浆,按照前述方案进行实验,利用高速相机对各种条件下的沉降过程进行高速摄像,内容包括:全范围摄像,为沉降轨迹的追踪提供数据基础;分阶段进行摄像,获取絮团沉降行为的细节。每组试验等放料速度稳定后拍摄10 s,得到约3000张bmp格式的图片。

4) 处理实验图像结果。每组试验数据选取中间时段2000张连续的图像进行区域选取、灰度拉伸等处理后计算生成速度矢量图像。

2 结果与讨论

2.1 垂直方向上各水平絮团沉降规律

絮团的沉降规律最终影响着出料浓度,由于出料口在沉降柱的右下方区域,为了对出料口附近絮团的沉降规律进行针对性的分析,本部分内容主要对沉降柱各个水平的右下方区域进行研究。本次实验将沉降柱划分为4个水平,分别截取不同水平的数据图像进行数值计算,获得了垂直方向上絮团的沉降轨迹和速度变化情况,见图4(以vr=0.1 m/s,n=0.2 r/min,10%浓度为例),速度矢量图中的箭头方向表示稳定状态下絮团沉降的平均方向。由于本次实验采用高速相机进行记录,受光照条件的影响造成各个阶段亮度不均衡。经前期实验验证,数据图像的明暗程度并不会影响最终数据的处理结果。

图4 垂直方向个水平絮团沉降规律

Fig. 4 Migration law of horizontal floc in vertical direction

由图4可以看出,当料浆由进料口进入到沉降柱后絮团速度整体呈现下降趋势。当进入第1水平时絮团运动轨迹呈“喷射状态”,由于入料口与沉降柱夹角为90°,絮团以抛物线形式下降,由于受到沉降柱内水体阻力的影响,不同絮团运动的速度不同,进入沉降柱后开始扩散,称絮团此时的运动状态为“喷射状态”。在入料口附近絮团迅速下降,絮团沉降方向指向右下方,絮团沉降的最大速度在此水平,达到0.06 m/s,而在远离入料口端絮团的沉降速度几乎为0。在第2水平内絮团运动进入稳定期,絮团保持较高的沉降速度,沉降方向指向下方,此时沉降速度保持在0.4~0.055 m/s之间。第3水平内絮团沉降速度减小至0.03 m/s,沉降方向向右下方偏移。第4水平内,沉降速度逐渐减小直至沉降到底部。单个絮团颗粒的轨迹追踪图也进一步表明,通过互相关方法计算的各水平的沉降规律絮团实际沉降规律相符。

经分析可知,当尾砂以“喷射状态”进入到沉降柱时,引发沉降柱内水体紊动,在经过剧烈的碰撞与结合后,絮团自身重量增大。絮团整体加速度由重力加速度和阻力加速度控制,此过程内絮团自身重力加速度大于所受阻力加速度,絮团沉降速度缓慢增加,所以第1水平内沉降速度极值出现。当絮团经过“2水平”后,此时絮团间沉降速度相差较小,絮团的重力加速度和运动阻力之间存在如下关系:

(3)

(3)

式中:dV/dT为絮团的总加速度,m/s2;g0为絮团的下降加速度,m/s2;R为絮团颗粒的运动阻力,m/s2;ρs和ρ1分别为絮团和水的密度,kg/m3;v为絮团沉降速度,m/s2; 为阻力系数。

为阻力系数。

由絮凝沉降模型(见式(3))可知[19] ,当v足够大时,总加速度变为负值,絮凝沉降过程受到阻碍,紊动能量减弱,沉降速度降低。当其在3水平、4水平时,由于絮团大小不一,絮团之间沉降速度存在差异,出现明显的速度梯度,速度大的絮团会先沉降至底部,但是沉降柱底部空间有限,固体颗粒体积的增加引起底部水流上升,当其他絮团与上升水流相遇时,絮团所受阻力增大。同时,由于絮团的沉降过程造成底部浓度增大,增加了絮团之间的碰撞概率促进了絮团结构的破碎过程。在上述两种情况的同时作用下,出现了絮团颗粒沉降速度先增大后减小的现象。

