DOI:10.19476/j.ysxb.1004.0609.2017.11.06

微纳石墨烯片增强铝合金的力学性能及其机理

邹高鹏,贺显聪,孙滨洲,朱建斌,白苏南,许永祥,张 慧,杨少锋

(南京工程学院 材料工程学院 江苏省先进结构材料与应用技术重点实验室,南京 211167)

摘 要:采用电化学加超声剥离制取微纳石墨烯片,通过粉末冶金制备石墨烯增强铝合金。使用纳米压痕和摩擦磨损试验机对样品的纳米硬度、弹性模量、室温蠕变以及摩擦性能进行研究。结果表明:铝合金的纳米硬度和弹性模量随着微纳石墨烯片含量的增加呈线性提高;当微纳石墨烯片含量为0.20%(质量分数)时,石墨烯增强铝合金的纳米硬度和弹性模量比纯铝合金的分别提高66%和52%,室温平均蠕变度在保载阶段为纯铝合金的54.56%,在稳定阶段平均蠕变速率仅为纯铝合金的1/10,摩擦因数随微纳石墨烯片含量的增加而逐渐降低。微纳石墨烯片的加入使得晶粒细化、产生高位错密度和晶格畸变,提高了石墨烯铝合金复合材料的纳米硬度以及弹性模量,微纳石墨烯片对部分可动位错钉扎提高了铝合金抗蠕变性能,微纳石墨烯片存在自润滑性提高了铝合金摩擦性能。

关键词:铝合金;微纳石墨烯片;电化学;纳米压痕;室温蠕变

文章编号:1004-0609(2017)-11-2228-08 中图分类号:TB331 文献标志码:A

铝合金复合材料由于质量轻、比强度高、热膨胀系数低、易于加工等特点,被广泛地应用在航空航天、汽车零部件等重要领域[1-5]。常用铝合金复合材料增强体有碳化硅、碳化硼和氧化铝[3-7]等,这些增强体的加入虽然提高了强度和弹性模量,但降低其韧性。在铝合金基体中添加纤维[8]、碳纳米管[9-13]或者晶须[14-16]可以同时具备高强度和高韧性,但一维增强材料比表面积小,完全覆盖基体需要较高体积比,从而增加了制备成本。而高强度二维结构石墨烯[17-20]具有超高比表面积,极少量石墨烯片完全能覆盖基体,增强增韧效果显著。同时,石墨烯本身是一种非常好的固体润滑剂,可以明显改善耐磨损性。KIM等[20]制备的石墨烯氧化铝陶瓷纳米复合材料断裂韧性值比纯氧化铝陶瓷提高了75%。燕绍九等[21]发现石墨烯纳米片掺入2024铝合金使屈服强度和抗拉强度分别提高了50% 和30%,且塑性被保留了下来。WANG等[22]研究发现0.3%石墨烯/铝复合材料相比于纯铝的,其抗拉强度从154 MPa 提高到259 MPa,断裂应变从27.5%减小到12.7%。迄今为止没有发现涉及室温蠕变性能的研究,承载周期长的铝合金易发生蠕变,研究其常温蠕变性能保证其工作可靠性具有重要意义。因此,本文作者使用纳米压痕法从微/纳米尺度系统研究石墨烯铝合金复合材料的纳米硬度、弹性模量和蠕变性能,并结合微结构分析微纳石墨烯片增强铝合金复合材料的 机理。

1 实验

将纯度为99.99% 的两片80 mm×30 mm×2 mm石墨分别作为阳极和阴极平行放置在1 mol/L的硫酸铵溶液中,两极间距为1 cm,加1.5 A 恒定直流持续电解。将电解后石墨烯进行反复抽滤、清洗。用功率为500 W 的超声波超声剥离1 h,最后将悬浊液导入离心管中,在XYJ-2型台式高速离心机中以5000 r/min的转速进行30 min离心处理,收集下层溶液,用去离子水洗涤至中性制得微纳石墨烯片(EG)。

