DOI: 10.11817/j.ysxb.1004.0609.2020-35866

预成形-高速冲击点焊工艺连接界面分析

孟正华1, 2, 3 ,钱多发1, 3,刘 维4,郭 巍1, 3,黄尚宇4,华 林1, 3

(1. 武汉理工大学 现代汽车零部件技术湖北省重点实验室,武汉 430070;

2. 湖南大学 汽车车身先进设计制造国家重点实验室,长沙 410082;

3. 武汉理工大学 汽车工程学院,武汉 430070;

4. 武汉理工大学 材料科学与工程学院,武汉 430070)

摘 要:本文采用预成形-高速冲击点焊工艺,获得到了连接强度较好的DP590/Al3003异种材料点焊接头。通过光滑粒子动力学模拟方法(SPH)分析了接头连接界面形成规律,并实验研究了接头界面特征与形成机理。结果表明:接头界面具有波形特征,连接强度与波形界面的波形参数存在一定关系;预成形直径较小或放电能量较低时外侧区域界面波形不明显;随预成形直径增加,外侧区域出现界面波且波长波幅呈增加趋势;一定范围内,随放电能量增加,即飞板速度增加时,连接界面中间区域的界面波的波长逐渐减小而波幅增加,外侧区域界面波波长和波幅均增大,连接强度增加;SEM和EDS分析结果表明,连接界面产生了裂纹和旋涡组织,并生成了少量金属间化合物。

关键词:冲击成形;异种金属;点焊;界面波形

文章编号:1004-0609(2020)-11-2586-11 中图分类号:TG456.9 文献标志码:A

汽车轻量化是目前世界汽车技术的重要发展方向,采用多元轻量化材料车身结构是实现车身轻量化的重要手段,但钢铝一体化车身构件的钢/铝连接难题限制了其应用[1-2]。采用传统车身熔化焊工艺时,钢/铝异种金属难以实现可靠连接[3]。为克服传统熔化焊接工艺缺陷,实现车身钢/铝异种材料之间的可靠、高效连接,众多研究人员开展了搅拌摩擦焊、爆炸焊、磁脉冲焊接等各种类型新工艺的探索,钢/铝异种材料连接理论与工艺控制已成为目前国际学术界和产业界的研究热点[4-6]。

刑丽等[7]研究了低碳钢/铝合金的搅拌摩擦焊工艺,当焊接工艺参数合适时,可以获得表面良好、无变形的对接接头和搭接接头。任航等[8]利用搅拌摩擦焊实现了铆钉与铝板和钢板的有效冶金结合。MAHTO等[9]采用搅拌摩擦焊获得了AA6061-T6与AISI 304不锈钢的连接接头,并分析了其力学性能和焊接区的金属间化合物成分。黄永宪等[10]通过优化工艺参数,实现对铝/钢搅拌摩擦焊中金属间化合物种类和厚度的调控。MEHTA等[11]利用冷却辅助焊接工艺,减少了焊道内的金属间化合物,提高了接头的拉伸强度。研究表明,通过异种材料接触表面剧烈塑性变形,可使钢/铝产生固相连接界面。

史长根等[12]和郑远谋[13]研究表明,爆炸焊工艺中高速冲击下,飞板与靶板由于剧烈塑性变形,形成良好波状界面,异种材料连接强度较高。杨明等[14]研究了Al/Fe爆炸焊接啮合界面的微观组织,表明在爆炸冲击下,Al/Fe界面处实现了无孔隙的冶金结合。HAN等[15]利用AA1050铝合金作为中间板,对AA5083铝合金和SS41钢板进行了爆炸焊接,并研究了金属间化合物对界面裂纹的影响。王建民等[16]研究结果显示铝/钢复合板的连接界面为一种直接结合与波状结合的混合结合方式,同时界面存在冶金反应。研究表明高速冲击可使异种材料产生良好冶金连接,但爆炸焊更适合于异种金属复合板制备。

利用高压电容对线圈放电可使邻近工件受电磁力作用产生高速运动[17],工艺参数合适条件下磁脉冲焊(Magnetic pulse welding, MPW)也可有效连接异种材料。研究表明[18-20],在磁脉冲高速冲击下,异种材料连接界面特征对连接强度存在较大影响。BEN-ARTZY等[18]研究了Al-Mg异种金属磁脉冲焊接中焊缝界面区,连接界面存在波形界面和熔化层。于海平等[19]通过磁脉冲焊接实现了3A21铝合金和20钢管件的连接,接头界面呈小波纹状,连接区域元素发生互扩散的冶金接头,接头附近的基体金属发生了剧烈塑性变形和晶粒细化。但磁脉冲焊受限于线圈强度和能量利用率,较适合于轻合金板材或管材连接。