2.2 入料速度对絮团沉降速度的影响

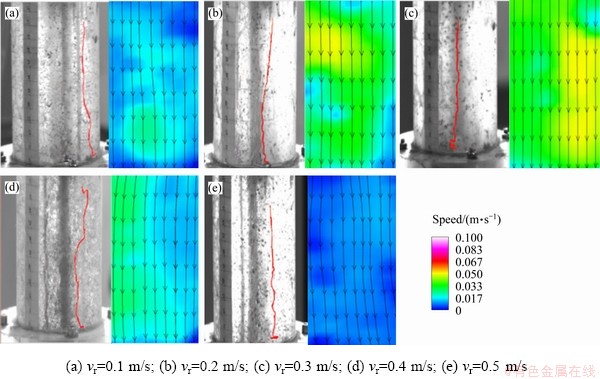

尾砂在浓密机的浓密过程中,入料速度是比较容易控制的条件,其对絮团沉降速度有较大的影响。同时,底部的沉降速度影响着最终的底流浓度,并且与压耙等事故的发生息息相关,所以本部分以入料速度为变量着重研究第4水平絮团的沉降规律。选取耙架搅拌速度n=0.2 r/min、料浆质量分数为5%的数据进行分析。其对絮团沉降行为的影响如图5所示。

图5表明改变入料口速度对于絮团沉降的方向影响不大,速度方向指向沉降柱底部,但入料口速度的增大会引发底部速度一致性变化,通过单絮团沉降轨迹可知,絮团沉降过程中会发生左右波动,且随着入口速度增大波动幅度增大。入料速度对底部絮团沉降速度的大小有显著影响,当入料口速度由0.1 m/s上升值0.3 m/s时,底部沉降速度随着入料速度增加而增大;在入料口速度为0.3 m/s时,沉降速度达到最大值0.065 m/s;当入料口速度由0.3 m/s增大至0.5 m/s时,底部絮团沉降速度反而降低。

沉降速度v主要和絮团直径有关,与粒径的平方成正比[20]。絮凝沉降过程中絮凝剂形成高分子链静电中合或者吸附尾砂颗粒,形成粒径较大的絮团[21]。但是,当絮凝剂所形成的高分子链受到的外力大于它自身的结构力时,会导致高分子链断裂,从而使得絮团变小、沉降速度下降,所以沉降速度还与受力Fp有关。研究表明,Fp与粒径df与絮团速度u0呈如下关系:

(4)

(4)

式中:Fp为絮团在紊动水体中所受的力,N;df为絮团粒径,mm; 和

和 分别为絮团和水的密度,kg/m3;u0为絮团切向速度,m/s。

分别为絮团和水的密度,kg/m3;u0为絮团切向速度,m/s。

由式(4)可以看出,Fp与絮团切向速度的平方成正比,与粒径的三次方成正比(Fp为絮团所受到紊动涡旋的离心力,在此认为其与絮团所受到的剪切作用力相当)。当入料速度u0较小时,沉降柱内的水体紊动剪切作用力不足以破坏絮团结构,反而促进絮团在沉降的过程中的碰撞、凝结,使得絮团颗粒变大。此时水体紊动剪切作用有益于絮团的沉降过程,且随着紊动剪切增大絮团沉降的时间缩短。由于低紊动剪切的促进作用絮团颗粒的凝结,使得粒径df缓慢增大,所以当入料速度持续增大时,导致Fp迅速增大直至超过高分子链所能承受的最大值,絮凝剂高分子链不足以继续维持絮团的结构,导致其分散成为较小的絮团颗粒,沉降速度明显下降。

图5 入料速度对絮团沉降速度的影响

Fig. 5 Effect of feed rate on flocculation settling velocity

2.3 耙架搅拌速度对絮团沉降速度的影响

由絮凝动力学可知[22],耙架搅拌速度对絮团沉降速度和浓密效率有着重要的影响,但是过高或者过低的耙架搅拌速度都会抑制絮团的沉降速度,对深锥浓密的过程产生不利的作用。因此,本部分着重研究耙架搅拌速度对絮团沉降的影响规律。选取入料速度0.2 m/s、料浆质量分数为5%的数据进行分析,实验结果如图6所示。

