文章编号:1004-0609(2017)-02-0392-07

全尾砂料浆磁化絮凝沉降特性

柯愈贤,王新民,张钦礼

(中南大学 资源与安全工程学院,长沙 410083)

摘 要:为了提高全尾砂料浆(CTR)的絮凝沉降指标,将磁化处理技术引入到全尾砂料浆沉降试验中,分析自然沉降、磁化沉降、絮凝沉降和磁化絮凝沉降4种条件下全尾砂料浆沉降速度和底流质量浓度的变化特性,探索磁化处理在全尾砂料浆絮凝沉降中的作用机理。结果表明:与未经磁化处理的全尾砂料浆相比,磁化处理后的全尾砂料浆沉降指标达到饱和时,PAC添加量节约40%;相同PAC添加量下,磁化处理后的全尾砂料浆沉降速度提高18~55 cm/h、底流浓度提高约0.8%~2.0%。全尾砂料浆磁化絮凝沉降的最优条件为:磁感应强度0.2 T,料浆速度2 m/s,磁化时间2 min,PAC添加量30 g/t;适合磁化处理条件下,对全尾砂料浆进行磁化处理可明显提高其沉降指标。

关键词:全尾砂;絮凝沉降;磁化处理;磁化机理

中图分类号:X753 文献标志码:A

矿业正面临两大难题:地表尾砂废石灾害化和资源开深部化[1-2]。目前业内学者普遍认为解决上述两大难题的最理想方法是采用全尾砂充填采矿法,将尾砂回填至井下采空区[3-5]。但是随着选矿技术的发展,选矿厂排出的尾砂粒度越来越细,直接造成尾砂在砂仓或浓密机中沉降速度缓慢,放砂浓度低,充填料浆浓度难以提高,充填体强度进而难以提高;同时还造成溢流水浑浊,难以达到工业水重复利用或排放标准,浪费水资源,污染环境。针对上述问题,国内外相关研究主要集中在添加絮凝剂上,絮凝沉降技术也因其操作简便、效果好等优点得到了广泛应用[6-9]。然而,絮凝剂的添加不仅增加了采矿成本,还会对充填体的强度带来不利影响,从一定程度上限制了全尾砂充填的全面推广应用。

工业污水处理[10-11]、空气防尘除霾[12]、油田防蜡降黏[13]等领域研究表明,较强磁场下对水溶液进行磁化处理,可增强水的物化活性,减小溶液中固体颗粒表面的水化膜厚度和ζ电位值,促进水溶液中的固液分离。因此,本文作者将磁化处理技术引入到全尾砂料浆(CTR)沉降试验中,分析自然沉降、磁化沉降、絮凝沉降和磁化絮凝沉降4种条件下全尾砂料浆沉降速度和底流质量浓度(以下简称底流浓度)的变化特性,揭示全尾砂料浆磁化处理的作用机理,以期为全尾砂料浆的沉降提供一种经济、高效的新工艺。

1 实验

1.1 试验材料与设备

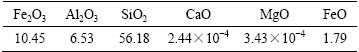

1) 全尾砂,取至某铁矿选厂尾砂排放口,其主要化学成分见表1,粒级组成见图1。从图1可知,74 μm以下颗粒质量所占比例达67.73%,中值粒径(d50)仅为32 μm,全尾砂粒度很细。根据絮凝沉降理论,全尾砂颗粒粒径越小,其所受的浮力与黏滞力越大,越难沉降澄清。

2) 絮凝剂,选用矿山目前使用效果较好的聚合氯化铝(PAC)。

3) 磁化处理设备,采用中科院特制的试验专用的可变永磁式磁水器,磁水器内的磁感应强度采用SG-4L型高灵敏数字特斯拉计测定。

表1 全尾砂的主要化学成分

Table 1 Primary chemical composition of crude tailings (mass fraction, %)