VIVEK等[21]提出了箔片气化冲击焊接工艺(Vaproizing foil actuator welding, VFAW),利用高压电容器充电后对金属铝箔放电,箔片在脉冲大电流作用下瞬间气化生成等离子体,从而驱动飞板产生剧烈塑性变形后高速冲击靶板并产生连接。研究表明[22-24],VFAW可使异种金属在连接界面形成波状的连接界面,连接强度高,能量利用率高。CHEN等[25]采用VFAW工艺实现了3003铝合金与纯钛的焊接,并研究了工艺参数对连接强度的影响。苏珊等[26]采用VFAW工艺,通过增加铝合金中间层,获得了5A06铝合金和0Cr18Ni10Ti不锈钢的焊接接头,并分析了其连接机理。LEE等[27]实验研究表明,VFAW工艺下异种材料界面波形对接头性能具有较大影响。为深入研究冲击连接工艺,WANG等[28]、NASSIRI等[29]采用光滑粒子动力学(Smooth particle hydrodynamics, SPH)方法分别分析了激光冲击点焊、VFAW工艺下异种金属连接界面的形成规律,显示SPH方法可较好的分析高速冲击条件下的波形界面形成,并初步分析了不同工艺参数对界面波形的影响规律。

MPW和VFAW工艺中,飞板与靶板之间需要一定间隔,以使飞板受到冲击载荷后变形获得较大的碰撞初速度和碰撞角度,而汽车车身构件连接一般采用直接搭接后点焊连接。为更好利用VFAW工艺实现车身异种金属构件的连接,本文采用预成形-高速冲击连接工艺,实现钢/铝异种金属的点焊连接,并研究钢/铝接头界面波形特征。

1 工艺原理

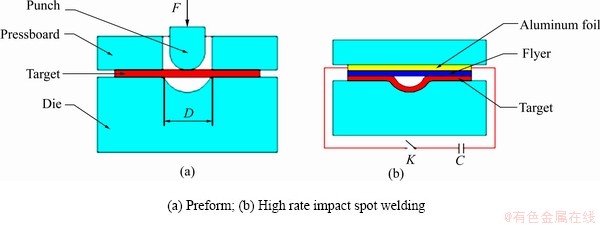

异种金属预成形-冲击点焊工艺[30]示意图如图1所示,首先将待连接异种金属板材其中一块(靶板)在模具中采用准静态冲压,胀形成一半球形待焊接区域;然后移开预成形凸模,将另一块板材(飞板)与靶板贴合,将VFAW气化铝箔压紧在飞板上,箔片中心对准焊接区域中心;随后将连接铝箔两端的电容进行充电至设定电压后放电;在强脉冲电流作用下,铝箔中心处瞬时气化并对飞板产生高速冲击力,飞板待焊接区受到剧烈塑性变形并高速冲击靶板形成连接。

2 实验和模拟方法

2.1 实验方法

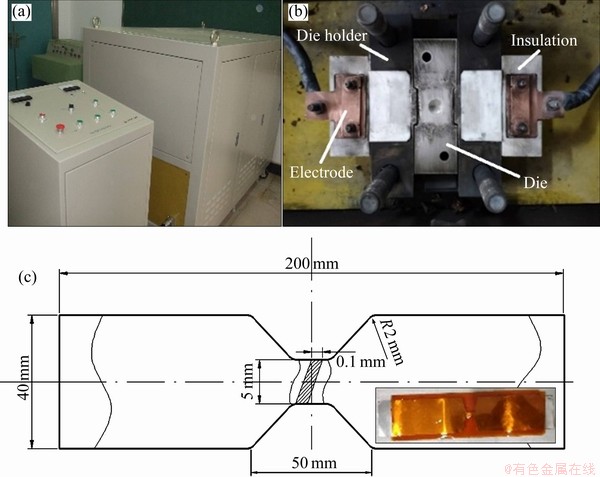

实验放电设备如图2(a)所示,设备参数见表1,连接工装如图2(b)所示,其中,凹模上具有两个定位孔,在靶板预成形时使凹模与凸模进行对准,凹模与电极之间采用聚四氟乙烯绝缘。实验所用的金属铝箔形状和尺寸如图2(c)所示,材质为1100纯铝,导电率为35 MS/m,厚度0.1 mm,双面与被焊接材料和模具接触区采用聚酰亚胺胶带包覆绝缘。

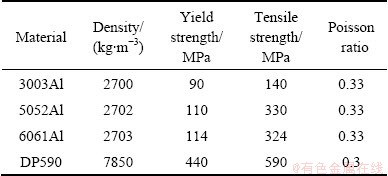

实验采用铝合金作为飞板,高强钢作为靶板,材料类型与尺寸参数如表2所示,力学性能参数如表3所示。靶板预成形尺寸由凹模尺寸决定,实验采用半球形凹模直径分别为12、14和16 mm。

分别进行放电能量为3.0、4.4、5.9、7.0和8.0 kJ的实验,并对不同材料连接件两端夹持后进行抗拉力测试。将获得的连接接头沿中线进行线切割后制作金相试样,利用JSM-IT300型扫描电镜(SEM)分析连接界面波形特征,并利用SEM自带能谱仪(EDS)分析界面成分,利用HV-1000A型显微硬度计测试界面上结合区的显微硬度。

