文章编号:1004-0609(2012)06-1738-09

镀Zn钢-6016铝合金异种金属的激光熔钎焊及数值模拟

周惦武,吴 平,彭 利,张 屹,陈根余

(湖南大学 汽车车身先进设计制造国家重点实验室,长沙 410082)

摘 要:熔钎焊是抑制或减少钢/铝异种金属激光焊接过程中FeAl脆性金属间化合物产生的有效工艺方法。采用光纤激光器,不添加任何钎料,对1.2 mm厚DC56D+ZF镀锌钢和6016铝合金平板试件进行激光搭接焊试验,利用MATLAB软件,针对焊接过程的实际情况,在一定的基本假设下建立准稳态下钢/铝异种金属激光焊接熔池形状的数学模型,基于准稳态形状控制方程数值计算获得的熔池几何形状分布,结合试验来调整焊接工艺参数,获得最佳焊接成形,利用卧式金相显微镜、扫描电镜和X射线衍射仪等手段研究焊接接头各区域的金相组织、主要元素分布与物相组成。结果表明:焊接激光束照射搭接在钢板上的铝板对接焊缝时,焊接功率和焊接速度对熔池几何形状的影响较大,随着激光功率的增大,熔深增加;而随着焊接速度的增加,熔深却变浅。当焊接功率为1 600~1 800 W、焊接速度v=30 mm/s、离焦量D=0 mm时,焊缝成形性良好,无明显裂纹、气孔等缺陷,焊接接头区域存在一个台阶状结构,在平台区域,钢/铝两钟金属存在明显的界限,界面结合依靠液态的铝在钢母材表面上的润湿、填充和铺展等作用;下凹区域,钢/铝熔合较好,Fe和Al元素的混合区宽度较大,未形成明显的FeAl脆性金属间化合物,Fe和Al的热扩散是该区域界面结合的主要原因。

关键词:激光熔钎焊;异种金属;数值计算;金属间化合物

中图分类号:TG113.26+3 文献标志码:A

Laser welding-brazing and numerical simulation of zinc-coated steel and 6016 aluminum alloy

ZHOU Dian-wu, WU Ping, PENG Li, ZHANG Yi, CHEN Gen-yu

(State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Hunan University, Changsha 410082, China)

Abstract: The laser welding-brazing is an effective process to inhibit or reduce FeAl brittle intermetallic compound produced during laser welding-brazing of steel and aluminum alloy. The laser lap welding test was carried out based on the DC56D+ZF galvanized steel with thickness of 1.2 mm and the 6016 aluminum alloy with the fiber laser. The Matlab software was used, according to the actual situation of welding process, the steel and aluminum dissimilar metal laser welding pool shapes of the mathematical model in the flight quasi-steady state was established under a certain basic assumption. Based on the quasi-steady numerical equations, the shape of molten pool geometry distribution was obtained. The welding process parameters were adjusted through the experiments to get the best welding forming. By optical microscopy, scanning electron microscopy and X-ray diffractometry, the microstructure, element distribution and phase composition of the steel/aluminum interface were studied. The results show that when the welding beam irradiates at the aluminum-seam interface, the welding power and welding speed have great influence on pool geometry. With the laser power increasing, the penetration increases; while with the welding speed increasing, the penetration depth becomes shallow. When the welding power is 1 600-1 800 W, the welding speed v is 30 mm/s and the defocus distance D is 0 mm, the best forming of welding is obtained, no cracks, holes and other defects are seen, and there is a bench-shape structure in the welding joint area. In the platform area, there is obvious boundary between the steel and aluminum. The interface bonding relies on the liquid aluminum on the wetting, filling and spreading of steel surface. In the concave region, the steel/aluminum fusion is better. The width is large for Fe and Al elements mixing zone, and FeAl brittle intermetallic compounds do not form, the thermal diffusion bonding between Fe and Al is the main reason for the region.