图1 全尾砂粒级组成

Fig. 1 Particle size distribution of crude tailings

1.2 试验方法

1) 全尾砂料浆制备,用自来水和全尾砂配置量浓度为15%的料浆(矿山选厂排出的全尾砂料浆浓度约为10%~20%,试验中取平均值)。

2) PAC絮凝剂溶液制备,在1000 mL的烧杯中配置质量浓度为1%的絮凝剂溶液并充分搅拌均匀。

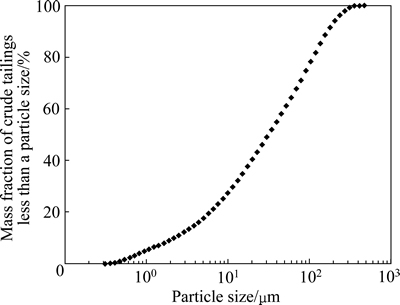

3) 磁化料浆制备(见图2),取部分配置好的质量浓度为15%的全尾砂料浆进行磁化处理,本组试验主要是为了探究磁化处理对全尾砂料浆沉降效果的影响,故磁感应强度设置为0.2 T,料浆速度为2 m/s,磁化时间为2 min。

图2 全尾砂料浆磁化处理示意图

Fig. 2 Schematic diagram of magnetizing CTR

4) 全尾砂沉降试验,依次用1000 mL的量筒取4份全尾砂料浆(2份为经过磁处理料浆,2份为未经过磁处理的料浆),分别进行自然沉降、磁化沉降、絮凝沉降(PAC添加量为20g/t)和磁化絮凝沉降(PAC添加量为20 g/t)试验,记录不同时间点对应的固液分界面高度以及3 d后的固液分界面高度。

2 结果与分析

2.1 沉降速度

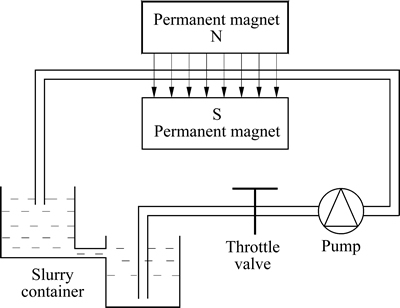

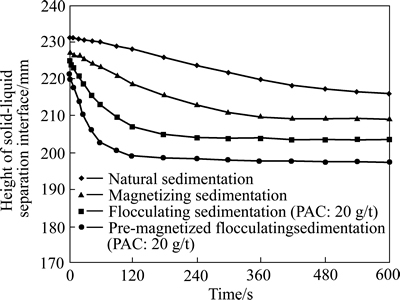

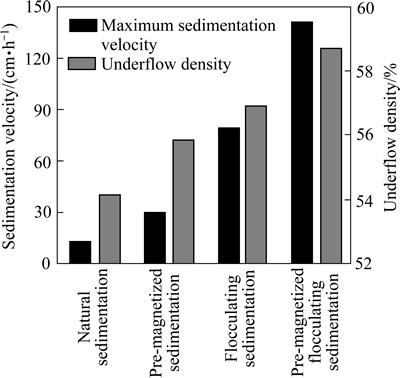

自然沉降、磁化沉降、絮凝沉降和磁化絮凝沉降4种条件下全尾砂料浆固液分界面高度的变化如图3所示,根据图3计算的全尾砂最大沉降速度见图4。

图3 固液分离界面高度变化曲线

Fig. 3 Change curves of solid-liquid separation interface height

图4 全尾砂的最大沉降速度和底流浓度

Fig. 4 Maximum sedimentation velocity and underflow density of crude tailings

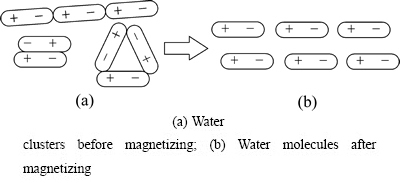

从图4中可知:1) 与自然沉降相比,磁化沉降的最大沉降速度大幅提高,其最大沉降速度为30.15 cm/h,较自然沉降的13.07 cm/h增加了2.31倍;2) 与絮凝沉降相比,磁化絮凝沉降的最大沉降速度也有较大增加,其最大沉降速度为141.57 cm/h,较絮凝沉降的80.21 cm/h增加了1.76倍。这主要是因为:1) 全尾砂料浆经过较强磁场时,洛仑兹力使料浆中较大极性水分子团中的水分子重新排列,原来较大的水分子团变成了较小的水分子团或者单个水分子(见图5),同时洛仑兹力也使水分子中氢键发生松弛并断裂,减小了水的黏度和表面张力,增强了水的活性,减小了全尾砂颗粒间的斥力,加速了全尾砂颗粒的沉降[8, 14-15];2) 全尾砂料浆经过较强磁场时,料浆中悬浮固体颗粒表面的吸附水层和类晶体结构被破坏,减小了固体颗粒表面的水化膜厚度和ζ电位值,固体颗粒变得不稳定,相互接触粘合加速沉降[16]。