结果表明,絮团在沉降柱中沉降时絮团沉降速度的方向受耙架搅拌速度改变的影响较小,可以看出沉降速度方向均指向沉降柱的底部且左侧距离耙架位置相对较近区域絮团的沉降速度明显大于其他区域的;由絮团的沉降轨迹可以看出,当耙架搅拌速度较低时絮团沉降轨迹基本上呈直线下降,随着耙架搅拌速度的升高絮团的沉降轨迹开始有大幅度的波动,但是絮团最后均沉降到底部。沉降速度随着耙架搅拌速度先升高后降低,耙架搅拌速度较低时絮团的沉降速度与耙架搅拌速度呈正相关,当其达到0.4 r/min时,絮团沉降速度达到最大0.07 m/s;此后随着耙架搅拌速度的持续提升可以看出絮团沉降速度明显下降,当耙架搅拌速度提升至最大1.0 r/min时絮团沉降速度减小为0.036 m/s。

分析可知,适当的耙架搅拌会增加絮团间的碰撞概率,促进絮团的相互凝结。当采用耙架搅拌时,造成水流紊动且紊动程度与耙架搅拌速度正相关。由前述分析易知,水体紊动会产生剪切作用力Fp,当耙架搅拌速度较低时Fp不足以破坏絮团的结构,此时水体紊动促进絮团凝结,有利于絮凝沉降过程;靠近耙架区域水体受耙架搅拌作用的影响较大,使得矢量图上出现了左侧速度大于右侧的现象。耙架转速过快时,水体紊动剧烈,会破坏絮团结构、抑制絮团的凝结,从而导致絮团沉降速度降低。

2.4 料浆质量分数对絮团沉降的影响

根据两相流沉降理论,多颗粒进行沉降时,彼此之间会产生影响。全尾砂浓密效率与底流浓度密切相关,而给料浓度对底流浓度影响较大,因此本部分主要研究给料浓度对底部絮团沉降速度的影响规律。选取入料速度为0.2 m/s、耙架搅拌速度为0.2 r/min的数据进行对比分析,实验结果如图7所示。

由实验结果看出,料浆质量分数10%时絮团颗粒较大,且絮团分布较为密集。料浆质量分数为5%时絮团的速度方向基本呈垂直状态指向底部,最大沉降速度达到了0.051 m/s,左侧速度略微大于右侧,沉降轨迹相对平稳可以看出颗粒间的碰撞结合概率较低;当料浆质量分数为10%时,絮团颗粒沉降速度的方向有一些波动但是最终其方向都是指向底部,左侧沉降速度大于右侧,沉降速度最大值为0.27 m/s,由沉降轨迹可以看出该浓度状态下,絮团体积明显大于前一组实验,絮团碰撞结合后最终沉降到沉降柱底部。

图6 耙架搅拌速度对絮团沉降速度的影响

Fig. 6 Effect of truss stirring speed on flocculation sedimentation velocity

图7 料浆质量分数对絮团沉降速度的影响

Fig. 7 Effect of mass fraction of slurry on flocculation settling velocity

经分析,由于选取的研究区域为沉降柱最底端的水平,经过一段时间的絮凝沉降之后底部絮团颗粒的浓度远远大于给料时的浓度,单位体积空间内的絮团颗粒较多,絮团之间的距离相对较近,由于絮凝剂分子链的静电吸附作用,不同絮团之间形成絮团网状结构,出现“制约沉降(Hindered settling)”现象[23]。同时,由于不同絮团间的结合力较小,当期受到耙架搅拌产生的剪切作用力时,絮网结构会发生破坏,靠近耙架的一侧絮网结构产生的阻力较小,导致絮团的沉降速度随着尾砂浓度的增大呈减小且左侧速度大于右侧的趋势。

2.5 絮团沉降速度与剪切强度关系

由上述分析可知,入料和耙架搅拌均会引发沉降柱内水体紊动产生剪切力,导致絮团结构发生变化,从而引起絮团沉降速度的改变。在实验过程中发现,随着剪切强度的持续增加,絮团沉降速度先增大后减小,存在一临界剪切强度使得絮团达到最大沉降速度。这种临界行为与COUFORT等[24]和DYER等[25]的研究成果具有很好的一致性。通过分析后发现絮团的沉降速度与剪切强度间符合如下关系,如图8所示。