Key words: laser welding-brazing; dissimilar metal; numerical simulation; intermetallic compound

车身轻量化是提高燃油经济性、节能减排的有效手段。采用轻量化材料是汽车车身减重的重要途径。相对于单一材料车身而言,多材料车身可以充分发挥不同材料的性能、成本优势,从而在性能和成本约束下,较好实现轻量化效果。通常汽车车身多材料结构要求两种不同类型的材料进行连接(如钢-铝、铸铁-铝、铝-镁等),对钢/铝异种金属材料连接而言,两者之间的固溶度很低,晶体结构、物理及化学性能差异明显,极易反应生成FeAl脆性金属间化合物[1-2]。由于传统熔焊热输入量大,热源难以准确控制,而激光焊热量集中,应力应变小,因此激光焊是钢/铝的理想焊接方法[3-8],FeAl脆性金属间化合物也成为影响激光焊接接头性能的主要因素。

抑制或减少FeAl脆性金属间化合物产生最有效的方法是通过激光熔钎焊工艺,使铝熔化,而钢母材不熔化或少量熔化,依靠液态铝在钢母材上良好的铺展性和液态铝和固态钢板相接触的熔池区域发生的热扩散作用,实现熔池凝固时形成良好的焊接接头。关于异种金属材料激光熔钎焊的实验研究,国内外很多学者开展了研究工作。DHARMENDRA等[9]以DP600镀锌钢和AA6016铝合金为实验材料,使用Nd:YAG激光器,焊接时在焊缝处加入含85%Zn和15%Al(质量分数)的焊接钎料,获得良好熔钎焊的焊接接头。通过研究钎料的润湿角度、焊缝形貌、金属间化合物的影响和接头力学性能,得出获得良好力学性能接头所要求的合适钎料运送速度和适宜的金属间化合物层的厚度。但这种方法需要添加钎料,送料设备复杂,同时钎料的加入对接头强度影响较大。兰天等[10]将激光直接作用在低熔点的金属母材,材料熔化通过深熔机制实现,高熔点的母材维持固态,进行3 mm厚6016铝合金和TC4钛合金的熔钎焊研究。KREIMEYER等[11]将激光作用在高熔点的钛合金上,通过热传导熔化铝合金,而钛合金保持固态,在未加入焊接钎料的条件下,实现了0.8 mm厚Ti6Al4V与1.0 mm厚AlMg0.4Si1.2以及0.8 mm厚Ti6Al4V与1.15 mm厚AA6016的熔钎焊连接。MATHIEU等[12]以AA-6016铝合金和低碳钢为实验材料,用Nd:YAG激光器,通过激光填丝(88%Al和12%Si(质量分数)),发现Si元素的加入利于润湿后的铝液在钢材表面发生毛细流动、填充和铺展等作用,由于增强了Fe和Al之间的亲和力,因而获得优质的钢/铝焊接接头。

本文作者以汽车车身用镀锌钢与6016铝合金为研究对象,在不添加任何钎料的条件下,进行激光搭接焊试验,利用MATLAB软件,针对焊接过程的实际情况,在一定的基本假设下建立准稳态下的钢/铝异种金属激光焊接熔池形状的数学模型,基于准稳态形状控制方程数值计算获得的熔池几何形状分布,结合试验来调整焊接工艺参数,获得最佳焊接成形,利用卧式金相显微镜、扫描电镜、X射线衍射仪等手段研究焊接接头各区域的金相组织、主要元素分布与物相组成。研究结果期望为激光焊接多材料车身结构提供重要的理论指导和技术支持。

1 实验

1.1 实验设备与材料

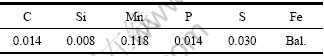

实验采用YLR-4000镱光纤激光器及六轴联动激光加工设备。激光器最大输出功率为4 000 W,连续输出的激光模式为TEM00,波长为1 070 nm,采用PRICIETER的焊接接头,准直镱焦距为150 nm,采用30 μm的光钎芯径,聚焦光斑直径为0.4 mm。实验材料为1.2 mm厚DC56D+ZF镀锌钢和6016铝合金的板材,其主要化学成分分别如表1和2所列。

表1 DC56D+ZF镀锌钢的化学成分

Table 1 Chemical composition of zinc-coated steel sheet (mass fraction, %)

表2 6016铝合金的化学成分

Table 2 Chemical composition of 6016 aluminum alloy (mass fraction, %)