图5 磁场对水分子的作用

Fig. 5 Effect of magnetic field on water molecules

2.2 底流浓度

底流浓度取静水极限质量浓度,即全尾砂料浆沉降达到一定时间后(本次试验取3 d),固液分界面不再下降,全尾砂沉降至极限状态时的质量浓度,其计算公式如下:

(1)

(1)

式中:wd为底流浓度,%;ms为全尾砂的质量,g;Mw为水的总质量,g;mw为上层澄清水的质量,g。

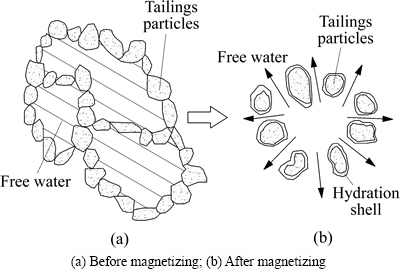

通过式(1)计算的4种沉降条件下全尾砂的底流浓度如图4所示,从图4中可知:1)与自然沉降相比,磁化沉降的底流浓度增大了2.19%,增幅为4.72%;2) 与絮凝沉降相比,磁化絮凝沉降的底流浓度增大了1.79%,增幅为3.14%。这主要是因为:1) 如前所述,全尾砂料浆经过较强磁场处理后,水的黏度和表面张力减小,料浆沉降区封闭的水更容易排出,提高了底流浓度;2) 全尾砂料浆经过较强磁场处理后,料浆中原本较大的全尾砂团状或絮状颗粒在洛仑兹力定向作用下分解重排,其中包裹的“自由水”得以释放,全尾砂颗粒中包裹的“自由水”减少(见图6),增大了底流浓度[17-18]。

图6 磁场对全尾砂颗粒的作用

Fig. 6 Effect of magnetic field on crude tailings particles

3 全尾砂磁化絮凝沉降参数优选

上述试验研究表明:全尾砂料浆经过磁感应强度为0.2 T、料浆速度为2 m/s、磁化时间为2 min时的磁化处理后,进行的磁化沉降和PAC添加量为20 g/t的磁化絮凝沉降的沉降速度和底流浓度均有较大增幅,因此有必要进一步研究磁感应强度、磁化时间、水流速度和PAC添加量对全尾砂料浆沉降速度和底流浓度的影响。

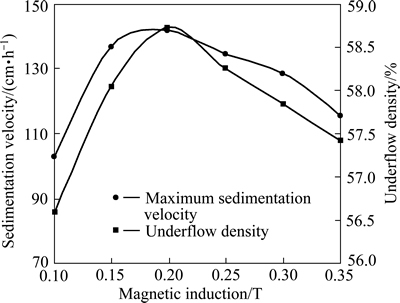

3.1 磁感应强度对絮凝沉降的影响分析

磁化时间控制为2 min,料浆速度为2 m/s,PAC添加量为20 g/t时,全尾砂料浆磁化絮凝沉降指标与磁感应强度的关系如图7所示。从图7中可知:全尾砂料浆的沉降速度和底流浓度随着磁感应强度的增大均呈先增大后减小的趋势,当磁感应强度为0.2 T时,沉降速度和底流浓度均达到最大值,分别为141.57 cm/h、58.72%,过大的磁感应强度反而造成沉降速度和底流浓度的减小。这主要是因为:1) 磁感应强度较小时,洛仑兹力随着磁感应强度的增加而增加,加速了料浆中较大极性水分子团中的水分子重排、分解成较小的水分子团或者单个水分子,并也加速了水分子中的氢键的松弛或断裂,水的黏度和表面张力随之减小,沉降速度和底流浓度随之增大;其次洛伦兹力的增大又加速了全尾砂料浆中固体颗粒表面的吸附水层和类晶体结构的破坏,固体颗粒表面的水化膜厚度和ζ电位值减小,同时也加速了料浆中原本较大的全尾砂团状或絮状颗粒分解重排,释放出其中包裹的“自由水”,进而有助于沉降速度和底流浓度的提高;2) 磁感应强度过大时,水分子中原本被拉断的氢键又互相靠近并重新组合,水的黏度和表面张力增大,同时全尾砂料浆中固体颗粒表面的吸附水层和类晶体结构的破坏与生成又趋于稳定,从而造成沉降速度和底流浓度下降[8,16]。