取微纳石墨烯片溶入20 mL乙醇中超声震荡60 min分散开。按Al、Cu、Zn 质量比为92.8:1.6:5.6称取10 g混合粉末倒入微纳石墨烯片乙醇溶液中,充分搅拌均匀后室温真空干燥。混合粉末以200 r/min球磨30 min,在5 MPa 的压力下压成d12 mm×5 mm样品。再将样品放入真空炉中抽真空并通入氩气保护,在550 ℃烧结1 h(升温速度为10 ℃/min)后随炉冷却到室温,得到微纳石墨烯片含量(质量分数)为0.05%、0.10%、0.15%和0.20%石墨烯铝合金复合材料样品。

使用金相显微镜(BX51M)、原子力显微镜(Veecodimension V)和扫描电镜(MERLIN Compact)观察样品的微观形貌;利用X射线衍射仪(Ultima-IV)和Raman谱仪(RENISHAW)分析样品的微结构。使用显微硬度计(DHV1000)测量微观硬度,利用摩擦磨损试验机(MFT-3000)对样品的摩擦性能进行研究。

采用Agilent G200纳米压痕试验机的连续刚度模式(CSM)测试纳米硬度、弹性模量以及蠕变性能。纳米硬度和弹性模量测试最大压痕深度为1000 nm,对每个样品测试10个压痕点计算弹性模量和硬度平均值。蠕变性能测试用100 nm/s的下降速度使压头缓慢靠近试样表面,当压头接触到试样表面后,以恒定加载速率/载荷的加载方式使压头压入样品,在50 mN保载20 min使样品发生蠕变,卸载到12.5 mN进行保载1.5 min,对实验数据进行热漂移校正,最后卸载到零。每个样品测10个点取平均值。

2 结果与讨论

2.1 微观结构

图1(a)所示为电化学制备的微纳石墨烯片(EG)SEM像。从图1(a)中可以看出,制备的微纳石墨烯片呈薄纱状,呈现出波浪状的褶皱结构。图1(b)所示为微纳石墨烯片的拉曼光谱。从图1(b)中可以见到D峰在1374 cm-1 附近,G峰在1577 cm-1 附近,2D 峰在2894 cm-1附近。拉曼谱2D 峰较高,根据 I2D/IG 的值与原子层数成反比[23],说明制备的是单层或少层微纳石墨烯片。与Hummers法制备的氧化石墨烯[24]相比,EG在制备过程中没有经过任何氧化过程,所以缺陷和含氧基团少,这结果与文献[20]中报道的电化学制备的低含氧量石墨烯片结果是一致的。图1(c)所示为微纳石墨烯片的AFM图。从图1(c)可以看出,制备的微纳石墨烯片的大小为微米级别,片为单层或少层石墨烯。图1(d)所示为微纳石墨烯片的XRD谱,出现了石墨烯(002)和(100)的典型特征峰[21]。

图1 电化学制备的微纳石墨烯片SEM像、拉曼光谱、AFM和XRD谱

Fig. 1 SEM image (a), Raman spectroscope (b), AFM (c) and XRD (d) patterns of graphene nanosheets prepared by electrochemical method