1.2 实验方法

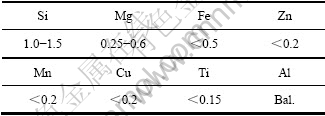

将镀Zn钢板与6016铝合金组合后用夹具夹紧进行激光搭接焊试验,焊接时有两种装夹方式,如图1,第一组直接将铝板搭接在钢板之上,焊接激光束偏转15°照射在铝板上;第二组将两块尺寸分别为35 mm×80 mm和35 mm×20 mm的铝板对接后搭接在钢板上,焊接激光束照射在对接缝上。因铝合金板材在激光焊接时反射较强,不易形成焊缝。同时板材较薄,不易开V型槽。铝板拼接相当于在铝板上预先开出缝隙,有利于焊缝形成。本实验选取第二组装夹方式。焊接时采用Ar对焊接熔池进行同轴保护。为提高焊缝质量,焊前将板材切割成35 mm×100 mm的试样,用240号砂纸打磨除去表面氧化层,同时增加表面粗糙度,以增加激光能量吸收率。板材用丙酮清洗除去油污,晾干待焊。

焊后,利用体视显微镜观察钢/铝焊缝的表面形貌,分析焊缝的成形性与表面质量;线切割取样,打磨抛光试样及4%(质量分数)的HNO3溶液腐蚀后制备金相试件,利用卧式金相显微镜分析钢/铝焊缝的金相组织;用点分辨率为1.0 nm的JSM-6400F冷场发射高分辨扫描电镜拍摄焊缝横断面的形貌;自带能谱EDS检测分析焊缝主要元素的成分分布,分析Fe和Al元素混合区的宽度;用Bruker D8-Advance 40 kV 40 mA Cu Kα X射线衍射仪分析焊缝区域的主要物相组成。

图1 钢/铝激光熔钎焊装夹方式

Fig. 1 Clamping means for laser welding-brazing of steel and aluminum: (a) Aluminum and steel direct lap welding; (b) Upper aluminum stitching

2 基本假设及数学模型

2.1 数值计算的基本假设

为建立钢/铝异种金属激光焊接熔池形状的数学模型,作了如下的基本假设:

1) 被加工材料视为均匀、各向同性,且材料的热物理性能参数(如比热、密度、热传导系数以及热扩散系数等)均不随温度发生变化,看作是常数。

2) 假设层与层之间没有热量的传递和质量的转移,即不考虑熔池深度方向的热传导及对流流动。

3) 不考虑工件表面的对流损失。

4) 假定焊接试件的初始温度与周围环境温度相同。

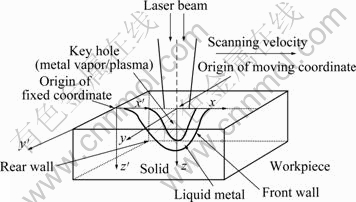

5) 假设准稳定状态,即把坐标系取在激光光束中心上,以速度v沿x轴方向移动,如图2所示。在这样的移动坐标系内,只要激光焊接过程持续了一段时间,激光束周围的空间温度场和流场处于稳定的不变状态。

2.2 熔池形状的控制方程

近似高斯分布的激光光束沿z轴方向垂直入射至材料,并以恒定的速度v(mm/s)沿x轴正方向运动,移动坐标系(x, y, z)的原点为激光光束的中心点,如图2所示。在上述假设前提下,对于钢/铝激光焊接熔池,汽/液分界面、固/液分界面的准稳态能量平衡方程分别表示为[13]

(1)

(1)

(2)

(2)

式中:qlaser为激光热流密度;x、y、z为计算区域的坐标;kl和ks分别为材料液相区的热传导系数和固相区的热传导系数;Lb和Lm分别为材料的汽化潜热和熔化潜热;sl和ss 分别表示材料的汽/液界面和 固/液界面;Ts和Tl分别为材料固相区的温度和液相区的温度;ρ为材料密度。

图2 钢/铝激光焊接熔池几何形状计算模型

Fig. 2 Calculation model for laser welding pool shape of steel and aluminum

经理论推导,获得汽/液相交界面的数学表达式为

(3)

(3)

同理,得出固/液相交界面的数学表达式为

(4)

(4)