3.2 料浆速度对絮凝沉降的影响分析

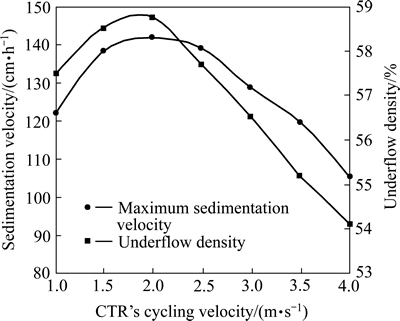

磁感应强度控制为0.2 T,磁化时间为2 min,PAC添加量为20 g/t时,全尾砂料浆磁化絮凝沉降指标与料浆速度的关系如图8所示。从图8中可知:全尾砂料浆的沉降速度和底流浓度随着料浆速度的增大也均表现出先增大后减小的趋势,当料浆速度为2 m/s时,沉降速度和底流浓度均达到最大值,分别为141.57 cm/h、58.72%,当料浆速度进一步增大后,沉降速度和底流浓度也呈下降趋势。这主要是因为:1) 料浆速度较小时,料浆中极性的水分子和悬浮固体颗粒通过磁场时获得的能量随着料浆速度的增加而增加,从而加速了较大极性水分子团中分解成较小的水分子团或者单个水分子、氢键的断裂、悬浮固体颗粒表面的水化膜厚度和ζ电位值的减小、较大的团状或絮状全尾砂颗粒的分解重排,沉降速度和底流浓度也相应的随之增大;2) 当料浆速度过大时,造成料浆的过渡紊流或其他某种相互作用,全尾砂料浆磁化处理效果欠佳,降低了沉降速度和底流浓度[8]。

图7 磁感应强度对全尾砂料浆絮凝沉降的影响

Fig. 7 Influence of magnetic induction intensity on flocculation sedimentation of CTR

图8 全尾砂料速度对絮凝沉降的影响

Fig. 8 Influence of CTR cycling velocity on its flocculation sedimentation

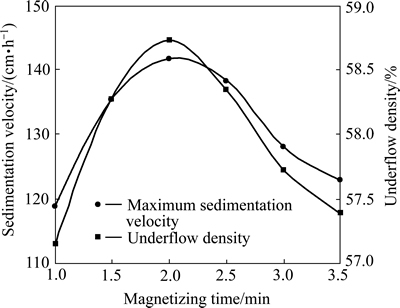

3.3 磁化处理时间对絮凝沉降的影响分析

磁感应强度控制为0.2 T、料浆速度为2 m/s,PAC添加量为20 g/t时,全尾砂料浆磁化絮凝沉降指标与磁化处理时间的关系如图9所示。从图9中可知:磁化处理时间较短时,全尾砂料浆的沉降速度和底流浓度均随磁化处理时间的呈先增大后减小的趋势,当磁化处理时间2 min时,沉降速度和底流浓度均达到最大值,分别为141.57 cm/h、58.72%,当磁化时间进一步延长后,沉降速度和底流浓度亦表现出下降趋势。这主要是因为:1) 磁化处理时间较短时,料浆中极性的水分子和悬浮固体颗粒通过磁场时获得的能量随磁化处理时间的延长而增加,有助于提高沉降速度和底流浓度;2) 磁化处理时间过长时,全尾砂料浆中极性水分子和固体颗粒因积蓄了较大能量产生磁能共振,分散的较小水分子团或固体颗粒又重新聚合,造成沉降速度和底流浓度降低[17]。