图1 预成形-高速冲击点焊工艺示意图

Fig. 1 Schematic diagrams of preform-high rate impact spot welding

图2 实验设备与工装图

Fig. 2 Photos of VFAW equipment(a), experimental tools(b) and schematic diagram of aluminum foil(c)

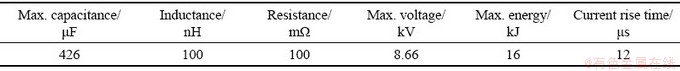

表1 放电设备参数

Table 1 Discharging equipment characteristics

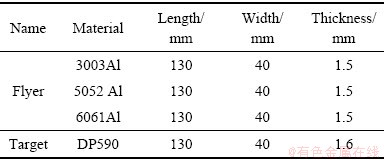

表2 实验板材形状尺寸参数

Table 2 Shape and size parameters of experimental plate

表3 实验板材力学性能参数

Table 3 Mechanical properties of experimental plate

2.2 数值模拟方法

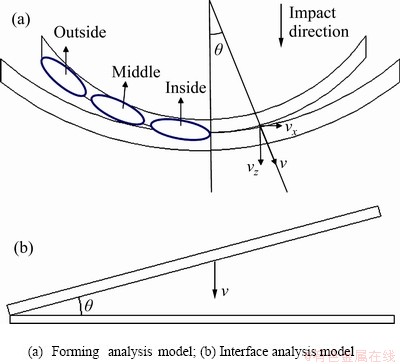

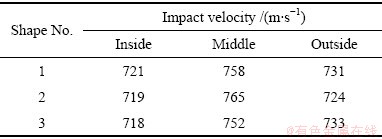

前期实验研究[31]表明预成形-冲击点焊过程中,飞板在冲击力下首先胀形成一个近似半球形再与靶板碰撞,因此飞板高速冲击靶板的过程模拟可简化为,接头飞板横截面先形成一定的弧度的弧形板并以一定初速度来冲击靶板。为分析飞板与靶板连接各区域的波形特征,将飞板等分为内侧、中间和外侧三个区域,成形平面模型和界面分区如图3(a)所示,冲击连接界面初始分析模型如图3(b)所示。本工艺条件下,采取三种形状的飞板(见图4)与靶板进行冲击碰撞,其中飞板1、2、3的圆弧曲率依次增大。模拟结果得到飞板各区域冲击靶板的速度, 如表4所示,可以看出不同形状的飞板与靶板碰撞后各区域的速度相差不大,弧度对飞板变形后速度场影响较小,为简化分析,所有冲击速度下均采用同一碰撞分析模型。

图3 分析模型简化图

Fig. 3 Simplified analysis models

图4 飞板不同的简化形状

Fig. 4 Different simplified shapes of flyer

表4 不同飞板的简化形状下各区域冲击靶板的速度

Table 4 Impact velocity of different regions on target under the simplified shape of different flyers

设定飞板不同的初始冲击速度,可以分析得到预成形后飞板与靶板接触时的初始冲击速度(vx、vz),按式(1)和(2)计算得到冲击角θ和冲击速度v。

(1)

(1)

(2)

(2)

式中:vx、vz分别为飞板经塑性变形后与靶板接触前的径向速度和切向速度;v为飞板与靶板冲击连接的初始冲击速度;θ为飞板与靶板初始冲击角。

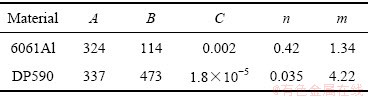

飞板材料为6061铝合金,靶板为DP590高强钢,材料的本构模型采用的是Shock状态方程下的Johnson-Cook模型,模型参数如表5所示。冲击速度模型的仿真基于ANSYS/Explicit Dynamics环境下进行,连接界面形成分析采用拉格朗日光滑粒子动力学分析,并采用SPH算法。

表5 材料的Johnson-Cook模型参数

Table 5 Johnson cook model parameters of materials

3 结果与讨论

3.1 连接强度的影响

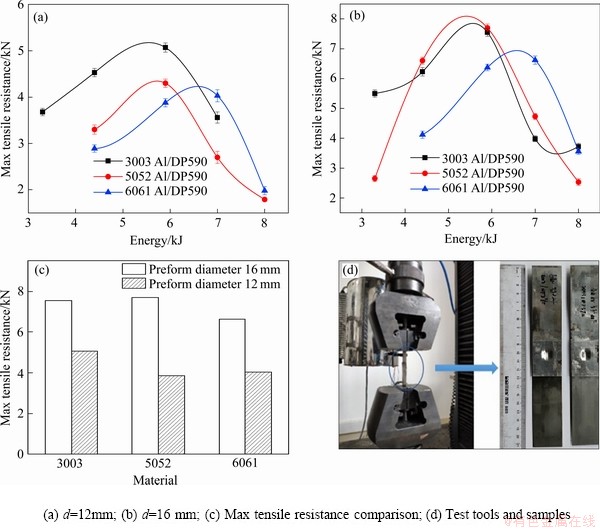

图5所示为不同飞板材料在不同能量输入下的最大抗拉力。由图5可知,随放电能量增加,不同飞板材料的连接件最大抗拉力均先增大后减小。这是因为随着放电能量的增加,铝箔气化产生的冲击力增大,进而飞板获得的冲击速度会增大[21],满足冲击连接工艺窗口条件,有利于冲击连接。但是能量过大会使得冲击速度过高、接头产生裂纹从而造成连接强度下降。