式中:A为材料对激光能量的吸收率;P为激光功率;cp为材料定压比热容;Tm为材料熔点;Tb为材料沸点;T0为初始温度;R0为激光光斑半径;Kl为汽/液界面曲

率影响因子的修正系数, ;Ks为固/液界面曲率影响因子的修正系数,

;Ks为固/液界面曲率影响因子的修正系数,

;xml和xms分别为汽/液界面

;xml和xms分别为汽/液界面

和固/液界面的底部在x方向上的位移量, ,

, ;Ll和Ls为汽/液分界面和固液分界面的

;Ll和Ls为汽/液分界面和固液分界面的

初始宽度标量, ,

,

;

; 和

和 分别为激光

分别为激光

光轴中心到熔池前沿的汽/液界面和固/液界面之间的距离, ,

, ;

; 和

和 分别为激光光轴中心到熔池后沿的汽/液界面和固/液界面之间的距离,

分别为激光光轴中心到熔池后沿的汽/液界面和固/液界面之间的距离, ,

, 。

。

2.3 计算参数

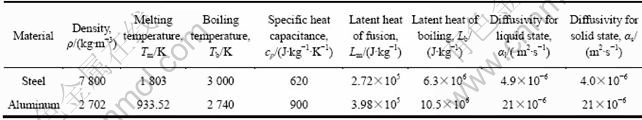

钢/铝异种金属激光焊接,计算时上层铝板厚度取1.2 mm,下层钢板设为半无限区域,假定焊接激光束照射在铝板上,钢/铝两种母材的热物性参数如表3 所列。

3 结果及讨论

3.1 焊缝成形性

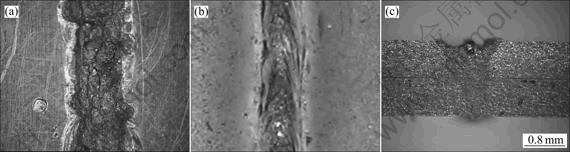

FeAl脆性金属间化合物是影响钢/铝激光焊接接头性能的主要因素,为避免激光焊接中形成较多的FeAl脆性金属间化合物,焊接时熔化熔点低的铝板,而钢板不熔化或少量熔化,使铝液在钢板上润湿、铺展。至此焊接过程中,激光热量的输入需要精确地控制。实验发现:当焊接激光功率低于1 600 W时,激光热输入不足,铝板不能熔化,仅形成一条细线,未形成熔池,无法实现焊接;当焊接激光功率高于1 800 W时,激光热输入过高,铝板和钢板都熔化,焊缝正面成形较差,存在大量深色的杂质、裂纹和气孔等缺陷,如图3(a)所示。焊缝背面熔透,焊缝形貌不太平整,如图3(b)所示,而分析焊缝横截面发现,焊缝贯穿两层板材,铝板一侧焊缝发生塌陷,上表面存在凹坑,下表面向下凸出,焊缝成形较差,如图3(c)所示。

图4所示为焊接功率在1 600~1 800 W之间时焊缝正面、背面及横截面的形貌。发现焊缝正面形态良好,未发现深色杂质,无明显可见的裂纹、气孔、未融合等缺陷,焊缝形貌平整。背面基本未发生形态变化,钢板未熔透,仅因热作用发生少许颜色改变。横截面发现:上层铝板熔化形成熔池,熔池表面的下陷和隆起都不严重,熔池底部与下层的钢板良好接合。

表3 钢和铝的热物理性能参数[14-16]

Table 3 Thermophysical properties parameters of steel and aluminum[14-16]

图3 激光率P>1 800 W时铝/钢激光焊接焊缝形貌

Fig. 3 Macro-morphologies of steel and aluminum at laser powder over 1 800 W: (a) Surface of weld; (b) Back of weld; (c) Cross section of weld

图4 激光率P为1 600~1 800 W时铝/钢激光焊接焊缝形貌

Fig. 4 Macro-morphologies of steel and aluminum at laser powder of 1 600-1 800 W: (a) Surface of weld; (b) Back of weld; (c) Cross section of weld

3.2 焊接熔池形状

控制熔池形状是保证焊接质量的关键,焊接工艺参数的选取直接影响熔池的几何形状,进而影响焊接质量。因此,准确获取熔池几何形状和焊接工艺参数的关系对于控制和改善激光焊接质量至关重要。由于MATLAB软件具有强大的数值计算、符号运算和图形处理等功能,能方便地处理诸如微分方程求解、插值与拟合、统计及优化等多方面的问题,是求解激光熔钎焊焊接熔池数学模型的理想平台,为此本研究通过建立如2.2节所述的准稳态下熔池形状数学模型,对不同工艺参数下钢/铝焊接区域的熔池几何形状进行计算。