图9 磁化时间对全尾砂料浆絮凝沉降的影响

Fig. 9 Influence of magnetizing time on flocculation sedimentation of CTR

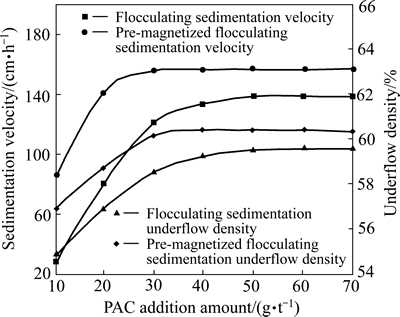

3.4 PAC添加量对絮凝沉降的影响分析

根据前面试验分析可知:PAC添加量为20 g/t时,最合适的磁化处理条件为磁感应强度0.2 T、料浆速度为2 m/s、磁化处理时间为2 min。此磁化处理条件下,全尾砂料浆的絮凝沉降、磁化絮凝沉降指标与PAC添加量的关系如图10所示。从图10中可知:1) 磁化处理后的全尾砂料浆沉降指标达到饱和(沉降速度和底流浓度最大)时的PAC添加量为30 g/t,较未经磁化处理的50 g/t节约PAC用量40%;2) 与未经未经磁化处理全尾砂料浆相比,相同PAC添加量下,磁化处理后的全尾砂料浆沉降速度提高了约18~55 cm/h,增幅约1.1~2.9倍,底流浓度提高约0.8%~2.0%,增幅约1.3%~3.6%;3) PAC添加量较小时,与未经磁化处理全尾砂料浆相比,磁化处理后全尾砂料浆沉降速度和底流浓度大幅增加;PAC添加量进一步增加时,两组试验的沉降速度和底流浓度逐渐增大后基本保持稳定。主要原因是PAC添加量较少时,其水解产物的压缩双电层、电性中和、卷带网捕以及吸附桥连4个方面的作用随着PAC添加量的增加而增强,加速了悬浮颗粒的沉降、提高了底流浓度;随着PAC添加量的进一步增加,上述4方面的作用趋于饱和,沉降速度和底流浓度也趋于稳定。

图10 PAC添加量对全尾砂料浆絮凝沉降的影响

Fig. 10 Influence of PAC addition amount on flocculation sedimentation of CTR

综合上述试验分析,全尾砂料浆磁化絮凝的的最优条件为:磁感应强度0.2 T,料浆速度2 m/s,磁化时间2 min,PAC添加量30 g/t。

4 结论

1) 通过自然沉降、磁化沉降、絮凝沉降和磁化絮凝沉降4种试验,发现对全尾砂料浆进行磁化处理可明显提高其沉降速度和底流浓度。

2) 与未经磁化处理全尾砂料浆相比,相同PAC添加量下,磁化处理后的全尾砂料浆沉降速度提高18~55 cm/h,底流浓度提高0.8%~2.0%;磁化处理后的全尾砂料浆沉降指标达到饱和时的PAC添加量为30 g/t,较未经磁化处理的50g/t节约用量40%。

3) 全尾砂料浆磁化絮凝沉降的最优条件为:磁感应强度0.2 T,料浆速度2 m/s,磁化时间2 min,PAC添加量30 g/t。

4) 由于试验条件的限制,本研究未对全尾砂料浆磁化絮凝沉降的微观作用机理未做深入分析;此外全尾砂料浆磁化絮凝沉降的工业应用和多因数耦合作用下的最优磁化条件将在后续研究中进一步研究。

REFERENCES

[1] 焦华喆, 王洪江, 吴爱祥, 吉学文, 严庆文, 李 祥. 全尾砂絮凝沉降规律及其机理[J]. 北京科技大学学报, 2010, 32(6): 702-707.

JIAO Hua-zhe, WANG Hong-jiang, WU Ai-xiang, JI Xue-wen, YAN Qing-wen, LI Xiang. Rule and mechanism of flocculation sedimentation of unclassified tailings[J]. Journal of University of Science and Technology Beijing, 2010, 32(6): 702-707.