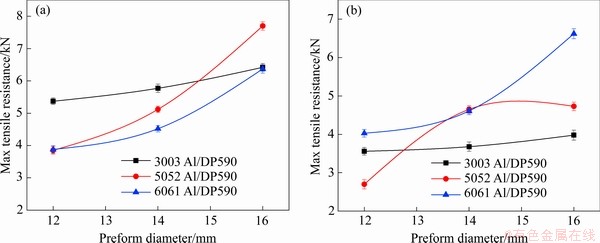

图6所示为不同预成形尺寸连接件的最大抗拉力。由图6可知,随成形尺寸(即冲击点焊焊点)直径的增加连接强度逐渐增加,这主要是试样接头受拉时主要承受剪切载荷,焊点面积增大,接头区域增大,承受剪切载荷的能力增大。

3.2 工艺参数对界面波形的影响

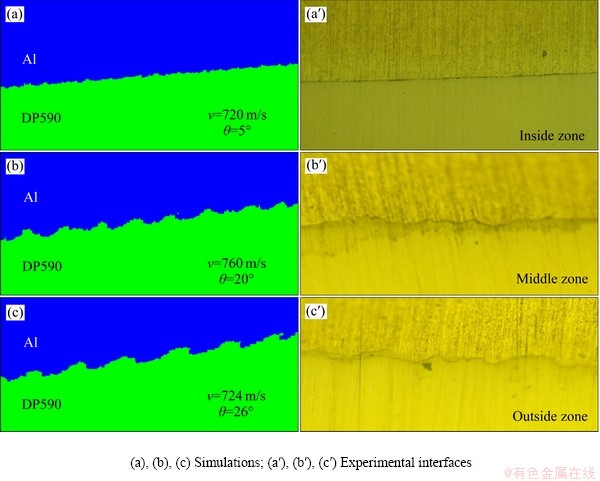

靶板预成形直径为16 mm时,3003Al/DP590接头各区域界面模拟图与实验样品界面图如图7所示,可以看出实验与仿真具有较好的对照性。由图7可以看出,内侧区域界面基本平直,中间区域呈现波形界面,波幅较小;外侧区域界面波波长较大。

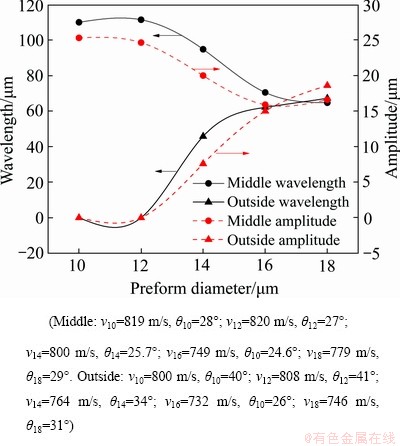

图8所示为SPH模拟下不同预成形直径的接头区域界面波形特征参数图。中间区域的波长和波幅随直径增大而减小的趋势明显,预成形直径较小时外侧区域并无界面波出现,随直径增加,外侧区域出现界面波且波长波幅呈增加趋势。预成形直径增加时,相同区域的碰撞角度会减小,但是冲击速度的变化不大,故主要是碰撞角度影响界面的波形特征。

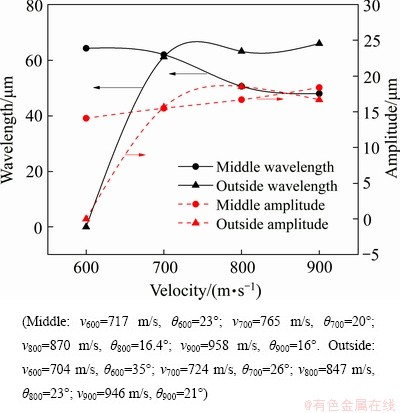

图9所示为显示预成形直径16 mm时冲击速度对区域界面波形特征参数影响的仿真结果。冲击速度的改变直接影响飞板与靶板各区域的碰撞速度。由图9可知,随冲击速度的提高,中间区域的界面波波长表现为逐渐减小的趋势,而界面波幅随冲击速度增加而增加。外侧界面区域在低速时未出现波形,后随着冲击速度增加,界面波出现且波长和波幅均增大,但冲击速度超过800 m/s后,界面外侧区域波长继续增大,波幅减小。

图5 不同放电能量下的最大抗拉力

Fig. 5 Maximum tensile force of different energy with preform diameters

图6 不同预成形尺寸连接件的最大抗拉力

Fig. 6 Maximum tensile force of different preform size with energy of E=5.9 kJ(a) and E=7 kJ(b)