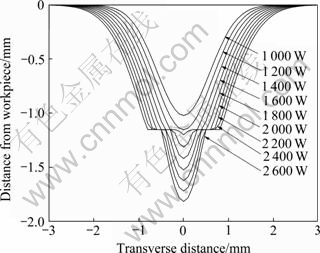

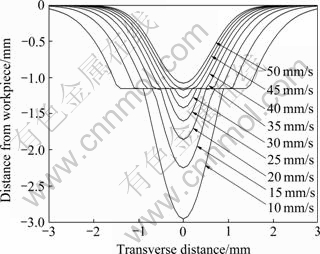

图5所示为保持焊接速度v=30 mm/s不变,焊接功率在1 000、1 200、1 400、1 600、1 800、2 000、 2 200、2 400、2 600 W时激光焊接熔池的几何形状。分析发现:当焊接功率大于或等于1 400 W以上时,焊接激光熔透了上层铝板,也熔化了一部分下层钢板,钢/铝界面处熔池几何形状存在一定程度的突变,焊接接头区域存在一个台阶状结构。图6所示为保持焊接功率1 800 W不变,焊接速度在10、15、20、25、30、35、40、45和50 mm/s时焊接熔池的几何形状。分析发现:当焊接功速度小于或等于40 mm/s时,焊接接头区域存在一个台阶状结构。

图5 不同焊接功率下的焊接熔池形状分布

Fig. 5 Distribution of welding pool shape under different welding powers

图6 不同焊接速度下的熔池形状分布

Fig. 6 Distribution of welding pool shape under different welding speeds

通常钢/铝激光焊接质量的好坏受多方面因素的影响,其中,焊接工艺参数的影响占主导地位,主要包括激光功率、焊接速度及离焦量等。激光功率直接决定光功率密度的大小。若功率过小,材料因热输入过少、熔化量不够导致焊缝填充不足;功率过大又会引起材料汽化形成等离子体屏蔽材料对激光的吸收或者使焊后焊缝表面产生飞溅;激光焊接速度影响焊接熔池存在的时间,决定其凝固时间的长短,进而影响内部晶粒的生长。若焊接速度过快,熔池内材料急剧冷却,得不到细化的晶粒,某些情况下甚至产生微裂纹、焊缝填充不足。从图5和6所示焊接熔池数值计算的几何形状来看,焊接功率和焊接速度的改变对熔池几何形状影响较大,随着激光功率的增大,熔深增加;而随着焊接速度的增加,熔深却变浅。

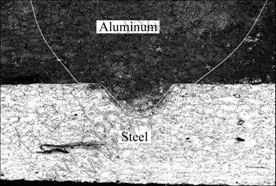

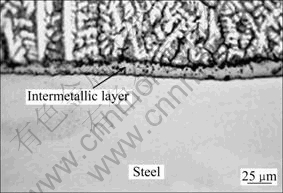

图7所示为焊接功率为1 600~1 800 W、焊接速度v=30 mm/s、离焦量D=0 mm时,高分辨扫描电镜观察试样横截面的焊缝形貌(该工艺条件下焊接接头的正面、背面及横截面焊缝成形性良好,如图4所示),发现焊接接头区域,铝熔池的下部,液态铝和钢板的接合区结晶凝固后也存在一个台阶状结构。在台阶结构的平台区域,钢/铝两种金属存在明显的界限,而在下凹区域,钢/铝熔合较好。