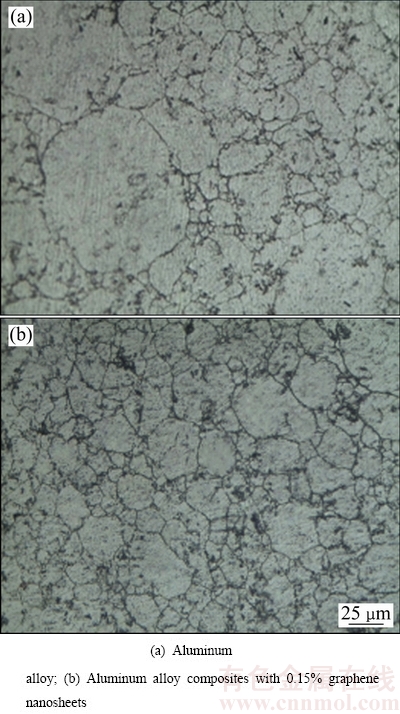

图2 (a)所示为铝合金的金相图,图2(b)所示为含0.15%微纳石墨烯片铝合金复合材料金相图。从图2(a)和(b)中可以看出,采用粉末冶金法制备的铝合金及其复合材料致密,无明显孔隙,其中含0.15%微纳石墨烯片铝合金复合材料密度为2.754 g/cm3。石墨烯铝合金复合材料的晶粒比纯铝合金更均匀细小,微纳石墨烯片分布在晶界上阻碍了晶粒的长大,从而得到了均匀细化的晶粒[20]。图3(a)所示为含0.15%微纳石墨烯片铝合金复合材料拉伸断口微观形貌。断裂方式为典型韧窝断裂,韧窝和撕裂棱均匀细小,撕裂的表面可以清晰地看到均匀分布的微纳石墨烯片,图3(b)所示为图3(a)中红色圆圈内放大的形貌,微纳石墨烯片裹在晶粒的界面上,被撕裂出来后形态与图1(a)是一致的。

图2 铝合金和含0.15%微纳石墨烯片铝合金复合材料的金相组织

Fig. 2 Metallographs of aluminum alloy and aluminum alloy composites with 0.15% graphene nanosheets

图3 含0.15%微纳石墨烯片铝合金复合材料拉伸断口的FESEM像

Fig. 3 FESEM images of tensile fracture surface of aluminum alloy composites with 0.15% graphene nanosheets

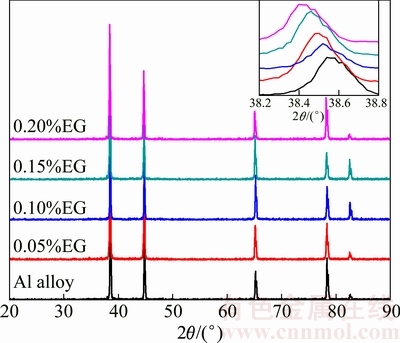

根据Al-Cu-Zn三元相图[25]可以看出,本实验中的合金成分落在T ′+α+β三相区,(α相是溶入Cu、Zn原子形成的保持纯铝FCC结构相,β相是溶入Cu、Al原子形成的保持纯锌HCP结构相,T ′是形成的三元化合物)。图4所示为不同微纳石墨烯片含量的铝合金复合材料样品XRD谱,对比PDF卡片(89-4037)可知全是α相的特征峰,并没有检测到T ′相和β相的衍射峰,这是因为合金中T ′相和β相的含量很少,XRD无法检测到。从图4右上角的插图可以看出,添加微纳石墨烯片后样品的特征峰整体向小角度发生了少量的偏移,根据布拉格方程,表明基体晶格发生膨胀,可能是由于微纳石墨烯少数碳原子插入铝基体晶格中发生晶格畸变,且随着微纳石墨烯片含量的增加使晶格畸变程度也增大。

图4 不同微纳石墨烯片含量的铝合金复合材料的XRD谱

Fig. 4 XRD patterns of aluminum alloy composites with different graphene nanosheets content

2.2 纳米压痕硬度和弹性模量

图5(a)所示为含0.2%微纳石墨烯片铝合金复合材料纳米压痕载荷-位移曲线。加载曲线可分为弹性和弹-塑性加载阶段,在卸载曲线的开始阶段压痕深度减小意味着正发生瞬时弹性恢复。图5(b)表示不同质量分数微纳石墨烯片铝合金复合材料的纳米硬度,随着微纳石墨烯片含量增加纳米硬度呈线性提高,根据实验纳米硬度值可以拟合成一次函数关系式:y=1.784+5.86x。图5(c)所示为不同微纳石墨烯片含量铝合金复合材料的维氏显微硬度,其维氏硬度值与微纳石墨烯片含量也呈一次函数关系,这一结果与纳米压痕所测得的纳米硬度相类似。可见无论是微观还是宏观角度分析,石墨烯铝合金复合材料的硬度值确实和微纳石墨烯片的含量存在着线性关系。图5(d)所示为不同质量分数微纳石墨烯片铝合金复合材料的弹性模量。样品的弹性模量与微纳石墨烯片含量也是呈一次函数关系:y=56.566+146.96x。铝合金复合材料的硬度和弹性模量都随微纳石墨烯片含量增加呈线性增加,基本符合混合定律[26],说明基体与增强相结合紧密可通过界面将载荷有效传递到增强相上。含0.2% 微纳石墨烯片铝合金复合材料的纳米硬度较纯铝合金的提高了66%,弹性模量提高了52%。石墨烯铝合金复合材料的硬度与弹性模量较大幅度提高,一方面弥散分布在铝合金基体中的微纳石墨烯片阻碍了晶粒长大,细化晶粒强化了铝合金;另一方面微纳石墨烯片与铝合金热膨胀不匹配也使微纳石墨烯片周围出现位错密度很高的塑性区[27]间接阻碍了位错的移动。此外,由XRD衍射峰位的偏移可知,微纳石墨烯片掺入使铝合金的晶格产生了畸变,这会引起材料内能增高,阻碍位错滑移,使得材料的硬度提高。微纳石墨烯片在塑性变形过程中本身也能承受很大一部分的机械负载。随着微纳石墨烯片含量增加,这些强化效果更明显,从而使硬度和弹性模量值不断提高[20-22]。