图8 沉降速度模型

Fig. 8 Settlement velocity model

图中,A~B阶段为沉降速度上升区。沉降速度随剪切强度升高而快速升高,此时水体紊动产生的剪切作用力小于絮团本身(或者絮凝剂分子链)的结构强度,水体紊动剪切作用促进絮团之间碰撞与粘结有利于絮凝沉降过程。可对应耙架搅拌速度为0~0.2 r/min、入料速度为0.1~0.2 m/s的实验条件。B~F阶段为速度峰值区。此时沉降速度达到峰值,水体紊动产生的剪切力大于絮凝剂分子链的结构强度,但是由于水体紊动强度较弱絮团形成的速率和紊动剪切破坏的速率相差不大,此时絮团的总体加速度为正值,絮团的沉降速度在缓慢的增加,在此过程内絮团沉降速度达到最大值且最有利于絮团沉降过程。对应耙架搅拌速度为0.2~0.6 r/min、入料速度为0.2~0.4 m/s时的实验条件。F~D阶段为沉降速度下降区,水体紊动产生的剪切力远远大于絮凝剂分子链的结构强度,絮团形成的速率和紊动剪切破坏的速率相差很大,絮团被破坏,此过程内絮团沉降速度快速减小。对应耙架搅拌速度为0.6~1.0 r/min、入料速度为0.4~0.5 m/s的实验条件。D~E阶段为稳定区。由于絮凝剂分子链结构强度和剪切强度之间相差极大,絮团的成形速度远远不及絮团破坏的速度。此时絮凝剂难以起到有效的絮凝作用,尾砂颗粒自身重力小于所受的阻力,所以此过程内沉降速度持续减小。对应耙架搅拌速度大于1.0 r/min、入料速度大于0.5 m/s的实验条件。当剪切强度处于B~F段时对絮团的沉降最为有利,此时耙架搅拌速度范围为0.2~0.6 r/min,入料速度范围为0.2~0.3 m/s。

3 结论

1) 絮团在垂直方向上沉降速度呈现先升高后降低的现象。絮团颗粒受到入料口与沉降柱结合区域水体紊动的影响,絮团颗粒间碰撞凝结此时总加速度变为正值,絮团沉降速度缓慢增加;当絮团沉降至装置底部时,由于受到装置底部水流回旋上升产生的阻力与底部浓度增大所造成絮团间碰撞的共同作用,沉降速度开始下降。

2) 絮团沉降速度随入料速度和耙架搅拌速度的增大而先上升后下降。入料和耙架搅拌会改变沉降柱内部水体的紊动剪切作用力且与剪切强度呈正相关,当紊动剪切作用较弱时,前述两种因素的变化对絮团沉降速度起到促进作用;当水体紊动剪切作用超过絮凝剂分子链的结构强度时,会破坏絮团的结构,抑制絮凝沉降过程。

3) 底部絮团沉降速度与给料质量分数呈负相关。底部浓度过大会造成不同絮团相互组合形成絮团网状结构,使得其所受阻力增大从而导致絮团沉降速度的降低。

4) 控制剪切强度使得沉降速度达到峰值区时有利于絮团的快速沉降。本实验条件下,建议最佳耙架搅拌速度范围为0.2~0.6 r/min,最佳入料速度范围为0.2~0.3 m/s。

REFERENCES

[1] 李夕兵, 周 健, 王少锋, 刘 冰. 深部固体资源开采评述与探索[J]. 中国有色金属学报, 2017, 27(6): 1236-1262.

LI Xi-bing, ZHOU Jian, WANG Shao-feng, LIU Bing. Review and practice of deep mining for solid mineral resources[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(6): 1236-1262.

[2] ESWARAIAH C, BISWAL S K, MISHRA B K. Settling characteristics of ultrafine iron ore slimes[J]. International Journal of Minerals, Metallurgy and Materials, 2012, 19(2): 95-99.

[3] 于润沧. 我国胶结充填工艺发展的技术创新[J]. 中国矿山工程, 2010, 39(5): 1-3, 9.

YU Run-cang. Development and innovation of cemented filling technology in China[J]. China Mine Engineering, 2010, 39(5): 1-3, 9.

[4] 陈秋松, 张钦礼, 王新民, 肖崇春, 徐 丹. 磁化水改善全尾砂絮凝沉降效果的试验研究[J]. 中南大学学报(自然科学版), 2015, 46(11): 4256-4261.

CHEN Qiu-song, ZHANG Qin-li, WANG Xin-min, XIAO Chong-chun, XU Dan. Experimental study on effect of magnetized water on flocculating sedimentation of unclassified tailings[J]. Journal of Central South University (Science and Technology), 2015, 46(11): 4256-4261.

[5] 郭 超, 何 青. 长江中下游洪枯季泥沙絮凝研究[J]. 泥沙研究, 2014(5): 59-64.