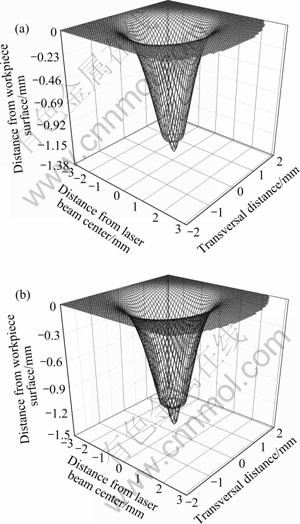

从图7所示的焊缝形貌来看,存在一个台阶状的结构。这是因为铝、钢两种材料的物性参数不同,在焊接激光作用下存在不同的熔化状态。进一步分析台阶结构的下凹区域,钢/铝异种金属熔合的深度大约为0.35 mm。与此相对应,图8所示为钢/铝异种金属台阶结构的下凹区域,熔池深度0.40 mm处所对应的激光焊接工艺条件为:焊接功率P=1 800 W,焊接速度v=30 mm/s。考虑到焊接熔池结晶凝固形成焊接接头的过程中要发生一定程度收缩,数值计算熔池几何形状做了一些假设,获得最佳焊接成形的工艺试验,因此,将焊接激光束照射搭接在钢板上的铝板对接焊缝时,当焊接功率在1 600~1 800 W之间、焊接速度v=30 mm/s、离焦量D=0 mm时,比较适宜实现钢/铝异种金属的激光熔钎焊焊接。

图7 试样横截面的焊缝形貌

Fig. 7 Cross-section morphology of weld of sample

图8 固/液分界面的三维形状

Fig. 8 Welding pool shape of solid and liquid interface: (a) P=1 600 W; (b) P=1 800 W

3.3 焊接接头的显微组织

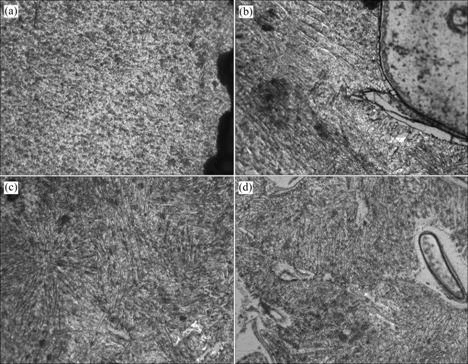

采用金相显微镜分析钢/铝焊缝界面处的结合情况,发现铝母材区晶粒较粗大,如图9(a)所示。台阶结构的平台区域,钢、铝两种金属界限明显(如图9(b)所示),表现为正常的激光熔钎焊特征。图9(c)所示为整个熔池形貌,下层钢板未受浸蚀作用。图9(d)所示为台阶结构的下凹区域(即热扩散区),可以看出熔池金属铝与钢母材之间存在一定熔合。

3.4 焊接接头的能谱与XRD分析

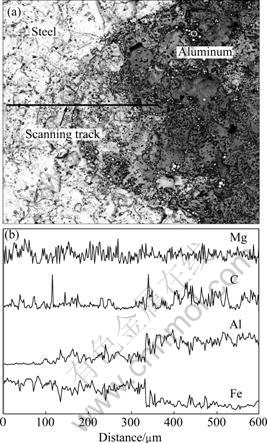

图10所示为焊接功率为1 600~1 800 W,焊接速度v=30 mm/s,离焦量D=0 mm时,焊接接头焊缝横向EDS元素的相对含量测试位置及测试结果。图10(a)中,扫描位置在焊缝区域,左边是钢材,右边是铝合金。从图10(b)可看出:铝母材区域,Al元素含量比较高,Fe元素含量较低。台阶结构的下凹区域,两种金属含量都发生突变,Fe元素含量急剧增高,Al元素含量陡然降低,Fe和Al明显混合,而这种含量关系在钢母材区域趋于稳定。

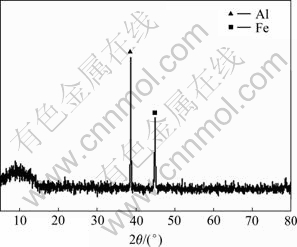

图11所示为焊缝区域X射线衍射的进一步分析结果。发现台阶结构的下凹区域,虽然存在较多的Al和Fe元素,但并未见到明显的FeAl金属间化合物。

3.5 分析与讨论

进行钢/铝薄板熔钎焊时,控制热量输入非常重要。当热输入不足时,低熔点的Al无法熔化。当热输入量过多时,Al达到熔点甚至沸点,形成熔池和匙孔,同时产生大量光致等离子体。温度越高,焊接熔池和匙孔深度越深,尽管有光致等离子体的影响,但仍有一部分激光能量可到达下层钢板,使钢板温度达到熔点,使钢板熔化,导致钢板熔池和铝板熔池连成一体,最终液态Fe和液态Al直接接触。这样钢/铝焊接熔池中Fe、Al、C、Mg等元素会进行剧烈扩散,在扩散等作用下,Fe和Al充分混合,极易发生化学反应,形成FeAl脆性金属间化合物。DHARMENDRA等[6]以DP600镀锌钢和AA6016铝合金为实验材料,使用Nd:YAG激光器,焊接时在焊缝处加入含85%Zn和15%Al(质量分数)的焊接钎料,试样横截面焊缝形貌如图12所示。发现形成FeAl金属间化合物,但适宜厚度的FeAl金属间化合物层的作用却类似“胶层”,利于Fe/Al界面结合,并未对激光焊接接头性能产生不利的影响。