图5 添加微纳石墨烯片含量与其纳米硬度、维氏显微硬度和弹性模量之间的关系

Fig. 5 Relationships among nano-hardness, Vickers hardness, elasticity Modulus and mass fraction of graphene nanosheets

2.3 蠕变性能

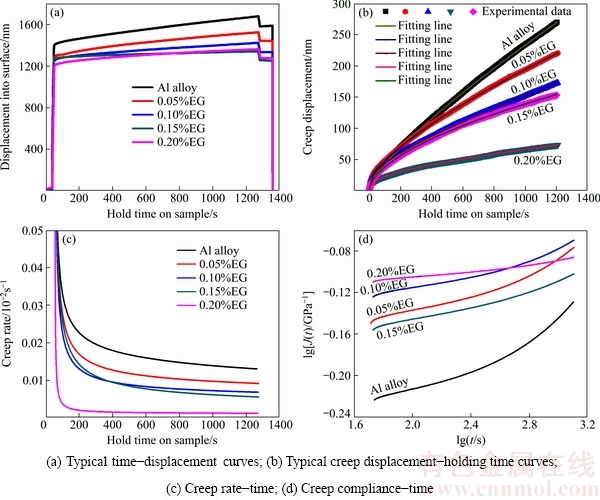

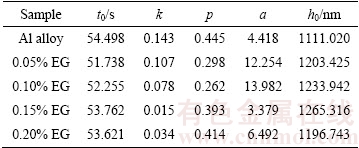

图6(a)所示为不同微纳石墨烯片含量铝合金复合材料的时间-位移曲线。样品保载大约在50 s处开始产生蠕变,且随着微纳石墨烯片含量增加,保载的初始位移量逐渐减小,这说明了样品的抗蠕变性增强。而0.2%微纳米石墨烯样品的位移量出现了异常,这可能是因为微纳石墨烯片含量高产生偏聚从而导致在某一区域其分布不均匀。图6(b)所示为典型的蠕变位移-时间曲线(为便于比较,将起始点移至原点)。根据经验方程[28] ( ,其中,t0为开始发生蠕变时间,s;h0为开始发生蠕变时的位移量,nm;a,p,k均为常数)对实验数据进行拟合得到各样品的拟合参数如表1所列。结果显示,拟合线和实验数据点重合度很高。从图6(b)看出,随着微纳石墨烯片含量增加,蠕变量逐渐减小。由Alden常温态蠕变理论机理[29]可知:金属的塑性变形主要是由金属材料内部的位错运动而产生的。当金属材料加载到所设定的最大载荷并进行保载时,会产生一定量的可动位错,这些可动位错在恒载开始时发生滑移,由此发生蠕变,而添加微纳石墨烯片对部分可动位错产生钉扎作用,从而可动位错转变为不动位错,有效减小了材料的蠕变变形量。图6(c)所示为蠕变速率随时间的变化曲线。所有样品在开始阶段蠕变速率急剧下降,然后出现了一个平台。在稳定阶段蠕变速率随微纳石墨烯片含量增加而降低,平均蠕变速率[30](