GUO Chao, HE Qing. Comparison study on flocculation between flood and dry season in Yangtze River[J]. Journal of Sediment Research, 2014(5): 59-64.

[6] KRANENBURG C. Effects of floc strength on viscosity and deposition of cohesive sediment suspensions[J]. Continental Shelf Research, 1999, 19(13): 1665-1680.

[7] BIGGS C A, LANT P A. Activated sludge flocculation: on-line determination of floc size and the effect of shear[J]. Water Research, 2000, 34(9): 2542-2550.

[8] LICK W, LICK J. Aggregation and disaggregation of fine-grained lake sediments[J]. Journal of Great Lakes Research, 1988, 14(4): 514-523.

[9] 柴朝晖, 方红卫, 王 茜, 刘同宦, SONG Yun-hao. 水流和电解质对黏性泥沙絮凝沉降影响试验[J]. 水科学进展, 2017, 28(2): 285-292.

CHAI Zhao-hui, FANG Hong-wei, WANG Qian, LIU Tong-huan, SONG Yun-hao. Effect of flow and electrolyte on the flocculation-settling of cohesive sediment[J]. Advances in Water Science, 2017, 28(2): 285-292.

[10] 张钦礼, 刘 奇, 赵建文. 全尾砂絮凝沉降参数预测模型研究[J]. 东北大学学报(自然科学版), 2016, 37(6): 875-879.

ZHANG Qin-li, LIU Qi, ZHAO Jian-wen. Study on the parameters prediction model of flocculating sedimentation of crude tailings[J]. Journal of Northeastern University (Natural Science), 2016, 37(6): 875-879.

[11] 张钦礼, 王 石, 王新民. 絮凝剂单耗对全尾尾砂浑液面沉速的影响规律[J]. 中国有色金属学报, 2017, 27(2): 318-324.

ZHANG Qin-li, WANG Shi, WANG Xin-min. Effect of single consumption of flocculant on the sinking speed of the whole tail mortar[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(2): 318-324.

[12] USHER S P, SCALES P J. Steady state thickener modelling from the compressive yield stress and hindered settling function[J]. Chemical Engineering Journal, 2005, 111(2/3): 253-261.

[13] 李宗楠, 郭利杰, 许文远, 史采星. 极细粒级尾砂絮凝沉降规律试验研究[J]. 中国矿业, 2014, 23(S2): 215-218.

LI Zong-nan, GUO Li-jie, XU Wen-yuan, SHI Cai-xing. Experimental study on flocculation sedimentation of fine tailings[J]. China Mining Magazine, 2014, 23(S2): 215-218.

[14] 刘晓辉, 吴爱祥, 王洪江, 严庆文, 容 苡. 膏体充填尾矿浓密规律初探[J]. 金属矿山, 2009(9): 38-41.

LIU Xiao-hui, WU Ai-xiang, WANG Hong-jiang, YAN Qing-wen, RONG Yi. A primary discussion on the thickening law of paste-filling[J]. Metal Mine, 2009(9): 38-41.

[15] 刘 凯, 黄德镛, 张明旭, 吴东旭. 大红山铜矿全尾砂絮凝沉降的试验研究[J]. 中国矿业, 2008, 17(12): 60-63.

LIU Kai, HUANG De-yong, ZHANG Ming-xu, WU Dong-xu. Experimental study on all tailings flocculation settiling in Dahongshan cooper mine[J]. China Mining Magazine, 2008, 17(12): 60-63.

[16] 卞继伟, 王新民, 肖崇春. 全尾砂动态絮凝沉降试验研究[J]. 中南大学学报(自然科学版), 2017, 48(12): 3278-3283.

BIAN Ji-wei, WANG Xin-min, XIAO Chong-chun. Experimental study on dynamic flocculating sedimentation of unclassified tailings[J]. Journal of Central South University (Science and Technology), 2017, 48(12): 3278-3283.

[17] 王洪江, 陈琴瑞, 吴爱祥, 翟永刚, 张新普. 全尾砂浓密特性研究及其在浓密机设计中的应用[J]. 北京科技大学学报, 2011, 33(6): 676-681.

WANG Hong-jiang, CHEN Qin-rui, WU Ai-xiang, ZHAI Yong-gang, ZHANG Xin-pu. Study on the thickening properties of unclassified tailings and its application to thickener design[J]. Journal of University of Science and Technology Beijing, 2011, 33(6): 676-681.