图7 各区域连接界面

Fig. 7 Joining interfaces of each zone

图8 不同预成形直径时区域界面波参数

Fig. 8 Interface wave parameters at different preform diameters

对比波形参数变化和连接件抗拉力可知,当工艺参数一定下,连接界面外侧区域波形特征对连接件抗拉力影响最大;当外侧区域波幅较大时,连接件抗拉力较大。当外侧区域波幅较小或无波形界面时,中间区域波幅越大,连接件抗拉力越大。这是由于连接件抵抗拉力时,接头承受剪切作用,界面外侧区域呈现波形界面时表明连接区域有效面积更大,因而抗拉力越大。在不同工艺参数下,当界面外侧区域无波形特征时,中间区域波幅越大表明界面两侧材料塑性变形越大,界面结合力更大,因而连接件抗拉力越大。

图9 不同冲击速度时各区域界面波形参数

Fig. 9 Interface wave parameters at different velocities

3.3 界面微观组织分析

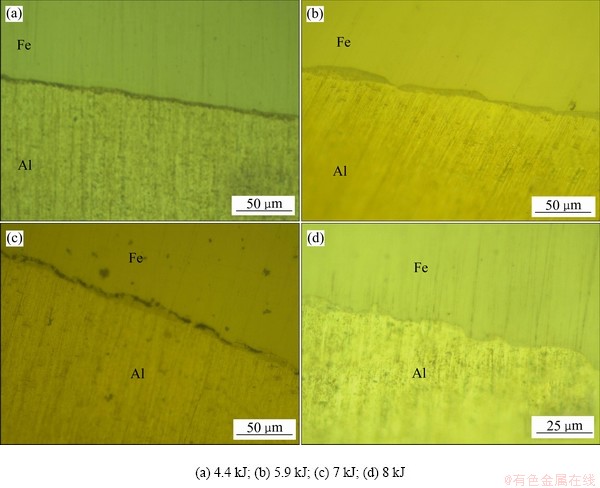

图10所示为预成形直径16 mm时不同放电能量下的接头连接界面的微观形貌。由图10可见,除放电能量为4.4 kJ的界面外,其他试样均呈现出明显但不规则的波状界面,两侧金属未出现明显的熔融状态。放电能量为5.9 kJ和7 kJ两组的界面处出现了一条不同于两侧金属的分层带,放电能量为7 kJ时连接界面并非一直连续,波状界面上出现了裂纹;放电能量为8 kJ的连接界面中出现了类似爆炸焊生成的漩涡组织特征。

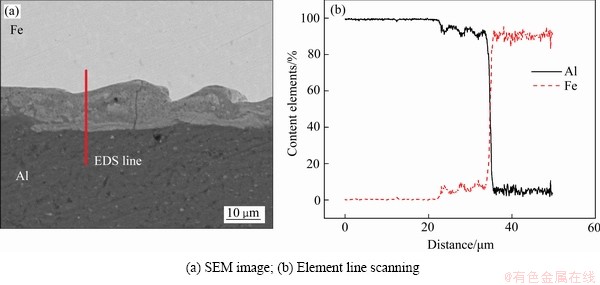

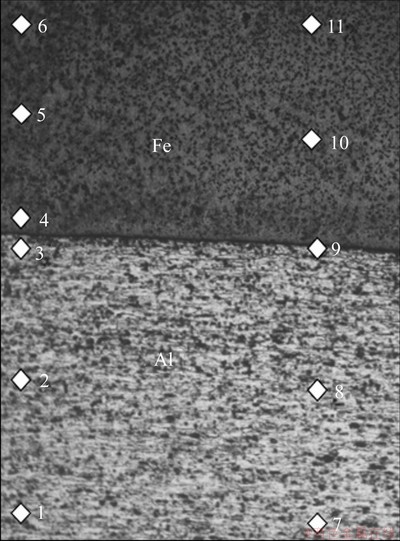

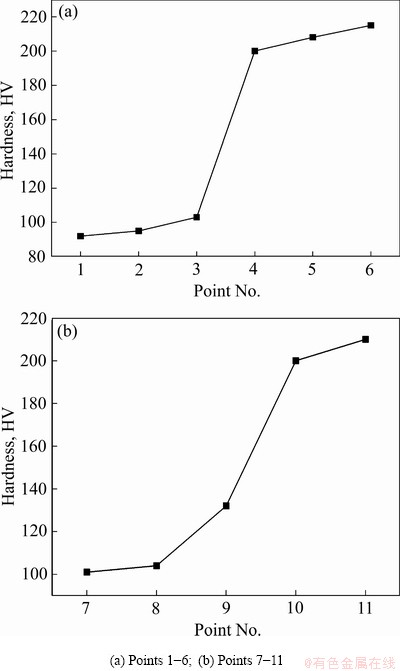

图11所示为放电能量7 kJ时6061Al/DP590连接界面形貌图和元素线扫描结果,可以看出,在界面连接区域发生了元素扩散行为,在连接界面中心处Al元素与Fe元素的摩尔分数比接近1:1,由铝-铁合金相图[8]可以推测在界面处产生了FeAl金属间化合物。在如图12所示的测试点下,测试点间距100 μm,界面各点显微硬度变化如图13所示。由图13可知,界面上铝材一侧越靠近界面硬度越高,而钢材一侧界面处硬度越靠近界面,硬度越低。这表明6061铝材在冲击连接时发生加工硬化,界面处存在富Fe相,硬度最高;而钢材一侧,由于受到预成形及冲击连接,加工硬化层较厚,界面处存在富Al相,硬度最低[32]。