,其中,t0为开始发生蠕变时间,s;h0为开始发生蠕变时的位移量,nm;a,p,k均为常数)对实验数据进行拟合得到各样品的拟合参数如表1所列。结果显示,拟合线和实验数据点重合度很高。从图6(b)看出,随着微纳石墨烯片含量增加,蠕变量逐渐减小。由Alden常温态蠕变理论机理[29]可知:金属的塑性变形主要是由金属材料内部的位错运动而产生的。当金属材料加载到所设定的最大载荷并进行保载时,会产生一定量的可动位错,这些可动位错在恒载开始时发生滑移,由此发生蠕变,而添加微纳石墨烯片对部分可动位错产生钉扎作用,从而可动位错转变为不动位错,有效减小了材料的蠕变变形量。图6(c)所示为蠕变速率随时间的变化曲线。所有样品在开始阶段蠕变速率急剧下降,然后出现了一个平台。在稳定阶段蠕变速率随微纳石墨烯片含量增加而降低,平均蠕变速率[30]( )为1.3×10-6 s-1,而含0.2%微纳石墨烯片铝合金复合材料平均蠕变速率仅为1.2×10-7 s-1。在保载阶段,纯铝合金平均蠕变度[30](

)为1.3×10-6 s-1,而含0.2%微纳石墨烯片铝合金复合材料平均蠕变速率仅为1.2×10-7 s-1。在保载阶段,纯铝合金平均蠕变度[30]( )是24.14%,而含0.2%微纳石墨烯片铝合金复合材料平均蠕变度仅为13.17%。图6(d)所示为蠕变柔量(J(t))随时间的变化曲线(

)是24.14%,而含0.2%微纳石墨烯片铝合金复合材料平均蠕变度仅为13.17%。图6(d)所示为蠕变柔量(J(t))随时间的变化曲线(

[30]。其中,A0和P0分别为接触面积和产生蠕变位移时对应的载荷;hin为加载阶段的最大深度)。所有样品的蠕变柔量随时间的变化都是先平缓后快速上升,这是由材料的软化分散所导致的[30]。

[30]。其中,A0和P0分别为接触面积和产生蠕变位移时对应的载荷;hin为加载阶段的最大深度)。所有样品的蠕变柔量随时间的变化都是先平缓后快速上升,这是由材料的软化分散所导致的[30]。

图6 在50 mN载荷下不同微纳石墨烯片含量铝合金复合材料的蠕变性能

Fig. 6 Creep of aluminum alloy composites with different graphene nanosheets at load of 50 mN

表1 各样品通过对实验数据的拟合得到蠕变参数

Table 1 Creep parameters of different samples by fitting experimental data

2.4 摩擦性能

图7(a)所示为不同微纳石墨烯片含量铝合金复合材料的摩擦因数-时间曲线图。从图7(a)可以看出,在0~50 s 内正处于磨损过程的磨合期,摩擦因数发生急剧增加,摩擦因数较大。经过磨合期之后随着摩擦时间的不断增加,摩擦因数逐渐趋于稳定状态,稳定在0.5~0.7之间。图7(b)所示为含不同微纳石墨烯片含量铝合金复合材料稳定状态的平均摩擦因数柱状图。由图7(b)可以看出,石墨烯铝合金复合材料的摩擦因数明显比铝合金的低,这是因为微纳石墨烯片是由石墨电解剥离而成的片层状物质,而石墨具有较低的摩擦因数和良好的润滑性,所以将微纳石墨烯片加入铝合金基体后,在摩擦过程中微纳石墨烯片和基体的磨削会在摩擦副接触表面形成具有润滑作用的薄膜,从而减少摩擦偶对基体的磨损,使摩擦因数降低[19-20]。由图7(b)还可以看出,在一定浓度范围内随着微纳石墨烯片含量的增加,复合材料的摩擦因数不断降低。这是由于微纳石墨烯片含量较少时薄膜大部分是由基体磨削组成,这样在摩擦副相对运动时就减少了固体润滑剂的作用,摩擦因数较大,随微纳石墨烯片含量增加,薄膜中所含微纳石墨烯片含量变多,微纳石墨烯片的润滑效果明显,从而使摩擦因数显著降低。

图7 各样品的摩擦因数-时间曲线图和200~600 s时的平均摩擦因数柱状图

Fig. 7 Friction coefficient-time curves (a) and 200-600 s histogram (b) of average friction coefficient of different samples