图9 钢/铝焊接接头的显微组织

Fig. 9 Microstructures of steel and aluminum welded joint: (a) Base metal of aluminum side; (b) Platform area; (c) Morphology in fusion zone; (d) Thermal diffusion zone

图10 试样接合区形貌和钢/铝焊接接头元素线分布

Fig. 10 Morphology of sample joint area(a) and elements distribution of steel and aluminum welded joint(b)

图11 钢/铝焊接接头相结构的XRD谱

Fig. 11 XRD pattern of phase structure in steel and aluminum welded joint

对本研究而言,焊接功率为1 600~1 800 W、焊接速度v=30 mm/s、离焦量D=0 mm时,激光热输入基本合适,铝熔化形成熔池,伴随生成焊接匙孔和大量光致等离子体。金属蒸汽和等离子体阻止激光热量向钢板的传递。在钢/铝焊接接头台阶结构的下凹区域,由于此区域位于熔池的底部,热输入量高,铝与钢两种金属发生强烈的相互作用,使得钢/铝在该部分的结合区域形成一个明显的热扩散区。虽然光致等离子体的作用和熔池金属液的存在,焊接时激光能量不能直接达到,但由于通过等离子体和液态金属进行了热量传导,Fe、Al元素的扩散作用增强,虽然未形成类似“胶层”、有利于Fe/Al界面结合的适宜厚度FeAl金属间化合物层( 如图10所示的X射线衍射分析结果),但钢/铝两种金属焊接接头台阶结构下凹区域发生Fe和Al元素的热扩散正是Fe/Al界面结合的主要原因。

图12 钢/铝激光焊接接头形成的FeAl金属间化合物[6]

Fig. 12 FeAl brittle intermetallic compound formed in steel and aluminum welded joint[6]

在钢/铝焊接接头台阶结构的平台区域,固态的Fe直接和液态的Al相接触,液态Al在固态Fe表面润湿,润湿角θ与固体表面张力Fs,液体表面张力Fl液固表面张力Fsl存在如下杨氏平衡式:

(9)

(9)

文献[16]表明:铝液在钢板表面有良好的润湿性,当润湿角θ<20o时,润湿后铝液在钢材表面发生毛细流动、填充和铺展等作用,钢/铝激光焊接结晶凝固形成良好焊接接头,因此,对本研究而言,钢/铝焊接接头台阶结构的平台区域,钢/铝两种金属界面结合依靠的可能就是这些填充和铺展等作用。

4 结论

1) 焊接激光束照射搭接在钢板上的铝板对接焊缝时,可实现钢/铝激光熔钎焊,适宜的焊接工艺参数为焊接功率为1 600~1 800 W,焊接速度v=30 mm/s,离焦量D=0 mm。

2) 钢/铝激光熔钎焊焊缝成形性良好,无明显裂纹、气孔等缺陷。

3) 钢/铝激光熔钎焊焊接接头区域存在一个台阶状结构,在平台区域,铝/钢两种金属存在明显的界限,界面结合依靠液态的铝在钢母材表面上的润湿、填充和铺展等作用;在下凹区域,Fe和Al元素的混合区宽度较大,未形成明显的FeAl脆性金属间化合物,Fe和Al的热扩散是该区域界面结合的主要原因。

REFERENCES

[1] 李亚江. 特种连接技术[M]. 北京: 机械工业出版社, 2007.

LI Ya-jiang. Special connection technology[M]. Beijing: China Machine Press, 2007.

[2] 刘中青, 刘 凯. 异种金属焊接技术指南[M]. 北京: 机械工业出版社, 1997.

LIU Zhong-qing, LIU Kai. Heterogeneous metal welding technical manual[M]. Beijing: China Machine Press, 1997.