[2] 张钦礼, 刘 奇, 赵建文, 刘贱刚. 深井似膏体充填管道的输送特性[J]. 中国有色金属学报, 2015, 25(11): 3190-3195.

ZHANG Qi-li, LIU Qi, ZHAO Jian-wen, LIU Jian-gang. Pipeline transportation characteristics of filling paste-like slurry pipeline in deep mine[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(11): 3190-3195.

[3] SHESHPARI M. A review of underground mine backfilling methods with emphasis on cemented paste backfill[J]. Electronic Journal of Geotechnical Engineering, 2015, 20(13): 5183-5208.

[4] FALL M, BENZAAZOUA M, SAA E G. Mix proportioning of underground cemented tailings backfill[J]. Tunnelling and Underground Space Technology, 2008, 23(1): 80-90.

[5] 杨 建, 王新民, 张钦礼, 柯愈贤. 含硫高黏性三相流态充填浆体管道输送性能[J]. 中国有色金属学报, 2015, 25(4): 1049-1055.

YANG Jian, WANG Xin-min, ZHANG Qin-li, KE Yu-xian. Pipeline transportation properties of high viscosity sulfur-content filling slurry in three-phase flow[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(4): 1049-1055.

[6] 焦华喆, 吴爱祥, 王洪江, 刘晓辉, 杨盛凯, 肖云涛. 全尾砂絮凝沉降特性实验研究 [J]. 北京科技大学学报, 2011, 33(12): 1437-1441.

JIAO Hua-zhe, WU Ai-xiang ,WANG Hong-jiang, LIU Xiao-hui, YANG Sheng-kai, XIAO Yun-tao. Experiment study on the flocculation settlement characteristic of unclassified tailings[J]. Journal of University of Science and Technology Beijing, 2011, 33(12): 1437-1441.

[7] RULYOV N N, LASKOWSKI J S, CONCHA F. The use of ultra-flocculation in optimization of the experimental flocculation procedures[J]. Physicochemical Problems of Mineral Processing, 2011, 47: 5-16.

[8] 陈秋松, 张钦礼, 王新民, 肖崇春, 徐 丹. 磁化水改善全尾砂絮凝沉降效果的试验研究[J]. 中南大学学报(自然科学版), 2015, 46(11): 4256-4261.

CHEN Qiu-song, ZHANG Qin-li, WANG Xin-min, Xiao Chong-chun, Xu Dan. Experimental study on effect of magnetized water on flocculating sedimentation of unclassified tailings[J]. Journal of Central South University of Technology: Science and Technology, 2015, 46(11): 4256-4261.

[9] 王新民, 赵建文, 张德明. 全尾砂絮凝沉降速度优化预测模型[J]. 中国有色金属学报, 2015, 25(3): 793-798.

WANG Xin-min, ZHAO Jian-wen, ZHANG De-ming. Optimal prediction model of flocculating sedimentation velocity of unclassified tailings[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(3): 793-798.

[10] 蒙志刚, 李 栋, 刘德华, 邓义清. 磁化技术在污水处理中的研究[J]. 科技信息, 2012(17): 434-435.

MENG Zhi-gang, LI Dong, LIU De-hua, DENG Yi-qing. The use of magnetization technology in the research of waste water treatment[J]. Science & Technology Information, 2012(17): 434-435.

[11] 陈秋芳, 农文贵, 崔 巍. 磁技术在污废水处理中的作用机理及应用[J]. 环境科学与管理, 2012, 37(8): 110-114.

CHEN Qiu-fang, NONG Wen-gui, CUI Wei. Mechanism and application of magnetic technology in wastewater treatment[J]. Environmental Science and Management, 2012, 37(8): 110-114.

[12] 夏 伟. 新型磁化雾降尘技术及煤尘润湿剂研究[D]. 徐州: 中国矿业大学, 2015.

XIA Wei. Study of new dustfall technology on magnetized fog and new coal wetting agent[D]. Xuzhou: China University of Mining and Technology, 2015

[13] 余 燕, 刘建仪, 白 杨, 刘从领, 彭海军. 托甫台磁防蜡动态实验研究[J]. 天然气勘探与开发, 2011, 32(2): 46-49.