3 结论

1) 加入微纳石墨烯片细化铝合金复合材料的晶粒,产生高位错密度和晶格畸变使其纳米硬度和弹性模量提高。

2) 微纳石墨烯片对可动位错有钉扎作用从而显著提高了铝合金的抗蠕变性能,在保载阶段铝合金的平均蠕变度为24.14%,而含0.2% 微纳石墨烯片铝合金复合材料的平均蠕变度仅为13.17%;在稳定阶段铝合金平均蠕变速率为1.3×10-6 s-1,而含0.2% 微纳石墨烯片铝合金复合材料平均蠕变速率仅为1.2×10-7 s-1。

3) 石墨烯微纳片的自润滑性提高了铝合金的耐摩擦性能,且随着微纳石墨烯片含量增加,铝合金复合材料的摩擦因数降低。

REFERENCES

[1] 刘 兵, 彭超群, 王日初, 王小锋, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1714.

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1714.

[2] 解立川, 彭超群, 王日初, 王小锋, 蔡志勇, 刘 兵. 高硅铝合金电子封装材料研究进展[J]. 中国有色金属学报, 2012, 22(9): 2578-2586.

XIE Li-chuan, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, CAI Zhi-yong, LIU Bing. Research progress of high aluminum-silicon alloys in electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2578-2586.

[3] 潘利科, 韩建民, 张颖骁, 杨智勇, 李志强, 李卫京. 高含量SiCp/A356复合材料衍生材料的组织与性能[J]. 中国有色金属学报, 2016, 26(10): 2078-2085.

PAN Li-ke, HAN Jian-min, ZHANG Ying-xiao, YANG Zhi-yong, LI Zhi-qiang, LI Wei-jing. Microstructure and properties of derived material for high content SiCp/A356 composites[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(10): 2078-2085.

[4] RAVIKUMAR K, KIRAN K, SREEBALAJI V S. Characterization of mechanical properties of aluminium/tungsten carbide composites[J]. Measurement, 2017, 102: 142-149.

[5] AL-MOSAWI B T, WEXLER D, CALKA A. Characterization and mechanical properties of α-Al2O3, particle reinforced aluminium matrix composites, synthesized via uniball magneto-milling and uniaxial hot pressing[J]. Advanced Powder Technology, 2017, 28(3): 1054-1064.

[6] 郝世明, 谢敬佩, 王爱琴, 王文焱, 李继文. 微米级SiC颗粒增强铝基复合材料的强化机制[J]. 材料热处理学报, 2016, 37(5): 1-6.

HAO Shi-ming, XIE Jing-pei, WANG Ai-qin, WANG Wen-yan, LI Ji-wen. Strengthening mechanism of micrometer SiC particle reinforced aluminum matrix composites[J]. Transactions of Materials and Heat Treatment, 2016, 37(5): 1-6.

[7] 范 涛, 刘博文, 孙艳荣, 王 虎, 唐伟忠, 贾成厂. Al2O3颗粒增强铝基复合材料的耐磨性研究[J]. 粉末冶金技术, 2015, 33(3): 186-189.

FAN Tao, LIU Bo-weng, SUN Yan-rong, WANG Hu, TANG Wei-zhong, JIA Cheng-guang. Study on wear resistance of Al2O3 particle reinforced Al matrix composites[J]. Powder Metallurgy Technology, 2015, 33(3): 186-189.

[8] SEYYED M A, SAEED K, SEYYED A J J, SIRUS J, SEYYED M Z. Fabrication of novel fiber reinforced aluminum composites by friction stir processing[J]. Materials Science and Engineering A, 2015, 632: 50-57.

[9] BAKSHI S R, ARVIND A. An analysis of the factors affecting strengthening in carbon nanotube reinforced aluminum composites[J]. Carbon, 2011, 49(2): 533-544.

[10] BONG K C, GIL H Y, SEUNGJUN L. Molecular dynamics studies of CNT-reinforced aluminum composites under uniaxial tensile loading[J]. Composites Part B, 2016, 91: 119-125.

[11] ANKUR G, GARIMA T, DEBRUPA L, KANTESH B. Compression molded ultra high molecular weight polyethylene hydroxyapatite aluminum oxide carbon nanotube hybrid composites for hard tissue replacement[J]. Journal of Materials Science & Technology, 2013, 29(6): 514-522.