综合图10和11可知,6061铝/钢预成形-高速冲击点焊工艺下,连接接头界面形成主要由界面材料塑性变形产生波形界面、部分界面金属熔融结合以及产生少量金属间化物。

图10 6061Al/DP590连接界面图

Fig. 10 6061Al / DP590 joining interface with different impact energies

图11 界面元素分布

Fig. 11 Interface element distribution

图12 界面测试点分布

Fig. 12 Distribution of interface test points

图13 测试点位置显微硬度值

Fig. 13 Hardness values of test point locations

4 结论

1) 通过预成形-高速冲击点焊工艺可获得连接性能较好的钢/铝连接接头,其界面形成表现为材料剧烈塑性变形产生波形界面、部分界面金属熔融结合以及产生少量金属间化物,结合界面处的硬度介于两侧母材之间。当放电能量为5.9 kJ时,6061Al/DP590连接界面就会形成波状特征;当放电能量提高到7.0 kJ时,界面会形成空洞和裂纹等缺陷;当放电能量增大到8.0 kJ时,连接界面中出现了漩涡组织特征。

2) 在合适的放电能量下,连接件的最大抗拉力随放电能量的增加而先增大后减小,随接头焊点直径的增加而连接强度逐渐增加。

3) 连接接头界面波形特征影响连接件抗拉性能,外侧区域波形特征明显时,钢/铝连接件抗拉力较大。外侧区域波形不明显时,中间区域波幅越大,连接件抗拉力越大。

4) 预成形直径较小或放电能量较低时,外侧区域无界面波出现;随着预成形直径增加,外侧区域出现界面波且波长波幅呈增加趋势;随着放电能量的增加,即飞板冲击速度增加时,连接界面中间区域的界面波波长逐渐减小而波幅增加,外侧区域界面波波长和波幅均增大;但冲击速度超过一定值时,界面波波长继续增大,而波幅减小。

REFERENCES

[1] 李永兵, 李亚庭, 楼 铭, 林忠钦. 轿车车身轻量化及其对连接技术的挑战[J]. 机械工程学报, 2012, 48(18): 44-54.

LI Yong-bing, LI Ya-ting, LOU Ming, LIN Zhong-qin. Light weighting of car body and its challenges to joining technologies[J]. Journal of Mechanical Engineering, 2012, 48(18): 44-54.

[2] 李亚江. 轻金属焊接技术[M]. 北京: 国防工业出版社, 2011: 17-35.

LI Ya-jiang. Welding of light metals[M]. Beijing: National Defense Industry Press, 2011: 17-35.

[3] 顾玉芬, 李 杰, 石 玗, 黄健康, 樊 丁. 铝/钢异种金属电弧熔钎焊焊接接头的腐蚀性[J]. 中国有色金属学报, 2016, 26(4): 758-765.

GU Yu-fen, LI Jie, SHI Yu, HUANG Jian-kang, FAN Ding. Corrosion property of arc welding brazed joint between aluminum and steel[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(4): 758-765.

[4] MISHRA R S, MA Z Y. Friction stir welding and processing[J]. Materials Science and Engineering R, 2005, 50(1): 1-78.

[5] UZUN H, DONNE C D, ARGAGNOTTO A. Friction stir welding of dissimilar Al 6013-T4 to X5CrNi18-10 stainless steel[J]. Materials & Design, 2005, 26(1): 41-46.

[6] BRAGA D F O, SOUSA L M C D, INFANTE V, DA S L F M. Aluminum friction stir weld bonding[J]. Procedia Engineering, 2015, 114: 223-231.

[7] 邢 丽, 柯黎明, 黄春平. 铝合金与钢搅拌摩擦焊焊缝成形及接头性能[J]. 焊接学报, 2007, 28(1): 29-32.

XING Li, KE Li-ming, HUANG Chun-ping. Weld appearances and mechanical properties of friction stir welded joint of Al alloy and mild steel[J]. Transactions of the China Welding Institution, 2007, 28(1): 29-32.

[8] 任 航, 刘 浩, 吴庚毅, 陈玉华. 铝/钢搅拌摩擦辅助铆接接头界面特性研究[J]. 精密成形工程, 2019, 11(5): 91-97.

REN Hang, LIU Hao, WU Geng-yi, CHEN Yu-hua. Interface characteristics of riveted Al/steel joints by assisted friction stir welding[J]. Journal of Netshape Forming Engineering, 2019, 11(5): 91-97.

[9] MAHTO R P, BHOJE R, PAL S K, JOSHI H S, DAS S. A study on mechanical properties in friction stir lap welding of AA6061-T6 and AISI 304[J]. Materials Science and Engineering A, 2016, 652: 136-144.