[18] GAD H M, IBRAHIM I A, ABDEL-BAKY M E, ABD E A, FARAG T M. Experimental study of diesel fuel atomization performance of air blast atomizer[J]. Experimental Thermal and Fluid Science, 2018, 99: 211-218.

[19] 焦华喆, 王洪江, 吴爱祥, 吉学文, 严庆文, 李 祥. 全尾砂絮凝沉降规律及其机理[J]. 北京科技大学学报, 2010, 32(6): 702-707.

JIAO Hua-zhe, WANG Hong-jiang, WU Ai-xiang, JI Xue-wen, YAN Qing-wen, LI Xiang. Rule and mechanism of flocculation sedimentation of unclassified tailings[J]. Journal of University of Science and Technology Beijing, 2010, 32(6): 702-707.

[20] 王桂连. 斯托克斯法测量液体黏度设计实验的研究[J]. 医学信息, 2007(3): 408-409.

WANG Gui-lian. Study on design experiment of measuring viscosity of liquid by stokes method[J]. Medical Information, 2007(3): 408-409.

[21] 刘清侠, 单忠健. “架桥”絮凝模型的高分辨电镜观察[J]. 矿冶工程, 1991(2): 40-42.

LIU Qing-xia, SHAN Zhong-jian. High-Resolution microscopic observation of a “bridging” flocculation model[J]. Mining and Metallurgical Engineering, 1991(2): 40-42.

[22] 唐海香, 庞鼎峰, 吴大为. 动力学因素对煤泥水絮凝沉降效果的影响[J]. 煤炭工程, 2006(8): 78-80.

TANG Hai-xiang, PANG Ding-feng, WU Da-wei. Dynam ics factor affected to flocculation settling results of slmie[J]. Coal Engineering, 2006(8): 78-80.

[23] ASENSI E, ALEMANY E, SECO A, FERRER J. Characterization of activated sludge settling properties with a sludge collapse-acceleration stage[J]. Separation and Purification Technology, 2019, 209: 32-41.

[24] COLOMER J, PETERS F, CELIA M. Experimental analysis of coagulation of particles under low-shear flow[J]. Water Research, 2005, 39(13): 2994-3000.

[25] ANSI S A, DYER K R, HUNTLEY D A. Measurement of the influence of salinity on floc density and strength[J]. Geo-Marine Letters, 1991, 11(3/4): 154-158.

Dynamic settlement law of flocs during unclassified tailings in deep cone thickening process

XUE Zhen-lin1, YAN Ze-peng1, JIAO Hua-zhe2, GAN De-qing1, ZHANG You-zhi1, LIU Zhi-yi1

(1. School of Mining Engineering, North China University of Science and Technology, Tangshan 063000, China;

2. School of Civil Engineering, Henan Polytechnic University, Jiaozuo 454000, China)

Abstract: In order to explore the dynamic settlement behavior of flocs in the deep cone thickening process of unclassified tailings slurries, dynamic flocculation sedimentation experiments were carried out based on a self-made apparatus. And the effects of inlet speed, harrow rake stirring speed and mass fraction of slurry on flocculation settlement behavior were analyzed by the cross-correlation theory. The results indicate that the settlement velocity of flocs decreases gradually in the vertical direction, which is caused by the flow turbulence and backflow at bottom. Both inlet speed and harrow rake stirring are positively correlated with the turbulent shear force. When the turbulent shearing is low, the flocculation sedimentation rate increases. On the contrary, the floc structure is destroyed and the flocculation sedimentation is suppressed. The settlement velocity of bottom flocs is negatively correlated with mass fraction of slurry. The shear strength at peak area is beneficial to the settlement of flocs. It is recommended that the mixing speed of rake rack is 0.2-0.6 r/min and the inlet speed is 0.2-0.3 m/s.

Key words: unclassified tailings; dynamic flocculation sedimentation; particle tracking; turbulent shear rate

Foundation item: Projects(51774137, 51804121) supported by the National Science Foundation of China

Received date: 2019-07-09; Accepted date: 2020-06-23

Corresponding author: JIAO Hua-zhe; Tel: +86-18439113018; E-mail: jiaohuazhe@126. com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51774137,51804121)

收稿日期:2019-07-09;修订日期:2020-06-23

通信作者:焦华喆,讲师,博士;电话:18439113018;E-mail:jiaohuazhe@126. com