[12] LIU Z Y, XIAO B L, WANG W G, MA Z Y. Modelling of carbon nanotube dispersion and strengthening mechanisms in Al matrix composites prepared by high energy ball milling-powder metallurgy method[J]. Composites Part A, 2017, 94: 189-198.

[13] ZHOU W W, YAMAMOTO G, FAN Y, KWON H, HASHIDA T, KAWASAKI A. In-situ characterization of interfacial shear strength in multi-walledcarbon nanotube reinforced aluminum matrix composites[J]. Carbon, 2016, 106: 37-47.

[14] ZHANG P, HU P, ZHANG X, HAN J, MENG S. Processing and characterization of ZrB2-SiC W ultra-high temperature ceramics[J]. Journal of Alloy & Compounds, 2009, 472(1): 358-362.

[15] MANIGANDAAN K, SRIVATSANB T S, QUICKC T. Influence of silicon carbide particulates on tensile fracture behavior of an aluminum alloy[J]. Materials Science and Engineering A, 2012, 534(1): 711-715.

[16] LU W J, GUO X L , MENG J L, WANG F G, WANG L Q, ZHANG D. Analysis of the coupling effects of TiB whiskers and TiC particles on the fracture toughness of (TiB+TiC)/TC4 composites: experiment and modeling[J]. Metallurgical and Materials Transactions A, 2015, 46(8): 3490-3501.

[17] 李多生, 吴文政, QIN Qing-hua, 周贤良, 左敦稳, 鲁世强, 郜有彬. 石墨烯/Al复合材料的微观结构及力学性能[J]. 中国有色金属学报, 2015, 25(6): 1498-1504.

LI Duo-sheng, WU Wen-zheng, QIN Qing-hua, ZHOU Xian-liang, ZUO Dun-wen, LU Shi-qiang, GAO You-bin. Microstructure and mechanical properties of graphene/Al composites[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1498-1504.

[18] KIM K S, LEE H J, LEE C, LEE S K, JANG H, AHN J H, KIM J H, LEE H J. Chemical vapor deposition-grown graphene: The thinnest solid lubricant[J]. ACS Nano, 2011, 5(6): 5107-5114.

[19] XIAO Y C, SHI X L, ZHAI W Z, YAO J, XU Z S, CHEN L, ZHU Q S. Tribological performance of NiAl self-lubricating matrix composite with addition of graphene at different loads[J]. Journal of Materials Engineering and Performance, 2015, 24(8): 2866-2874.

[20] KIM H J, LEE S M, OH Y S, YANG Y H, LIM Y S, YOON D H, LEE C, KIM J Y, RUOFF R S. Unoxidized graphene/alumina nanocomposite: Fracture and wear-resistance effects of grapherne on alumina matrix[J]. Scientific Reports, 2014, 4(7503): 5176-5176.

[21] 燕绍九, 杨 程, 洪起虎, 陈军洲, 刘大博, 戴圣龙. 石墨烯增强铝基纳米复合材料的研究[J]. 材料工程, 2014(4): 35-39.

YAN Shao-jiu, YANG Cheng, HONG Qi-hu, CHEN Jun-zhou, LIU Da-bo, DAI Sheng-long. Research of graphene-reinforced aluminum matrix nanocomposites[J]. Journal of Materials Engineering, 2014(4): 35-39.

[22] WANG J Y, LI Z Q, FAN G L, PAN H H, CHEN Z X, ZHANG D. Reinforcement with graphene nanosheets in aluminum matrix composites[J]. Scripta Materialia, 2012, 66(8): 594-597.

[23] FERRARI A C, MEYER J C, SCARDACI V, CASIRAGHI C, LAZZERI M, MAURI F, PISCANCE S, JIANG D, NOVOSELOV K S, ROTH S, GEIM A K. Raman spectrum of graphene and graphene layers[J]. Physical Review Letters, 2006, 97(18): 13831-13840.

[24] HE X C, TANG T, LIU F C, TANG N J, LI X Y, DU Y W. Photochemical doping of graphene oxide thin film with nitrogen for photoconductivity enhancement[J]. Carbon, 2015, 94: 1037-1043.