YU yan, LIU Jian-yi, BAI Yang, PENG Hai-jun. Dynamic experiment on magnetic anti-waxing in tuo pu tai block[J]. Natural Gas Exploration and Development, 2011, 32(2): 46-49.

[14] 李慧芝. 磁化水混凝土及其性能研究[D]. 大连, 大连理工大学, 2006.

LI Hui-zhi. Research on the properties of concrete with magnetie water[D]. Dalian: Dalian University of Technology, 2006.

[15] 王新民, 李 帅, 张钦礼, 贺 严, 康 虔. 基于磁化水的含硫高黏性全尾砂充填新技术[J]. 中南大学学报(自然科学版), 2014, 45(12): 4245-4250.

WANG Xin-min, LI Shuai, ZAHNG Qin-li, KANG Qian. New technique of high viscosity sulfur-content total tailings backfilling based on magnetized water[J]. Journal of Central South University of Technology: Science and Technology, 2014, 45(12): 4245-4250.

[16] 李建军, 乔尚元, 朱金波, 闵凡飞, 刘令云, 张丽亭. 煤泥水磁化改性及磁化-絮凝沉降研究[J]. 洁净煤技术, 2015, 21(4): 1-4.

LI Jian-jun, QIAO Shang-yuan, ZHU Jin-bo, MIN Fan-fei, LIU Ling-yun, ZHANG Li-ting. Magnetization modification and pre-magnetization flocculation and sedimentation of slime water[J]. Clean Coal Technology, 2015, 21(4): 1-4.

[17] AMIRI M C, DADKHAH A A. On reduction in the surface tension of water due to magnetic treatment[J]. Colloids and Surfaces A: Physicochemical and Engineering, 2006, 278(1): 252-255.

[18] 曾宪桃, 任振华, 王兴国. 磁化水降低喷射混凝土粉尘浓度与减少回弹的试验研究[J]. 煤炭学报, 2014, 39(4): 705-712.

ZENG Xian-tao, REN Zhen-hua, WANG Xing-guo. Experimental investigations on reducing the dust density and the rebound rate of shotcrete by using magnetized water[J]. Journal of China Coal Society, 2014, 39(4): 705-712.

Flocculating sedimentation characteristic of pre-magnetized crude tailings slurry

KE Yu-xian, WANG Xin-min, ZHANG Qin-li

(School of Resources and Safety Engineering, Central South University, Changsha Hunan 410083, China)

Abstract: In order to improve flocculating sedimentation effect of crude tailings slurry (CTR), magnetic treatment technique was introduced into sedimentation experiment of CTR. The variational laws of sedimentation velocity and underflow density of CTR were investigated under natural sedimentation, pre-magnetized sedimentation, flocculating sedimentation and pre-magnetized flocculating sedimentation experiments, and their magnetic mechanism was discussed. The experimental results show that compared with unmagnetized CTR, PAC addition amount for pre-magnetized CTR decreased by 40% at saturation sedimentation, sedimentation velocity and underflow density of pre-magnetized CTR increases by 18-55 cm/h and 0.8%-2.0%, respectively, at the same PAC addition amount. The experimental results also suggest that flocculating sedimentation has the best effect when magnetic induction is 0.2 T, CTR’s cycling velocity is 2 m/s, magnetizing time is 2 min, and PAC addition amount is 30 g/t, and the sedimentation effect of CTR can be improved under suitable condition of magnetic treatment.

Key words: crude tailings slurry; flocculating sedimentation; magnetic treatment; magnetic mechanism

Foundation item: Project(2008BAB32B03) supported by the National Science and Technology Pillar Program during the 11th “Five-year” Plan Period, China

Received date: 2016-03-28; Accepted date: 2016-07-29

Corresponding author: WANG Xin-min; Tel: +86-13187011058; E-mail: wxm1958@126.com

(编辑 王 超)

基金项目:国家“十一五”科技支撑计划资助项目(2008BAB32B03)

收稿日期:2016-03-28;修订日期:2016-07-29

通信作者:王新民,教授,博士;电话:13187011058;E-mail: wxm1958@126.com