[3] 雷 振, 王旭友, 王伟波, 林尚扬. 铝/镀锌钢复合热源熔-钎接头中的Al-Fe金属间化合物层分析[J]. 焊接学报, 2007, 28(11): 65-71.

LEI Zhen, WANG Xu-you, WANG Wei-bo, LIN Shang-yang. The aluminum/galvanizes in the steel compound heat source melt-rock drill attachment Al-Fe intermetallic compound level analysis[J]. Transactions of The China Welding Instiution, 2007, 28(11): 65-71.

[4] 董皕喆. 铝-钢激光搭接焊的工艺及组织性能研究[D]. 兰州: 兰州理工大学, 2011.

DONG Bi-zhe. Investigation on laser welding of aluminum-steel laser lap welding and microstructure and mechanical properties[D]. Lanzhou: Lanzhou University of Technology, 2011.

[5] 倪加明, 李俐群, 陈彦宾, 封小松. 铝∕钛异种合金激光熔钎焊接头特性[J]. 中国有色金属学报,2007, 17(4): 617-626.

NI Jia-ming, LI Li-qun, CHEN Yan-bin, FENG Xiao-song. Characteristics of laser welding-brazing joint of Al/Ti dissimilar alloys[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(4): 617-626.

[6] TORKAMANY M J, TAHAMTAN S, SABBAGHZADEH J. Dissimilar welding of carbon steel to 5754 aluminum alloy by Nd:YAG pulsed laser[J]. Materials Design, 2010, 31(1): 458-465.

[7] SHI Y, ZHANG H, TAKEHIRO W, TANG J. CW/PW dual-beam YAG laser welding of steel/aluminum alloy sheets[J]. Optics and Laser in Engineering, 2010, 48(7/8): 732-736.

[8] BOZZI S, HELBERT-ETTER A L, BAUDIN T, CRIQUUI B, KERBIGUET J G. Intermetallic compounds in Al 6016/IF-steel friction stir spot welds[J]. Materials Science and Engineering A, 2010, 527(16/17): 4505-4509.

[9] DHARMENDRA C, RAO K P, WILDEN J, REICH S. Study on laser-brazing of zinc coated steel to aluminum alloy with zinc based filler[J]. Materials Science and Engineering A, 2011, 528(1/2): 1497-1503.

[10] 兰 天, 董 鹏, 肖荣诗. 铝/钛异种合金激光深熔钎焊试验分析[J]. 焊接学报, 2010, 31(8): 109-112.

LAN Tian, DONG Peng, XIAO Rong-shi. Analysis of laser deep penetration brazing of aluminium and titanium alloys[J]. Transactions of the China Welding Institution, 2010, 31(8): 109-112.

[11] KREIMEYER M, WAGNER F, VOLLERTSEN F. Laser processing of aluminum-titanium-tailored blanks[J]. Optics and Lasers in Engineering, 2005, 43(9): 1021-1035.

[12] MATHIEU A, PONTEVICCI S, VIALA J C, CICALA E, MATTEI S, GREVEY D. Laser brazing of a steel/aluminium assembly with hot filler wire[J]. Materials Science and Engineering A, 2006, 435/436(1/2): 19-28.

[13] PECHRAPA W, KAR A. Effects of phase changes on weld pool shape in laser welding[J]. Journal of Physics D: Applied Physics, 1997, 30: 3322-3329.

[14] ZHU X K. Numerical simulation of transient temperature and residual stresses in friction stir welding of 304L stainless steel [J]. Journal of Material Processing Technology, 2004, 146(2): 263-272.

[15] GOLDAK J, CHAKRAVARTI A, BIBBY M. A new finite element model for welding heat sources[J]. Metallurgical Transaction B, 1984, 15(6): 299-305.

[16] SIERRA G, PEYRE P, BEAUME F D. Steel to aluminum key-hole laser welding[J]. Materials Science and Engineering A, 2007, 447(1/2): 197-208.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2007AA042006);国家自然科学基金资助项目(50805045);湖南大学汽车车身先进设计制造国家重点实验室自主课题(71075003)

收稿日期:2011-05-13;修订日期:2011-12-28

通信作者:周惦武,教授,博士;电话:13017297124;E-mail: zdwe_mail@yahoo.com.cn