[25] 陈 辉, 信 昕, 任玉平, 郝士明. Al-Zn-Cu系室温相图低Cu区的研究[J]. 金属学报, 2004, 40(8): 84l-845.

CHEN Hui, XIN Xin, REN Yu-ping, HAO Shi-ming. Phase diagram of Al-Zn-Cu system in low copper side at room temperature[J]. Acta Metallurgica Sinica, 2004, 40(8): 84l-845.

[26] CHU K, JIA C. Enhanced strength in bulk graphene-copper composites[J]. Physica Status Solidi A, 2014, 211(1): 184-190.

[27] CHEN F Y, YIN J M, WANG Y F, DU S Y, LIU Z P, HUANG Q. Effects of graphene content on the microstructure and properties of copper matrix composites[J]. Carbon, 2016, 96: 836-842.

[28] WANG J, LI R, HUA N, HUANG L, ZHANG T. Ternary Fe-P-C bulk metallic glass with good soft-magnetic and mechanical properties[J]. Scripta Mtaerialia, 2011, 65(6): 536-539.

[29] ALDEN T H. Theory of plastic and viscous[J]. Metallurgical Transactions, 1987, 18: 811-826.

[30] PI J H, WANG Z Z, HE X C, BAI Y Q, ZHEN R. Nanoindentation mechanical properties of glassy Cu29Zr32Ti15Al5Ni19[J]. Journal of Alloys and Compounds, 2016, 657: 726-732.

Mechanics performances and mechanism of aluminum alloy reinforced by graphene nanosheets

ZOU Gao-peng, HE Xian-cong, SUN Bin-zhou, ZHU Jian-bin, BAI Su-nan, XU Yong-xiang, ZHANG Hui, YANG Shao-feng

(Jiangsu Key Laboratory of Advanced Structural Materials and Application Technology, School of Material Science and Engineering, Nanjing Institute of Technology, Nanjing 211167, China)

Abstract: Graphene nanosheets (EG) were produced by electrochemical and ultrasonic method. Graphene aluminum alloy composites were prepared via powder metallurgy method. Nano-hardness, elasticity modulus, room temperature creep and tribological properties of the samples were investigated by using nano-indentation and friction wear testing machine, respectively. The nano-hardness and elasticity modulus increase linearly with the increase of EG content. When EG content is 0.20%, nano-hardness and elastic modulus of graphene aluminum alloy composite are 66% and 52% higher than those of aluminum alloy, respectively. The average creep degree of the aluminum alloy composites with 0.2% EG in holding stage is 54.56% of aluminum alloy, and the average creep rate of the aluminum alloy composites with 0.2% EG in steady-stage is only 1/10 of that of aluminum alloy. The friction coefficients of graphene aluminum alloy composites decrease with the increase of EG content. The nano-hardness and elasticity modulus of graphene aluminum alloy composites are enhanced through grain refinement, high dislocation density and lattice distortion. The creep resistance properties of graphene aluminum alloy composites are improved via EG pinning the movable dislocation. And the friction properties are improved because of the self-lubricating properties of the EG.

Key words: aluminum alloy; graphene nanosheets; electrochemical method; nano-indentation; room temperature creep

Foundation item: Project(51671104) supported by the National Natural Science Foundation of China; Project (BK20151461) supported by the Natural Science Foundation of Jiangsu Province, China; Projects(CKJA201403, ZKJ201302) supported by the Nanjing Institute of Technology Research Fund, China; Projects(201611276049x, TB201702057) supported by Outstanding Scientific and Technological Innovation Team in Colleges and Universities, and Innovation and Entrepreneurship Training Program Jiangsu Province, China

Received date: 2016-09-27; Accepted date: 2017-05-03

Corresponding author: HE Xian-cong; Tel: +86-25-86118274; E-mail: hexiancong@njit.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51671104);江苏省自然科学基金资助项目(BK20151461);南京工程学院科研基金资助项目(CKJA201403,ZKJ201302);江苏高校优秀科技创新团队和大学生创新创业计划资助项目(201611276049x,TB201702057)

收稿日期:2016-09-27;修订日期:2017-05-03

通信作者:贺显聪,副教授,博士;电话:025-86118274;E-mail:hexiancong@njit.edu.cn