[10] 黄永宪, 黄体方, 万 龙, 刘 鑫. 铝/钢异种材料搅拌摩擦焊研究进展[J]. 精密成形工程, 2018, 10(1): 23-30

HUANG Yong-xian, HUANG Ti-fang, WAN Long, LIU Xin. Research progress of dissimilar friction stir welding between aluminium and steel[J]. Journal of Netshape Forming Engineering, 2018, 10(1): 23-30.

[11] MEHTA K P, CARLONE P, ASTARITA A, SCHERILLO F, RUBINO F, VORA P. Conventional and cooling assisted friction stir welding of AA6061 and AZ31B alloys[J]. Materials Science and Engineering A, 2019, 759: 252-261.

[12] 史长根, 王耀华, 蔡立艮, 康丽霞. 爆炸焊接界面的结合机理[J]. 焊接学报, 2002, 23(2): 55-58.

SHI Chang-gen, WANG Yao-hua, CAI Li-gen, KANG Li-xia. Bonding mechanism of interface in explosive welding[J]. Transactions of the China Welding Institution, 2002, 23(2): 55-58.

[13] 郑远谋. 爆炸焊与异种金属的焊接[J]. 焊接技术, 2001, 30(5): 25-26.

ZHENG Yuan-mou. Explosion welding and dissimilar meters welding[J]. Welding Technology, 2001, 30(5): 25-26.

[14] YANG Ming, MA Hong-hao, SHEN Zhao-wu, CHEN Dai-guo, DENG Yong-xin. Microstructure and mechanical properties of Al-Fe meshing bonding interfaces manufactured by explosive welding[J].Transactions of Nonferrous Metals Society of China, 2019, 29(4): 680-691.

[15] HAN J H, AHN J P, SHIN M C. Effect of interlayer thickness on shear deformation behavior of AA5083 aluminum alloy/SS41 steel plates manufactured by explosive welding[J]. Journal of Materials Science, 2003, 38: 13-18.

[16] 王建民, 朱 锡, 刘润泉. 爆炸焊接工艺对铝-钢复合板界面性能的影响[J]. 武汉理工大学学报, 2007, 29(7): 103-105.

WANG Jian-min, ZHU Xi, LIU Run-quan. Effect of explosive welding technology on bonding interface property of aluminum-steel cladding[J]. Journal of Wuhan University of Technology, 2007, 29(7): 103-105.

[17] LI Jiang-jun, QIU Wei, HUANG Liang, SU Hong-liang, TAO Huan, LI Pei-yue. Gradient electromagnetic forming (GEMF): A new forming approach for variable-diameter tubes by use of sectional coil[J]. International Journal of Machine Tools & Manufacture, 2018, 135: 65-77.

[18] BEN-ARTZY A, STERN A, FRAGE N, SHRIBMAN V. Interface phenomena in aluminium-magnesium magnetic pulse welding[J]. Science & Technology of Welding Joining, 2008, 13(4): 402-408.

[19] 于海平, 徐志丹, 李春峰, 赵志学. 3A21铝合金-20钢管磁脉冲连接实验研究[J]. 金属学报, 2011, 47(2): 197-202.

YU Hai-ping, XU Zhi-dan, LI Chun-feng, ZHAO Zhi-xue. Experimental research on magnetic pulse joining of 3A21 aluminum alloy-20 steel tubes[J]. Acta Metallurgica Sinica, 2011, 47(2): 197-202.

[20] CUI Jun-jia, LI Ya, LIU Quan-xiao-xiao, ZHANG Xu, LI Guang-yao. Joining of tubular carbon fiber-reinforced plastic/aluminum by magnetic pulse welding[J]. Journal of Materials Processing Technology, 2019, 264: 273-282.

[21] VIVEK A, HANSEN S R, LIU B C, DAEHN G S. Vaporizing foil actuator: A tool for collision welding[J]. Journal of Materials Processing Technology, 2013, 213(12): 2304-2311.

[22] CHEN S, DAEHN G S, VIVEK A, LIU B, HANSEN S R, HUANG Ji-hua, LIN San-bao. Interfacial microstructures and mechanical property of vaporizing foil actuator welding of aluminum alloy to steel[J]. Materials Science and Engineering A, 2016, 659(6): 12-21.

[23] VIVEK A, LIU B C, HANSEN S R, DAEHN G S. Accessing collision welding process window for titanium/ copper welds with vaporizing foil actuators and grooved targets[J]. Journal of Materials Processing Technology, 2014, 214 (8): 1583-1589.

[24] LIU B, VIVEK A, DAEHN G S. Joining sheet aluminum AA6061-T4 to cast magnesium AM60B by vaporizing foil actuator welding: Input energy, interface, and strength[J]. Journal of Manufacturing Processes, 2017, 30: 75-82.

[25] CHEN Shu-hai, HUO Xu-chen, GUO Cheng-xiang, WEI Xiao, HUANG Ji-hua, YANG Jian, LIN San-bao. Interfacial characteristics of Ti/Al joint by vaporizing foil actuator welding[J]. Journal of Materials Processing Technology, 2019, 263: 73-81.

[26] 苏 珊, 陈树君, 肖 珺, YU Mao, VIVEK A, DAEHN G. 基于中间过渡层的5A06/0Cr18Ni10Ti气化冲击焊接工艺研究[J]. 金属学报, 2019, 55(8): 1041-1048.

SU Shan, CHEN Shu-jun, XIAO Jun, YU Mao, VIVEK A, DAEHN G. Study on vaporizing foil actuator welding process of 5A06/0Cr18Ni10Ti with interlayer[J]. Acta Metallurgica Sinica, 2019, 55(8): 1041-1048.

[27] LEE T, ZHANG Shun-yi, VIVEK A, DAEHN G, KINSEY B. Wave formation in impact welding: Study of the Cu-Ti system[J]. CIRP Annals, 2019, 68(1): 261-264.

[28] WANG Xiao, SHAO Meng, GAO Shuai, GAU J T, TANG Heng, JIN Hao, LIU Hui-xia. Numerical simulation of laser impact spot welding[J]. Journal of Manufacturing Processes, 2018, 35: 396-406.

[29] NASSIRI A, ABKE T, DAEHN G. Investigation of melting phenomena in solid-state welding processes[J]. Scripta Materialia, 2019, 168: 61-66.

[30] 孟正华, 黄尚宇, 胡建华, 华 林. 一种异种金属材料预成形高速冲击连接工艺: 中国, 201711465563.8[P]. 2017-12-28.

MENG Zheng-hua, HUANG Shang-yu, HU Jian-hua, HUA Lin. Dissimilar metal material pre-forming high-speed impact connection process: China, 201711465563.8[P]. 2017-12-28.

[31] MENG Zheng-hua, WANG Xu, GUO Wei, HU Zhi-li, VIVEK A, HUA Lin, DAEHN G S. Joining performance and microstructure of the 2024-7075 aluminium alloys welded joints by vaporizing foil actuator welding[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed, 2019, 34(2): 368-372.

[32] 张保奇, 王德和, 李晓杰, 杨文彬. 321-15CrMoR爆炸焊接复合板结合界面区的显微组织分析[J]. 焊接学报, 2006, 27(2): 108-112.

ZHANG Bao-qi, WANG De-he, LI Xiao-jie, YANG WEN-bin. Analysis of microstructure in bond interfacial zone of 321-15CrMoR composite plate by explosive welding[J]. Transactions of the China Welding Institution, 2006, 27(2): 108-112.

Analysis of joining interface of preform-high rate impact spot welding

MENG Zheng-hua1, 2, 3, QIAN Duo-fa1, 3, LIU Wei4, GUO Wei1, 3, HUANG Shang-yu4, HUA Lin1, 3

(1. Hubei Key Laboratory of Advanced Technology for Automotive Components, Wuhan University of Technology, Wuhan 430070, China;

2. State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Hunan University, Changsha 410082, China;

3. School of Automotive Engineering, Wuhan University of Technology, Wuhan 430070, China;

4. School of Materials Science and Engineering, Wuhan University of Technology, Wuhan 430070, China)

Abstract: The preform-high rate impact spot welding process was proposed to join the aluminum and steel in this paper, and DP590/Al3003 joints with satisfied joining strength were obtained. The joint interface formation rule was investigated with smooth particle hydrodynamics (SPH) analytical method, and the interface characters and formation mechanism were experimental analyzed. The results show that, the joint interface shows the wave characters and the joint tensile resistance is related to the interface wave parameters. Few wave shows in the outside zone of interface when the preform diameter or discharging energy is small. With the preform area enlarges, the wavelength and amplitude increase in the outside zone. With the increase of discharging energy in a range, meanwhile with the increase of impact rate of flyer sheet, the wavelength decreases and amplitude increases in the middle zone of interface, but both increase in outside zone, and the tensile resistance enhances. The SEM and EDS results show that micro-crack and vortex microstructures appear inside the interface and interlayer metal compounds generate.

Key words: impact forming; dissimilar metals; spot welding; interface waveform

Foundation item: Project(U1564202) supported by the National Natural Science Foundation of China; Project(WUT 2019Ⅲ116CG) supported by the Fundamental Research Funds for the Central Universities, China; Project(B17304) supported by the Program of Introducing Talents of Discipline to Universities, China; Project(31815008) supported by the Open Fund of State Key Laboratory of Advanced Design and Manufacturing, China;

Received date: 2019-12-02; Accepted date: 2020-05-07

Corresponding author: MENG Zheng-hua; Tel: +86-13277972099; E-mail: meng@whut.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(U1564202);中央高校基本科研业务费专项资金资助项目(WUT 2019Ⅲ116CG);教育部新能源汽车科学与关键技术学科创新引智基地资助项目(B17034);湖南大学汽车车身先进设计制造国家重点实验开放基金资助项目(31815008)

收稿日期:2019-12-02;修订日期:2020-05-07

通信作者:孟正华,副教授,博士;电话:13277972099;E-mail:meng@whut.edu.cn